Heat pump calculation example

We will select a heat pump for the heating system of a one-story house with a total area of 70 sq. m with standard ceiling height (2.5 m), rational architecture and thermal insulation of enclosing structures that meet the requirements of modern building codes. For heating the 1st sq. m of such an object, according to generally accepted standards, you have to spend 100 W of heat. Thus, for heating the whole house you will need:

Q \u003d 70 x 100 \u003d 7000 W \u003d 7 kW of thermal energy.

We choose a heat pump brand "TeploDarom" (model L-024-WLC) with a heat output of W = 7.7 kW. The compressor of the unit consumes N = 2.5 kW of electricity.

Collector calculation

The soil in the area allotted for the construction of the collector is clayey, the groundwater level is high (we take the calorific value p = 35 W/m).

Collector power is determined by the formula:

Qk \u003d W - N \u003d 7.7 - 2.5 \u003d 5.2 kW.

Determine the length of the collector pipe:

L = 5200 / 35 = 148.5 m (approx.).

Based on the fact that laying a circuit longer than 100 m is irrational due to excessively high hydraulic resistance, we accept the following: the heat pump collector will consist of two circuits - 100 m and 50 m long.

The area of the site that will need to be taken under the collector is determined by the formula:

S = L x A,

Where A is the step between adjacent sections of the contour. We accept: A = 0.8 m.

Then S = 150 x 0.8 = 120 sq. m.

Types of designs of heat pumps

There are the following varieties:

- TN "air - air";

- TN "air - water";

- TN "soil - water";

- TN "water - water".

The very first option is a conventional split system operating in heating mode. The evaporator is mounted on the street, and a block with a condenser is installed inside the house. The latter is blown by a fan, due to which a warm air mass is supplied to the room.

If such a system is equipped with a special heat exchanger with branch pipes, an air-to-water heat pump will be obtained. It is connected to the water heating system.

An air-to-air or air-to-water heat pump evaporator can be placed not on the street, but in the exhaust ventilation duct (it must be forced). In this case, the efficiency of HP will be increased several times.

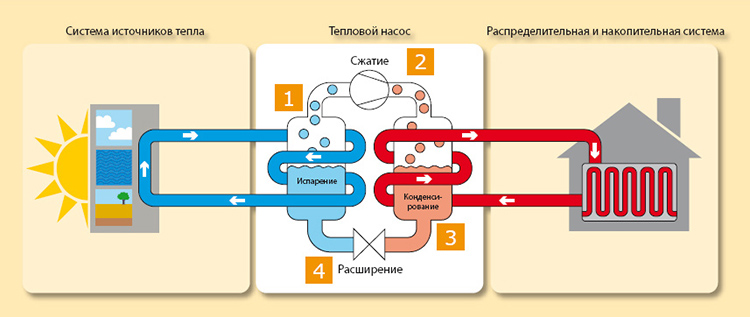

Heat pumps of the "water - water" and "soil - water" types use the so-called external heat exchanger or, as it is also called, a collector for heat extraction.

Schematic diagram of the heat pump

This is a long looped pipe, usually plastic, through which a liquid medium circulates, washing the evaporator. Both types of HP are the same device: in one case, the collector is immersed to the bottom of a surface reservoir, and in the second, to the ground. The condenser of such a HP is located in a heat exchanger connected to a water heating system.

Connecting HP according to the "water - water" scheme is much less laborious than "soil - water", since there is no need for excavation. At the bottom of the reservoir, the pipe is laid in the form of a spiral. Of course, only such a body of water is suitable for this scheme, which does not freeze to the bottom in winter.

Making a heat generator with your own hands

List of parts and accessories for creating a heat generator:

-

to measure the pressure at the inlet and outlet of the working chamber, two pressure gauges are needed;

- thermometer for measuring the temperature of the inlet and outlet liquid;

- valve for removing air pockets from the heating system;

- inlet and outlet pipes with taps;

- sleeves for thermometers.

