How to eliminate typical malfunctions of circulation pumps

In circulation pumping devices, there are a number of typical malfunctions that you can fix yourself. Each block will describe the symptoms of a malfunction, its causes and do-it-yourself repair steps.

Pump hums, no rotation

The cause may be the oxidation of the motor shaft during a long idle time of the pump. Troubleshooting guide.

- Turn off the power to the equipment.

- We remove water from the pump and pipelines adjacent to it.

- We remove the screws fixing the housing and the electric motor.

- We dismantle the electric motor complete with the rotor.

- We turn the rotor by hand or with a screwdriver, resting against the working notch.

The next reason for such a malfunction may be the ingress of foreign objects.

- Turn off the power to the equipment.

- We remove water from the pump and pipelines.

- We remove the screws fixing the housing and the electric motor.

- Remove the foreign object.

- We protect the inlet pipe of the pump with a strainer.

Also, the reason for the lack of rotation can be a lack of power supply. To do this, with a tester, we check the presence of power at the terminals in the box and the correct connection of the electrical wires.

The pump does not hum or rotate

The main cause of such a malfunction may be a lack of power supply or insufficient voltage in the network. To eliminate it, it is necessary to check the voltage at the terminals with a tester and, if necessary, the correct connection of the device to the power supply.

Many electric pumps are equipped with a fuse. During power surges, it burns out and needs to be replaced.

Pump starts but stops after a while

The cause of such a malfunction may be the deposition of limescale between the stator and the rotating rotor. The malfunction is eliminated by dismantling the electric motor and cleaning it from limestone deposits.

The pump makes a lot of noise when turned on

The cause of such a malfunction may be the presence of air in the pipeline of the heating system. To eliminate it, it is necessary to release air from the pipes. For automatic air release, it is recommended to install an automatic unit in the upper segment of the pipeline.

If a sharp noise is accompanied by increased vibration, it is recommended to increase the pressure at the inlet to the pumping device. Insufficient pressure can be compensated by increasing the level of the coolant in the system.

Pump vibrates a lot

The cause of such a malfunction is usually a strong wear of the bearing that ensures the rotation of the impeller. The malfunction is eliminated by replacing the worn bearing.

What to do if the pump produces insufficient pressure?

The cause of such a defect may be the wrong direction of rotation of the wheel with blades. The reason for this phenomenon is usually an incorrectly connected phase with a three-phase connection of equipment.

Also, a decrease in pressure can be caused by an increased viscosity of the coolant, then the impeller encounters too much resistance. To eliminate it, it is necessary to clean the filter on the inlet pipe from deposits, check the cross section of the inlet pipeline and set the necessary parameters for adjusting the pump.

What to do if the pump stops after starting?

Most likely, the cause of such a malfunction may be the incorrect connection of the wires in phases in the terminal box. The fuse on your pump may not be tight enough. Remove it and clean the clamps.

Seal materials for Wilo

Durability, reliability, high quality of mechanical seals for Vilo pumps are ensured by the use of modern innovative materials. They are resistant to abrasion and corrosive liquids. The sliding joint is selected according to pump models and pumping liquids.Some sealing elements must be resistant to gasoline, grease, oil. Others must show resistance to acid, alkali, chemical compounds.

Secondary seal:

NBR is nitrile butadiene rubber. Effectively functions in the temperature range from -20°С to +120°С. EPDM is ethylene propylene rubber. Operating temperature range from -30°С to +170°С. VITON - fluoroelastomer, successfully operates at temperatures from -30°С to +185°С. PTFE - fluoroplastic, operating temperature range from -260°С to +260°С. The precise selection of sealing materials allows for the pumping of a wide range of liquids, including chemically aggressive and toxic liquids.

Implementation

You can always buy sealing components for WILO pumps on our website. To do this, you need to fill out a simple application, call by phone or write to the company's e-mail.

