Characteristics of refractory bricks

A lot of fakes of this type of stone are present on the open spaces of the modern Internet. In this regard, I immediately want to protect you and advise you to purchase it only in specialized stores, construction hypermarkets or other such places where you can touch it and evaluate the quality.

The first thing you need to know is that it must be beige in color. The hue should not be faded or, conversely, saturated, this indicates marriage or deceit. The weight of each brick is approximately three kilograms.

The material must not have cavities or any other holes. The ingress of air is fraught with a decrease in heat resistance and, therefore, leads to the unsuitability of the product. The dimensions of the standard sample do not exceed 25 centimeters in length, 12 in width and 6.5 in height.

Unfortunately, you won’t be able to check his abilities in the store, so at least ask the seller for information on this issue. If he answers that the fireclay bricks they provide for sale have high heat resistance and low thermal conductivity, then you can easily give preference to the type of material under discussion. This is the product you need.

Possible consequences

Certain errors, of course, are permissible, but a disregard for the manufacture of a special heat-resistant solution leads to disastrous consequences. Incorrect mixing can cause the formation of severe cracks or complete looseness of the inter-brick connector. Subsequently, you will see how the entire structure is deformed and collapses right before your eyes.

A fairly large number of owners of stoves, pipes, barbecues and grills, built by irresponsible, disgusting craftsmen, asked for help. But all we could do was disassemble and reassemble the entire structure completely.

It was unbearably painful to see the look of a man who had already marinated meat and realized that he would have to fry it on an ordinary fire. It got even worse at the moment when he turned his head, and part of the chimney collapsed into the built fireplace. It was doubly insulting, because it was far from being broken by Santa Claus.

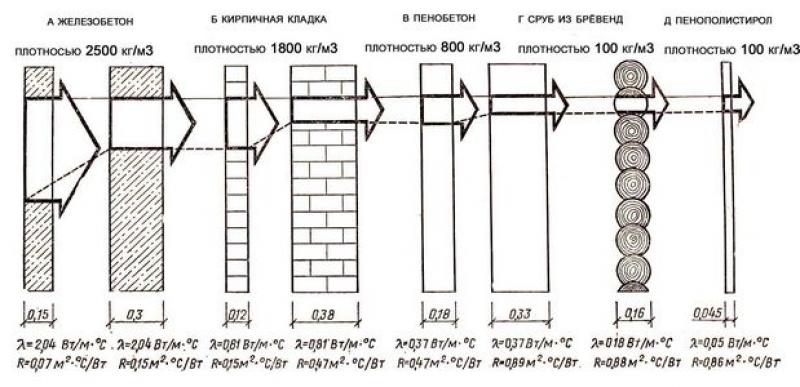

Brick heat transfer coefficient general information

Brick heat transfer coefficient

The thermal conductivity of a brick is characterized by its ability to conduct heat energy. Such a "talent" is usually displayed in a special indicator. Each species will present its data in this regard:

- Clinker bricks have a thermal conductivity in the range of 0.8 to 0.9 W/m K.

- The thermal conductivity of silicate brick depends on the number of voids contained in it (for slotted brick it will be equal to 0.4 W / m K), for having technical voids, the figure rises to 0.66, and for a full-bodied variant, the data will already be 0.8 W / m TO.

- Ceramic bricks also have different thermal conductivity coefficients (depending on the type presented): the thermal conductivity coefficient of a solid brick gives numbers from 0.5 to 0.8, a slotted one has 0.34-0.43, and a porous one - 0.22 W / m K The thermal conductivity of a ceramic brick with pores inside will be approximately 0.57 W / m K (however, even these figures may depend on the pores located in it).

As part of this analysis, it must be noted that the heat transfer coefficient of a brick is not yet the highest - aerated concrete, for example, is an even better conductor. In order for the buildings being erected to be truly warm, it is necessary to combine many components during the construction, the main of which will be the number of pores.

