dangerous temperature

For comparison, consider a number of studies conducted by scientists in the twentieth century, to observe the effects of the influence of regular visits to the steam room, heated to extreme values of 110-130 ° C.

Professor H. Teir in the 80s of the last century put forward an assumption about the connection between the high temperature in Finnish saunas and the occurrence of cancer, which was subsequently confirmed by the results of a large study. After reviewing a significant number of cases of lung cancer among those who like to take a steam bath at 110-130 ° C, it was found that staying in a steam room heated to such temperatures contributes to the formation of this disease.

The fact is that in such conditions it is possible to be only when the air in the room is very dry, and this excludes the hydrostatic effect of steam on the body. As a result, the lungs are not well supplied with blood, and they get burned due to the inability to adapt to the elevated temperatures to the necessary extent.

A number of other studies have also found that exposure to dry, superheated sauna air negatively affects sperm production and also leads to digestive problems in children born to mothers who frequented such baths during pregnancy.

Discussions "what bath oven temperature

” or about the temperature around the stove in the steam room - a lot. Unfortunately, all of them are conducted on an intuitive level and only a few experts devote entire studies to this issue using pyrometers, thermometers and other equipment. How does the temperature of the sauna stove and the steam room really differ from the one that the thermometer shows us?

Bath lovers are not builders and for the most part they coordinate the oven modes with their feelings. The other half of the bathers glance at the thermometer. I decided to find out what is the difference between our perceptions, between the data of the arrow of a universal thermometer and what a remote digital temperature meter will show us.

Some of the temperature measurement data puzzled me, which I wrote about in the conclusions after the video.

By and large, we are not interested in the temperature of the furnace, but in the conditions in the steam room. Your skin is more expensive than the cover of a piece of iron. Therefore, I measured everything where I shot the laser pointer of the device. I wanted to draw temperature measurements with a diagram, but decided to make a video with remarks

Attention! I used a device with a maximum measurement threshold of 330 degrees (frames in the furnace furnace)

The correct temperature in the steam room

You can talk a lot about the rules of classic health-improving bath procedures, but in this article we will dwell on the temperature in detail. If we talk about the temperature in the steam room that is most suitable for health in all respects, then this indicator lies between 50 °C and 70 °C

. In the classic Russian bath, stoves were always built of brick and, as a rule, they were with closed heaters. Such a design was simply not able to heat the steam room above 60 ° C and in order to sweat well, it would be necessary to sit in it for too long, but a way out was found.

A ladle of water was poured onto the stones heated to red from a direct flame, which instantly turned into a light hot finely dispersed steam, the most comfortable for both the respiratory tract and the skin. A cloud of steam rose to the ceiling and a person lying on a shelf with the help of brooms was gradually doused with this steam in small portions. With a competent technique of injecting steam into various parts of the body, the process of soaring brings not only unforgettable positive sensations, but also the strongest healing effect.

When designing your own bath, it is important to understand that in addition to the correct temperature, in order to obtain the full range of positive effects of soaring on the body, the bath must also have a certain humidity. The optimal indicator lies within 60%

It is this combination of temperature and humidity that provides ideal conditions for the healing of the whole organism.

It is possible to achieve that the steam room has both the indicated temperature and the correct humidity at the same time only if the stove in it with a closed heater

It is very important to obtain high-quality finely dispersed steam that the stones in the furnace are heated to at least 300 ° C. And if the heater is open, then when the stones are heated in it to such an extent, the stove itself will be so hot that the temperature of the steam room will go beyond 70 ° C

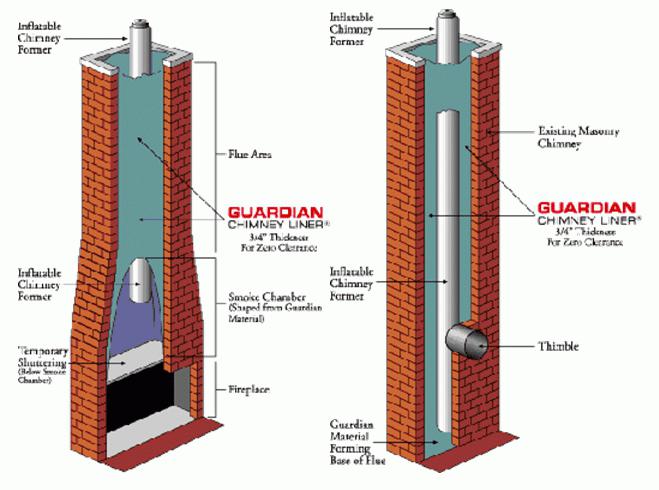

Chimney materials

Before purchasing materials, it is necessary to determine the design features of the chimney.

brick system

The construction is made of heat-resistant bricks using a special dry mix or kiln clay. In addition, material may be needed to create a fungus over the pipe.