| Wilo BN, DPn, IPn | ||

| Seal type | STU | Aritkul |

| Mechanical seal 18/32/174/274 | STU1 | 120613693 |

| Mechanical seal 45/55/274/394 | STU2 | 120613796 |

| Wilo DP, IP, IPL | ||

| Seal type | Shaft diameter | vendor code |

| Mechanical seal 32/40/50/65/80 | 17 | 122097593 |

| Mechanical seal 32/40/50/65/80 | 17 | 2062360 |

Mechanical seal MG1, MG12, MG13

| Wilo BL, DL, IL | ||

| Seal type | Shaft diameter | vendor code |

| MG12/18 G60 AQ1EGG | 18 | 2026901 |

| MG12/18 G60 Q1Q1VGG | 18 | 2064430 |

| MG12/24 G60 AQ1EGG | 24 | 2026902 |

| MG12/24 G60 Q1Q1VGG | 24 | 2064431 |

| MG12/32 G60 AQ1EGG | 32 | 2026903 |

| MG12/32 G60 Q1Q1VGG | 32 | 2064432 |

| MG12/43 G60 AQ1EGG | 43 | 2052335 |

| MG12/43 G60 Q1Q1VGG | 43 | 2064433 |

| MG12/55 G60 AQ1EGG | 55 | 2052336 |

| MG12/55 G60 Q1Q1VGG | 55 | 2064434 |

| MG12/80 G60 AQ1EGG | 80 | 2056452 |

| MG12/80 G60 Q1Q1VGG | 80 | 2064435 |

| Wilo MHI 2/4/8/16 | ||

| Pump brand | Seal type | vendor code |

| Wilo MHI 2/4/8/16 | MG12/14-z AQ1VGG | 4027348 |

| Wilo MHI 2/4/8/16 | MG12/14-z AQ1EGG | 4027347 |

| Wilo MVI 2/4/8/16/32/52/70/95 | |||

| Pump brand | Seal type | Shaft diameter | vendor code |

| WILO MVI 2/4/8 | MG12/14-z AQ1EGG | 14 | 4027301 |

| WILO MVI 16/32/52 | MG12/22-z AQ1EGG | 22 | 4043156 |

| Wilo MVI 70/95 | MG12/24-z AQ1EGG | 24 | 4100494 |

| WILO SCP | |

| vendor code | Seal brand |

| 2793291 | MG1/100-G60 AQ1EGG |

| 2793284 | MG1/75-G60 AQ1EGG |

| 2790293 | MG1/80-G60 AQ1EGG |

| 2796181 | MG1/40-G60 AQ1EGG |

| 2793288 | MG1/50-G60 AQ1EGG |

| 2793285 | MG1/60-G60 AQ1EGG |

| 2793290 | MG1/95-G60 AQ1EGG |

| 2796183 | M74/130-00-Q1AEGG |

| 2796129 | M74/115-00-Q1AEGG |

| 2796130 | M7N 90 Q1AEGG |

| 2790441 | H75N/35-00 Q1Q1VGG |

Wilo Bn, DPn, IPn 18/32/174/274 120613693;

Wilo Bn, DPn, IPn 45/55/274/394 120613796;

Wilo NL, AQ1EGG d24mm 2104402;

Wilo NL, AQ1EGG d32mm 2104407;

Wilo NL, AQ1EGG d45mm 2104413;

Mechanical seal for Wilo pumps IL, BL, DL, DP, IP, IPL, MVI, DPn, IPn, Bn, NL

Mechanical seal for WILO MVI pumps

Cartridge mechanical seal for WILO MVI 9505 pumps

1 Design and technical features

Vilo pumps significantly increase the efficiency of the heating system and the heat transfer of the coolant. Their use makes it possible to use pipes with a smaller cross section when assembling the line, which will reduce fuel costs, reduce carbon dioxide emissions, and make it possible to achieve savings without losing the quality of operation. This is achieved through a properly thought out and developed design, designed for continuous operation.

Checking the water jacket of the rotor

The Wilo pump consumes no more than 250 W per day, the operation is silent, since there is no fan and similar technical elements that produce noise. There are two types of circulating equipment on sale - with a dry and wet rotor. The latter are used in the installation of heating systems, as a rule, inside small buildings. The difference also lies in the power and volume of the pumped medium. The weakest model is able to make the heating system more efficient on an area of 200 sq.m.

Powerful is designed for heating buildings, the area of which reaches 1000 sq.m. Both the one and the other unit has the most simplified design and small dimensions. The technical characteristics regarding the head height make it possible to raise water from 8 meters at a flow rate of 5 m3/h.

Distinctive features are the strength and corrosion resistance of the Wilo pump material. For example, the body is cast iron, the shaft located inside it is stainless steel. Its fastening is possible thanks to graphite bearings. The water flow rate is equipped with a three-stage adjustment.

1.1 Operating requirements and prevention

In order to avoid premature repair of Wilo pumps, the manufacturer urges to adhere to the following:

- Do not allow the appliance to idle when there is no water in the system. Dry running destroys the insulation, disturbs the cooling of the electric motor and disables all equipment.

- The operating mode is set strictly in accordance with the maximum-minimum capabilities of a particular model.

