Radiator electric home heating

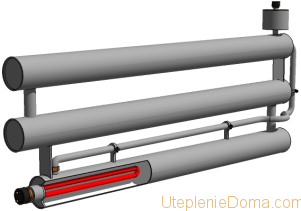

Scheme of installing a heating element in a radiator

Before inserting a heating element into the heating system, the parameters of the radiator are needed. The main one is the diameter of the connecting pipe. Currently, manufacturers produce products with two standard sizes - 1/2 and 3/4 inches. Then a comparative analysis of the heating parameters is carried out before and after the installation of the heating element.

Connecting the heating element to the existing heating

If it will be used as an additional method of heating water, it is necessary to take into account the change in hydraulic pressure when passing through the radiator. Since the passage diameter of the system will be smaller this month, it is recommended to install a larger pump.

When a radiator is connected to the system, installation of a heating element for heating a house will not be possible. To do this, you must either change the connection scheme to the top, or install a heating element on the top of the battery, which is not recommended by experts.

Often they make installation in old cast-iron batteries. Before performing work, you must first check the thread direction of the pipe (right or left) and also measure its diameter. Then you should follow this scheme:

- Coolant drain. It is forbidden to install a heating element in a heating radiator if there is water in it;

- Checking the battery level. Even with a slight angle of inclination, the likelihood of air pockets is significantly increased;

- Installing the heating element in the pipe. To seal the holes, you must use the gaskets supplied with the heating element or make them yourself;

- Installation of a unit with a thermostat, if one is included in the kit.

An example of installing a heating element in a cast iron radiator

After that, it is necessary to fill the system with water. With the help of the installed Mayevsky crane, possible air plugs are removed. Before switching on, to ensure safety, a tester checks a possibly occurring heating coil-battery circuit. If it is, you need to dismantle the heating element and install it again, improving the sealing.

Radiator electric heating

When organizing heating on heating elements made by oneself, the installation of a pipeline is not necessary. A heating element must be installed on each radiator. At the same time, it is possible to mount models of different power depending on the thermal regime in a particular room of the house. The advantages of such a system are as follows:

- Savings on the purchase of materials and reducing the complexity of installation work;

- If a heating element with a thermostat is used for heating and a temperature sensor connected to it, the degree of heating of the room will be adjusted automatically;

- Minimum heating inertia of the system.

But all these positive qualities can be covered by the total cost of maintenance. Therefore, before heating with electric heaters, it is necessary to calculate not only the cost of purchasing materials and components, but also the subsequent costs of electricity. Only after that to introduce a heating system of this type.

It is recommended to purchase factory radiators with installed heating elements. The efficiency of their work is higher than that of home-made ones, since special oil is used as a coolant. Even with the heating element turned off, it will give off heat to the room for some time.

How to choose heating elements

Heating element for heating with plates

How to choose the right heater for the heating system? Currently, there are many manufacturers that offer similar products. However, both the quality and the technical parameters do not always correspond to the required

Therefore, before purchasing, you need to pay attention to the following performance characteristics of the heater:

- Rated and maximum power. If a heating element is needed in the heating boiler, its power should be enough to operate the system. The simplest calculation method is for 10 sq.m. houses need 1 kW of thermal energy;

- Mains type. For models with a power of up to 3 kW, you can use a 220 V home network. If it is planned to install a heater for a heating system of greater power, a three-phase 380 V network should be installed. This may be due to difficulties in paperwork;

- The presence of a thermostat. For an electric radiator heating system, this is the main selection factor. If you purchase a ten without the ability to adjust the power, it will constantly work at maximum mode. Thus, electricity costs will rise sharply;

- Price. The average price of a 2 kW model starts at 900 rubles. The cost of more powerful ones can be up to 6,000 rubles. Often they are made to order.

The appearance of the heating element can also affect its performance and efficiency. The best option would be to purchase a finned heating element in a heating boiler. It differs from the usual ones in that additional heat exchange plates are located on the protective shell.

Thanks to them, the heating area increases. This design is typical for heating elements in heating radiators of larger diameter. Reviews about them speak of increased heat transfer even with a minimum operating mode. But not always their overall dimensions make it possible to install them in a battery. Therefore, most often they purchase simple tubular-type heaters. To increase the efficiency, you can buy a block of heating elements with a thermostat. It differs from traditional ones by the presence of several heating elements on the same basis.

