Use of valves with thermal heads

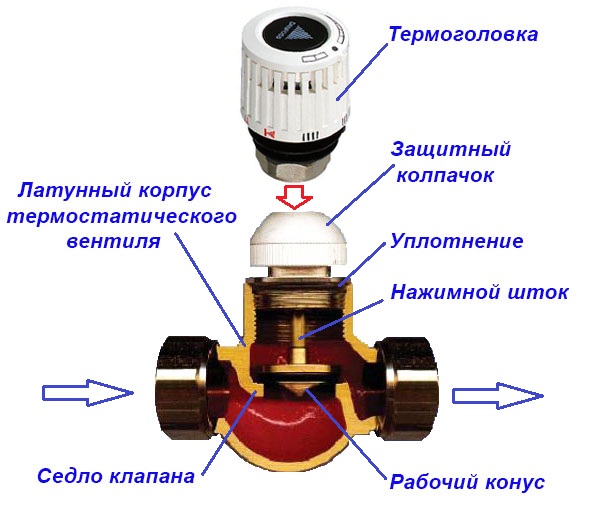

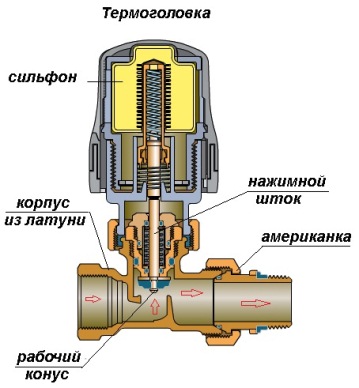

These are the best taps that can only be put on radiators in the heating system of a private house. Adjusted to a certain air temperature, the thermal head acts on the valve stem, forcing it to open or close its flow area. Thus, there is an automatic quantitative regulation of the coolant passing through the heater.

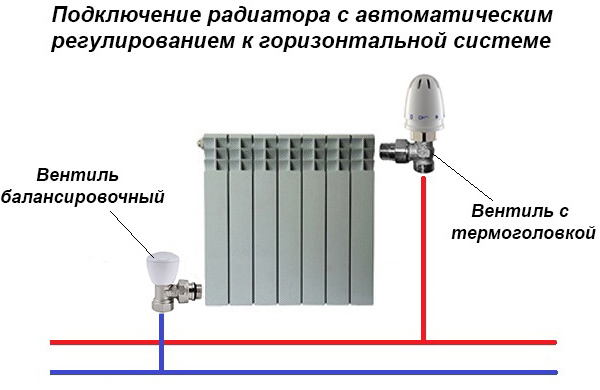

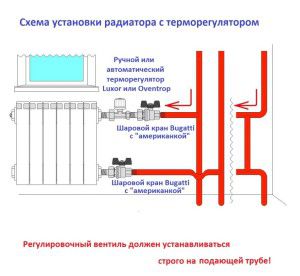

The thermostatic valve is installed on the supply line to the battery, and a balancing valve is placed on the return line. It is a mistake to assume that the system will be automatically balanced by thermal heads; valves are needed in any case. The installation of conventional ball valves instead of them is allowed for centralized heating or in systems with a passing movement of the coolant (Tichelmann loop). But it is unacceptable to regulate the coolant flow using a ball valve, and it will not work.

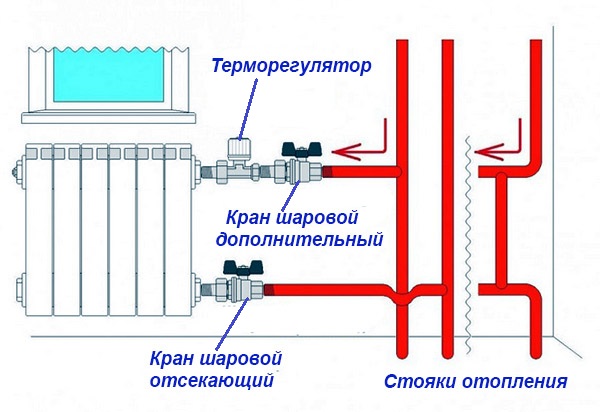

Advice. Most models of thermal valves have a mode of mechanical blocking of the flow section. If you got products without such a mode, then you will have to install an additional cutter to service the battery, as shown in the diagram:

Purpose. Characteristic

With the help of taps, the efficient operation of water pipes is ensured. The heating system cannot work without these devices, and in some situations its use without them becomes simply dangerous.

When the riser leaks, it is the shutoff valves that shut off the water, which makes it possible to make repairs without stopping the entire system.

An important function will also be the management of battery heat dissipation.

The minimum set for the normal functioning of a conventional heating system consists of several types of shut-off and control valves. When connected to the radiator, shut-off ball valves are mounted on the supply pipes, on the outlet and on the bypass. A mechanism is installed on the supply to adjust the pressure of the coolant. The radiator itself must be equipped with a Mayevsky crane. to bleed air. As you can see, the number of such products is significant and this is by no means an excessive option.