Peculiarities

Now it's time to get acquainted with the main features of this material. It is reasonable to divide them into positive and negative ones.

Advantages

- The key advantage of silicate over other materials is its low price. This fact is explained by a simpler production system and cheap raw materials. Its production cycle is no more than 18 hours, while for ceramic bricks it reaches 6 days.

- It has increased sound insulation, which significantly reduces construction costs. Thanks to its ability to absorb noise and vibration, it provides a comfortable environment in the premises. As the instructions say, it does not need to install additional soundproofing.

- It should also be noted that it perfectly counteracts aggressive environmental influences: mold, bacteria, fungus, etc. This eliminates the need to apply antiseptics.

- The already mentioned wide range of colors can also be included in the asset of this material. It allows you to create unique facade designs, which many designers use with pleasure. Moreover, it is painted completely, and not just on the front side.

- Facades made of silicate bricks do not need additional finishing, which significantly reduces time and financial costs. This item is completely finished.

- Increased frost resistance makes silicate brick a real bestseller for regions with a harsh climate (for example, Siberia). He is not afraid of even terrible northern frosts down to -65 degrees.

Key characteristics of the main varieties

Flaws

Of course, there was a place for negative points, even if there are not so many of them:

- Limited use in the construction of the foundation and basement floors. This limitation is due to the fact that the impact of salts contained in groundwater adversely affects the silicate brick. It may begin to dry out over time.

- Compared to other analogues, it has lower indicators of such characteristics as fire and water resistance. This significantly reduces its operational period.

- Under extreme conditions, this material begins to instantly lose all its qualities. So, for example, in regions with frequent rains, it is not advisable to use it, since it will quickly begin to dry out.

Components of silicate brick

On this list of qualities can be completed. Having stated all of the above, we can say that silicate brick is an excellent material for various types of outdoor work. In addition, it has an excellent price-quality ratio, thanks to which it has received wide recognition in our country.

Features of fireclay bricks

Firebrick is one of the most durable types of refractory building material and can withstand temperatures up to 1000°C. That is why it is used in the construction of stoves and fireplaces.

For its manufacture, the so-called chamotte powder is used, which is mixed in certain proportions with refractory clay, ground to the required consistency. After that, bricks are formed, which are fired at high temperatures.

Possible schemes for laying fireclay bricks.

Chamotte brick has a fairly recognizable appearance: it has a granular structure and has a yellowish-sand color.

There are two main standard sizes of refractory bricks: 23x11.3x6.5 cm and 23x113x6.5 cm. This size is due to the fact that such proportions are optimal so that the number of seams is minimized and the surface of the finished masonry is as even and smooth as possible .

Brick of this type is an ideal building material for laying out furnaces, fuel chambers and chimneys.

When buying this building material, you must remember that a quality brick will make a sound similar to metal when tapped. After the impact, a brick made according to all requirements will not crumble, but will break into several pieces.

Cases in which you will need it

In most cases, the need for heat-resistant bricks arises from the owners of private houses or summer cottages. Apartment dwellers do not need it, as fire safety regulations forbid you from creating an uncontrolled open fire on the territory of an apartment building. Alas, building a barbecue on a balcony or loggia is not the best idea.

This type of stone will serve you well when building stoves for heating a house, a pipe used for the same purpose, a fixed installation for a grill, or when planning an English fireplace that will show off against the central wall of your future home. It will create comfort and coziness for you, which will add warm and bright colors to your rest. In addition to all this, do not forget that on New Year's Eve you will have somewhere to hang holiday socks so that Santa Claus puts sweets in them for your children.

It is not worth saving on material, because the quality directly depends on the price, and since fireclay brick buildings are not cheap, their reconstruction will cost a lot of money.

The solution recipe, which I will now tell you, can also be used for repair work. It is possible that one stone may fall off inside the structure, which must be put in place using just such a mixture.

Strength grades

The safety of a building depends on the strength of its walls and foundations. Density determines not only the weight of red ceramic bricks, but also its strength characteristics. The tensile strength of the material is indicated by the letter "M". It shows the maximum allowable load per sq. see product surface.

