Use of a heat accumulator in everyday life

The thermal accumulator has become an indispensable device for many modern heating systems. With this addition, it is possible to ensure the accumulation of excess energy generated in the boiler and usually wasted. If we consider the models of heat accumulators, then most of them look like a steel tank, which has several upper and lower nozzles. The heat source is connected to the latter, while the consumers are connected to the former. Inside is a liquid that can be used to solve various problems.

The thermal accumulator is used in everyday life quite often. Its work is based on the impressive heat capacity of water. The operation of this device can be described as follows. The pipeline of boiler equipment is connected to the upper part of the tank. A hot coolant enters the tank, which turns out to be heated to the maximum.

The circulation pump is at the bottom. It takes in cold water and runs it through the heating system, directing it to the boiler. The cooled liquid is replaced by a heated one in a short time. As soon as the boiler stops working, the coolant begins to cool in pipes and pipelines. Water enters the tank, where it begins to displace the hot coolant into the pipes. Heating of the room will continue for some time according to this principle.

Battery buffer volume

Let's figure out how much heat storage should be. There are different opinions, which are based on the calculation based on:

- area of the premises;

- boiler power.

Let's take a look at each of them. If you start from the area of \u200b\u200bthe room, then there can be no exact recommendations. Since there are many factors that affect the battery life of the system without a boiler, the main of which is the heat loss of the room. The better the house is insulated, the longer the buffer tank will be able to provide housing with heat.

An approximate calculation, based on the area of \u200b\u200bthe room, is that the volume of the heat accumulator should be four times the number of square meters. For example, a house with an area of 200 square meters is suitable for a TA with a volume of 800 liters.

Of course, the larger the tank, the better, but in order to heat a larger amount of coolant, more heater power is needed. The calculation of the boiler power is made based on the heated area. One kilowatt heats ten meters. You can also put a five-ton tank, only if the boiler does not pull such volumes, there will be no point in installing such a large heat accumulator. So, you need to make adjustments to the calculation of the power of the boiler itself.

It turns out that, perhaps, it is more correct to make a calculation based on the power of the boiler. Let's take for example the same house of 200 sq. m. An approximate calculation of the volume of the buffer tank is as follows - one kilowatt of energy heats up 25 liters of coolant. That is, if there is a heater with a power of 20 W, then the volume of the TA should be about 500 liters, which is clearly not enough for such housing.

Based on the results of the calculations, we can conclude that if you are going to install a heat accumulator, then you need to take this into account when selecting the boiler power and take not one, but two kilowatts per ten meters of heated area. Only then will the system be balanced. The volume of TA also affects the calculation of the capacity of the expander. An expansion tank is an expansion tank that compensates for the thermal expansion of the coolant. To calculate its volume, you need to take the total volume of the coolant in the circuit, including the capacity of the buffer tank, and divide by ten.

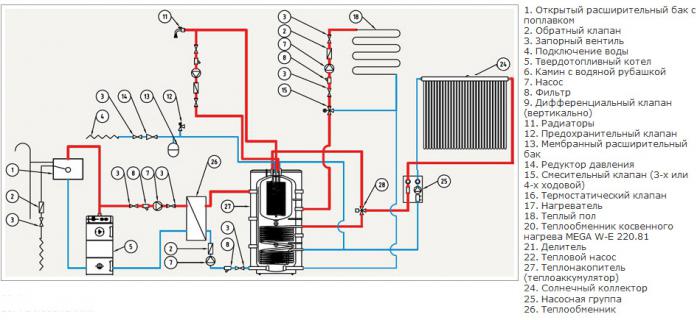

When is it profitable to install a heat accumulator

You have a solid fuel boiler;

You are heated by electricity;

Solar collectors have been added to help with heating;

It is possible to utilize heat from units and machines.

The installation scheme for a solid fuel boiler with a heat accumulator is an ideal solution for a private house, when you want both comfort and economy. With such a layout, you melt a solid fuel boiler, heat water in a thermal accumulator and get as much heat as you need. In this case, the boiler will operate at maximum power and with the highest efficiency. How much heat wood or coal will give, so much will be stored.