Metal construction

Before purchasing material for the manufacture of a metal chimney in a bath, it is necessary to draw up its exact diagram with a detailed location of all the corners and turns of the pipe.

You will also need 2 iron sheets with holes corresponding to the diameter of the pipe. They are fixed on the ceiling of the bath and on the floor of the attic. You will also need heat-resistant material, which will be fixed around the pipe at the point of its exit to the wooden attic.

To create a waterproofing around the chimney on the roof, it is necessary to prepare a sealant or a special rubber seal.

Pipe selection: what to look for

When buying iron chimney pipes, you need to decide on their cross section. Basically, it depends on the power of the stove, but for most bath options this parameter is 15-20 cm. Do not take too large a diameter, as it will retain heat poorly. And too small - it will not create the draft necessary to remove the smoke. Whatever it was, the pipe section should not be less than the diameter of the outlet pipe of the heating structure.

There are a number of requirements for the elements of the chimney in the bath:

- The minimum height of the pipe is 5 m. Neglect of this requirement threatens to worsen traction. The exact value is calculated depending on the location of the pipe on the roof. In any case, it should rise above the ridge by at least half a meter. The ideal height from the ridge is 1.5 m, but this is not necessary;

- The minimum thickness of the metal used to create the pipe is 1 mm;

- If it is planned that the chimney system will be equipped with a hot water tank, then it must be reflected in a pre-drawn diagram. It is better if the tank is made of stainless steel.

Functions and features of the operation of the chimney in the bath

The main purpose of the chimney in the steam room is the high-quality and controlled removal of combustion products in order to completely eliminate the accumulation of harmful carbon dioxide and the formation of burning on surfaces. The resulting draft (with air suction into the combustion chamber) maintains a stable operation of the heat generator. By manipulating the flows, the user regulates the calorific value of the furnace and the fuel consumption. You can heat such a sauna stove for as long as you like, and all this time you can steam.

Features of heat distribution in various ways of connecting the heater to the chimney

The stove in the bath is heated intermittently. Accordingly, the smoke channel cools down completely between sessions, so the chimney parts experience the strongest multiple thermodynamic loads. The second important factor is the operating temperature. Unlike boilers and stoves used for heating, gases heated to 700 degrees or more are discharged here.Often, once-through stoves are used in the bath, due to the lack of heating shields or water jackets that remove some of the heat, the smoke is so hot. Therefore, the problem of burning chimneys (the danger of gas contamination and fire) always remains relevant. Chimneys for furnaces in a bath are made of high-quality materials. If these are factory products, they must be approved by the manufacturer for such difficult operating conditions.

Protective thermal screens

As the main protection for the walls of the bath, heat-resistant screens are used - special insulation shields to close the side surfaces of the stove and reduce the intensity of the propagation of IR radiation in the room.

Screens are divided into two categories: metal and brick.

metal

Protective screen made of steel or cast iron sheets. It is mounted along the perimeter of the sauna stove, while maintaining small technological gaps (3-5 cm) between the screen and the outer walls of the heating structure to provide additional air convection.

Depending on the characteristics of the walls of the bath and the type of furnace, metal screens can be front and side. Some models of metal furnaces are produced with an additional protective casing, which is installed during the installation of the firebox.

Installation of metal screens is carried out using adjustable legs with fixation to the floor covering with bolts. In addition, the legs allow you to provide a gap in the lower part of the structure for additional ventilation. To increase the service life, the screens are covered with a refractory coloring layer.

Advantages:

- decrease in the intensity of IR rays;

- improvement of air convection between the furnace walls and the screen;

- reduction in the overall heating temperature of the outer walls of the heating structure.

brick

A protective screen made of bricks is designed to protect the walls of the sauna stove.

Masonry is carried out in ½ bricks around the perimeter, observing technological gaps of 6 cm. The lower part of the structure is equipped with additional air ducts at a distance of 2.5 cm from each other.

To equip the brick screen for furnaces, heat-resistant fireclay bricks without voids are used. As a connecting mixture - a thick mortar of cement or clay.

Finished screen walls should be 22–25 cm higher than the wall of the heating structure.

Advantages:

- low thermal conductivity of the material from which the screen is made;

- resistance to high humidity and high temperatures;

- prolonged accumulation of heat in the room;

- getting soft heat from the oven.

Brief description and dimensions of the metal stove

Our design will have a separate tank for heating water and a heater built into the top of the stove. The flame heats the heater from all sides, which significantly increases the efficiency of the stove. You can take arbitrary sizes, consider the parameters of the steam room and the number of people washing at the same time. For example, we give the dimensions of our stove.