There are eight strength grades - from M75 to M300. The most optimal options for low-rise construction in terms of price and reliability are the M100 and M125 brands. They have standard dimensions of 250x120x65 mm, and the mass of ceramic bricks is 2.5-3.6 kg. Permissible deviations from dimensions are not more than 3-4 mm.

Photo 3. Strength grade often determines the purpose of the material

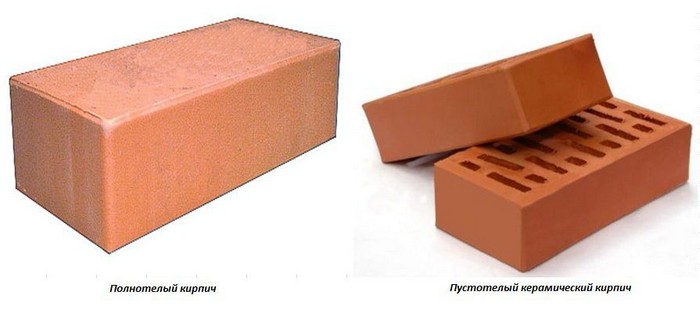

The thermal conductivity of products depends on the structure, which is corpulent and hollow. Various forms of voids are allowed: oval, rectangular, round. The material is environmentally friendly, only clay and plasticizers are used for its production.

Attention! Products of grades M100 and M125 with low frost resistance do not have the ability to withstand climatic influences for a long time, they need to be finished with plaster or cladding. The technical characteristics of the ceramic brick M100 are somewhat inferior to those of the M125 brand

Its durability is 25% lower. Such a brick is recommended for private and low-rise construction as load-bearing and self-supporting walls, in high-rise construction - as self-supporting or partitions. The thermal insulation properties of materials and frost resistance within the same manufacturer are the same (table 1):

The technical characteristics of the ceramic brick M100 are somewhat inferior to those of the M125 brand. Its durability is 25% lower. Such a brick is recommended for private and low-rise construction as load-bearing and self-supporting walls, in high-rise construction - as self-supporting or partitions. The thermal insulation properties of materials and frost resistance within the same manufacturer are the same (table 1):

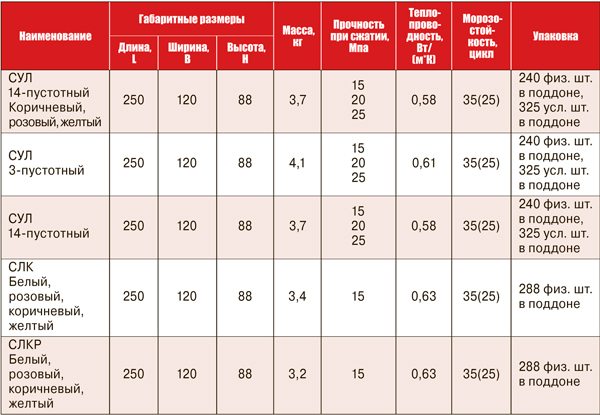

Table 1. Technical and operational characteristics of hollow red brick M100-M150

|

Parameter |

ceramic brick |

||

|

M100 |

M125 |

M150 |

|

|

Compressive strength, kgf/cm2 |

at least 100 |

at least 125 |

at least 150 |

|

Bending strength, kgf/cm2 |

at least 15 |

at least 17 |

at least 19 |

|

Water absorption, % |

8-13 |

||

|

Frost resistance, cycles |

35-100 |

||

|

Average density, kg/m3 |

970-1100 |

||

|

Thermal conductivity, W/m*K |

0,36-0,4 |

Characteristics of ceramic brick M125 provide a wider scope of its application. It is used in the construction of residential buildings, industrial facilities, garages, fences and outbuildings. The rough surface contributes to high-quality adhesion to the masonry mortar.