Selection of circulation pump

To do this, you need to determine the required parameters of the device. The first characteristic is the ability of the pump to work with high temperature liquids. If this condition is neglected, the pump will quickly fail.

Next, you need to select the operating pressure that the pump can create.

For a heat generator, it is enough that a pressure of 4 atmospheres is reported at the inlet of the liquid, you can raise this figure to 12 atmospheres, which will increase the rate of heating of the liquid.

The pump performance will not have a significant effect on the heating rate, since during operation the liquid passes through a conditionally narrow nozzle diameter. Typically, up to 3–5 cubic meters of water per hour is transported. The coefficient of conversion of electricity into thermal energy will have a much greater influence on the operation of the heat generator.

Making a cavitation chamber

But in this case, the flow of water will be reduced, which will lead to mixing it with cold masses. The small nozzle opening also works to increase the number of air bubbles, which increases the operating noise and can cause bubbles to form already in the pump chamber. This will reduce its service life. The most acceptable, as practice has shown, is considered to be a diameter of 9–16 mm.

According to the shape and profile of the nozzle, there are cylindrical, conical and rounded shapes. It is definitely impossible to say which choice will be more effective, it all depends on the rest of the installation parameters. The main thing is that the vortex process arises already at the stage of the initial entry of liquid into the nozzle.

Calculation of the horizontal collector of a heat pump

The efficiency of a horizontal collector depends on the temperature of the medium in which it is immersed, its thermal conductivity, as well as the area of contact with the pipe surface. The calculation method is rather complicated, therefore, in most cases, averaged data are used.

- 10 W - when buried in dry sandy or rocky soil;

- 20 W - in dry clay soil;

- 25 W - in wet clay soil;

- 35 W - in very damp clay soil.

Thus, to calculate the length of the collector (L), the required thermal power (Q) should be divided by the calorific value of the soil (p):

L = Q / p.

The values given can only be considered valid if the following conditions are met:

- The land above the collector is not built up, shaded, or planted with trees or bushes.

- The distance between adjacent turns of the spiral or sections of the "snake" is at least 0.7 m.

When calculating the collector, it should be taken into account that the soil temperature drops by several degrees after the first year of operation.

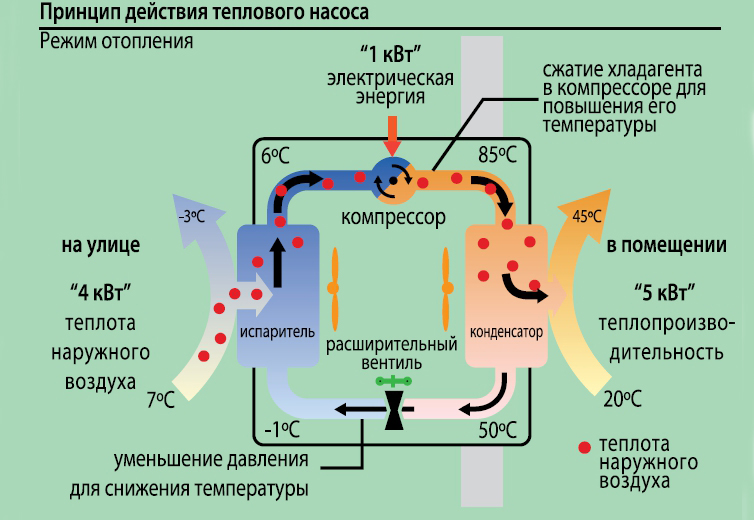

How heat pumps work

In any HP there is a working medium called a refrigerant. Usually freon acts in this capacity, less often - ammonia. The device itself consists of only three components:

- evaporator;

- compressor;

- capacitor.

The evaporator and condenser are two reservoirs that look like long curved tubes - coils. The condenser is connected at one end to the compressor outlet, and the evaporator to the inlet. The ends of the coils are joined and a pressure reducing valve is installed at the junction between them. The evaporator is in contact - directly or indirectly - with the source medium, while the condenser is in contact with the heating or DHW system.