All together, this system allows:

- turn off the radiator without shutting off the entire circuit for repair, replacement, maintenance;

- direct the entire heat carrier through the heater when the bypass is off;

- control the power of the pressure through the radiator to reduce or increase the temperature;

- drain water, bleed air;

- to protect the system from hydraulic shocks, breakdowns;

- regulate the efficiency and level of heat supply, which saves heating costs.

Requirements

The criteria for the species diversity of taps placed on heating radiators are: design, principle of operation and material

It is important to know that mechanisms of this type are divided into shut-off and control valves. What are the best faucets? It should be borne in mind that they have a rather complex device and must meet a number of requirements in order to function in difficult conditions.

- coolant temperature up to 200°C;

- must withstand a pressure of 16–40 bar;

- high corrosion resistance;

- resistance to mechanical stress.

For heating systems, such mechanisms are made more stable. Ordinary taps and valves for cold water cannot be installed in radiators.

Each connection has its own characteristics: there are ordinary and corner (for the bottom connection) taps. This separation allows you to maximize the distribution of pipes during the installation of the heating system.The design features of the valves make it possible to hide the pipes behind the decor, in the screed, to mount radiators in a small space under the window opening.

In everyday life, a generalized name is used - "faucets". But from a technical point of view, it is correct to distinguish between:

Heating systems also use temperature controllers, it is not recommended to use dampers or valves in radiators - they quickly become inoperative. If shut-off valves are needed, then ball valves will be the best for this. They have only two positions - closed / open. Valves with a cone are designed for manual pressure control. There are also mechanisms for automatic adjustment - these are thermostats with valves or cones.

Design

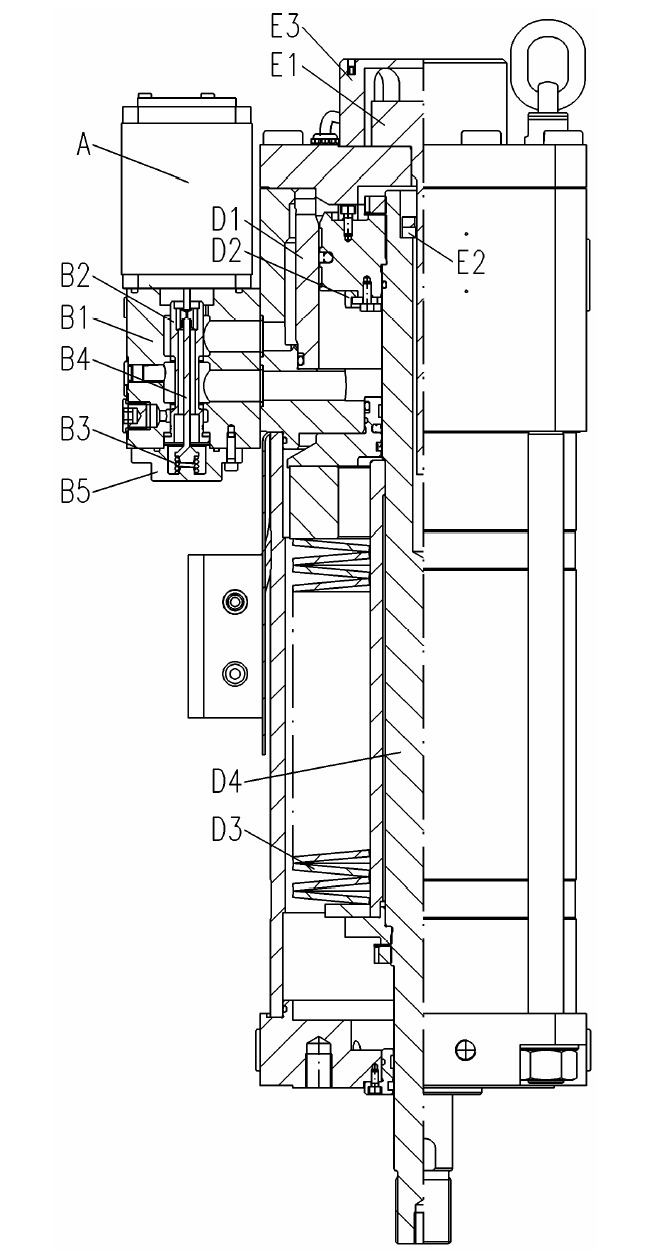

HP control valve drive

The servomotor consists of the following functional parts:

Voith control magnet VRM (A)

With integrated position and magnetic force adjustment

Control hydraulic valve, consisting of the following components:

Valve body (B1)

Control piston (B2)

Control spring (B3)

Rod (B4)

Cover (B5)

Drive unit consisting of the following components:

Power cylinder (D1)

Damper (D2)

Compression spring (D3)

Piston rod(D4)

Electronic position determination, consisting of the following components:

Position sensor (E1)

Sensor magnet (E2)

Cover (E3)

(Visited 1 217 times, 1 visits today)

Control valves

Operating principle

The control valve on the heating radiator is a device that allows you to automatically control the movement of the coolant.

