Squeegee connection device and its designation

Steel couplings with zinc coating or without it, having a double-sided thread, are designed to connect water and gas pipes in heating systems, gas pipelines, water pipes and other lines with a non-aggressive working fluid at temperatures up to +175 C. and pressure less than 1, 6 MPa. (16 atm. or bar.). To connect the pipeline with plumbing and gas equipment, the fitting includes a coupling (it has side longitudinal ribs for coupling with a gas wrench) and a lock nut with standard dimensions corresponding to the external pipe thread of the fitting in accordance with GOST 8969-75.

Fitting marking according to GOST 8969-75 includes the name of the part (spur), nominal diameter, material of manufacture (letter C for galvanized steel) and an indication of the above standard. Marking example - Sgon 25-C GOST 8969-75.

Rice. 4 Squeeze installation

Connecting the circuit and batteries

To understand the methods of connecting heating pipes to a radiator, let's start by considering the materials from which heating systems can be made. They can be different:

- steel;

- copper;

- propylene;

- PVC;

- PEX;

- metal-plastic.

All of them perform one single function - this is the transportation of the coolant from the boiler room (boiler) to the radiators, which, in turn, give off heat and thereby heat the room. All batteries are threaded to the system. To do this, fittings with a transition to the thread are installed on the circuit. They are placed on polymer circuits by soldering or pressing. Copper is only brazed, while steel can be connected with press fittings and threads.

In any case, a threaded connection is connected to the battery. How to connect a heating battery with

Schemes for connecting batteries to heating

pipe, diagrams:

- bottom connection;

- side connection;

- diagonal connection.

The most effective option is the diagonal. In this case, the supply to the battery is carried out from above, and the return line exits from the bottom of the opposite end. The difference in temperature of the radiator with different connection methods is insignificant, therefore, first of all, you should start from the location of the battery. Complete with new batteries there are always parts for connecting them:

- nuts marked "S" and "O";

- plug;

- Mayevsky crane.

Before connecting the heating radiator to the pipe, nuts are screwed into the holes at the ends of the battery, and then, depending on the wiring, plugs, a Mayevsky tap and an American are screwed into them.

An American is a nut that can spin with a fixed fitting. By the way, when connecting heating pipes to a heating boiler, it is also necessary to install taps with an American. At the same time, it is necessary that the American is wound not on the boiler pipe, but on the circuit. Then it will be possible to safely remove the boiler and water will not pour out of it.

Some masters do not put cranes when tying batteries, which leads to difficulties in further operation. If you want to remove and clean the battery, you will have to drain all the water from the system, and then fill it up. And if a water hammer happens in winter and breaks the radiator, what then? It turns out that it will be necessary to stop the entire heating system in order to replace it. This is despite the fact that hardly anyone has a spare radiator on duty at home.

You will need to go to the store, buy it, find the master. It will take at least half a day, at sub-zero temperatures outside there is a risk of defrosting the system. And then it will be necessary not only to change the batteries, but also to repair the entire circuit. If you install taps, you can cut off the radiators without stopping the entire system.

What are sgons

Sgon is a connecting piece that looks like a short tube with a short thread at one end and a longer thread at the other.The locknut and the entire coupling are put on here.

It is recommended to take shackles for pipes with sufficiently long threads, otherwise all the parts will not fit in the threaded area, and then it will be necessary to increase the distance between the connected ends of the pipe and the shackle, as a result, the strength of the connection will be reduced.

This connecting part is most often used when laying water pipes. Therefore, it must be treated with anti-corrosion agents.

The most common types of metal pipe fittings are:

- Nickel-plated. These surges give the pipeline a more beautiful look, therefore, they are most often used in residential premises. However, they are more expensive than conventional steel parts.

- Galvanized. They are used in open areas where atmospheric phenomena will affect the pipeline.

- Steel. Used for pipelines laid in the ground. They are painted to prevent corrosion.