The cladding material is distinguished by a clear geometry, a solid color (except for special colors) and the absence of external defects.Usually, a thickened front ceramic brick 250x120x88 mm hollow (photo 4) has a weight of 2.7-3.2 kg, a single one - 2.2-2.7 kg. This reduces the load on the foundation and provides additional thermal insulation.

Photo 4. One and a half hollow front element

A little personal experience

Friends, I have repeatedly worked with the construction of elements that were later used for heating with wood. Based on my experience, the biggest mistake owners have made is saving money. I was glad that they did not decide to save money on professionals, but I was very disappointed with the quality of the materials they bought.

All work related to the construction of heat-resistant elements can be done by hand.

Better save your money and don't overpay expensive builders, but you can't save on fireclay bricks and refractory clay. No matter how cool the master is, he will not be able to make candy out of underground raw materials. You can blame him later, but I'm sure you will be warned about this outcome.

Friends, remember my advice and keep your savings by saving on the right things, and not on those that are vital to you! Warmth, comfort and speedy completion of the repair!

In the process of laying a stove, fireplace or barbecue oven with your own hands, you will definitely need refractory bricks.

It perfectly withstands high temperatures, therefore it is necessary for laying out the walls of the furnace fuel chamber. It is made from fireclay powder and very high quality kaolin (refractory clay). The material has many advantages: resistance to frost, acids and alkalis.

When heated to 1600 degrees, it does not lose its strength characteristics. It has a rough surface, the structure in the form of grains is easily felt. The weight of fireclay bricks is about 3 kg.

When working with structures that will be operated at high temperatures, do-it-yourself masonry should be done with fireclay bricks. There are 2 standards for the dimensions of such a stone: 230 × 114 × 65 and 230 × 113 × 65 mm.

These dimensions are not taken from the ceiling. They are made in such a way that working with it with your own hands was easier and the thickness of the seams was minimal, and their number also decreased. The laying should be as even as possible.

Dividing refractory bricks into pieces or cutting corners is a laborious process. It is better to do this with a grinder with a diamond-coated disc installed.

Fireclay bricks do not need to be soaked with water, like ceramic ones, before laying. But from it you need to remove any crumbs, earth and the like with a brush. The bricklayer's work should be carried out in such a way that the seam between fireclay bricks should not be more than 3 mm.

Advantages and disadvantages of buildings built from silicate bricks

Silicate brick and buildings built from it have a number of other advantages. Of these, we can distinguish:

- Low cost of products;

- Environmental friendliness of the material;

- Good product geometry;

- High aesthetic qualities;

- The indicator of strength, density and frost resistance is quite competitive;

- Soundproof characteristics;

- Variety of sizes, colors and manufacturers;

- A large number of options for finishing both external and internal;

- Wide scope of material application;

- The ability to make laying yourself, for this you need only instructions.

As for thermal conductivity, then, rather, this indicator can be attributed to pluses, since it is worth considering the high density of products.

The disadvantages are as follows:

- The material is quite heavy, especially in comparison with cellular concrete;

- moisture absorption;

- There are no decorative elements in the product range, which does not allow expanding the architectural possibilities when using the material;

- Limitation of the use of silicate brick in the construction of premises, which are characterized by constant humidity. For example, this is a bath.

Table brick density, calculation formula, description and examples

Brick has been one of the main building materials for hundreds of years.

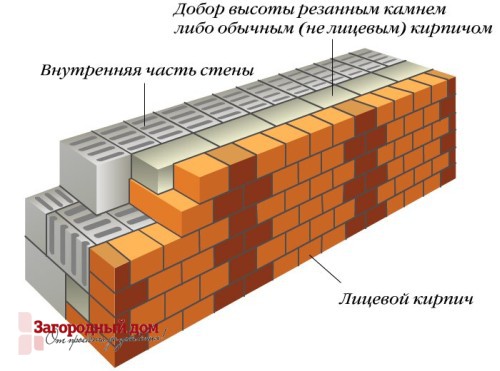

Therefore, the density of the brick plays a critical role, knowing the value of which you can understand the thermal conductivity and volumetric weight, as well as the weight of the sample per unit volume. Binding rows of bricks

silicate brick

This type of building material is made from sand and lime in a ratio of 1/9. With a very low cost, this brick is one of the most affordable on the market.