- When the pump is switched on, the coolant flow must not be blocked.

Dismantling the circulation pump

Subject to these rules, the pump will be characterized by maintaining a stable pressure, and the sound emitted during operation will be uniform and quiet. Most pumps do not need to be repaired for 5 years from the moment they are put into operation. It is required only when the main components are completely worn out or force majeure circumstances that caused the device to fail.

Prevention is another type of periodic measures, the implementation of which insures the pump and its elements against premature breakdowns. At the same time, simple maintenance is carried out with his own hands, without the intervention of a specialist. To do this, visual inspection of the external and internal parts of the unit should be carried out at least 3-4 times annually and cleaned if necessary.

Practice shows that cleaning becomes mandatory after 2-3 years of operation. The quality of the coolant, the general conditions under which the heating system operates affects the conduct of cleaning procedures.

For prevention, it is necessary to prepare a Phillips and flat screwdriver, a spanner wrench, and a cleaning brush. Inspection requires disassembly, during which you will find the main components of the hydraulic structure: housing, impeller, motor shaft, rotor, terminal box, propeller and the motor itself

Pay attention to such nuances:

- grounding performance;

- absence of leaks at the joints;

- pressure value in accordance with technical standards;

- lack of vibration and extraneous sounds (knocking, clanging);

- hull condition. It must be clean and dry;

- the pump should not get very hot;

- the amount of grease on bearings, flanges and driving units must be sufficient;

Also make sure that the terminal box cables are free of moisture and securely fastened, gaskets provide a seal, and connections to the mains are strong. Before dismantling the device, water is drained from the system, the area of \u200b\u200bits receipt is blocked, after which the pump is removed.

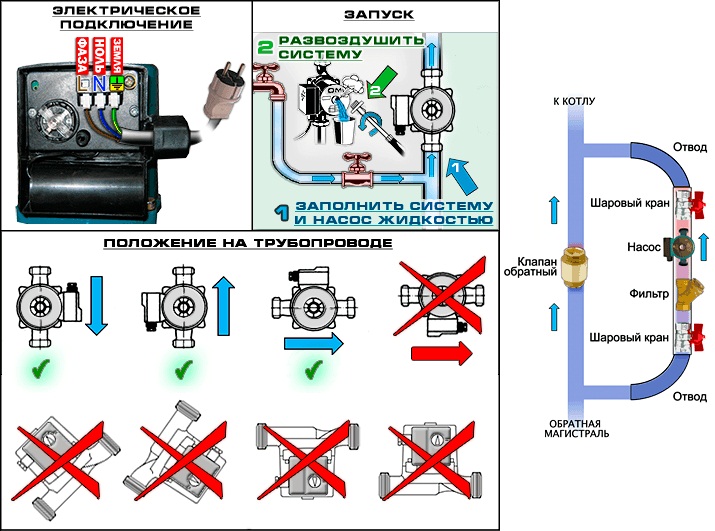

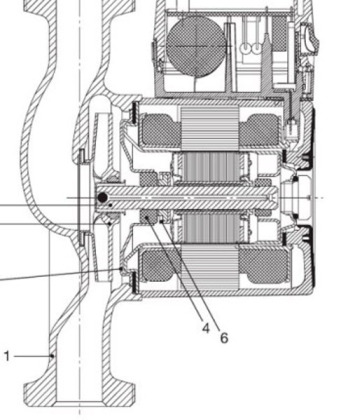

Rules for installing and connecting a circulation pump

6 bolts connecting the shell of the pump part and the motor housing are unscrewed with a spanner. When the shell is removed, access to the drainage holes will appear. The impeller remains on the motor rotor. With the help of a narrow flat-type screwdriver, a shirt is prying off, which serves for the impeller and motor compartment. The actions taken will bring the rotor shaft and impeller out of the stator cup.

Variety of species, their features

Vilo pumps are designed for:

- on personal plots;

- in country cottages;

- in offices;

- in municipal and industrial systems.

The main areas for which the manufacturer develops and modernizes its products are:

- domestic water supply systems;

- hot water and heating systems;

- pressure control in the water supply system;

- removal and drainage of sewage.

Vilo pumps create unique technological conditions for saving energy (circular models reduce energy consumption by up to 50%). The technical characteristics of Vilo pumps comply with the standards that are in force in the European Community.

The range of WILO AG is wide and varied, the company supplies equipment to the market, which is divided into three types:

- Pumps with a "wet" rotor (circular).

- Models with a dry rotor.