Second option. Installation of a heat accumulator with an electric boiler. This solution will work if you have a two-tariff electricity meter. We store heat at the night rate, we use it both day and night. If you decide to use such a heating system, it is better to look for a heat accumulator with the ability to install an electric heater directly into the barrel. An electric heater is cheaper than an electric boiler, and material for tying the boiler is not required. Minus the work on the installation of the electric boiler. Can you imagine how much you can save?

The third option is when there is a solar collector. All excess heat can be thrown off into a heat accumulator. In the demi-season, excellent savings are obtained.

System from Isentropic

The system, which was developed by the now bankrupt British firm Isentropic, worked as follows. It included two insulated containers filled with crushed rock or gravel; a heated vessel that stores thermal energy at high temperature and pressure, and a cold vessel that stores thermal energy at low temperature and pressure. The vessels are connected by pipes at the top and bottom, and the entire system is filled with an inert gas, argon.

During the charging cycle, the system uses off-peak electricity to act as a heat pump. Argon from the top of a cold vessel at a temperature and pressure comparable to atmospheric pressure is adiabatically compressed to a pressure of 12 bar, heated to about 500C (900F). The compressed gas is distilled to the top of a heated vessel, where it seeps through the gravel, transferring its heat to the rock and cooling to ambient temperature. Cooled, but still under pressure, the gas settles to the bottom of the vessel, where it expands again (again adiabatically) to 1 bar and a temperature of -150C. Then the cold gas passes through a cold vessel, where it cools the rock, heating up to its original state.

The energy is converted back into electricity when the cycle is reversed. The hot gas from the heated vessel expands to start the generator and is then sent to cold storage. The cooled gas rising from the bottom of the cold vessel is compressed, heating the gas to ambient temperature. The gas is then directed to the bottom of the heated vessel to be heated again.

The compression and expansion processes are provided by a specially designed reciprocating compressor using sliding valves. The additional heat generated during process deficiencies is released to the environment through heat exchangers during the discharge cycle.

The developer claims that a cycle efficiency of 72-80% is quite real.This makes it possible to compare it with the storage of energy from a pumped storage power plant, the efficiency of which is over 80%.

Another proposed system uses turbines and is capable of handling much higher amounts of energy. The use of salt heaters as energy storage will move research forward.

Molten salt technology

The sensible heat of molten salts is also used to store solar energy at high temperatures. Salt melts can be used as a method for storing residual thermal energy. At the moment, this is a commercial technology for storing heat collected by solar concentrators (for example, from tower-type solar power plants or parabolic cylinders). The heat can later be converted to superheated steam to power conventional steam turbines and generate electricity in bad weather or at night. This was demonstrated in 1995-1999 as part of the Solar Two project. Estimates in 2006 predicted an annual efficiency of 99%, referring to a comparison of energy stored as heat before conversion to electricity and direct conversion of heat to electricity. Various eutectic mixtures of salts are used (for example, sodium nitrate, potassium nitrate and calcium nitrate). The use of such systems as a heat transfer medium is noticeable in the chemical and metallurgical industries.

Salt melts at 131C (268F). It is stored in a liquid state at 288C (550F) in insulated "cold" storage containers. The liquid salt is pumped through solar collector panels, where focused solar heat heats it up to 566C (1,051F). It is then sent to a hot storage tank. The tank insulation itself can be used to store thermal energy for a week. In the event of a need for electricity, the hot molten salt is pumped into a conventional steam generator to produce superheated steam and run a standard turbine generator set used in any coal, oil or nuclear power plant. A 100 MW turbine would require a vessel 9.1 m (30 ft) high and 24 m (79 ft) in diameter to run it within four hours in a similar manner.

A single tank with a separating plate for storing both cold and hot molten salts is under development. It will be much more economical to achieve 100% more energy storage per unit volume compared to twin tanks, as the molten salt storage tank is quite expensive due to the complex design. Salt heaters are also used to store energy in molten salts.

