Explanation of comparative values of heating appliances

From the data presented above, it can be seen that the bimetallic heating device has the highest heat transfer rate. Structurally, such a device is presented by RIFAR in a ribbed aluminum case. in which metal tubes are located, the entire structure is fastened with a welded frame. This type of batteries is installed in houses with a large number of storeys, as well as in cottages and private houses. The disadvantage of this type of heating device is its high cost.

Important! When this type of battery is installed in houses with a large number of floors, it is recommended to have your own boiler station, which has a water treatment unit. This condition for the preliminary preparation of the coolant is associated with the properties of aluminum batteries.

they can be subjected to electrochemical corrosion when it enters in a poor quality form through the central heating network. For this reason, aluminum heaters are recommended to be installed in separate heating systems.

Cast iron batteries in this comparative system of parameters lose significantly, they have low heat transfer, a large weight of the heater. But, despite these indicators, MS-140 radiators are in demand by the population, which is caused by such factors:

The duration of trouble-free operation, which is important in heating systems.

Resistance to the negative effects (corrosion) of the thermal carrier.

Thermal inertia of cast iron.

This type of heating device has been operating for more than 50 years, for it there is no difference in the quality of the preparation of the heat carrier. You can not put them in houses where there may be a high working pressure of the heating network, cast iron is not a durable material.

Comparison by other characteristics

One feature of battery operation - inertia - has already been mentioned above. But in order for the comparison of heating radiators to be correct, it must be done not only in terms of heat transfer, but also in other important parameters:

- working and maximum pressure;

- the amount of water contained;

- mass.

The operating pressure limitation determines whether the heater can be installed in multi-storey buildings where the height of the water column can reach hundreds of meters. By the way, this restriction does not apply to private houses, where the pressure in the network is not high by definition. Comparing the capacity of radiators can give an idea of the total amount of water in the system that will need to be heated. Well, the mass of the product is important in determining the place and method of its attachment.

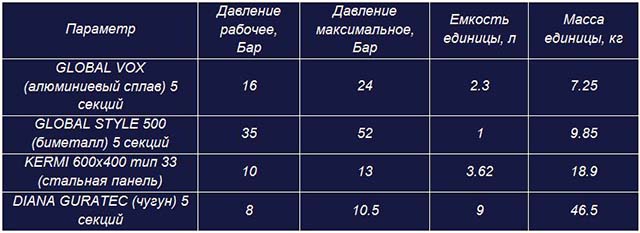

As an example, a comparison table of the characteristics of various heating radiators of the same size is shown below:

Note. In the table, a heater of 5 sections is taken as 1 unit, except for a steel one, which is a single panel.

Thermal conductivity and density of aluminum

The table shows the thermophysical properties of aluminum Al depending on temperature. The properties of aluminum are given in a wide temperature range - from minus 223 to 1527°C (from 50 to 1800 K).

As can be seen from the table, the thermal conductivity of aluminum at room temperature is about 236 W/(m deg), which makes it possible to use this material for the manufacture of radiators and various heat sinks.

In addition to aluminum, copper also has a high thermal conductivity. Which metal has the highest thermal conductivity? It is known that the thermal conductivity of aluminum at medium and high temperatures is still less than that of copper, however, when cooled to 50K, the thermal conductivity of aluminum increases significantly and reaches a value of 1350 W/(m deg). In copper, at such a low temperature, the thermal conductivity value becomes lower than that of aluminum and amounts to 1250 W / (m deg).

Aluminum begins to melt at a temperature of 933.61 K (about 660 ° C), while some of its properties undergo significant changes. The values of properties such as thermal diffusivity, the density of aluminum and its thermal conductivity are significantly reduced.

The density of aluminum is mainly determined by its temperature and depends on the state of aggregation of this metal. For example, at a temperature of 27 ° C, the density of aluminum is 2697 kg / m 3, and when this metal is heated to a melting point (660 ° C), its density becomes equal to 2368 kg / m 3. The decrease in the density of aluminum with increasing temperature is due to its expansion upon heating.

from here

The table shows the values of thermal conductivity of metals (non-ferrous), as well as the chemical composition of metals and technical alloys in the temperature range from 0 to 600°C.

Non-ferrous metals and alloys: nickel Ni, monel, nichrome; nickel alloys (according to GOST 492-58): cupronickel NM81, NM70, constantan NMMts 58.5-1.54, kopel NM 56.5, monel NMZhMts and K-monel, alumel, chromel, manganin NMMts 85-12, invar; magnesium alloys (according to GOST 2856-68), electron, platinum-rhodium; soft solders (according to GOST 1499-70): pure tin, lead, POS-90, POS-40, POS-30, Rose alloy, Wood alloy. Continue reading →

What all the same to put a radiator? I think each of us asked the same question when we came to the market or to a spare parts store, examining a huge selection of radiators for every taste, satisfying even the most perverted picky. Do you want two-row, three-row, bigger, smaller, with a large section with a small one, aluminum, copper. That's exactly what metal the radiator is made of and will be discussed.