- Vilo centrifugal pumps.

Recommend owners of private houses to use devices with a "wet" rotor. The advantages of these models:

- They work silently.

- Mounting is easy and simple.

- Differ in the long term of operation.

- In service unpretentious.

- Save energy.

- Compact, light weight.

Wilo circulation pumps are a new generation of equipment, because they consume little electricity and smoothly regulate the flow. Representatives of the Wilo-Stratos PICO series are considered the most effective.

The Wilo Stratos pump regulates the flow by changing the rotor speed, while the Wilo-TOP-S model protects the housing and prevents condensate from destroying it.

Dry rotor pumping equipment from WILO AG can be:

- With single or double valve.

- Special.

- With block single valve.

- Cantilever double-sided.

Single or double samples are ergonomic units that are used to supply water without abrasive inclusions, and block single equipment is used for pumping water glycol mixtures.

How to prepare circulation pumps for the winter heating season

In order for your heating pump to work smoothly throughout the cold season, routine maintenance must be carried out before the start of the heating season.

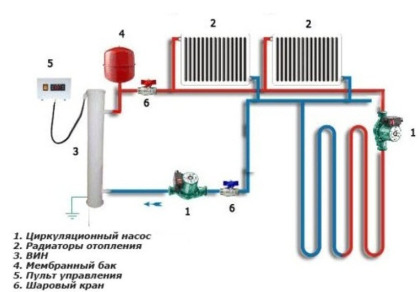

- Check that the pump is correctly connected to the heating pipe network. Pumping equipment must be installed in a place in the irrigation network where there is a minimum possibility of air locks. It is rational to place it on the return line, in front of the heating boiler.

- Before starting operation, make sure that all connecting elements of the network have retained their tightness. To prevent drying out of the gaskets, the inlet and outlet pipes are covered with preservative grease during a break in operation.

- Check the condition of the filter in front of the pump inlet. Replace or clean it if necessary.

- Check that the device is properly connected to the power supply. It checks not only the tightness of the contacts on the terminal box, the health of the fuse, but also the correct connection of the phases and the magnitude of the operating voltage in the network. It is best to check these characteristics with a tester.

- Before starting the operation of the heating circulation pump, it is imperative to carry out a test run, which must confirm the complete tightness of the system and the serviceability of all its components and equipment.

Sectional pump

How to dismantle and disassemble the circulation pump

If, during the test run of the equipment, shortcomings of the pumping device were identified that cannot be eliminated without dismantling and disassembling it, you will have to perform the following operations.

- At the preparatory stage, the pumping equipment is de-energized. When installing the pump, a bypass is built into the piping system - a heating bypass pipe. During normal operation, it is blocked. For long-term repairs, it may be necessary to connect an additional pumping device to the system.

- Unscrew the shut-off valves securing the pump, remove it.

We disassemble the circulation pump

Scheme of pumping equipment

With a serious repair of pumping equipment, it is necessary not only to dismantle it, but also to disassemble it. It is performed in the following sequence.

- The cover of the circulation pump is fixed on the body with bolts. These can be bolts for a Phillips screwdriver or a hexagon. During operation, the bolts can "stick". This problem can be solved with the help of specialized aerosols, also called "liquid key". It is applied to the bolt and after a few minutes it can be easily unscrewed.

- We remove the cover. Before us is a rotor with a rotor fixed on it with a wheel with blades. Usually it is held on by clips or bolts. Remove it and you will get access to the "insides" of the pumping equipment.

- Inspect the pump, identify the faulty part and replace it.

Helpful Hints

Self-repair of circulation pumps should be carried out only after the end of the warranty period or if it is impossible to obtain qualified technical assistance. A number of pump assemblies are quite difficult to find on the open market.This is usually caused by the trade policy of the manufacturers, so be prepared for the fact that in some cases it is cheaper to buy new equipment, rather than fix broken equipment.

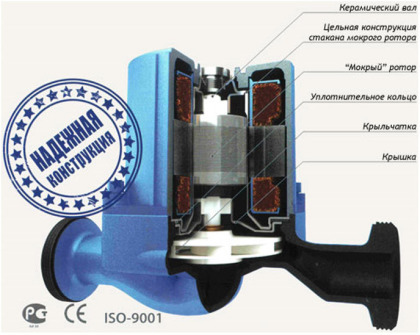

Glandless pump device

To learn more about repair technologies for circulation pumps, watch the training video.