Several parabolic power plants in Spain and Solar Reserve, a developer of solar power towers, use this concept to store thermal energy. The Solana power plant in the United States can store energy in molten salts, which is generated for 6 hours. In the summer of 2013, the Gemasolar Thermosolar power plant, operating as both a solar concentrator and a molten salt power plant in Spain, for the first time managed to produce electricity continuously for 36 days.

Why is a heat accumulator needed and how does it work

Those whose housing is heated with a solid fuel boiler know how difficult it is to achieve a stable temperature in batteries. Since the temperature in the heater furnace is constantly changing and it is practically impossible to influence this process. And how to do this when the fuel is put into the furnace and has already flared up? You can, of course, cover the air supply, but the effect will be subtle and long-term. In other words, it is not possible to take prompt measures.

The second problem is the time between fuel loading. Naturally, the less often you need to throw firewood or coal into the boiler, the better, less hassle. To solve both of these problems, you can install storage tanks for heating. What it is?

A heat accumulator (TA) is a sealed buffer tank of large volume, in which heat is accumulated during the operation of the boiler. After all the fuel burns out in the boiler, the accumulator tank installed in the heating system gradually releases the accumulated heat to the circuit. This reduces the number of fuel loads and increases the efficiency of the heater.

Inside the heat accumulator is a coolant. It can be water or antifreeze, while you need to understand that this is the same coolant that circulates throughout the circuit. The principle of operation of the battery tank in the heating system:

- the boiler heats the water, and it enters the TA, which is constantly filled with coolant;

- then the coolant goes into the heating circuit, while giving off part of the heat to the total volume of the reservoir liquid;

- gradually the temperature of the water in the heat accumulator increases;

- from the circuit, the return also comes to the TA;

- from the buffer tank, the return flow is transferred to the boiler.

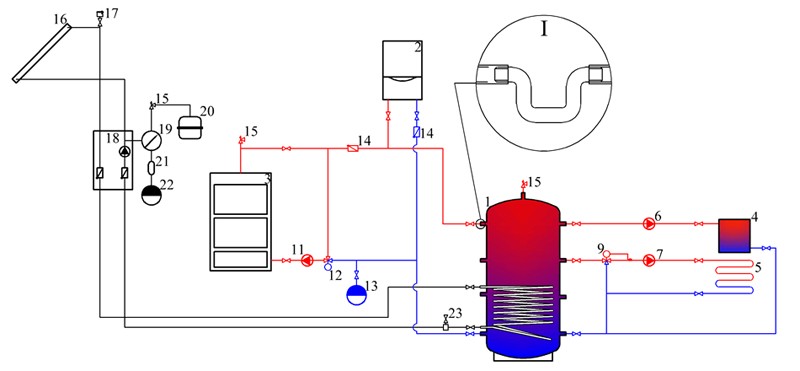

TA connection diagram

The water supply to the storage tank for heating is carried out at the top, and the return exits at the bottom. These flows move in the reservoir in different directions. The problem is that they intersect and heat exchange takes place. Otherwise, no heat storage will occur. In this case, it is necessary not only to mix the water in the container, but to do it correctly.

What does it mean? The circulation must be set in such a way that the supply flow goes down to the return flow, while the return flow should not rise up. Only in this case, the liquid layer, which is located between the flows, will heat up.

The circulation is adjusted by selecting the power of the pumps before and after the storage tank for heating, as well as setting one of the three speeds of their operation

It is important to put filters for the heating system in front of the pumps. Otherwise, the circulation pump may need to be repaired.

In addition to the fact that the storage tank for the heating system heats the home, a hot water circuit can be installed in it. Also, the unit is equipped with additional heating sources, which act as auxiliary ones.

The heat accumulator ceases to take part of the heat from the coolant supplied to it only if it is fully charged. That is, the water temperature is the same in all layers and is equal to the supply temperature from the boiler.

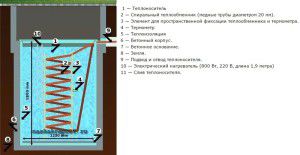

Do-it-yourself thermal accumulator

The complexity of manufacturing buffer tanks for heating lies in the creation of reliable thermal insulation. For this, you cannot use an ordinary barrel or a similar container. In addition to this parameter, the capacity of the heating radiator must withstand the load of water on the walls and possible hydraulic shocks.