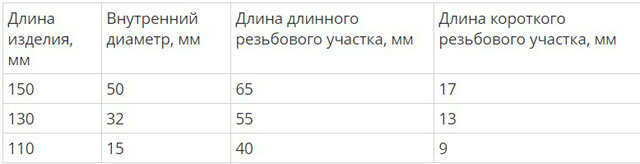

The State Standard defines the following sizes of spurs for pipes:

- 150×50×65×17 mm, where the first value is the length, the second is the inner diameter, the third is the length of one threaded section, the last is the length of the other threaded section;

- 130×32×55×13 mm;

- 110×15×40×9 mm.

How to choose a sgon

When choosing a drive, you need to consider:

- type of connecting fitting;

- fitting material;

- technical specifications.

Varieties of sgons

It is possible to classify sgons according to the following criteria:

- depending on the design, there are:

- direct drive, designed for installation on a flat section of the highway (figure above);

- corner run, designed for areas with the need to change the direction of the pipeline system;

Fitting for changing the direction of the main

Straight and corner sgons differ only in appearance and purpose. All other parameters are completely identical.

- depending on the scope of application, there are:

- compensating slopes. In most cases, such devices are installed at the points of connection of plumbing or gas equipment, heating radiators, as they allow compensating for pipe deviation within 5 cm;

- short and long spurs used to connect other equipment of the pipeline system.

Varieties of squeezing for the pipeline

Many, especially novice plumbers, classify fittings such as barrels and threads as varieties of squeegee. However, this assertion is erroneous.

The barrel is a piece of pipe with threaded ends. In contrast to the squeegee, threads of the same length and size are applied to the pipe on both sides. Such a device is intended for connecting pipes without welding.

Fitting for connecting pipes to each other

A thread is a fitting made from a piece of pipe with a thread at one end. The device is used to connect other types of threaded fittings to a water, gas or heating system.

Device for mounting threaded fittings

Selection of manufacturing material

For the manufacture of sgons, materials such as:

- carbon steel. Steel fittings are characterized by low cost and a large margin of safety. However, due to the strong susceptibility to corrosion, their installation is carried out mainly on gas supply systems;

- galvanized steel. Such fittings are not subject to the formation of corrosive deposits, therefore they can be used in water supply systems, including drinking water supply and heating, as well as on other pipelines in places where precipitation is possible;

- stainless steel. Unlike galvanized fittings, stainless steel fittings are more expensive and are mainly intended for drinking water systems, as well as for connecting pipes in the ground;

- brass. Currently, due to the high cost, it is practically not used.

Brass pipe fitting

Definition of technical parameters

Metal slings are made in accordance with GOST 8969-2010. When choosing parameters, consider:

- thread type. Spurs can be left-handed or right-handed, internally or externally threaded. The selection of this parameter is carried out on the basis of the data of the equipment that needs to be connected using a fitting;

- conditional passage of the fitting in accordance with the diameter of the pipeline;

- the size of the thread applied to the fitting.