Calculation of the power of devices

In order not to overpay for electricity and prevent emergency situations, it is necessary to calculate the required power before installing heating elements in the heating system. And to do it "by eye" will not work. Calculations are made on the basis that for heating 10 sq.m. premises require 1 kW of thermal energy. The formula for calculating the power of the heater is as follows:

where Pm is the design power, m is the mass of the coolant, T1 is the initial temperature of the coolant before heating, T2 is the temperature of the coolant after heating, and t is the time required to heat the system to the optimum temperature T2.

Consider the calculation of power using the example of an aluminum radiator in 6 sections. The volume of the coolant of such a radiator is about 3 liters (exactly indicated in the model passport). Let's say we need to heat the radiator by connecting the heating element to the heating battery, in 10 minutes from 20 degrees to 80. We substitute the values \u200b\u200binto the formula:

Pm \u003d 0.0066 * 3 (80-20) / 10 \u003d 1.118. that is, the power of the heating element should be about 1-1.2 kW.

The heating element is installed in the lower section of the radiators

However, this is only valid if water is used as the heat carrier. If it is necessary to make calculations for oil or antifreeze. then a correction factor is applied, which is about 1.5. Simply put, the power of heating elements for heating oil heaters should be increased by about one and a half times. Otherwise, the estimated time to reach the optimum temperature will increase.

Finned tubular electric heaters

Finned heaters also belong to the tubular type of elements, but they also have ribs that are located in planes perpendicular to the axis of the heater tube. Such ribs are made from a metal tape, and they are attached to the tube using washers and clamping nuts. The device itself is made of stainless steel or structural steel.

This type of heating element is used in heating devices that heat air or gas.Often they are found in devices such as thermal curtains or convectors (read: "Electric heating convectors: how to choose - little tricks"). They are used for space heating by means of thermal air mass.

Pros and cons of using heating elements for home heating

The main disadvantage of this heating method, as in the case of other electrical appliances, is the cost of operating costs. Electricity is still the most expensive source of heat (unless, of course, you have the opportunity to use free solar or wind energy, and you are connected to the main power grid). Another disadvantage is the impossibility of repair in case of failure of the spiral. However, there are some positive aspects, which in some cases may become a priority.

- Environmental friendliness of the heating system. When using electric heaters, there is no need to store and store any kind of fuel, and there are no harmful combustion products that enter the environment;

- The possibility of autonomous installation of the heating system in the absence of access to other thermal resources (for example, gas);

- Small dimensions and a large selection of models in terms of power and functionality;

- Possibility of automating the heating process: installation of heating elements with a thermostat;

- Low purchase and installation costs. There are models, the cost of which does not exceed 1000 rubles. And the installation of heating elements in heating radiators can be done independently.

And finally, a few tips for self-installation of tubular electric heaters. How to properly embed a heating element in a heating system? First of all, you need to choose the right model by measuring the diameters of the radiators where the heating element is supposed to be installed and making power calculations. Then carefully read the instructions for the device, which should indicate whether additional sealing is required or not. This is one of the most important points, since contact of the conductor with the heat transfer fluid will cause your radiators to be energized, and this is dangerous for residents. If the manufacturer indicates the need for additional sealing, then it must be done. In addition, the use of electrical heating devices without grounding is unacceptable.

Location of heating elements in a cast-iron radiator

The installation of heating elements in cast iron radiators has a number of features. They are associated with the diameter of the pipe and the direction of the thread. In general, the procedure for installing heating with heating elements in an existing system is as follows: disconnect the heating system from the heat source, drain the water, install the heating element, fill in the coolant, check the system's performance. When using heating elements with thermostats in the system of heating radiators, it is also necessary to check their performance after installation. It is also advisable to install water sensors and check the angles of the radiators. Since air congestion can significantly affect the operation of the entire system and disable the heating element.

Heating elements in the heating system

Different types of heaters

Often, electric heaters are used to heat rooms. One of the varieties of such heating heating elements is tubular electric heaters. What is this widespread device? A heating element is a device for medium temperature heating of a coolant. Structurally, this is a thin-walled metal tube with a spiral placed inside, which is made of a high-resistance material - nichrome. The ends of the spiral come out in the form of a contact rod, are sealed and serve to connect to the mains.