Some believe that copper. These are original Old Believers, as they would have been called in the 17th century. Yes, if we take not new cars of the 20th century, then copper radiators were installed everywhere. Regardless of the make and model, whether it was a budget minicar or a heavy multi-ton truck. But there is another army of car owners claiming that radiators made of aluminum are better than copper ones. Because they are installed on new modern cars, on heavy-duty engines that require high-quality cooling.

And what is most interesting, they are all right. Both have their pros and cons of course. Now for a little physics lesson. The most excellent indicator, in my opinion, are the numbers, namely the coefficient of thermal conductivity. In simple terms, this is the ability of a substance to transfer thermal energy from one substance to another. Those. we have a coolant, a radiator made of N-th metal and the environment. Theoretically, the higher the coefficient, the faster the radiator will take thermal energy from the coolant and release it to the environment faster.

So, the thermal conductivity of copper is 401 W / (m * K), and aluminum - from 202 to 236 W / (m * K). But this is under ideal conditions. It would seem that copper has won in this dispute, but this is “+1” for copper radiators. Now, in addition to everything, it is necessary to consider the actual design of the radiators themselves.

Copper tubes at the base of the radiator, as well as copper strips of the air radiator for transferring the received heat to the environment. Large cells of the radiator honeycomb allow to reduce the loss of air flow velocity and allow to pump a large volume of air per unit of time. Too low concentration of the tape part of the radiator reduces the efficiency of heat transfer and increases the concentration and strength of the local heating of the radiator.

I found two types of radiators based on aluminum and steel tubes. Here is the not unimportant part, because. the thermal conductivity of steel is very low compared to aluminum, only 47 W/(m*K). And actually, only because of the high difference in performance, it is no longer worth installing aluminum radiators with steel tubes. Although they are stronger than purebred aluminum and reduce the risk of leakage from high pressure, for example, with a stuck valve in the cap of the expansion tank.A high concentration of aluminum plates on the tubes increases the area of the radiator blown by air, thereby increasing its efficiency, but at the same time, the resistance of the air flow increases and the volume of air pumped decreases.

The pricing policy on the market has developed in such a way that copper radiators are much more expensive than aluminum ones. From the overall picture, we can conclude that both those and other radiators are good in their own way. Which one to choose anyway? This question is up to you.

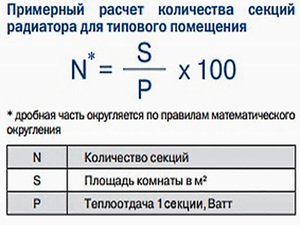

How to correctly calculate the thermal power

Competent arrangement of the heating system in the house cannot do without a thermal calculation of the power of the heating devices necessary for heating the premises. There are simple proven methods for calculating the heat output of a heater. needed to heat the room. It also takes into account the location of the premises in the house on the cardinal points.

- The south side of the house is heated per cubic meter of space 35 watts. thermal power.

- The northern rooms of the house per cubic meter are heated by 40 watts. thermal power.

To obtain the total thermal power required for heating the premises of the house, it is necessary to multiply the actual volume of the room by the presented values \u200b\u200band add them up by the number of rooms.

Important! The presented type of calculation cannot be accurate, these are enlarged values, they are used for a general presentation of the required number of heating devices. The calculation of bimetallic heating devices, as well as aluminum batteries, is carried out based on the parameters specified in the product's passport data

According to the regulations, the section of such a battery is equal to 70 units of power (DT)

The calculation of bimetallic heating devices, as well as aluminum batteries, is carried out based on the parameters specified in the product's passport data. According to the regulations, the section of such a battery is equal to 70 units of power (DT).

What is it, how to understand? Passport heat flow of the battery section can be obtained subject to the condition of supplying a heat carrier with a temperature of 105 degrees. To obtain a temperature of 70 degrees in the return heating system of the house. The initial temperature in the room is taken as 18 degrees Celsius.

the coolant is heated to 105 degrees

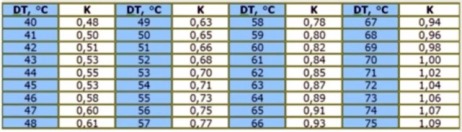

DT= (supply media temperature + return media temperature)/2, minus room temperature. Then multiply the data in the product passport by the correction factor, which are given in special reference books for different values of DT. In practice, it looks like this:

- The heating system works in direct supply 90 degrees in processing 70 degrees, room temperature 20 degrees.

- The formula is (90+70)/2-20=60, DT= 60

According to the reference book, we are looking for a coefficient for this value, it is equal to 0.82. In our case, we multiply the heat flow 204 by a factor of 0.82, we get the real power flow = 167 W.

Thermal power comparison

If you carefully studied the previous section, you should understand that heat transfer is greatly affected by air and coolant temperatures, and these characteristics do not depend much on the radiator itself. But there is a third factor - the heat exchange surface area, and here the design and shape of the product plays a big role. Therefore, it is difficult to ideally compare a steel panel heater with a cast iron one, their surfaces are too different.