Also, the pluses include an extensive color palette in which silicate brick is produced.

However, it has a high thermal conductivity and a large weight, which is why it is not used in the construction of load-bearing walls, partitions and fireplaces due to the deformation of this building material under the influence of high temperatures. Silicate brick is divided into two types: hollow and solid, and has a density of 1100 to 1950 kg/m3.

ceramic brick

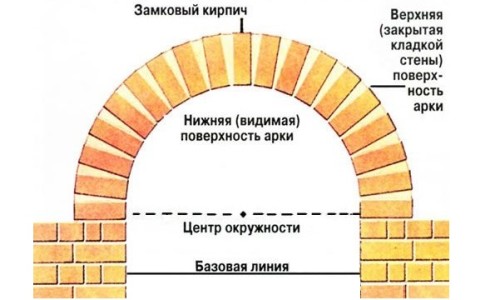

Solid ceramic bricks are used to build a variety of objects - load-bearing, internal and external walls, as well as columns and arches. Its hollow counterpart is used to build lightweight structures and fill frames.

The density for the first option is at least 2000 kg / m3, and for the second - from 1100 to 1400 kg / m3.

solid brick

It is also commonly known as "construction" or "ordinary". It is used for the construction of literally all structures, whether it be pillars, load-bearing systems, arches, etc. due to its high strength and cold resistance, although walls built using this building material need additional insulation.

Its approximate concentration is 1900 kg/m3. There is a red solid brick that we often see as the main building material for the exterior walls of houses, window frames and basement floors.

Withstands such loads due to very high strength - 2100 kg / m3.

hollow brick

It has internal voids from 13% to 50% by volume and has a porous structure, as a result of which it is quite fragile and light. It has excellent noise and heat insulation and is perfect for interior walls and partitions, as well as as a frame filler.

The density of this brick is from 1000 to 1450 kg/m3.

Clinker brick

It is made from red clay, which is dried and fired at extremely high temperatures, which gives the building material a high density - 2100 kg / m3 - and increased wear resistance.

However, the disadvantage of this brick is the high price, which is justified by labor-intensive production.

The second disadvantage is the increased thermal conductivity. It is often used in the construction of roads, for cladding facades and basement floors of residential buildings.

fireclay brick

Probably one of the most expensive building materials on the market. The high price is justified by fire resistance, which allows it to withstand temperatures up to +1600°C, being a leader in this direction.

It is produced mainly in trapezoidal, conical and arched shapes in yellow and bright red colors. Density ranges from 1700 to 1900 kg/cm3.

Facing brick

It has a rather narrow application due to its even and “glossy” surface and is used for laying exterior walls with a requirement for a special plane.

It is produced in a variety of colors, which are achieved by selecting different clay masses, fired at different temperatures and times spent in firing. Like other clay-based building materials, facing bricks have enhanced thermal insulation properties and are practically not subject to corrosion.

The density of this brick is measured in the range from 1300 to 1450 kg/m3.

The path to great results

After adding sand, pour water in small portions and begin to mix until the components turn into a homogeneous mixture of sour cream consistency.The resulting mixture should lag behind the trowel, slowly slipping. It shouldn't leave big marks.

A high-quality refractory mixture will remain plastic, without delamination, and the masonry based on it will be strong enough. The solution does not have large pieces of clay or thickening. If you press the applied mixture with a stone, it will hide all the imperfections of the masonry and allow the brick to move smoothly across the bed.

A solid solution does not need additional components. But if there is any doubt about how strong the masonry solution turned out, you can add about 10-15 g of table salt per liter there.