The simplest design is a cube, inside of which there is a U-shaped pipeline or a copper pipe coil. The latter is preferable, since it has a large heat exchange surface area, and copper has an optimal thermal conductivity value. This design is connected to a common highway. For the manufacture of a heating system tank, you will need steel sheets with a thickness of at least 1.5 mm and a metal pipe. Its diameter must be equal to the cross section of the pipeline in this heating section.

The minimum set of tools includes the following:

- Welding machine;

- Angle grinder (Bulgarian);

- Drill with drills for metal;

- Measuring tool.

The easiest way is to make a container for heating radiators of a cubic shape. A drawing is drawn up in advance, according to which all further work will be carried out. The presence of a heating element is not required, but preferred. He will be able to maintain the level of water heating at the proper level.

The procedure for manufacturing a heat accumulator

First, rectangular sheets are cut out, of which the body of the heating system tank will consist.At this stage, you need to take into account the gap for welding - it can be from 1 to 3 mm, depending on the device and the selected electrodes. Then, holes are cut in the blanks for fastening the pipeline, heating element and nozzles for filling the container. Cast iron radiators cannot be attached directly to it. Therefore, it is necessary to calculate the heat losses from the tank to the radiator.

After assembling the structure, you need to make the thermal insulation of the body. For a storage heating tank, it is best to use basalt insulation. It has the following important qualities:

Not hot. Melting occurs at temperatures above 700°C;

Easy to install. Basalt wool is quite elastic;

Has vapor barrier properties

This is important for the removal of condensate, which will inevitably accumulate on the body of the storage tank during heating operation.

The use of polymeric materials (polystyrene foam or polystyrene) is unacceptable, as they belong to the group of flammable. Thermal insulation of the buffer tank is best done after connecting to the heating system. In this way, heat losses at the inlet and outlet pipes can be reduced.

An old steel tank can be used as a container. But the thickness of its wall should not be less than 1.5 mm.

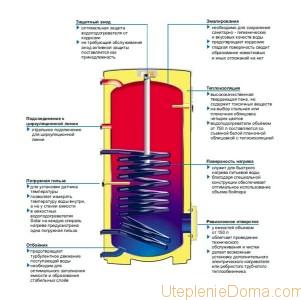

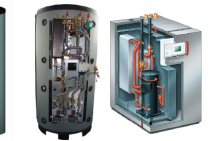

The design of the storage tank for heating

Sectional view of an accumulator tank for heating

Now let's take a closer look at the design of the heat accumulator. If the tank is intended only for the heating circuit, then its design is quite simple:

- sealed housing;

- insulation layer;

- branch pipe in the upper part for supply;

- return pipe at the bottom.

Nothing else is required, but if it is necessary for the storage tank for heating to also heat water for household needs, then a copper coil and, of course, two branch pipes (inlet / outlet) are built into the tank body. Cold water is connected to the inlet pipe. It passes through the coil and heats up from the coolant that is in the buffer tank. Already heated water comes out of the tank, which is supplied to the bathroom and kitchen faucets. At the same time, the length of the copper coil depends on how long the water will stay inside the TA and, accordingly, how much it will heat up.

The HE design can have not only several heat transfer circuits, but also several heating sources. So, the heating of the coolant in the tank can be carried out in several ways:

- from the heater;

- from electric heaters.

Electric heaters can be fed directly into the network and turn on when necessary. Also, modern buffer tanks for heating accumulators are equipped with a heating element connected to solar panels, which allows you to use free solar energy.

As always, craftsmen are interested in whether it is possible to make a battery tank for heating with their own hands. Of course, you can if your hands are in place, but it’s impossible to say that it’s very simple.

What you need to pay attention to:

- the top of the tank should not be flat, otherwise it will squeeze out with pressure;

- the supply and return pipes must be in the right planes;

- the whole structure is absolutely sealed;

- metal about 5 mm thick.

