Why is it needed

- When calculating heating devices;

- To estimate the amount of heat loss in pipelines transporting coolant.

Heating appliances

What kind of heaters are used as heat transfer elements of the pipe?

Of the widely used, it is worth mentioning:

- Warm floor;

- Towel dryers and various coils;

- Registers.

Warm floor

Pipes almost always act as a heating element for a water-heated floor (there is also a warm floor with electric heating); however, recent use has become rare.

The reasons are obvious: a steel pipe is subject to corrosion and a decrease in clearance over time; installation requires welding; mounting a steel pipe on is always a potential leak. And what are leaks in the floor, under the screed? Wet ceiling on the lower floor or in the basement and the gradual destruction of the ceiling.

That is why, quite recently, it was preferred to use coils made of metal-plastic pipes as a heating element for underfloor heating (with the obligatory installation of fittings outside the screed), but now reinforced polypropylene is increasingly being placed in the screed.

It has a low coefficient of thermal expansion and, when properly installed, does not require repair and maintenance for many decades. Other plastics are also used.

Towel dryers

Steel heated towel rails are very common in Soviet-built houses. More recently, they were part of the standard project of any house under construction, and up to the 80s they were always mounted on threaded connections.

Circulation tie-ins in elevator units, providing constantly hot heating risers, also appeared relatively recently.

If so, the mode of operation of the heated towel rail was repeated cooling and heating. Extensions - compressions. How did the threaded connections react to this? Right. They started to flow.

Later, when heated towel rails became part of the heating risers and warmed up around the clock, the problem of leaks faded into the background. The size of the dryer itself (and, accordingly, the effective heat transfer area) has sharply decreased. The reason is the change in the average daily temperature.

If earlier the coil in the bathroom heated up only when the owners of the bathroom used hot water, now it heated constantly.

Registers

In many industrial premises, warehouses, and even some stores that have not been renovated for a long time, several rows of thick pipes under the window, from which there is a noticeable heat, attract attention. Before us is one of the cheapest heating devices of the era of developed socialism - a register

It consists of several thick pipes with welded ends and bridges made of thin pipes. In the simplest version, it can generally be one thick pipe running along the perimeter of the room.

It is amusing to compare the heat transfer of a steel register with a modern aluminum battery occupying a comparable volume in a room. Differences in heat transfer at times.

Both due to the greater thermal conductivity of aluminum, and due to the huge surface of heat exchange with air in a modern solution. About aesthetics in the case of the register, you understand, it is not necessary to speak at all.

However, the register was a cheap and accessible solution. In addition, it rarely required repair or maintenance: a pipe that was even half-clogged continued to heat, but a seam welded by electric welding began to flow after about five hundred hits with a sledgehammer.

How many sections do you need

where N is the number of radiator sections;

S is the area of the room;

K - the amount of thermal energy spent on heating one cube of the room;

Q - heat transfer of one section of the radiator.

The value of K is assumed to be 100 W per 1 sq. m of area for a standard room. For corner and end rooms, a coefficient from 1.1 to 1.3 is applied.The average value of heat transfer per section (Q) is taken equal to 150 watts. A more accurate value is indicated in the technical specifications of a particular radiator.

For example, for heating a room of 20 sq. m, the number of sections is determined by the product of 20 * 100 divided by 150. The result is 13 sections.

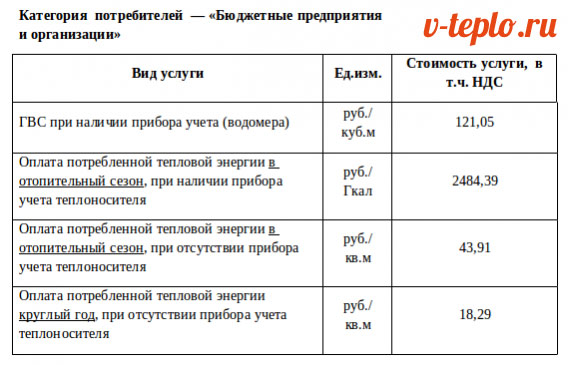

What is Gcal

Let's start with a related definition. A calorie refers to a certain amount of energy that is required to heat one gram of water to one degree Celsius (at atmospheric pressure, of course). And in view of the fact that from the point of view of heating costs, say, at home, one calorie is a miserable amount, in most cases, gigacalories (or Gcal for short), corresponding to one billion calories, are used for calculations. With that decided, let's move on.