How a heat pump works

The operation of HP is based on the interdependence of volume, pressure and temperature of the gas. Here is what happens inside the aggregate:

- Ammonia, freon or other refrigerant, moving through the evaporator, heats up from the source medium, for example, to a temperature of +5 degrees.

- After passing the evaporator, the gas reaches the compressor, which pumps it into the condenser.

- The refrigerant pumped by the compressor is held in the condenser by a pressure reducing valve, so its pressure is higher here than in the evaporator. As you know, with increasing pressure, the temperature of any gas increases. This is exactly what happens to the refrigerant - it heats up to 60 - 70 degrees. Since the condenser is washed by the coolant circulating in the heating system, the latter is also heated.

- Through the pressure reducing valve, the refrigerant is discharged in small portions into the evaporator, where its pressure drops again.The gas expands and cools, and since part of the internal energy was lost by it as a result of heat transfer at the previous stage, its temperature drops below the initial +5 degrees. Following the evaporator, it heats up again, then it is pumped into the condenser by the compressor - and so on in a circle. Scientifically, this process is called the Carnot cycle.

The main feature of HP is that thermal energy is taken from the environment literally for nothing. True, for its production it is necessary to spend a certain amount of electricity (for the compressor and the circulation pump / fan).

But HP still remains very profitable: for each kWh of electricity spent, it is possible to get from 3 to 5 kWh of heat.

Sources

- http://aquagroup.ru/articles/skvazhiny-dlya-teplovyh-nasosov.html

- http://VTeple.xyz/teplovoy-nasos-voda-voda-printsip-rabotyi/

- https://6sotok-dom.com/dom/otoplenie/raschet-moshhnosti-teplovogo-nasosa.html

- https://microklimat.pro/otopitelnoe-oborudovanie/otopitelnye-pribory/teplovoj-nasos-dlya-otopleniya-doma.html

- http://avtonomnoeteplo.ru/altenergiya/148-teplovye-nasosy-voda-voda.html

- http://avtonomnoeteplo.ru/altenergiya/290-burenie-skvazhin-dlya-teplovyh-nasosov.html

- https://kotel.guru/alternativnoe-otoplenie/teplogenerator-kavitacionnyy-dlya-otopleniya-pomescheniya.html

- http://skvajina.com/teplovoy-nasos/

- http://www.burovik.ru/burenie-skvazhin-teplovye-nasosy.html

Features of wells for heat pumps

The main element in the operation of the heating system when using this method is a well. Its drilling is carried out in order to install a special geothermal probe and a heat pump directly in it.

The organization of a heating system based on a heat pump is rational both for small private cottages and for entire farmlands. Regardless of the area that will need to be heated, before drilling wells, an assessment of the geological section in the territory of the object should be carried out. Accurate data will help to correctly calculate the number of required wells.

The depth of the well should be selected in such a way that it can not only provide sufficient heat to the object under consideration, but also allow the selection of a heat pump with standard technical characteristics. To increase heat transfer, a special solution is poured into the cavity of the wells, where the mounted circuit is located (clay can be used as an alternative to the solution).

The main requirement for drilling wells for heat pumps is the complete isolation of all, without exception, groundwater horizons. Otherwise, the ingress of water into the underlying horizons can be regarded as pollution. If the coolant gets into groundwater, it will have negative environmental consequences.

Prices for drilling wells for heat pumps

The cost of installation of the first geothermal heating circuit

| 1 | Well drilling in soft rock | 1 p.m. | 600 |

| 2 | Well drilling in hard rock (limestone) | 1 p.m. | 900 |

| 3 | Installation (lowering) of a geothermal probe) | 1 p.m. | 100 |

| 4 | Crimping and filling the outer contour | 1 p.m. | 50 |

| 5 | Backfilling of the well to improve heat transfer (granite screenings) | 1 p.m. | 50 |

Why did I choose a heat pump for my home's heating and water supply system?