Related video

Do-it-yourself circulation pump repair - step by step instructions

Do-it-yourself circulation pump repair

Circulation pumping devices are very popular with owners of private houses and summer residents. The range of pumping equipment is quite wide, but the general principles of the device are the same. Such equipment can stop from minor breakdowns, for example: the pressure switch of the pumping station does not work, what should I do? Take a broken pump to a service center? It costs money, and in many regions there are simply no service companies. Therefore, the economic owner of the house must know how to install a do-it-yourself water pump.

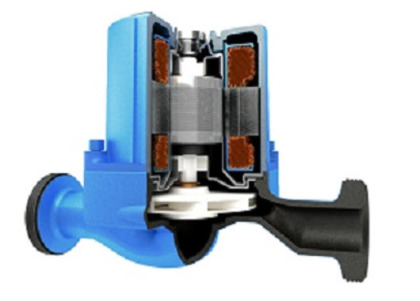

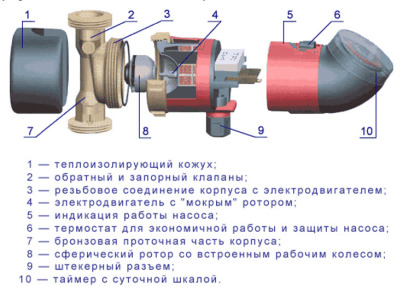

Circulation pump device

To understand how to independently disassemble, maintain, repair the circulation pump, you need to know its device. Such equipment is arranged as follows:

- all components and mechanisms are housed in a housing made of steel (mainly stainless steel), aluminum and other alloys;

- inside the housing there is an electric motor with a rotor;

- a wheel with wings is installed on the rotor - an impeller, which is usually made from technical polymers.

Circulation pump device

The principle of operation of circulation pumps

After turning on the electrical circuit, the engine begins to rotate the rotor with the impeller mounted on it. Liquid is supplied to the central part of the pump. The blades rotate and throw water or other coolant to the outside of the housing. Under the action of centrifugal forces, the liquid moves and enters the outlet pipe of the pump.

Circulation pump in the heating system

Types of circulation pumps

Currently, there are two main types of circulating pump devices on the market.

- "Wet type" - in such equipment, the rotor is completely immersed in the pumped liquid. A significant advantage of this configuration is the cooling of rubbing and heating parts by contact with the liquid. Such equipment is quieter and less expensive. When installing it, it is necessary to maintain the position of the body specified by the manufacturer (usually horizontal), since the rotor must be completely immersed in the liquid. Also, wet-type devices are easier to maintain, but very sensitive to the lack of fluid in the system (running dry can quickly disable the pump).

- "Dry type" - in such devices, the pump motor is placed in a separate compartment or module, and the torque is transmitted to the rotor through a drive device (coupling). Dry type pumps are more efficient, but also more complex. A "dry" pump can operate without damage and without liquid in the system, but such operation will lead to increased wear on the drive.

Also, circulation pumps can be divided into types according to the method of execution:

- monoblock;

- console, consisting of separate blocks.

Pump with cap removed

How to properly operate the circulation pump

- Never turn on the pumping device without liquid in the heating pipelines.

- Keep the volume of water pumped by the pump within operating specifications. Exceeding or lowering the volume of pumped water, relative to the indicators specified in the technical passport, is unacceptable. If the pump is designed to pump from 5 to 100 liters of water per hour - pumping 3 or 103 liters of water wears it out a lot.

- If your pump is idle for a long time, then once a month turn it on for about a quarter of an hour. This will help prevent oxidation of moving parts and subsequent damage.

- Maintain the temperature in the water supply pipes no more than 65 degrees. If the coolant temperature is exceeded, the sediment can damage the moving parts of the pumping device. Water temperatures above 65 degrees (for example, 70-80 ° C) contribute to the rapid wear of equipment.

How to perform regular pump maintenance

Pump device option

- Turn on the pump and check for abnormal noise and excessive vibration while operating.

- Check the pressure of the coolant supplied by the pump. It must correspond to the indicators stated in the technical passport.

- Make sure that there is no excessive heating of the electric motor of the device.

- Check the presence of grease on the threaded flanges and, if necessary, restore it.

- Make sure there is a ground connection between the pump housing and the appropriate terminal.

- Inspect the pump from all sides and make sure there are no leaks. Typically, such vulnerabilities are the junction of the pipeline and the housing of the pumping device. Check the level of tightening of the bolts and the normal condition of the gaskets.

- Examine the terminal box. All wires must be securely fixed. The presence of moisture is unacceptable in the node.