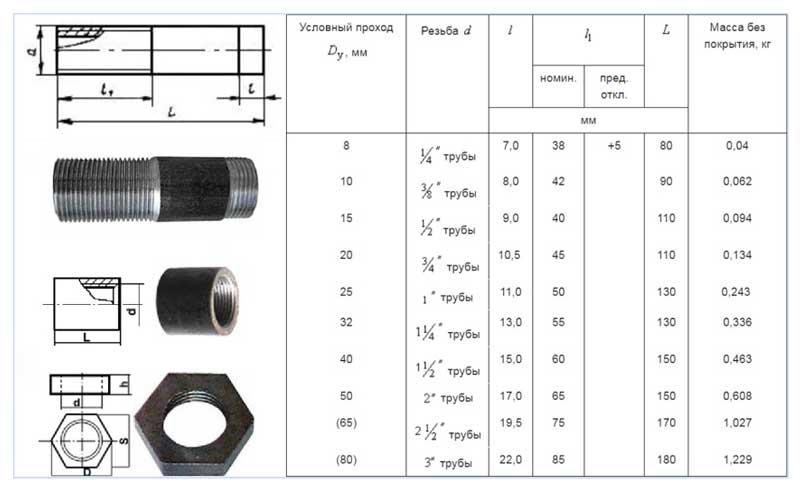

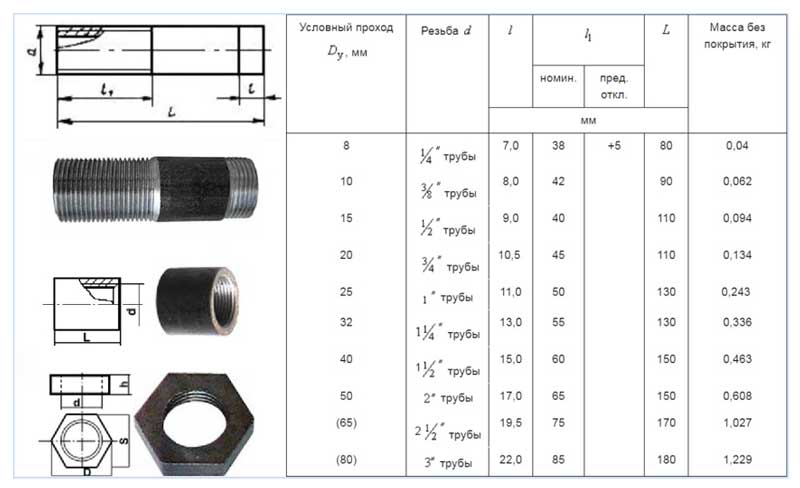

Standard sizes of metal spurs in accordance with GOST

All technical parameters are indicated in the fitting marking, which is applied in accordance with GOST 8969-75. For example, Sgon40-Ts GOST 8969-75 indicates that the fitting is made of galvanized steel (Ts) in accordance with the technical regulations and has a nominal bore of 40 mm.

How to crash into a pipe without welding

How to crash into a pipe without welding is of interest to that owner of the house who decided to redevelop or expand the living space. Not every person owns the technology of welding. Yes, and the equipment is expensive enough to acquire it in the property for a one-time work. Therefore, the question always arises of how to carry out work without welding.

There are three methods of tapping into a pipe without welding:

- With the help of a pipe;

- Tapping under pressure with an adapter;

- Tapping without pressure with the help of a sitter.

Problems in the course of work performed

All work is carried out with a water pipe. The following problems may occur during this process:

- The water pipe may be placed in the wall or run too close along the wall. This greatly complicates the work ahead.

- Some designs require a male-female connection. At the end of the pipe there is a socket with a seal. It is quite difficult to insert it into another pipe.

- When replacing, usually one long pipe is replaced by two segments that are joined together by a branch pipe. Such a connection is not very simple.

Features of tapping with a nozzle

This process is carried out without a cutting tool, because. nothing needs to be disconnected. You just need to purchase a pipe in a hardware store. The main thing is that its size matches the diameter of the water supply.

Stages of work:

- A hole for the pipe is drilled on the surface of the pipe. It is done using a special core drill.

- Fixing the nozzle on the water pipe. The cut hole must be completely aligned with the notch of the nozzle. A wrench and a screwdriver are used in the work.

- A rubber seal is taken and inserted into a pipe fixed to the pipe.

- Inserting the drainage hose into the pipe through the rubber seal.

Because the plumbing system has a weakness for leaks, then all joints must be treated with sealants. It is sold in automotive beauty stores. The silicone substance smears around the hole, but this should be done at a distance of 1 cm.

If the pipe is made of steel, then the created hole must be sealed with a clamp. If the pipe is polyethylene, then ordinary electrical tape will do.