So, I bought a plot to build a house without gas. The prospect of gas supply is in 4 years. We had to decide how to live up to this time.

The following options were considered:

-

1) gas tank

2) diesel fuel

3) pellets

The costs for all these types of heating are commensurate, so I decided to make a detailed calculation using the example of a gas tank. The considerations were as follows: 4 years on imported liquefied gas, then replacing the nozzle in the boiler, supplying main gas and minimizing the cost of rework. The result is:

- for a house of 250 m2, the cost of a boiler, a gas tank is about 500,000 rubles

- the whole area needs to be cleared

- availability of a convenient entrance for the tanker for the future

- maintenance of about 100,000 rubles per year:

- the house will have heating + hot water

- at a temperature of -150°C and below costs 15-20,000 rubles per month).

Total:

- gas tank + boiler - 500,000 rubles

- operation 4 years - 400,000 rubles

- supply of the main gas pipe to the site - 350,000 rubles

- nozzle replacement, boiler maintenance - 40,000 rubles

In total - 1,250,000 rubles and a lot of fuss around the issue of heating in the next 4 years! Personal time in terms of money is also a decent amount.

Therefore, my choice fell on a heat pump with commensurate costs for drilling 3 wells of 85 meters and its purchase with installation. The heat pump Buderus 14 kW has been working for 2 years. A year ago I installed a separate meter for it: 12,000 kWh per year!!! In terms of money: 2400 rubles per month! (Monthly gas payment would be higher) Heating, hot water and free air conditioning in summer!

Air conditioning works by lifting the coolant at a temperature of +6-8°C from the wells, which is used to cool the premises through conventional fan coil units (a radiator with a fan and a temperature sensor).

Ordinary air conditioners are also very energy intensive - at least 3 kW for each room. That is 9-12 kW for the whole house! This difference must also be taken into account in the payback of the heat pump.

So a payback of 5-10 years is a myth for those who sit on a gas pipe, the rest are welcome to the club of “Green” energy consumers.

Installation nuances

When choosing a water-to-water heat pump, it is important to calculate the conditions for its operation. If the main is immersed in a reservoir, its volume must be taken into account (for a closed lake, pond, etc.), and when installed in a river, the flow rate

If the calculations are incorrect, the pipes will freeze with ice and the efficiency of the heat pump will be zero.

What is a chiller and how does it work

When sampling groundwater, seasonal fluctuations must be taken into account. As you know, in spring and autumn the amount of groundwater is higher than in winter and summer. Namely, the main time of operation of the heat pump will be in the winter. For pumping and pumping water, you need to use a conventional pump, which also consumes electricity. Its costs should be included in the general costs and only after that the efficiency and payback period of the heat pump should be considered.

A great option is to use artesian water. It emerges from deep layers by gravity, under pressure. But you will have to install additional equipment to compensate for it. Otherwise, parts of the heat pump may be damaged.

The only disadvantage of using an artesian well is the cost of drilling. The costs will not pay off soon due to the lack of a pump to lift water from a conventional well and pump it into the ground.

Heating heat generator operation technology

In the working body, the water must receive increased speed and pressure, which is carried out using pipes of various diameters, tapering along the flow. In the center of the working chamber, several pressure flows are mixed, leading to the phenomenon of cavitation.

In order to be able to control the speed characteristics of the water flow, braking devices are installed at the outlet and during the working cavity.

Water moves to the branch pipe at the opposite end of the chamber, from where it flows in the return direction for reuse by means of a circulation pump. Heating and heat generation occurs due to the movement and sharp expansion of the liquid at the outlet of the narrow nozzle opening.

Positive and negative properties of heat generators

Cavitation pumps are classified as simple devices. In them, the mechanical motive energy of water is converted into thermal energy, which is spent on heating the room. Before building a cavitation unit with your own hands, the pros and cons of such an installation should be noted. The positive characteristics include:

- efficient generation of thermal energy;

- economical in operation due to the absence of fuel as such;

- an affordable option for purchasing and making your own hands.