- External stone. Width 50 cm, length 50 cm, height 80 cm.

- Internal stone. Width 40 cm, length 40 cm, height 50 cm. The distance between the walls of the inner and outer heater is five centimeters around the perimeter.

- Bake. Width 50 cm, length 90 cm, height 50 cm. You can change the length of the stove, make it only for an external heater 50 cm long (then the water tank will have to be mounted on stops from the side) or increase the length to increase the volume of the tank.

- Water tank. Width 40 cm, length 50 cm, height 60 cm. 120 liters of water are placed in the tank, which is quite enough for washing three or four people. Of course, hot water must be diluted with cold.

Normal flue gas temperature

In order for the water present in hot gases to evaporate better,

the temperature of the latter should be increased. On well heated walls

pipes settled drops of moisture quickly evaporate.

The normal temperature of the exhaust gases from the furnace before

outlet into the chimney - 12O ... 14O ° С, when leaving the chimney into the atmosphere - not lower than

100°C.

If the flue gases when exiting the pipe, that is, at the view,

reach a temperature of about 250 ° C, then condensation does not form, improves

draft, stoves heat up faster, while consuming less fuel.

The flue gas temperature can be determined using

dry splinter, which is placed across the opening of the view during the firebox. If

after 30 ... 40 minutes, remove the splinter and scrape the smoked

surface, you can set the temperature of the gases. The color of the torch does not change when

temperatures up to 150°C. If the splinter turns yellow (to the color of white bread crust),

means that the temperature has reached 200 ° C; if it turns brown (to the color of the crust

rye bread), the temperature rose to 250°C. Blackened Torch

indicates a temperature of 300 ° C, and when it turns into coal, it means

that the temperature reaches 400°C.

Thus, when the furnace is fired, the temperature of the gases must be

adjust so that the view is within 250 ° C.

You should be aware that in summertime condensate or not at all

formed, or occurs in small quantities. Condensation in

to a greater extent depends on the size of the grate, correctly raised

hearth and furnace devices in the Russian furnace, channel dimensions, wall thickness,

clay and the height of the chimney, the temperature of its heating, the humidity of the applied

fuel, flue gas temperature from the pipe and excess

chimneys in the oven.

The height of the chimney must be at least 5 ... 6 m,

counting from the level of the ash chamber or the hearth of the Russian stove. Thickness

laying of the pipe walls should be done in half a brick 20 mm).

Thinner pipe walls heat up quickly and cool down quickly, which

leads to condensation. Such pipes must be insulated.

Various cracks in the chimney and furnace through which cold

air, also contribute to the cooling of gases and the formation of condensate.

When the cross section of the pipe channel (chimney) is higher than required for a given furnace, then

flue gases rise through it very slowly and cold outside air

cools them in a pipe. Great influence on the thrust force, that is, on the output of smoke

gases, renders smoothness of walls of flues. The smoother they are, the

stronger pull. All the roughness in the pipe contribute to the reduction of thrust and

hold on to the soot.

Sometimes, to improve traction in furnaces, it is necessary to shift

pipes, reducing the size of the chimney, lowering or raising the height of the pipe on the roof.

Do this until you get a satisfactory result. V

in places where the chimney narrows, right angles should be cut to ensure more

smooth transition of gases.

Do-it-yourself stove laying

How to simplify the choice of chimney

What is a fireplace chimney? This is a set of pipes, in which one end is connected to a heating device, and the other is brought out into the street. Its installation is a rather complicated and time-consuming process that requires certain knowledge and professionalism. Chimneys can be made of brick, stainless steel, ceramics. Each of these types has its own advantages, disadvantages, as well as installation features. Of course, in order to make the right choice, it is better to seek the advice of professionals. However, in order to have some idea about the arrangement of chimneys, we give below a brief description of the most common types.

Key points to consider when choosing a chimney

When choosing a chimney design, you need to pay attention to the following factors:

- The chimney material needs to be stable so that it can withstand the high temperature of the outgoing products; (See also: )

- Must withstand a mixture of soot and condensation;

- The design of the chimney must fully comply with all required standards (construction, fire, technological, operational).

For a fireplace that will be heated by gas, a stainless steel chimney is perfect, for coal it is better to choose a brick chimney, and for firewood a ceramic, brick and stainless steel construction is suitable.

Chimney design

Each individual building and each fireplace require a suitable chimney with individual parameters and characteristics.