Average density

This characteristic is used to determine the porosity and thermal conductivity of the product. The lower its density, the lower the level of thermal conductivity. The individual indicator is calculated in the laboratory. The average density is determined by the formula: p=m/v, where m is the mass, v is the volume, its units of measurement are kg/m3. The steps for calculating such a characteristic include:

- In a drying cabinet, keep the brick at a temperature slightly above 100 ̊С.

- Determine the volume of material by multiplying the height, length and width parameters.

- Weigh the cleaned material on scales that are approved by the standard.

- Calculate the value by substituting the values into the formula. It is recommended to measure several specimens at once to obtain a reliable arithmetic average index.

Factors Affecting Density

There are several reasons that determine the characteristics of the product:

- Moisture. Its main volume is absorbed by the material at the masonry stage. The degree of humidity is determined by vapor permeability. It is easier for air to pass through the building product in which moisture does not linger. For the construction of basements, moisture-retaining bricks are used.

- The presence of cracks. They are necessarily present in clay materials. At the same time, modern developments of mixtures allow them to be avoided by increasing the density.

- Types of source material. The raw materials from which the product is made (clay, sand) differ in mass per unit volume due to the place of extraction.

Chamotte brick properties, dimensions

The best material for laying the furnace is fireclay bricks. Its characteristics are unmatched among refractory materials:

- withstand t=1500 C, are characterized by a low degree of hygroscopicity, large temperature differences do not affect the integrity of the structure.

Fireclay for masonry is made from refractory clay mixed with fireclay powder.

Its quantitative composition is 70%. Manufacturing requires compliance with the smallest details: overburning will make it glassy, and underburning will cause more moisture absorption. Standard sizes of fireclay bricks:

The color is yellow-beige with splashes of red or brown. The composition is regulated by GOST 390-96.

Chamotte brick is abbreviated as ША or ШБ. It is with this material that the laying of the combustion chamber is necessarily carried out. In metal furnaces, it is used for lining the furnace.

Mix for laying fireclay bricks

Ceramic stone is placed on red clay, while refractory #8212; fireproof only. It is possible to make a masonry mortar yourself or buy a prepared mixture. It is also called fireclay mortar.

Only soft water without dirt and oils should be added to the solution. The approximate consumption of the solution is as follows: 40 kg (three buckets) per hundred stones. We advise you to calculate the required volume in advance so as not to buy or cook too much.

A mixture called "fireclay mortar" is easy to prepare: you need to gradually add a measured amount of water.

Its amount should be such that the final mixture is as thick as sour cream. Mixing is carried out using a construction mixer or a drill with a special nozzle.It is effective to use a concrete mixer for large volumes; one batch is done for at least five minutes.

The finished solution is left for 60 minutes, and then the mixing is repeated. The mixture can become even stronger if about 15% cement is added to it (calculated from the original dry matter).

After that, you can start laying out the stones. Mortar allows you to spend less time and effort on mixing the solution, but it also has disadvantages: strong shrinkage and lower strength relative to a mixture based on fireclay sand and kaolin clay. This makes a do-it-yourself solution recommended for use.

Refractory clay is soaked for a period of 12 hours to 3 days.

You can replace kaolin clay with blue Cambrian. Clay from the bag is placed in a container and filled with water to the top, it requires regular mixing. After the expiration date, the clay must be passed through a sieve with a mesh of 3 mm.

Clay should be smelled, if there is no smell, then this is a good sign. And the presence of an unpleasant pungent odor indicates the presence of additives.

After soaking and wiping, fireclay sand is poured into it. It is impossible to use quartz sand and crumbs from marble.

In an exceptional case, you can take mountain sand, in which there are no foreign inclusions and silt. Before mixing, you need to take a sieve and sift this sand through it. Sand and clay should be taken in a ratio of 2:1.

So what to do

For laying fireclay bricks, a special clay mortar is used. Many of you have heard about him, some have seen him, and only a few have worked with him. Therefore, I will talk about its features.