The use of this value is regulated by the relevant document of the Ministry of Fuel and Energy, issued back in 1995.

Note! On average, the consumption standard in Russia per square meter is 0.0342 Gcal per month. Of course, this figure may vary for different regions, since it all depends on climatic conditions.

So, what is a gigacalorie if we “transform” it into more familiar values for us? See for yourself.

1. One gigacalorie equals approximately 1,162.2 kilowatt-hours.

2. One gigacalorie of energy is enough to heat a thousand tons of water to +1°C.

The procedure for calculating the power of heating radiators

To perform the calculation of bimetallic heating radiators or cast iron batteries, based on the heat output, it is necessary to divide the required amount of heat by 0.2 kW. As a result, the number of sections that need to be purchased to ensure the heating of the room will be obtained (for more details: “Correct calculation of the heat output of the heating system by area of the room“).

If cast-iron radiators (see photo) do not have flushing taps, experts recommend taking into account 130-150 watts per section, taking into account the power of 1 section of the cast-iron radiator. Even when they initially give off more heat than required, impurities that appear in them will reduce heat transfer.

As practice has shown, it is desirable to mount batteries with a margin of about 20%. The fact is that when extreme cold weather sets in, there will be no excessive heat in the house. Also, the choke on the eyeliner will help to deal with increased heat transfer. Buying a few extra sections and a regulator will not greatly affect the family budget, and warmth in the house in cold weather will be provided.

Towel dryers

In old houses, heated towel rails made of steel pipes are very common, because in most cases they were laid down by the project, and almost until the end of the last century they crashed into the system on the thread.

Not so long ago, circular inserts began to be used in elevator units, which provide a stable hot temperature of the device.

Since the heating circuits in heated towel rails were constantly subjected to temperature changes - they either heated up or cooled down - it was difficult for the threaded connections to withstand this regime, so they periodically began to leak.

Somewhat later, when the heating of these devices became stable due to the insertion into the heating risers, the problem of leaks became not so urgent. At the same time, the size of the coil has become much smaller, resulting in a reduction in the heat transfer area of the steel pipe. However, such a heated towel rail remained warm not only during the use of hot water, but constantly.

Adjustment of results

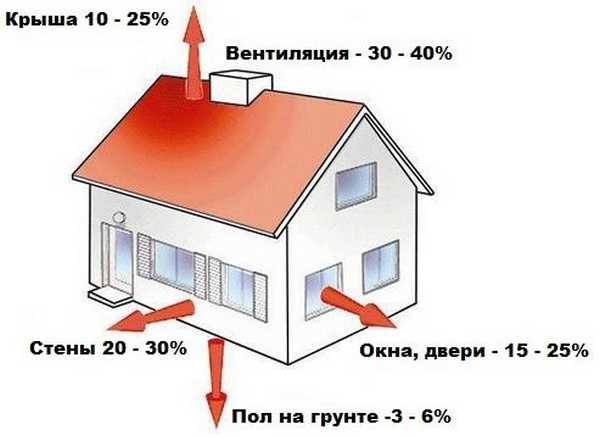

In order to get a more accurate calculation, you need to take into account as many factors as possible that reduce or increase heat loss. This is what the walls are made of and how well they are insulated, how big the windows are, and what kind of glazing they have, how many walls in the room face the street, etc.To do this, there are coefficients by which you need to multiply the found values \u200b\u200bof the heat loss of the room.

The number of radiators depends on the amount of heat loss

Windows account for 15% to 35% of heat loss. The specific figure depends on the size of the window and how well it is insulated. Therefore, there are two corresponding coefficients:

- ratio of window area to floor area:

- 10% — 0,8

- 20% — 0,9

- 30% — 1,0

- 40% — 1,1

- 50% — 1,2

- glazing:

- three-chamber double-glazed window or argon in a two-chamber double-glazed window - 0.85

- ordinary two-chamber double-glazed window - 1.0

- conventional double frames - 1.27.