The design of such products is quite complicated, but they also work much more efficiently than valves for manual adjustment:

The bellows is responsible for the perception of the outside temperature - a container filled with liquid or gas. As the temperature rises, the bellows expands, affecting the adjusting assembly.

Please note! The price of liquid and gas-filled devices is approximately the same, but the features of operation are different. So, gas models respond faster to temperature changes, and liquid models more accurately convey the effect on the coolant flow

- The expanded bellows presses on the valve stem, which lowers and gradually closes the valve saddle, through which hot water enters the battery.

- During cooling, the opposite situation is observed: the stem rises, and the saddle lumen expands.

We set the degree of initial compression of the bellows ourselves, either by setting the desired temperature value on the digital display, or by rotating the mechanical adjustment knob. It is also possible to connect the thermal valve with external sensors - in this case, the movement of the stem is controlled not by a bellows, but by a servo drive under the action of an electrical or hydraulic system.

Installing a thermostatic valve

Among specialists, the question of whether it is necessary to put taps on heating radiators is practically not discussed. Even the installation of a simple ball valve provides a number of advantages, and the presence of a high-quality thermostat even more so. However, the instruction advises to follow a number of rules when installing such devices:

Example of correct product installation

- First, you need to choose the appropriate modification of the valve. For systems with one pipe, we use products of the RTD-G type, for two-pipe systems - RTD-N.

- Secondly, before putting taps on heating radiators, we check the direction of movement of the coolant (indicated by an arrow on the body). If we confuse, then the device will work as you like, just not the way we need.

- Thirdly, we place the thermoregulatory head perpendicular to the plane of the battery. so that the heat flow does not affect its operation.

How to regulate heating radiators with taps is also a fairly simple question:

- Having installed the valve on the radiator, we check the tightness and supply the coolant to the system.

- Using the handle or dial, set the average temperature.

- After about an hour, we adjust the valve setting according to our feelings and referring to the thermometer in the room.

- If necessary, repeat the adjustment again. however, this is usually not required.

The system is adjusted by turning the handle

After that, it is usually necessary to intervene in the operation of the device no more than once a month - with sudden changes in external temperature.

Why do you need to adjust

Setting the optimal temperature of the radiators allows you to create the most comfortable conditions for your stay indoors. In addition, the adjustment allows:

- Remove the effect of airing in the batteries, allow the coolant to move freely through the pipeline of the heating system, effectively giving off its heat to the interior space of the room.

- Reduce your heating costs by up to 25%.

- Do not keep windows open all the time in case of excessive overheating of the air in the room.

Setting the heating and adjusting the batteries, it is advisable to do before the start of the heating season. This is necessary so that later you do not experience discomfort in the apartment and do not adjust the heating temperature of the batteries in emergency mode. Before setting up and adjusting radiators, it is initially necessary to insulate all windows in the summer. In addition, you need to take into account the features of the location of the apartment:

- In the middle or in the corner of the house.

- Lower or upper floor.

After analyzing the situation, it is advisable to use energy-saving technologies to maximize the preservation of heat inside the apartment:

- Insulate walls, corners, floors.

- Conduct hydro and thermal insulation of the seams between the concrete joints of the panel house.

Without these works, it will be useless to regulate the temperature of the radiators, since the lion's share of the heat will heat the street.

Criterias of choice

A radiator faucet is usually a ball-type device that regulates the flow of water and connects pipes to a radiator. It is installed on the bypass, risers, at the top of the battery, in places where air accumulates to bleed it.

Choosing the right faucet is not difficult, it is enough to know a few nuances:

- the diameter of the pipes to which it will be connected (DN, in millimeters or inches);

- working pressure (PN, in the range of 15–40 and above);

- type of connection, the presence of a thread inside or outside, American.

The choice should take into account the purpose of the reinforcement, its localization, the properties of the medium

It is also important the ratio of the inlet and outlet of the valve in the radiator, their relative position

When choosing, consider the characteristics of cranes:

- ball valves, although the most common and affordable, are not very effective. It has only two modes: closing/opening;

- a cone valve is a more acceptable option due to the possibility of an intermediate position. Disadvantage: the crane must be returned to its original position and constantly monitored;

- an automatic thermostat is the most efficient, reliable, but also much more expensive than others. When it is installed on a one-pipe system, a bypass must be present.