The fourth factor affecting heat transfer is the material from which the heater is made. Compare for yourself: 5 sections of the aluminum radiator GLOBAL VOX with a height of 600 mm will give 635 W at DT = 50 °С. Cast iron retro battery DIANA (GURATEC) of the same height and the same number of sections can only deliver 530 W under the same conditions (Δt = 50 °C). These data are published on the official websites of manufacturers.

Note. The characteristics of aluminum and bimetallic products in terms of thermal power are almost identical, there is no point in comparing them.

You can try to compare aluminum with a steel panel radiator, taking the nearest standard size that is suitable in size. The mentioned 5 GLOBAL aluminum sections 600 mm high have a total length of about 400 mm, which corresponds to the KERMI 600x400 steel panel. It turns out that even a three-row steel device (type 30) will give out only 572 W at Δt = 50 °C. But keep in mind that the depth of the GLOBAL VOX radiator is only 95 mm, and the KERMI panels are almost 160 mm. That is, the high heat transfer of aluminum makes itself felt, which is reflected in the dimensions.

In the conditions of an individual heating system of a private house, batteries of the same power, but made of different metals, will work differently. Therefore, the comparison is quite predictable:

- Bimetallic and aluminum products quickly warm up and cool down. Giving more heat over a period of time, they return colder water to the system.

- Steel panel radiators occupy a middle position, as they transfer heat not so intensively. But they are cheaper and easier to install.

- The most inert and expensive are cast iron heaters, they are characterized by a long warm-up and cool-down, which causes a slight delay in the automatic regulation of the coolant flow by thermostatic heads.

From the foregoing, a simple conclusion suggests itself.

It does not matter what material the radiator is made of, the main thing is that it is correctly selected in terms of power and suits the user in all respects. In general, for comparison, it does not hurt to get acquainted with all the nuances of the operation of a particular device, as well as where which one can be installed

Thermal power calculation

To organize space heating, it is necessary to know the required power for each of them, and then calculate the heat transfer of the radiator. The heat consumption for heating a room is determined in a fairly simple way. Depending on the location, the value of heat for heating 1 m3 of the room is taken, it is 35 W/m3 for the south side of the building and 40 W/m3 for the north. The actual volume of the room is multiplied by this value and we get the required power.

Attention! The above method of calculating the required power is an enlarged one, its results are taken into account only as a guideline. In order to calculate aluminum or bimetallic batteries, one must start from the characteristics specified in the manufacturer's documentation

In accordance with the standards, the power of 1 section of the radiator is given there at DT = 70. This means that 1 section will give the specified heat flow at a coolant temperature at the supply of 105 ºС, and at the return - 70 ºС. In this case, the calculated temperature of the internal environment is assumed to be 18 ºС

In order to calculate aluminum or bimetallic batteries, one must start from the characteristics specified in the manufacturer's documentation. In accordance with the standards, the power of 1 section of the radiator is given there at DT = 70. This means that 1 section will give the specified heat flow at a coolant temperature at the supply of 105 ºС, and at the return - 70 ºС. In this case, the design temperature of the internal environment is assumed to be 18 ºС.

Based on our table, the heat transfer of one section of a bimetallic radiator with an interaxal size of 500 mm is 204 W, but only at a temperature in the supply pipe of 105 ºС. In modern systems, especially individual ones, there is no such high temperature, respectively, and the output power will decrease. To find out the real heat flow, you must first calculate the parameter DT for existing conditions using the formula:

DT = (tsub + trev) / 2 - troom, where:

- tsub - water temperature in the supply pipeline;

- tobr - the same, in the return line;

- troom is the temperature inside the room.

After that, the nameplate heat transfer of the heating radiator is multiplied by the correction factor, taken depending on the value of DT according to the table:

For example, with a coolant schedule of 80 / 60 ºС and a room temperature of 21 ºС, the DT parameter will be equal to (80 + 60) / 2 - 21 = 49, and the correction factor will be 0.63. Then the heat flow of 1 section of the same bimetallic radiator will be 204 x 0.63 = 128.5 W. Based on this result, the number of sections is selected.

https://youtube.com/watch?v=nSewFwPhHhM

Impurities in copper alloys

from here

The impurities contained in copper (and, of course, interacting with it) are divided into three groups.

Solid solutions forming with copper

Such impurities include aluminum, antimony, nickel, iron, tin, zinc, etc. These additives significantly reduce electrical and thermal conductivity. The grades that are mainly used for the production of conductive elements include M0 and M1. If antimony is contained in the composition of the copper alloy, then its hot working by pressure is much more difficult.

Impurities that do not dissolve in copper

These include lead, bismuth, etc. Not affecting the electrical conductivity of the base metal, such impurities make it difficult to process it with pressure.

Impurities that form brittle chemical compounds with copper

This group includes sulfur and oxygen, which reduces the electrical conductivity and strength of the base metal. The presence of sulfur in the copper alloy greatly facilitates its machinability by cutting.