Below in the video you can see how one of the craftsmen made a storage tank for heating with his own hands from a barrel.

What else you need to know about the features of use in everyday life

To date, there are several methods for calculating the volume of a reservoir. As experience shows, for every kilowatt of equipment power, 25 liters of water are needed. The efficiency of the boiler, which provides for the need for a heating system with a heat accumulator, rises to 84%. The combustion peak is leveled, due to this, energy resources are saved in the amount of up to 30%.

The thermal accumulator ensures the preservation of temperature due to reliable thermal insulation made of foamed polyurethane. Additionally, it is possible to install heating elements, which allow, if necessary, to heat water.

Connecting the heat accumulator piping to the heating system

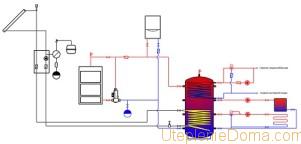

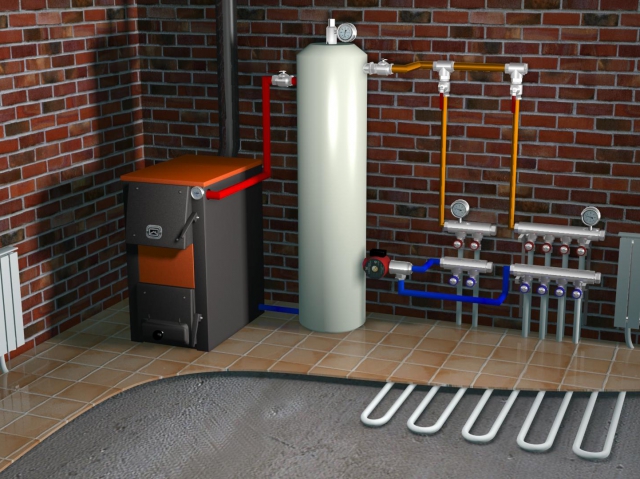

As a general rule, the buffer tank is connected to the heating system in parallel with the heating boiler, therefore this scheme is also called the boiler piping scheme.

Let us give the usual scheme for connecting TA to a heating system with a solid fuel heating boiler (to simplify the scheme, shutoff valves, automation, control devices and other equipment are not indicated on it).

Simplified heat accumulator piping scheme

This diagram shows the following elements:

- Heating boiler.

- Thermal accumulator.

- Heating devices (radiators).

- Circulation pump in the return line between the boiler and the heater.

- Circulation pump in the return line of the system between heating devices and TA.

- Heat exchanger (coil) for hot water supply.

- Heat exchanger connected to an additional heat source.

One of the upper pipes of the tank (pos. 2) is connected to the boiler outlet (pos. 1), and the second one is connected directly to the supply line of the heating system.

One of the lower branch pipes of the HE is connected to the boiler inlet, while a pump (pos. 4) is installed in the pipeline between them, which ensures the circulation of the working fluid in a circle from the boiler to the HE and vice versa.

The second lower branch pipe THAT is connected to the return line of the heating system, in which a pump (pos. 5) is also installed, which provides the supply of heated coolant to the heaters.

To ensure the functioning of the heating system in the event of a sudden power outage or failure of the circulation pumps, they are usually connected in parallel to the main line.

In systems with natural coolant circulation, there are no circulation pumps (pos. 4 and 5). This significantly increases the inertia of the system, and at the same time makes it completely non-volatile.

The DHW heat exchanger (pos. 6) is located in the upper part of the HE.

The location of the additional heat exchanger (pos. 7) depends on the type of heat input source:

- for high-temperature sources (heating element, gas or electric boiler) it is placed in the upper part of the buffer tank;

- for low-temperature ones (solar collector, heat pump) - at the bottom.

The heat exchangers indicated in the diagram are optional (pos. 6 and 7).

Heat accumulator calculation

The calculation formula is very simple:

Q = mc(T2-T1), where:

Q is the accumulated heat;

m is the mass of water in the tank;

c is the specific heat capacity of the coolant in J / (kg * K), for water equal to 4200;

T2 and T1 are the initial and final temperatures of the coolant.