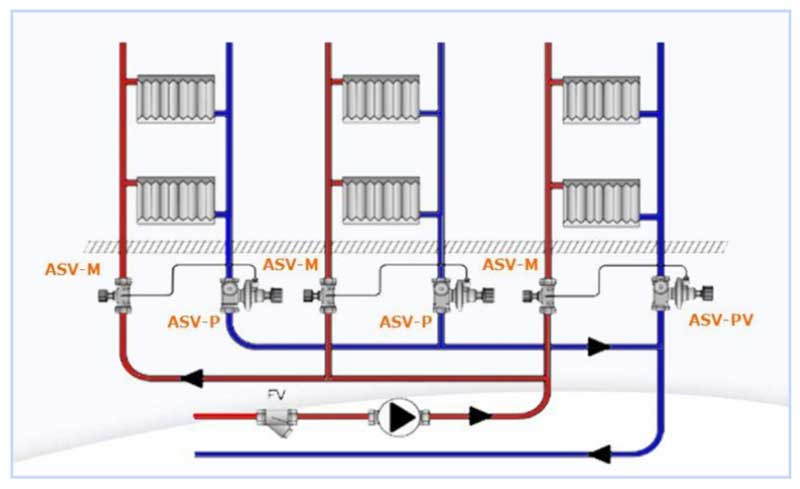

Balancing valve for heating system

Existing heating systems are conditionally divided into two types:

- Dynamic. They have conditionally constant or variable hydraulic characteristics, these include heating lines with two-way control valves. These systems are equipped with automatic balancing differential regulators.

- Static. They have constant hydraulic parameters, include lines with or without three-way control valves, the system is equipped with static manual balancing valves.

Rice. 7 Balancing valve in the line - installation diagram of automatic fittings

In a private house

A balance valve in a private house is installed on each radiator, the outlet pipes of each of them must have union nuts or another type of threaded connection. The use of automatic systems does not require adjustment - when using a two-valve design, the coolant supply to radiators installed at a great distance from the boiler is automatically increased.

This is due to the transfer of water to the actuators through the impulse tube at a lower pressure than the first batteries from the boiler. The use of another type of combined valves also does not require the calculation of heat transfer using special tables and measurements, the devices have built-in control elements, the movement of which occurs with the help of an electric drive.

If a hand balancer is used, then it must be adjusted using measuring equipment.

Rice. 8 Automatic balancing valve in the heating system - connection diagram

To determine the volume of water supply to each radiator and, accordingly, balancing, an electronic contact thermometer is used, with which the temperature of all heating radiators is measured. The average feed volume per heater is determined by dividing the total value by the number of heating elements. The largest flow of hot water should flow to the farthest radiator, a smaller amount to the element closest to the boiler. When carrying out adjustment work with a manual mechanical device, proceed as follows:

- Open all the adjusting taps to the stop and turn on the water, the maximum surface temperature of the radiators is 70 - 80 degrees.

- The temperature of all batteries is measured with a contact thermometer and the readings are recorded.

- Since the most distant elements must be supplied with the maximum amount of coolant, they are not subject to further regulation. Each valve has a different number of revolutions and its own individual settings, so it is easiest to calculate the required number of revolutions using the simplest school rules based on the linear dependence of the radiator temperature on the volume of the passing heat carrier.

Rice. 9 Balancing fittings - installation examples

For example, if the operating temperature of the first radiator from the boiler is +80 C., and the last +70 C. with the same supply volumes of 0.5 cubic meters / h, on the first heater this indicator is reduced by a ratio of 80 to 70, the flow will go less, and the resulting volume will be 0.435 cubic meters / h. If all valves are set not to the maximum flow, but to set the average value, then the heaters located in the middle of the line can be taken as a guide and similarly reduce the throughput closer to the boiler and increase it at the farthest points.

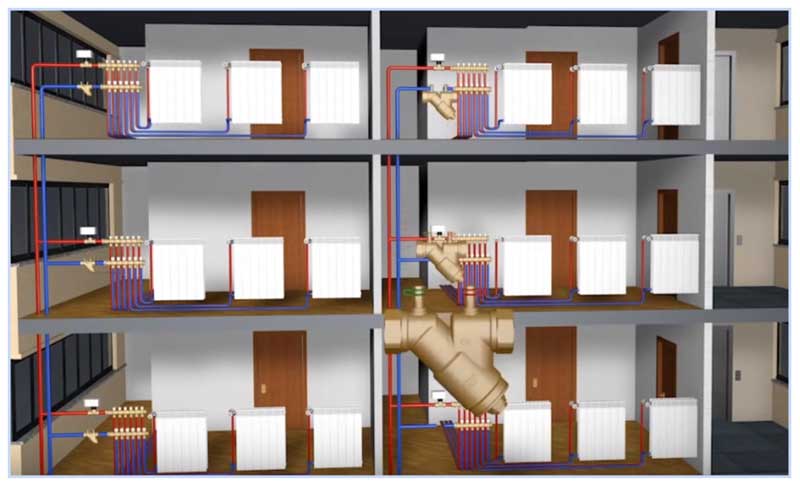

In a multi-storey building or building

The installation of valves in a multi-storey building is carried out in the return line of each riser, with a large remoteness of the electric pump, the pressure in each of them should be approximately the same - in this case, the flow rate for each riser is considered equal.