Walls and roof

To account for losses, the material of the walls, the degree of thermal insulation, the number of walls facing the street are important. Here are the coefficients for these factors.

- brick walls with a thickness of two bricks are considered the norm - 1.0

- insufficient (absent) - 1.27

- good - 0.8

The presence of external walls:

- indoors - no loss, coefficient 1.0

- one - 1.1

- two - 1.2

- three - 1.3

The amount of heat loss is influenced by whether or not the room is heated from above. If there is a habitable heated room above (the second floor of the house, another apartment, etc.), the reducing factor is 0.7, if the heated attic is 0.9. It is generally accepted that an unheated attic does not affect the temperature in and (factor 1.0).

It is necessary to take into account the features of the premises and climate in order to correctly calculate the number of radiator sections

If the calculation was carried out by area, and the height of the ceilings is non-standard (a height of 2.7 m is taken as the standard), then a proportional increase / decrease using a coefficient is used. It is considered easy. To do this, divide the actual height of the ceilings in the room by the standard 2.7 m. Get the required ratio.

Let's calculate for example: let the height of the ceilings be 3.0 m. We get: 3.0m / 2.7m = 1.1. This means that the number of radiator sections, which was calculated by the area for a given room, must be multiplied by 1.1.

All these norms and coefficients were determined for apartments. To take into account the heat loss of the house through the roof and basement / foundation, you need to increase the result by 50%, that is, the coefficient for a private house is 1.5.

climatic factors

You can make adjustments depending on the average temperatures in winter:

Having made all the required adjustments, you will get a more accurate number of radiators required for heating the room, taking into account the parameters of the premises. But these are not all the criteria that affect the power of thermal radiation. There are also technical subtleties, which we will discuss below.

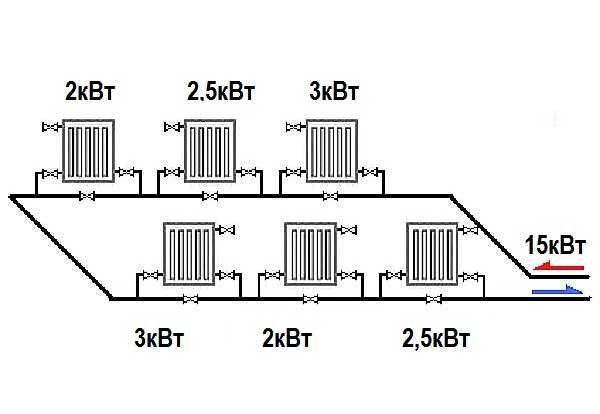

Determination of the number of radiators for one-pipe systems

There is one more very important point: all of the above is true for a two-pipe heating system. when a coolant with the same temperature enters the inlet of each of the radiators. A single-pipe system is considered much more complicated: there, colder water enters each subsequent heater. And if you want to calculate the number of radiators for a one-pipe system, you need to recalculate the temperature every time, and this is difficult and time consuming. Which exit? One of the possibilities is to determine the power of the radiators as for a two-pipe system, and then add sections in proportion to the drop in thermal power to increase the heat transfer of the battery as a whole.

In a single-pipe system, the water for each radiator is getting colder and colder.

Let's explain with an example. The diagram shows a single-pipe heating system with six radiators. The number of batteries was determined for two-pipe wiring. Now you need to make an adjustment. For the first heater, everything remains the same. The second one receives a coolant with a lower temperature. We determine the % power drop and increase the number of sections by the corresponding value. In the picture it turns out like this: 15kW-3kW = 12kW. We find the percentage: the temperature drop is 20%. Accordingly, to compensate, we increase the number of radiators: if you needed 8 pieces, it will be 20% more - 9 or 10 pieces.This is where knowledge of the room comes in handy: if it is a bedroom or a nursery, round it up, if it is a living room or other similar room, round it down

You also take into account the location relative to the cardinal points: in the north you round up, in the south - down

In single-pipe systems, you need to add sections to the radiators located further along the branch

This method is clearly not ideal: after all, it turns out that the last battery in the branch will have to be simply huge: judging by the scheme, a coolant with a specific heat capacity equal to its power is supplied to its input, and it is unrealistic to remove all 100% in practice. Therefore, when determining the power of a boiler for single-pipe systems, they usually take some margin, put shutoff valves and connect radiators through a bypass so that heat transfer can be adjusted, and thus compensate for the drop in coolant temperature. One thing follows from all this: the number and / or dimensions of radiators in a single-pipe system must be increased, and as you move away from the beginning of the branch, more and more sections should be installed.