Insertion into the water supply

Feature of tapping under pressure

If the water supply is under pressure, then the tie-in into such a pipe is done using a special device. It's called a nurse. It consists of two parts that wrap around the water supply on both sides. Among plumbers, there is such a slang name for a nurse as a tie-in collar.

The nurse helps to very quickly create the required number of branches from the pipe for the organization of drinking water supply systems, for technical needs.

The nozzle in this situation rotates 360 degrees

It is very important that the part is made of the same material as the pipe. Then the overall structure will be able to withstand the pressure under the pressure of which the water supply functions.

Feature of tapping without pressure

To implement this method, you need to use an adapter. All work must be done in stages:

- First you need to turn off all the water in the house;

- Using a drill and a core drill, a round hole is made in the plumbing.

- Aligning with the hole on the pipe, the adapter is located. Then it is fixed in place with bolts. If conventional fixation is used, then the surface of the water supply must be cleaned and degreased. Only then apply the adapter and tighten the nut.

After each method of tapping into the water supply, you need to resume the water supply and test the new design.

The video below shows how to make a tie-in using a clamp outlet:

Do-it-yourself production of a squeegee

If necessary, you can make a squeegee of the desired size yourself. To complete the work you will need:

- metal steel pipe - a pipe cut of the appropriate length;

- carpentry vise to facilitate work;

- equipment for threading: a die with a die holder for external threads or a tap for applying internal threads;

- file (intended for chamfering);

- grinder (hacksaw) for cutting, if you need to cut off part of the pipe for harvesting the drive;

- lubricant.

The work is done in the following order:

- with the help of a grinder or a hacksaw, a workpiece is cut off for a drive of the appropriate length;

Cutting a pipe with a grinder for making a squeegee

In accordance with the recommendations of experts, the length of the run should be 3-5 mm longer than the pipe break.

- chamfer is removed from the ends of the prepared cut;

- edges are treated with grease to facilitate threading;

- the drive is clamped in a vice;

- the selected equipment is threaded. The short part of the thread must be at least 5 threads, and the long part must be 20 threads. If necessary, the long part can be increased to 30 threads.

Thread cutting

When making the squeegee on your own, you should not forget about the personal protective equipment of the master. It is recommended to use gloves and a protective mask when cutting pipes.

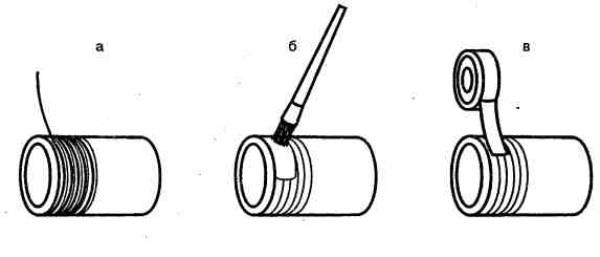

Types of seals

Previously, there was no such variety of seals as today. Some plumbers use the full range of materials in their work, and there are conservatives who still recognize only linen. Are they right? Let's figure it out. How to seal the thread on the heating pipe:

- fum tape;

- flax with paste;

- anaerobic adhesive sealant;

- sealing thread.

Flax dries in systems with a hot coolant, and rots in cold water. In the first and second cases, the result of the process will be the appearance of a leak. Thanks to the paste, the fitting can be released a little after twisting, making a turn back no more than 45 degrees. Universal material, suitable for connecting metal heating pipes, as well as for polymers.

Flax is suitable for all types of threads on heating pipes, regardless of diameter. It is the cheapest of seals.

It is important to wind it correctly:

- with the help of a cloth for metal or a file, notches are made on the thread;

- a strand of flax is rolled into something like a thread;

- winding is carried out in the course of fitting tightening (usually clockwise);

- protective paste is evenly applied.