Let's say we have a radiator heating system. Radiators are selected for the temperature regime 70/50/20. Those. when the temperature in the battery tank drops below 70C, we will begin to experience a lack of heat, that is, simply freeze. Let's calculate when this happens.

90 is our T1

70 is T2

20 - room temperature. We don't need it in our calculations.

Let's say we have a heat accumulator for 1000 liters (1m3)

We consider the heat reserve.

Q

\u003d 1000 * 4200 * (90-70) \u003d 84,000,000 J or 84,000 kJ

1 kWh = 3600 kJ

84000/3600=23.3 kW heat

If the heat loss at home is 5 kW during a cold five-day period, then we have enough stored heat for almost 5 hours. Accordingly, if the temperature is higher than calculated for a cold five-day period, then the heat accumulator will be sufficient for a longer time.

The selection of the volume of the thermal accumulator depends on your tasks. If you need to smooth the temperature, set a small volume. If you want to accumulate heat in the evening in order to wake up in a warm house in the morning, you need a large unit. Let there be a second task. From 2300 to 0700 - there must be a supply of heat.

Suppose that the heat loss is 6 kW, and the temperature regime of the heating system is 40/30/20. The coolant in the heat accumulator can be heated up to 90C

Stock time 8 hours. 6*8=48 kW

M

=

Q

/4200*(T2-T1)

48*3600=172800 kJ

V

=172800/4200*50=0.822 m3

A heat accumulator from 800 to 1000 liters will satisfy our requirements.

Solar energy storage

The most widely used solar heating systems can store energy from a few hours to several days. However, there has been an increase in the number of facilities using seasonal thermal energy storage (SHS), which allows solar energy to be stored in the summer to be used for space heating in the winter. Solar community Drake Lanling of Alberta, Canada has now learned to use 97% of solar power all year round, a record only made possible by the use of SATE.

The use of both latent and sensible heat is also possible in high-temperature solar thermal receiving systems. Various eutectic mixtures of metals such as Aluminum and Silicon (AlSi12) offer a high melting point for efficient steam production, while cement-based alumina mixtures offer good heat storage properties.

Solubility frontier alloy technology

Alloys at the solubility boundary are based on the phase change of the metal in order to store thermal energy.

Instead of pumping liquid metal between tanks as in a molten salt system, the metal is encapsulated in another metal that it cannot fuse with (immiscible). Depending on the choice of two materials (phase change material and capsule material), the energy storage density can be 0.2-2 MJ/L.

The working medium, typically water or steam, is used to transfer heat to and from the alloy at the solubility boundary. The thermal conductivity of such alloys is often higher (up to 400 W/m*K) than that of competing technologies, which means faster possible “loading” and “unloading” of thermal storage. The technology has not yet been implemented for use on an industrial scale.

Making a heat accumulator with your own hands

The simplest battery model can be made independently, while you should be guided by the principles of the thermos. Due to the walls that do not conduct heat, the liquid will remain hot for a long time. For work, you should prepare:

- Scotch;

- concrete slab;

- thermal insulation material;

- copper pipes or heating elements.

When it is made, when choosing a tank, it is necessary to take into account the desired capacity, it should start from 150 liters. You can pick up any metal barrel. But if you choose a volume less than mentioned, then the meaning is lost. The container is prepared, dust and debris are removed from the inside, areas where corrosion has begun to form must be treated accordingly.

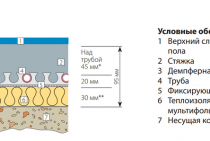

Advantages of using a heat accumulator in a house with insulation

If your site does not have a national treasure - main gas, it's time to think about the right heating system. The best time is when the project is just being prepared, and the worst time is when you already live in the house and realize that heating is very expensive.

An ideal house for installing a solid fuel boiler and a heat accumulator is a building with good insulation and a low-temperature heating system. The better the insulation, the less heat loss and the longer your heat accumulator will be able to maintain comfortable heat.