Heat generators have disadvantages:

- noisy operation of the pump and cavitation phenomena;

- materials for production are not always easy to get;

- uses decent power for a room of 60–80 m2;

- takes up a lot of usable room space.

Well drilling for heat pump system

It is better to entrust the device of a well to a professional installation organization. It is optimal that representatives of the company selling the heat pump do this. So, you can take into account all the nuances of drilling and the location of the probes from the structure, and fulfill other requirements.

A specialized organization will contribute to obtaining permission to drill a well for probes for a ground source heat pump. According to the law, the use of groundwater for economic purposes is prohibited. We are talking about the use for any purpose of waters located below the first aquifer.

As a rule, the procedure for drilling vertical systems must be agreed with the state administration. Lack of permits leads to penalties.

After receiving all the necessary documents, installation work begins, according to the following order:

- The drilling points and the location of the probes on the site are determined, taking into account the distance from the structure, landscape features, the presence of groundwater, etc. Maintain a minimum gap between the wells and the house of at least 3 m.

- Drilling equipment is being imported, as well as equipment necessary for landscape work. Both vertical and horizontal installation require a drill and a jackhammer. To drill the ground at an angle, drilling rigs with a fan contour are used. The caterpillar model has received the greatest application. Probes are placed in the resulting wells and the gaps are filled with special solutions.

Drilling wells for heat pumps (with the exception of cluster wiring) is allowed at a distance of at least 3 m from the building. The maximum distance to the house should not exceed 100 m. The project is carried out on the basis of these standards.

How deep should the well be?

Depth is calculated based on several factors:

- The dependence of efficiency on the depth of the well - there is such a thing as an annual decrease in heat transfer. If the well has a great depth, and in some cases it is required to make a channel up to 150 m, each year there will be a decrease in the indicators of heat received, over time the process will stabilize. Making a well of maximum depth is not the best solution. Usually, several vertical channels are made, remote from each other. The distance between the wells is 1-1.5 m.

- The calculation of the depth of drilling a well for probes is carried out taking into account the following: the total area of \u200b\u200bthe adjacent territory, the presence of groundwater and artesian wells, the total heated area. So, for example, the depth of drilling wells with high groundwater is sharply reduced, compared with the manufacture of wells in sandy soil.

The creation of geothermal wells is a complex technical process. All work, starting with the project documentation and ending with the commissioning of the heat pump, must be carried out exclusively by specialists.

To calculate the approximate cost of work, use online calculators. Programs help to calculate the volume of water in the well (affects the amount of propylene glycol required), its depth and perform other calculations.

How to fill a well

The choice of materials often falls entirely on the owners themselves.

The contractor may advise you to pay attention to the type of pipe and recommend the composition for filling the well, but the final decision will have to be made independently. What are the options?

- Pipes used for wells - use plastic and metal contours. As practice has shown, the second option is more acceptable. The service life of a metal pipe is at least 50-70 years, the walls of the metal have good thermal conductivity, which increases the efficiency of the collector.Plastic is easier to install, so construction organizations often offer it.

- Material for filling the gaps between the pipe and the ground. Plugging a well is a mandatory rule to be followed. If the space between the pipe and the ground is not filled, shrinkage occurs over time, which can damage the integrity of the circuit. The gaps are filled with any building material with good thermal conductivity and elasticity, such as Betonit. Filling the well for the heat pump should not interfere with the normal circulation of heat from the ground to the collector. Work is carried out slowly so as not to leave voids.

Even if the drilling and positioning of the probes from the building and from each other is done correctly, additional work will be required after a year due to the shrinkage of the collector.