The tube itself is made of steel, carbon or stainless steel. After being placed inside and centering the spiral, the tube is filled with a special coolant - periclase and sealed.Being under high pressure, the periclase fixes the spiral along the axis and after that the heating element is bent and given the necessary shape depending on the model.

Regardless of how exactly the heating elements will be used - in a solid fuel heating boiler or in an infrared heater - there are certain rules for the installation and operation of heaters of this type. At the same time, electric heaters can be used for a variety of purposes: for heating the garage. home heating, for installation in heating boilers or radiators. Let us consider in more detail how to use heating elements for heating.

Tubular electric heater device

The right choice of heating element model

Going to buy a heating element, the buyer needs to know a number of technical characteristics:

- the required power of the device;

- length, diameter and shape of the tube;

- length of the insulator cap;

- overall length;

- connection type;

- fastening method.

To calculate the power of a heating element designed to heat water of a certain volume, use the formula:

P is the power of the heated element, measured in kW;

m is the mass of the heated coolant circulating in the device, in kilograms;

tH is the initial temperature of the water or liquid, in °C;

tK is the final temperature of the water or liquid, in °C;

T is the time of heating water or liquid.

TEN in a heating radiator - video review:

The use of TENs

Recently, more and more people are thinking about the possibility of autonomous heating of their homes. Every year the cost of traditional heating increases, so quite often with the help of an autonomous system there is a chance to save.

Also, sometimes it is simply not possible to connect to the central heating system - this is especially true for summer cottages. The only option to heat the house in this case is to install a heating boiler. Solid fuel and gas boilers continue to be the most popular, but their use is also not always possible - access to the main gas pipeline is not always available.

The best way out of such situations is to install electric heating equipment, since there are power grids almost everywhere. The main element of any such heating device is TEN. The efficiency of the heating system largely depends on its type. Typically, domestic heating equipment uses tubular heating elements, as well as elements with a thermostat. The latter make it possible to regulate the operation of the heating system.

Electric heating systems are very convenient in operation: they do not emit harmful substances, as they do not form combustion products, do not require installation in a separate room, are safe to use, easy to install and adjust. But still, when installing electric heating equipment, you should first check whether the electrical network can withstand a high load. You also need to prepare in advance for the fact that you will have to pay a lot of money for electricity.

Advantages of heating elements

Heating elements (heating elements) have many positive characteristics:

- economy and efficiency - when converting electricity into heat, there is practically no energy loss;

- simple installation - a heating element for a heating battery can even be installed independently and for this it is not required to issue a special permit in various instances. Each device is accompanied by detailed manufacturer's instructions explaining the connection procedure and operating rules;

- durability - it is achieved through chrome and nickel plating;

- compactness;

- safety;

- electric heater with a thermostat for capillary heating allows you to control the temperature with a high degree of accuracy;

- save electricity consumption allow the device to work with impulses;

- affordable cost;

- availability of additional functions.

In addition to the positive qualities, such a device as a heating element for heating batteries has several disadvantages:

- high cost of electric heating of residential premises due to electricity prices;

- not in all settlements on the territory of the country, the electric power from the substation allows the use of these devices.

What are electrics

Now popular are tubular electric heaters for heating, which consist of one or several nichrome spirals in a metal sheath. Periclast is placed between the spiral and the shell - this material has excellent insulating qualities.

Modern devices have heating elements that have good strength and at the same time can change their size and shape under the influence of high temperatures. At the same time, TENs do not change their technical characteristics. These electric heating elements are used in the production of not only heating equipment for domestic purposes, but also various industrial appliances. TENY in industrial devices must have high power. Any tubular element, regardless of its type, has a long service life. Today, there are several types of heating elements that are produced by manufacturers of electric heating equipment. First of all, they differ in the way they are made, but also have other features. Manufacturers take into account the needs and interests of consumers: some heating devices are produced in large quantities, while others are produced in small quantities. Heating equipment produced in small quantities, as a rule, is used in heating systems that have certain features. Accordingly, electric heating elements in such devices are more expensive.