For setting up in an apartment building with a large number of risers, it uses the data on the volume of water supplied by the electric pump, which is divided by the number of risers. The value obtained in cubic meters per hour (for the Danfoss LENO MSV-B valve) is set on the digital scale of the device by turning the handle.

Features of installation and maintenance of regulators

Temperature controller installation diagram

After choosing the optimal model of a thermostat or a tap for adjusting the heating temperature, you should perform their correct installation. The location of the reinforcement directly depends on its function and design.

Most often, the adjustment components are mounted in the piping of a specific heating radiator. They are installed on the supply pipe or on the bypass.At the same time, in order to comfortably adjust the temperature of the heating batteries, it is recommended to adhere to the following rules:

- The device should not be covered with decorative panels or other interior items;

- The service life of thermostats largely depends on the quality of the coolant. Therefore, a strainer should be installed in front of it, which will protect the valve seat from limescale;

- When installing the heating temperature control valve, follow the installation diagram. Arrows on the body of the device show the direction of movement of the coolant;

- Many thermostats and servos are connected to the mains. Therefore, it is necessary to provide a power supply to them.

Before installing and further adjusting the heating batteries in the apartment, you must read the manufacturer's instructions. It prescribes the installation conditions for the operation of a particular adjusting element.

One of the important indicators of apartment heating control valves is the maximum and minimum throughput. They must match the current system settings.

Maintenance of regulators and taps

Pressurization is carried out only after the installation of control valves

After installation, pre-adjust the taps on the heating radiators. To do this, the temperature regime of operation and the pressure in the system must be normal. Then, by changing the degree of heating of the coolant, the operation of the control valves is checked. The system is tested in several modes. Alas, it will not work to independently adjust the heating in an apartment-type house according to this scheme, since consumers do not have the opportunity to change the degree of heating of the coolant.

In fact, it is possible to check the performance of a particular element only when starting the central heating supply. Those. correct adjustment of heating radiators in the apartment is carried out during the heating season.

During the start-up of the heating system, the heating system of a private house must be fully adjusted. It should include the following steps:

- Checking the performance of taps and thermostats;

- Compliance of their actual parameters with passport data;

- If a defective element is detected during the control adjustment of the degree of heating of the heating batteries, it must be replaced.

In addition, it must be remembered that a number of external factors affect the operation of the system: the degree of thermal insulation of the house, the climatic features of a particular region. This must also be taken into account when adjusting the temperature of the heating radiator.

The video shows an example of organizing the adjustment of heating radiators in a house:

Design and principle of operation

The principle of operation of the balancing fittings is to block the flow of liquid by a retractable valve or a stem, causing a decrease in the cross section of the passage channel. Devices have a different design and connection technology, in the heating system they can additionally:

- Maintain pressure drop at the same level.

- Limit coolant flow.

- Shut off the pipeline.

- Perform the function of draining the working fluid.

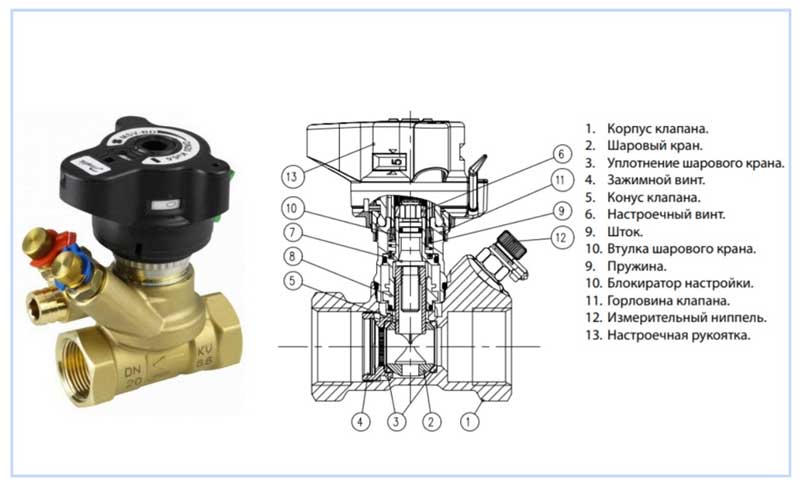

Structurally, balancing valves resemble ordinary valves, their main elements are:

- Brass body with two grommets with an internal or external thread section, designed for connection to a line with standard pipe diameters. Connection in the pipeline in the absence of a threaded fitting with a movable threaded nut (American) is made through its analogues - additional adapters with different union nuts.

- A locking mechanism, by moving which the degree of overlapping of the channel for the passage of the heat carrier is regulated.

Rice. 4 Danfoss LENO MSV-B manual balancing valve device

- Adjustment knob with scale and setting indicators, allowing you to adjust the flow inside the device.

- Modern models are equipped with additional elements in the form of two measuring fittings, with the help of which measurements of the flow volumes (throughput) at the inlet and outlet of the device are made.