I recommend using the so-called fatty samples of this type of mixture, as they only crack a little when they dry. There is no getting away from this, because you will not be able to achieve the most acceptable consistency. There is no standard in this matter, and we can only endlessly try to get closer to the ideal.

Clay should not be ordinary, which you found on the lake near the parent's house, but fire-resistant.

Even in ancient times, dishes were made from this, which solidified during heat treatment in an oven. It is light brown in color and quite hard in normal condition. Before buying, consult with friends who have encountered a similar problem about the place of purchase, so as not to fall for low-quality raw materials.

A little higher, I mentioned well-wishers who have no idea about this issue. Several times I came across articles in which it was written that a chimney can be made using standard solutions.

This is true, but not the whole, but only its upper part. At a distance of one and a half meters from the place where the fire is concentrated, everything should be processed with a clay look. I will talk about the consequences a little later.

Characteristics of ceramic bricks

The operational properties of artificial stone depend on the raw materials used and the production technology. Red brick is corpulent and hollow. Some of its characteristics also depend on the structure of the product.

Density

One of the main characteristics is the density of ceramic bricks, measured in kg/m3. It directly depends on the number of pores in the product and affects the strength, thermal conductivity and weight. Solid material has no more than 13% voids, which ensures high strength. It is used in the laying of load-bearing walls. The hollow block is distinguished by the presence of voids that make up 14-45% of the volume.

Photo 1. Solid and hollow artificial stone

Thermal conductivity of blocks

The thermal conductivity of a material indicates its energy saving efficiency. This indicator is affected by the structure of the product, the more voids with air, the less heat loss.

The thermal conductivity coefficient of ceramic hollow brick is 0.34-0.47 W / m * K, solid - 0.6-0.8 W / m * K, facing - 0.35-0.8 W / m * K.

The thermal insulation capabilities of the building material are taken into account when calculating the thickness of the outer walls. Its ability to transfer heat directly depends on the density. When using full-bodied products in masonry, the installation of a heater is subsequently required. The construction of walls from hollow products is more efficient. The presence of air reduces heat loss, allowing the width of the masonry and/or the thickness of the thermal insulation layer to be reduced.

Photo. The use of hollow blocks reduces the thermal conductivity of the walls

Frost resistance

The durability of the structure depends on the ability of the artificial stone to withstand alternate freezing and thawing without destruction. The indicator is denoted by the letter F. The minimum limit is 15 cycles, the optimal value is 35-50 cycles for internal structures and 50-100 cycles for external ones.

Attention! All building materials are tested under extreme conditions. With the declared indicator F50, an artificial stone usually withstands a greater number of cycles

Density of clinker brick

Clinker blocks are made from dry red clay. After hardening at high temperature conditions, the composition acquires a stable density - from 1900 to 2100 kg/cm3. Wear resistance is also due to low porosity - only 5%, which is achieved by sintering the mineral composition, which reduces the volume of cracks in bricks, and reduces the likelihood of moisture entering the raw material.

Block grades differ in shades and textures, which are produced by selecting special clay compositions, changing temperature conditions and time during firing. But the indicators of composition compaction remain at the average level for the subspecies.

Disadvantages - high price and thermal conductivity. Therefore, when laying, the cost of thermal insulation work will be required.

Density of fireclay bricks

The compaction of fireclay bricks is average and varies from 1700 to 1900 kg/cm3. High wear resistance is achieved due to low porosity, which is no more than 8%. The material is durable and does not deform under the influence of high temperatures, the maximum figure is + 1600 ° С.

70% of the material consists of refractory clay, which is very heavy. When designing, it is necessary to take into account the mass of building material in order to avoid increasing the load on the load-bearing parts of the building.

Varieties of fireclay bricks (arched, classic, trapezoidal or wedge-shaped) have similar density indicators. Blocks are used for laying stoves and fireplaces, industrial facilities, industrial steel plants, etc. Manufacturing technology, composition and wear resistance indicators determined the high price of building materials.