Linen seal

When winding flax, it is important not to overdo it. First you need to make the first turn, which will secure the seal on the thread

This leaves a tail. On the second turn, the remaining tail is picked up and wound together with the common fiber. Make sure there are no twists. It is necessary to distribute the material along the thread evenly from the end to the body of the fitting. When working with flax, when connecting heating pipes, you need to watch your hands, as they are constantly smeared with paste. If you take hold of a polypropylene pipe with such hands, an imprint will remain.

Fum tape is used for thin-walled fittings and connectors with fine threads. It is easy to work with the material, hands are always clean.At the same time, fum tape is quite expensive and is mainly used for small diameters. A significant drawback of this seal is the impossibility of adjustment. That is, if the joint of the heating pipes is twisted and needs to be released a little to center it, then the connection loses its tightness.

The sealing thread, like the fum tape, does not need lubrication and the use of a special paste. It can be wound on dirty or wet threads, suitable for plastic.

Sealants are applied to clean and degreased threads (usually new). They are:

- dismantled;

- difficult to dismantle.

And in fact they are not dismantled. Before connecting the heating pipes using a sealant, you must be prepared for the fact that the connection can be disassembled only after heating. And only then, perhaps, it will be possible to unscrew it. But during installation, the joints do not even need to be tightened with keys.

Installation of spurs

The main advantages of installing sleds are:

- ease of installation. Connecting pipes with a drive does not require a welding machine and skills to work with it. The work can be done by a novice master;

- low cost;

- obtaining a detachable connection;

- the possibility of carrying out repairs without shutting down the entire pipeline.

Fitting Locations

Sgons are recommended to be installed:

- after taps and / or valves, which will allow you to turn off the subsequent section of the pipeline system for repair or maintenance work;

- on the central risers of any system;

- when connecting equipment (heating radiators, boilers, individual metering devices, and so on);

- on fixed liners.

Places where installation of a drive is required

fitting installation

To install the pipeline, you will need to purchase a shackle with a coupling and a lock nut (a standard fitting kit).

Fitting set "Sgon"

The connection of the sleeves with a coupling is carried out according to the following scheme:

- a lock nut is installed at the end of the long thread, and then the coupling is screwed on;

- sections of the pipeline system are connected;

- the coupling moves smoothly over a short section of the thread until it stops (“jamming”, as professional plumbers prepare);

- a long section of the thread is sealed in any way: you can use an ordinary linen thread with additional fixation with paint or a special composition; you can use specialized tools, such as FUM tape, Tangit Unilok thread and so on;

Thread seal options

- the coupling is fixed with a locknut;

- all assembly elements of the connection are fixed with a gas key;

The sequence of assembly of the pipeline with the help of squeegees

- the tightness of the resulting connection is checked. If there is a leak through the fitting, it is recommended to increase the amount of sealing material and tighten the nut more tightly.

What is squeezing and how to install it, look at the video.

Standard shackles can be installed on piping systems subject to the following conditions:

- the maximum pressure inside the line does not exceed 16 atmospheres;

- the maximum temperature of the working environment is 175°C.

If it is necessary to install spurs on systems with other parameters, it is required to manufacture spurs according to individual parameters.

Where are sleds used and installed

Surges are used in water pipes, heating systems, gas pipelines, they are installed:

- In the water supply and heating lines after the valve on the riser. This allows you to remove the shut-off valve from the pipeline in case of a malfunction for repair or replacement.

- When connecting to a heating radiator from cast iron of an old sample of pipes, their use also allows you to clean the pipeline from lime deposits and rust.

- On the eyeliner when connecting autonomous equipment for heating water - gas boilers, boilers, expansion tanks and plumbing fittings (faucets with a herringbone connector).

- On the pipeline for supplying gas to household and water heating equipment - stoves, boilers.

- Sometimes spurs are used in sections of the system to obtain an additional outlet, while the coupling is replaced with a tee, and the distance between the pipes is increased.

Rice. 3 Steel cylindrical drive - dimensions according to GOST 8969-75.