- Some models are equipped with a shut-off ball mechanism that allows you to completely shut off the flow, or have the function of draining the liquid from the water supply.

- High-tech modern types can be controlled automatically, for this, instead of a rotary head, a servo drive is installed, which, when power is supplied, pushes the locking mechanism, while the degree of channel overlap depends on the magnitude of the applied voltage.

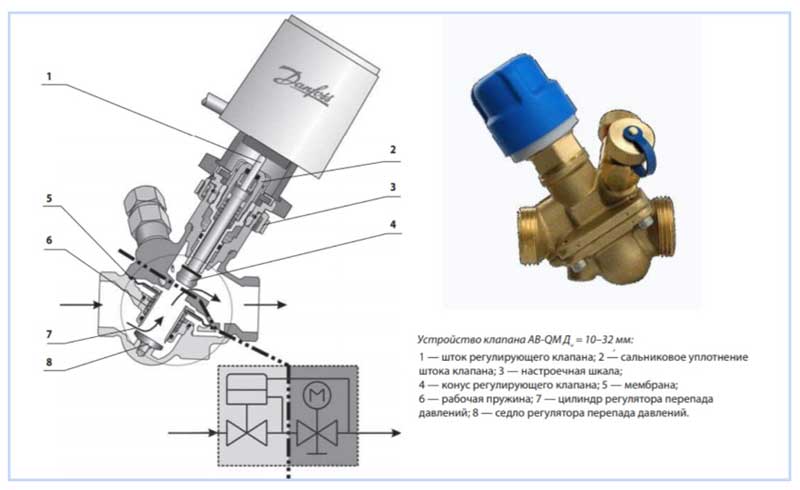

Rice. 5 Danfos AB-QM automatic balancers - design

Locking devices

Valves used for installation in a room heating system should be divided into two groups - shut-off and control. This division is largely arbitrary, since the shut-off valves also allow you to regulate the movement of the coolant. Naturally, in this case, the adjustment accuracy is quite low, but you can cut off the battery from the water source.

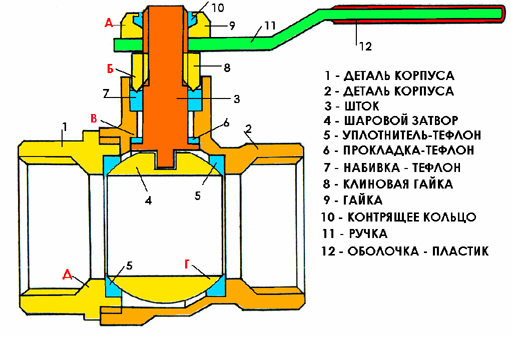

Scheme of a spherical structure

The simplest and most commonly used type of valves are ball valves:

The ball valve is designed to turn off the radiator. Its design allows the device to be set either in the open or in the closed position, so that the adjustment is carried out quite according to the principle of "there is heat - there is no heat."

Ball valves for heating radiators provide two-position adjustment

Please note! In principle, it is possible to fix the valve in an intermediate position, but then its wear rate will increase many times due to the friction of particles suspended in water against the locking element. So it is better not to do this unless absolutely necessary

- Blocking of the coolant flow is carried out due to the movement of a metal ball with a hole coaxial to the tube lumen. When the valve handle is turned, the rod comes into action, which rotates the sphere inside the body, aligning the hole in it with the lumen of the pipe.

- As a rule, faucet parts are made of steel, bronze or brass. Fluoroplastic gaskets are responsible for sealing the joints and the obturator, which, if necessary, can be replaced with your own hands.

- Connection to the radiator is carried out either with the help of a conventional nut, or with the help of an "American".

Ball design with an American

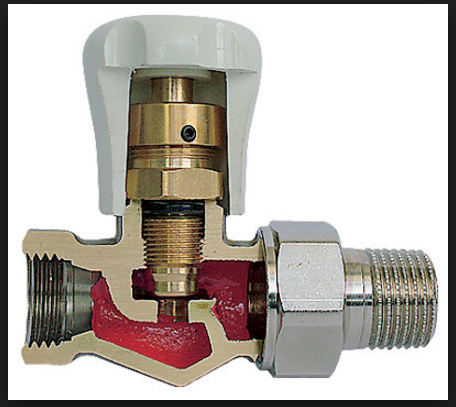

Unlike ball valves, cone valves make it possible to regulate the flow of coolant more smoothly. This is ensured by the features of their design:

Sectional device

- The locking element is a conical rod, on the surface of which a thread is applied.

- When we rotate the flywheel, the rod moves along the thread, moving in a vertical plane.

- In the lowest position, the lumen of the pipe is completely blocked. The tightness of the overlap is provided by elastic gaskets that are put on the annular grooves of the stem.

- Raising the shut-off part, we slightly open the gap, and the coolant begins to flow into the radiator.

