Water pump repair Kid video

Before starting the repair of the "Kid" pump, it is necessary to accurately establish the cause that caused this or that malfunction. This will depend on the correct troubleshooting.

- The detachment of the electromagnet can lead to the fact that the water pressure will be much weaker than that provided for in the data sheet. In the normal state, the electromagnet is attached to the bottom of the housing using a special epoxy potting compound. As a result of long-term operation, it may peel off, as a result of long-term operation of the device. To eliminate this problem, we remove the magnet from the case, beat off the remains of the compound that has not exfoliated from its surface, and with the help of a sharp object draw small grooves on its surface. Then we coat the electromagnet with sealant, the composition for glass is better suited, and again we press it into the body. When the sealant is fully set, the "Kid" can be assembled and launched.

- When the size of the gap between the coils of the piston and the electromagnet of the vibrator is not correct, the engine may fail. Normal operating clearance should be between 4 and 5 mm. With a higher value, the electromechanism will overheat, and with a lower value, the likelihood of coil wear increases. To adjust the gap, we disassemble the vibrator, up to the shock absorber. Then we assemble all the components again on the rod, if necessary, adding or removing washers between the piston sleeve and the shock absorber, achieving the clearance between the coils to the required value of 4-5 mm.

- The pump hums when turned on, but water does not flow through the hose. There are several reasons for this. The most harmless - the nut on the adjusting screw is too tightened. It should be weakened and try to start the "Kid" again. Another reason is the rupture of the rubber piston cuff. In this situation, it does not make sense to glue it, but it is easier to buy and install another one. Another reason, also beyond repair, is a broken central piston rod. Here you should also purchase a new part and install all other parts of the vibrator on it.

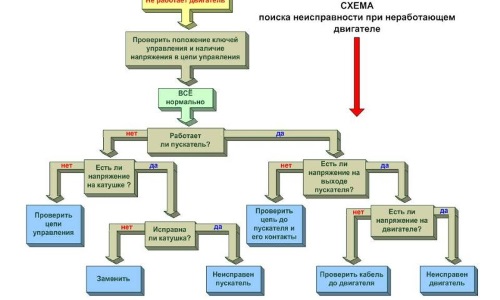

Troubleshooting Algorithm

Troubleshooting.

If the unit pumps water weakly or stops working completely, you need to turn it off and lift it up. Then you should disconnect the hose and check for obvious damage to the device.

Stage 1: careful external examination

If microcracks are visible on the surface of the case, it is necessary to replace it. If the integrity of the unit is not broken, the tester should check the resistance of the coils (the norm is about 10 Ohms) and the absence of their short circuit to the metal casing. A burnt coil should be replaced by a specialist.

Then you need to lightly blow into both nozzles of the pump - the air should pass unhindered. With sharp exhalations into the inlet, the valve should close.

Then we immerse the apparatus for 5-6 hours in water with the addition of 9% table vinegar to dissolve limescale. Rinse it again with clean water.

Then, gradually releasing the locknut and the clamping nut on the pump intake, we repair the valve clearances. The norm is 0.5-0.8 mm. At a finely adjusted device, lowered into a container of water without a hose, a fountain appears 0.5-1 m high.

Stage 2: a closer look from the inside

To find a defect, disassembly of the unit is required. You can do it yourself. Necessary:

To find the cause of the breakdown, it is necessary to disassemble the pump.

- Scratch the symbols on the case with a sharp object, so that later, during assembly, exactly combine the lower and upper parts along them.

- Loosen all the screws fixing the pump cover at the same time. If they are very rusty, cut off the hats with a grinder.

- Take out the piston, core, rubber gaskets.

Assemble the device in the exact reverse order. In this case, it is necessary:

- accurately seat the piston disc, it must be at least 4 mm from the coil;

- combine the openings of the housing and gaskets, otherwise the unit will be depressurized;

- free from litter all its internal space;

- check - if it is in good condition, a fountain 0.5-1 m high should appear.

Step 3: Troubleshooting the electrical problem

If you need to repair an electrician, it is better to contact the factory. A burnt coil is easier and cheaper to replace with a new unit.

If the electromagnet has completely peeled off, you can try to fix this problem with your own hands:

- take out the electromagnet;

- apply on it and on the inner surface of the body with a grinder intersecting grooves up to 2 mm deep;

- lubricate the compound with glass sealant and press the magnet into place using a press;

- after the composition has solidified, assemble the pump.

Stage 4: correction of mechanical violations

Procedure:

- The tearing of the membrane can be eliminated with rubber glue.

- A broken shock absorber should be replaced with a new spare part.

- A worn piston must also be replaced. From it you need to pull out the sleeve and press it into a new part. Between the piston and the housing, it is necessary to adjust the gap of 4-5 mm by removing or adding washers.

- The required distance between the anchor and the yoke is achieved by adjusting the washers and locknuts, the final tightening of which is carried out when it is 6-8 mm.

- The projections of the coils and the rod anchor must necessarily match. Adjustment is carried out by loosening the nuts.

- A gap of 0.6-0.8 mm between the new valve and the water intake hole is achieved by tightening the screw.

The operating conditions of the vibration pump must be exactly observed. They are described in detail in the technical data sheet of the device. Then the probability of breakdowns of the "Baby" will be minimal.

Pump modifications and characteristic differences

Many of the same type of vibration devices have only a body of a different configuration and a different name:

- "String";

- "Chestnut";

- "Brook";

- "Neptune";

- "Sega" and others.