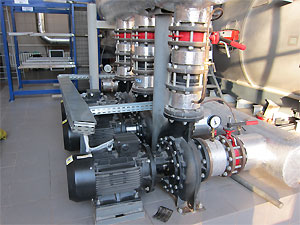

Example of diagnosing seal leakage on a group of pumps

An application was received at the Service Center for the replacement of seals on a group of pumps. The reason for the call is leaking seals. The pumps were installed no later than one year. Installation of pumps and commissioning were carried out independently without the involvement of Certified Specialists of the manufacturer or a Certified Service Center.

Seals were replaced on two pumps. After that, the pumps stopped leaking. A test run was made. Everything works fine. The seals were warranted for one (1) year. This means that if the seals fail within a year, they will be replaced under warranty. Such Grundfos Authorized Service Center Service Rules.

A few days later, an application was received: both pumps are leaking again.

As already known, the warranty conditions are fulfilled by the manufacturer only if the client observes the rules of installation, commissioning and operation. To do this, Certified Service Technicians must inspect the pumps for compliance with the manufacturer's requirements.

So let's go directly to the diagnosis of these pumps.

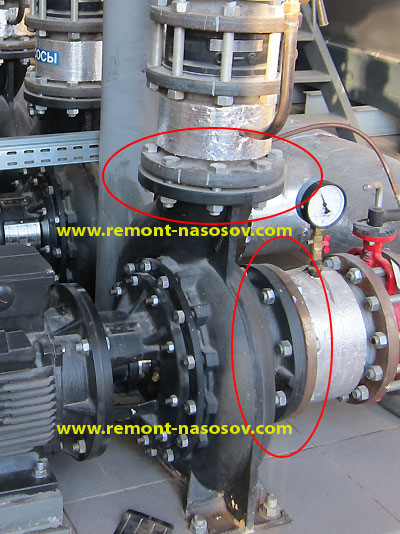

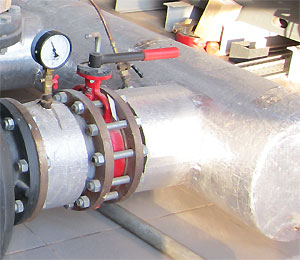

During visual inspection, many parameters are evaluated. In the article, we will consider the process of diagnosing flange connections of problematic pumps - in the photo they are circled in red.

To diagnose flange connections, they need to be unwound and an inspection of the junction of pipelines to the pump flanges should be carried out.

First, disassemble the upper flange connection.

After unwinding all the bolts, the flanges parted to the sides by 5-7mm. This is clearly visible in the photo. This indicates that the installation of the pump was incorrect. The pipe flange is not correctly aligned with the pump flange. And when assembling the connection, the pipe pulls and warps the pump. The pumps belong to the heating system. When pumping a hot liquid, the materials of pipes and connections expand and additional tension is caused on the flange. Compensators - vibration inserts are not installed. Although on heating systems they are required.

Next, we disassemble the second flange connection.

The result of the analysis of the horizontal flange connection is that the pipe flange settled below the pump flange by 7-8 mm. Vibration inserts are not installed on the pipe.This downward tension is exacerbated by the expansion of materials when pumping hot heating fluid and the absence of vibration expansion joints.

These violations of the installation of the pumps lead to a transverse bending of the shaft of the pump part. In other words, there is a bending of the shaft and a divergence of the ceramic parts of the seal, which leads to leakage and rapid wear of the seals.

After dismantling one pump, the load on the pipelines partially decreased and the leakage of the second pump stopped. This is a secondary confirmation of shaft misalignment due to tension on the flanges.

During visual inspection of the pipelines, another reason was determined - the lack of proper supports under the lower pipelines. This also creates an additional load on the flanges.

Since the leakage of the flanges disappeared when the flanges were unloaded, it means that the seals did not have time to be damaged by the misalignment of the shafts. They do not need to be replaced.

If the seals would fail. they would void their warranty because they were not installed correctly. This means that the replacement of seals would have to be carried out on a paid basis.

In this case, the Service Specialists drew up a Diagnostic report, where they indicated all the detected errors in the installation of the pumps.

In this case, the payment for the visit for diagnostics is paid by the client, since the installation of the pumps does not comply with the manufacturer's warranty conditions.

Further, the Customer must independently eliminate the installation errors indicated in the act and install the pumps into the system.

We reviewed a brief overview of pump installation errors leading to pump leakage and pump seal failure using a real, fairly common example. We hope this will help you avoid similar problems in the operation of the pumps you have purchased.

Service Service.