Please note! It is possible to regulate the microclimate in the room only approximately by reducing or increasing the amount of hot water in each battery

Model in polypropylene case

In practice, bronze or brass cone valves for heating radiators are most often used: only systems are equipped with polypropylene, some of the pipes in which are also made of plastic. This is due to the relatively low strength and wear resistance of polymers compared to sanitary alloys.

On the other hand, polypropylene taps for heating radiators are somewhat cheaper, therefore, in conditions of a budget deficit, they can be used.

Mayevsky crane

When the coolant is poured into the heating system, air enters along with water or antifreeze.

To remove it, special devices are used - the so-called Mayevsky cranes:

Air release device

- The design of such a product is quite simple: it is based on a shut-off rod installed in a housing with a thread for a radiator plug.

- The stem is driven either by a screwdriver or a special key, opening the pipe clearance in the saddle.

Pay attention! If possible, buy valves for a screwdriver, since you will regularly lose the key, which is not surprising - you will have to use it once or twice a year. It must be borne in mind that the throughput of such a tap is small, so, for example, you should not put it on an expansion tank: it will take about an hour to bleed excess air

In such a situation, a conventional valve or a tap installed with a spout up is more suitable.

It must be borne in mind that the throughput of such a tap is small, so, for example, you should not put it on an expansion tank: it will take about an hour to bleed excess air. In such a situation, a conventional valve or a tap installed with a spout up is more suitable.

Photo of installed valve

Balancing Valve Manufacturers

Models of foreign and domestic manufacturers are widely represented on the construction market, some companies are leading suppliers of energy-saving equipment.

Danfoss is a Danish company founded in Nordborg in 1933 and is one of the world's leading manufacturers and suppliers of energy saving systems. The concern produces refrigeration equipment, power electronics, heat pumps, thermal and industrial automation, cable heating systems (warm floors). The product line is represented by shut-off, automatic and manual balance valves of the ASV and MSV series, combined models AB-QM, AB-PM.

Broen is a Danish company founded in 1948 by the Swedish engineer Paul Broen and entered the Russian market in 1996. The company's plant has been operating in the Kolomensky district since 2010. The concern is engaged in the production of a wide range of pipeline fittings, which include: ball valves, shut-off valves, check and balancing gates (Broen Ballorex), safety valves, cast iron filters. The line of fittings for balancing is represented by the Broen series: Venturi Fodrv, DRV, Dynamic, Venturi DRV.

Rice. 13 Balancing fittings from Danfoss and Broen

Giacomini is an Italian supplier of pipe fittings. The concern was founded in 1951, has a turnover of 170 million euros per year, 3 factories in Italy and 18 branches around the world, employing about 1000 employees. The concern produces control and shut-off valves for radiators, thermostats, collectors for heating and water supply, pipes and fittings for energy metering equipment, solar panels. Balance valves are represented by modifications R206 A, R206 B.

ADL is a Russian manufacturer of engineering equipment for the housing and communal sector and various industries. The company was founded in 1994, and since 2002 it has had its first plant in the village of Raduzhny, Kolomna district, Moscow region.

The company produces a wide range of sanitary equipment: control check valves, pumping units, gate valves, valves and ball valves, circulation and steam condenser pumps, heating points, separators. The line of balancing valve devices is called Granbalance and consists of models of the DN series.

Fig.14 Giacomini automatic balancing valve and ADL

The balancing valve for the heating system is the most important device for maintaining a constant temperature in risers or heating radiators. Their use in everyday life is not entirely justified.The cost of one device from a well-known manufacturer reaches 100 USD, domestic devices are also not cheap. It is more rational to use devices to maintain the temperature in the risers of apartment buildings with a large number of radiators.

Any heating system must be configured properly. The main goal of this setting is to ensure the same performance in all parts of the network. For example, if this is the heating system of a multi-storey building, then the heat should be both on the top and bottom floors. These indicators should not only be equivalent, but also close to the normative ones. One of the most effective ways to adjust is to use a balancing valve, the installation of which should ideally be thought out at the stage of creating a heating system project.

Why are there taps on radiators?

Each heater is a separate element of the system that needs adjustment and periodic maintenance. If, however, the flow of coolant through the batteries is controlled depending on the need for heat, then good results can be achieved in terms of energy savings. That is, radiator valves and taps for heating are designed to solve such problems:

- Complete isolation of the heating device from the system.

- Restriction of the coolant flow through the battery.

- Change in coolant flow depending on external conditions.

- Bleeding air from the radiator and piping network.

There are many situations in which it is difficult to do without disconnecting the battery. For example, a properly functioning central heating in the middle of spring, when it is already warm outside, and the apartment is just hot. Another case is the need to remove the heater in order to replace, flush or repair. In the absence of shut-off valves, it becomes problematic to carry out any action with the radiator.