All these units use the same electromechanical circuit. There are 4 types of such devices:

- "Kid" is the most popular among villagers, summer residents and the most powerful option from the entire line of vibration submersible pumps. This is a design with a lower water intake. However, the device is not suitable for use in the near-bottom zone, since it often sucks in silt deposits and quickly breaks down.

- "Kid-K" - a similar device, also with a lower water intake. But it differs from the basic model with a built-in thermal relay, the presence of which increases the reliability of the unit and extends its service life. Because of this, it costs more. In addition, the pump is equipped with a three-wire wire and has a ground connection. Previously, the model was produced only for export.

- "Kid-M" - an option with an upper water intake. In terms of power, it is slightly weaker, but does not absorb dirty slurry from the bottom of the well. It is not exposed to overheating during prolonged operation and breaks less often. When the water level is insufficient and the intake becomes impossible, the hull is still cooled, because. partially submerged in the source.

- "Kid-3" is the smallest model with a diameter of only 80 mm, which has an upper water intake. Ultra-small dimensions allow it to be placed in narrow wells and wells. Water heating is allowed up to +35°С. The maximum depth of the operating apparatus is 3 m.

The main types of malfunctions and their causes

Devices with a lower water intake are more likely to break down, because the engines in them heat up more. The causes of defects due to which the pump does not pump water lie either in its mechanics or in the electrician.

The most common problems of the "Baby":

- loosening nuts due to vibration of the core;

- valve wear caused by abrasive impurities in the water;

- breakage of the core rod.

Electrical faults

Due to strong heating, such breakdowns often occur:

- a short circuit occurs;

- the electrical wire is charred or broken;

- the copper winding burns out in the coil;

- exfoliates from the body of the compound.

Mechanical breakdowns

Most often, such defects are detected:

- clogging of the internal cavity of the pump with mechanical impurities;

- liming parts due to excessive water hardness;

- loosening nuts due to strong vibration;

- damage to the device from impacts on the concrete wall of the well;

- weakening of the properties of the rubber shock absorber;

- loss of valve elasticity;

- piston failure.

Disassembly of the pump Kid

Before repairing the Baby pump, it must be properly disassembled. The main thing in this matter is not to damage the whole parts, and remember the procedure in order to properly assemble the mechanism after repair. Before disassembly, drain the water from the pump and turn it off. Next, you need to use a sharp object or a marker to apply marks on the two halves of the case in order to properly dock them during assembly.

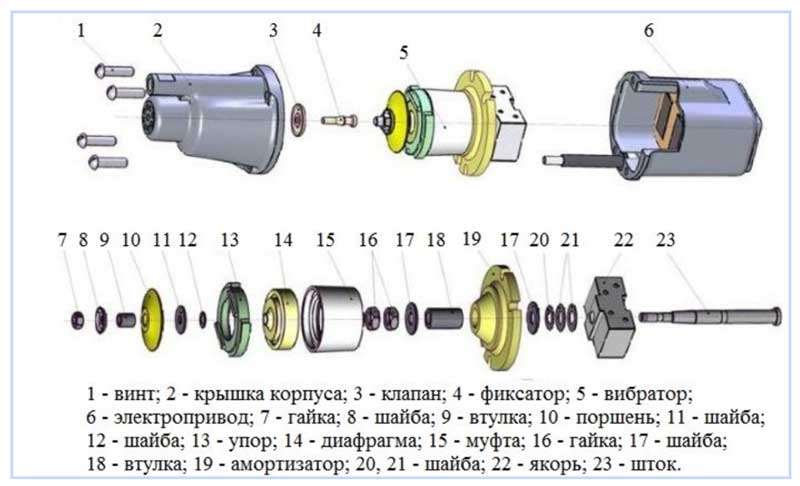

Then the body of the "Kid" is clamped in a vice in a vertical position, just below the butt joint of the upper and lower parts. All fixing bolts are unscrewed, and the upper part of the mechanism case is removed. Next, we unscrew and remove the fixing nut from the vibrator bushing, and remove all the parts put on the rod. The main components of the vibration pump:

- Piston.

- Focused diaphragm.

- Electro coupling.

- shock absorber.

- Anchor.

All of the above parts are strung on the central rod, and washers and locknuts are installed between them.

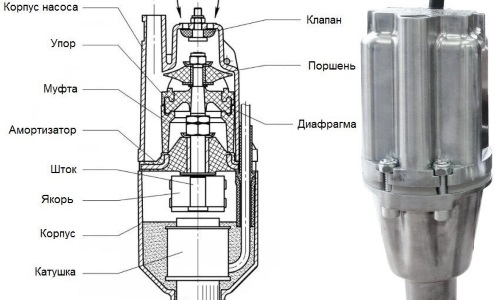

Device and principle of operation of the unit

Pump device.

Its body is divided into 2 parts. A yoke is pressed in at the bottom. These are 2 electric coils with a core, filled with a compound (polymer resin), an anchor. In the upper half is the mechanical system. A vibrator with a piston rests on a shock absorber made of elastic rubber. A non-return valve can be installed on the water intake pipe and pumped out.

The principle of operation of the device is simple. When it is connected to the network, the coil creates an electromagnetic field. The heart starts to vibrate. The membrane does not allow it to sway much, and the shock absorber returns to the neutral position. The piston attached to the anchor pushes the elastic mixture of fluid with air, and the water pump starts to work. This creates a movement of fluid in a hose or pipe.

The core performs 50 vibrations per second. With a similar speed, the piston makes forward-return movements. The portions of water regulated by the valve rush in the set direction and pour out from an outlet branch pipe.