—

CAUTION 1

ÐлаÑÑово-поÑовÑе Ð²Ð¾Ð´Ñ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð¿¿¿¼ðð𸸸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸¸ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð · Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð δÐ Ð Ð Ð Ð δ »ÐµÐ³Ð°ÑÑие ÑÑеди ÑолÑи глин. ногда Ð²Ð¾Ð´Ñ Ð¸Ð¼ÐµÑÑ ÑпоÑадиÑеÑкий ÑаÑакÑøкÑÑÐÐÐÐ

a

ÐлаÑÑово-поÑовÑе Ð²Ð¾Ð´Ñ ÑвÑÐ · Ð ° Ð½Ñ Ñ Ð¾ÑÐ »Ð¾Ð¶ÐμниÑми ÑÐμÑо-ÑвÐμÑной Ñгл ÐμноÑной и пÐμÑÑÑоÑвÐμÑной пÑÐμимÑÑÐμÑÑвÐμнно конÑинÐμнÑÐ ° Ð »Ñной ÑоÑмР° Ñий. Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ² РРРРРРо Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð'РРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРони доÑÑигаÑÑ 3 - 10 л / Ñ. ÐÐμÐ ± иÑÑ ÑкÑпР»ÑÐ ° ÑÐ ° ÑионнÑÑ ÑквР° жин, вÑкÑÑвР° ÑÑÐ¸Ñ ÑÑÑкиÐμ конгл омÐμÑÐ ° ÑÑ ÐÐμÑÑнÐμ-СокÑÑÑкого Ð ° ÑÑÐμÐ · иР° нÑкого баÑÑейна, ÑоÑÑавлÑÑÑ 75 — 60 л / С. инеÑализаÑÐ¸Ñ Ð¸ ÑииÑеÑкий ÑоÑÑав вод ÑимиÑеѺий п2 Ð ²ÐððÐμÐðð½½½½ºðððð½½ñÐμμñððÐðÐμÐμкÐμÐðÐ °Ð °μ½ÐμÐðÐ °Ð½Ð ·ÐμÐðÐð¸ññ μμμμμ пððμ Ð Ðμñ 0 4 - 0 7 г / l - 12 г / Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ññññññððñññññññññññññññññññññññ Row Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð »ÑÑаÑной агÑеÑÑиноÑÑÑÑк обÑÑнÑм ÑеменÑам.

a

ÐлаÑÑово-поÑовÑе Ð²Ð¾Ð´Ñ ÑвÑÐ · Ð ° Ð½Ñ Ñ Ð¾ÑÐ »Ð¾Ð¶ÐμниÑми ÑÐμÑоÑвÐμÑ-ной Ñгл ÐμноÑной и пÐμÑÑÑоÑвÐμÑной пÑÐμимÑÑÐμÑÑвÐμнно конÑинÐμнÑÐ ° Ð »Ñной ÑоÑмР° Ñий. Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð » ¸ÑÑÑв единиÑнÑÑ ÑлÑÑаÑÑ Ð´Ð¾ 11 л / С. Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ² Ð Ð Ð Ð Ð Ð Ð ² 4, иногда до 8 - 12 г / л, Ñеже пÑеÑнÑе водÑ.

a

ÐлаÑÑово-поÑовÑе Ð²Ð¾Ð´Ñ ÑÑÑлÑÑ Ð¿Ð¾ÐºÑовнÑÑ Ð¾Ñлоù¶ÐµÐ в Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð · Ð Ð Ð Ð Ð Ð · Ð Ð Ð Ð Ð Ð · ° C. ððñðð¶ð𺾾 оμððððμμ ñðμÐμÐμññðð °''ððÐμнРРРРРРРРРРРРРРРРРРРÐμй¹¹¹¹²²²²¹¹¹¹¹¹¹ Ðμμðμ'кººÐº ññðð¶μμÐððÐðÐðÐðÐμðÐðн Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð

a

Ð1 ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ðμ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð δ SHOT. Ð ²ÐðÐгÐðÐμÐμÐðÐÐðÐðÐðÐμÐðÐðÐðÐðÐμÐðÐðÐðÐðÐμÐμÐðÐðоÐμÐμμñññññññññññññññññ back.

a