Valves put on batteries in retro style

Restriction of the flowing coolant is carried out in order to balance individual heating in a private house or apartment

No matter what type of heating system you have, without balancing with valves, the first batteries will always receive more water than the last ones. To limit the coolant flow at the beginning of the network and thereby equalize all the devices with each other is the task of the control radiator fittings

Automatic control of the flow of the incoming coolant is a way to save energy used to heat the house. If each faucet on the heating battery maintains the set air temperature in the room, controlling the flow of water through the radiator, then in general the system will consume only the required amount of heat, no more. And that's a big savings.

Well, the problem of air release when filling the system or during operation is also solved by special air valves installed on all modern radiators. Below is a list of varieties of shut-off and control valves, listed in the same order as the tasks it solves:

- Semi-turn ball valves in straight and angle versions. They are made of brass, bronze or polypropylene with a metal insert.

- Balancing valves for radiators - straight and angled.

- Adjusting valves with thermal heads (thermostatic valves).

- Drain valves - automatic and manual.

For reference. Some home craftsmen use three-way mixing valves to connect heaters. But such a solution is unreasonably expensive and rarely used in practice.

Now we should consider in detail which taps are best placed on radiators in various conditions and circumstances. Some options are clearly shown in the video:

balancing valve

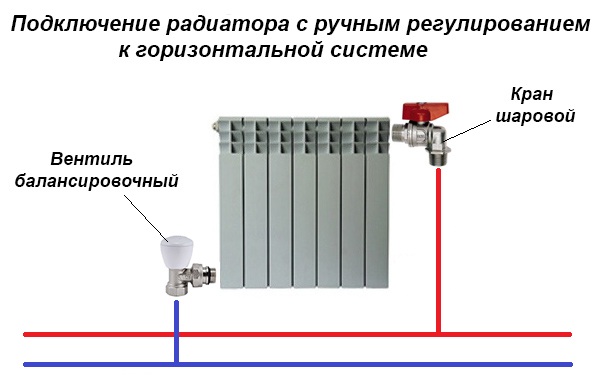

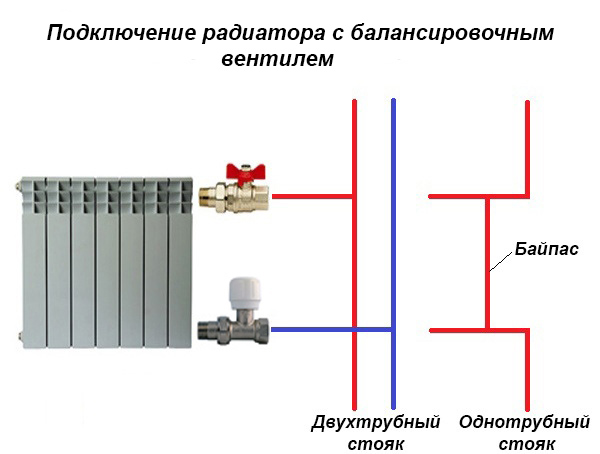

The valve for adjusting heating differs in design from a conventional ball valve in that it can smoothly close the flow area in a few turns. Moreover, after balancing, the position of the valve can be fixed so that no one accidentally violates the settings. This type of control valves is placed at the outlet of the radiator, as shown in the diagram:

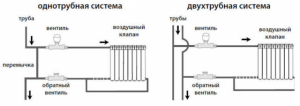

Shown here is the connection to a two-pipe horizontal system, the most common in private houses and apartments with individual heating. By the way, the principle of mounting fittings with a single-pipe scheme remains the same. An ordinary ball valve is placed on the supply line, and an adjusting valve is placed on the return line. In the case when a system with vertical risers takes place in a two-story house, then the installation diagram of the associated fittings looks like this:

The principle of product selection is the same as in the previous section.

Direct or angular execution is accepted depending on the layout of equipment and pipelines, it is also important to use American women when assembling

Pay special attention to the quality of the casting and the thickness of the brass walls of the reinforcement. If you have networks of polypropylene pipes, do not rush to buy PPR taps, it is better to put adapters and reliable metal products

Advice. Balancing valves are placed on all radiators, except for the last one, which is at the dead end of the branch. On the connections to it, it is enough to put simple ball valves.

Step by step instructions for adjusting the temperature

To ensure a comfortable stay in the room, you need to perform some basic actions.

- Initially, on each battery, it is necessary to bleed the air until water flows in a trickle from the tap.

- Then you need to adjust the pressure in the batteries.

- To do this, in the first battery from the boiler, you need to open the valve by two turns, in the second - by three, and then in the same way, increasing the number of turns of the opened valve on each radiator. Thus, the coolant pressure is evenly distributed over all radiators. This will ensure its normal passage through the pipes and better heating of the batteries.

- In a forced heating system, control valves will help to pump the coolant, control the rational consumption of heat.

- In the flow system, the temperature is well regulated by the thermostats built into each battery.

- In a two-pipe heating system, it is possible to control not only the temperature of the coolant, but also its amount in the batteries using both manual and automatic control systems.