Parameters by which to choose a chimney:

- flue material;

- The location of its structure;

- Steel chimney. The structure of the steel chimney includes pipes, insulation and an external contour. For the manufacture of pipes, stainless or galvanized steel is used. The design of the steel chimney is easy to install and light in weight.

The galvanized steel pipe has a lower cost, but it is less reliable than the previous model. Accordingly, the best stainless steel chimneys.

- Ceramic chimney design. Installation of a ceramic chimney requires some training and, very important, accuracy. Ceramics provides excellent thermal insulation. The service life of the material is approximately 30 years. The ceramic structure consists of an internal ceramic liner, lightweight concrete blocks on the outside and, mandatory, a heat-insulating gasket that must be laid between the layers. (See also: )

- Glass construction is considered the most expensive, it is very difficult to install. Some installation experience is required, but the glass fits perfectly into the interior of the house and looks very impressive and irresistible. Glass is very resistant to the formation of corrosive plaque, heat from the resulting combustion products and any exposure to moisture. Undoubtedly, these design advantages bring it to a high level of use.

Advantages and disadvantages of ceramic chimneys for a fireplace

The advantages of a ceramic pipe include the following characteristics:

- the material is very fast in installation and assembly;

- is a guarantee of high efficiency;

- long service life;

- the range of blocks is large, which makes it possible to mount a chimney with any configuration;

- the presence of a special hole that makes it possible to clean the chimney;

- the emerging condensate drains thanks to the hole located at the bottom of the chimney.

Among the disadvantages of block ceramic pipe systems, it is customary to single out the following:

- relatively high price;

- due to the fact that most of these chimneys are manufactured abroad, the delivery time is sometimes very long.

dangerous temperature

For comparison, consider a number of studies conducted by scientists in the twentieth century, to observe the effects of the influence of regular visits to the steam room, heated to extreme values of 110-130 ° C.

Professor H. Teir in the 80s of the last century put forward an assumption about the connection between the high temperature in Finnish saunas and the occurrence of cancer, which was subsequently confirmed by the results of a large study. After reviewing a significant number of cases of lung cancer among those who like to take a steam bath at 110-130 ° C, it was found that staying in a steam room heated to such temperatures contributes to the formation of this disease.

The fact is that in such conditions it is possible to be only when the air in the room is very dry, and this excludes the hydrostatic effect of steam on the body. As a result, the lungs are not well supplied with blood, and they get burned due to the inability to adapt to the elevated temperatures to the necessary extent.

A number of other studies have also found that exposure to dry, superheated sauna air negatively affects sperm production and also leads to digestive problems in children born to mothers who frequented such baths during pregnancy.

The manufacturing technology of the sauna stove imposes special requirements on the equipment of all its departments, including the chimney. Its device is slightly different from the chimney system of a home stove. It should provide long-term heat conservation and safety for visitors to the steam room. Before organizing the chimney in the bath, it is worth knowing a few important nuances.

The design of sauna stoves includes 2 types of chimneys:

- Indigenous. They are organized next to the stove, using a special pipe for connection, through which the smoke goes into the main channel. One chimney can be used for 2-3 ovens. The main thing is that its inner diameter should have the appropriate parameters, and the pipes from each heater should be located at different heights;

- Systems with a built-in pipe are mounted directly on the stove pipe and are led out through the roof. This version of the chimney is the most common for sauna stoves.

The classification of chimneys at the installation site includes 2 types:

- Outdoor. Their main part is located on the street and fixed on the wall with a bracket. Not recommended for baths, as they cool down quickly, losing precious heat.

- Internal. These are vertical structures with good traction, located inside the building.

According to the material used, chimneys are:

- Brick. The traditional look, characterized by the complexity of masonry and high requirements for compliance with all parameters. They have a lot of advantages: durability, fire safety, strength, good thermal insulation and heat storage. The disadvantages include the roughness and angularity of the inner surface, on which soot deposits accumulate;

- A metal chimney is faster to install and cheaper. It has a perfectly smooth surface, but weaker heat-preserving characteristics;

- Combined version, including 2 parts: the lower one is made of bricks, the upper one is made of a modern sandwich pipe. Allows you to organize neat, small passages that are easier to close with heat-resistant material.

DIY sandwich chimney installation video

A feature of modern bath stoves is their heating temperature, which can reach 400 degrees. An important indicator of the efficiency of the furnace is the instantaneous heating of the body and maximum heat transfer.

The entire heating process is accompanied by the release of infrared radiation, which is distributed on the surfaces adjacent to the furnace. Under the influence of high temperature conditions, the wooden structure of the bath can char or ignite.

That is why it is so important to ensure reliable insulation of wooden surfaces from the heat of the furnace. For this, a protective screen and sheathing made of refractory materials are suitable.