Low temperature heating system. Above, we gave an example with radiators when the temperature regime was 90/70/20. In low-temperature mode, the conditions will be - 35/30/20. Feel the difference. In the first case, already when the temperature drops below 90 degrees, you will feel a lack of heat. In the case of a low-temperature system, you can sleep peacefully until morning. Why be unfounded. Let's just calculate the benefits.

We calculated the method above.

Variant with low temperature heating system

Q

=1000*4200*(90-35)=231

000

000 J (231000 kJ)

231000/3600=64.2 kW.This is almost three times more with the same volume of heat accumulator. With heat loss - 5 kW, this reserve is enough for the whole night.

And now about finances. Suppose we have mounted a heat accumulator with electric heaters. We store at night rate. Tenov power - 10 kW. 5 kW goes to the current heating of the house at night, we can store 5 kW for the day. Night rate from 23-00 to 07-00. 8 ocloc'k.

8*5=40 kW. Those. during the day we will use the night rate for 8 hours.

From January 1, 2015, in the Krasnodar Territory, the daily rate is 3.85, the night rate is 2.15.

The difference is 3.85-2.15 \u003d 1.7 rubles

40 * 1.7 = 68 rubles. The amount seems small, but do not rush. Above, we gave links to an insulated house and an uninsulated one. Imagine that you made a mistake - the house is built, you have already passed the first heating season and realized that heating with electricity is very expensive. Above, we gave an example of heat loss in an uninsulated house. In the example, the heat loss is 18891 watts. This is on a cold weekday. The average for the heating season will be exactly 2 times less and will be 9.5 kW.

Therefore, for the heating season we need 24 * 149 * 9.5 = 33972 kW

In rubles 16 hours, 2/3 (22648) at the daily rate, 1/3 (11324 kW) at the night.

22648 * 3.85 = 87195 rubles

11324 * 3.85 = 24346 rubles

Total: 111541 rubles. The figure for heat is simply terrifying. Such an amount can devastate any budget. If you store heat at night, you can save. 38502 rubles for the heating season. Big savings. If you have such expenses, it is necessary to put a solid fuel boiler or a fireplace with a water jacket in pair with the electric boiler. There is time and desire - they threw firewood, stored heat in a thermal accumulator, and finish the rest with electricity.

In an insulated house with a heat accumulator, the cost of the heating season will be comparable to similar non-insulated houses that have main gas.

Our choice when there is no main gas is as follows:

Well insulated house;

Low temperature heating system;

Thermal accumulator;

Solid fuel boiler or water fireplace;

Electric boiler.

If you have a solid fuel boiler in your house, then you should be aware that it is not able to function for a long time without human intervention. This is due to the need to periodically load firewood into the firebox. If this is not done in time, the system will begin to cool down, and the temperature in the rooms will drop.

If the electricity is turned off when the firebox is flaring up, then there will be a danger of water boiling in the equipment jacket, which will result in its destruction. These problems can be solved by installing a heat accumulator. It also performs the role of protecting cast iron installations from cracking when there is a sharp drop in the temperature of the network water.

Conclusion

A heat accumulator for a rocket is a device that is far from the understanding of an ordinary consumer. But you can easily connect the heat accumulator for the heating system yourself. To do this, a return pipeline will have to pass through the tank, at the ends of which an exit and an entrance are provided.

At the first stage, the tank and the boiler return should be connected to each other. Between them there is a circulation pump, it will distill the coolant from the barrel to the shut-off valve, heaters and expansion tank. On the second side, a circulation pump and a shut-off valve are installed.

Photo source - site http://www.devi-ekb.ru

Using thermal energy storage it is possible to cost-effectively shift the consumption of gigawatts of energy. But today the market for such drives is catastrophically small compared to the potential. The main reason lies in the fact that at the initial stage of the emergence of heat storage systems, manufacturers paid little attention to research in this area.Subsequently, manufacturers in pursuit of new incentives have led to the fact that the technology has deteriorated, and people began to misunderstand its goals and methods.

The most obvious and objective reason for using a heat storage system is to effectively reduce the amount of money spent on energy consumed, moreover, the cost of energy during peak hours is much higher than at other times.