An approximate calculation of the number of sections of heating radiators is a simple and quick matter. But clarification, depending on all the features of the premises, size, type of connection and location, requires attention and time. But you can definitely decide on the number of heaters to create a comfortable atmosphere in winter.

New construction

The design of the heating system of a new building must obviously be carried out taking into account the principles of energy saving. The basis of the project is the calculation of heat transfer, in other words, the amount of heat released from the surface of pipes and other elements of the heating system into the environment.

This calculation is necessary for:

- Determining the optimal parameters of the heating system to create a certain temperature regime in the premises of your home.

- Making decisions on measures of insulation, taking into account heat losses through the main structures of the building.

Previously, heating main pipelines were made mainly of steel products, but today more practical and reliable materials are used. For example, polypropylene products have several significant advantages: low weight and low elasticity, which increases strength.

Calculation of heat transfer

Before starting construction work, it is necessary to make the necessary calculations to extract the maximum benefit from the heating pipes. If you do not know which formulas to use and how to calculate correctly, the instructions below will help you with this.

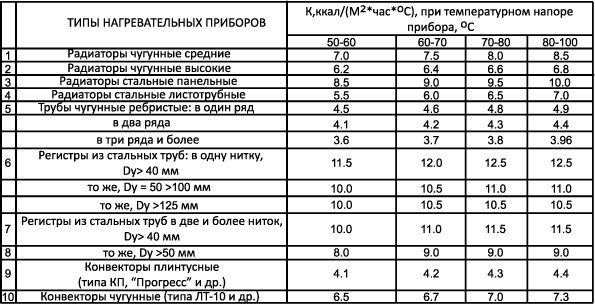

Self-calculation of heat transfer from the pipe surface is carried out according to the formula Q = K x F x ∆t, where:

- Q is the desired heat transfer, Kcal/h.

- K is the heat transfer coefficient of water in the pipe, Kcal / (m2 x h x 0 C).

- F is the area of the heated surface, m2.

- ∆t – thermal head, 0 С.

The thermal conductivity coefficient (K), in turn, is calculated using complex formulas, so we use a ready-made value from technical sources - from 8 to 12.5 Kcal / (m2 x h x 0 C) for steel pipes.

The surface area of the pipe is calculated according to the geometric formula familiar to everyone from the school program for determining the area of the lateral surface of the cylinder F \u003d P x d x l, where:

- P = 3.14 mathematical constant.

- d - diameter is indicated in meters.

- l is the length of the pipe, also counting in m.

To calculate the thermal pressure, there is a formula ∆t \u003d 0.5 x (t p + t o) - t in, where:

- t p is the temperature of the coolant at the inlet.

- t o is the temperature of the coolant at the outlet.

- t in - the temperature in the room.

The theoretical heat transfer of a steel pipe is calculated taking into account the conditionally specified values of the temperature of the coolant at the inlet-outlet and the room according to SNiPs, which are:

- t p \u003d 80 degrees

- t o \u003d 70 degrees

- t in = 20 degrees

As a result of simple calculations (0.5x (80 + 70) -20), we obtain the value of the thermal pressure ∆t = 55 degrees.

Calculation example

Let's perform a theoretical calculation of heat transfer for the most running steel pipe in the heating system with a diameter of 25 mm and a length of one meter.

- First of all, we calculate the area of our pipe section F = 3.14 x 0.025 x 1 = 0.0785 m2.

- Next, we look at the table of heat transfer coefficients of a steel pipe with a diameter of 25 mm. It is (for pipes with a diameter of up to 40 mm, laid in one thread with a theoretical thermal head of 55 degrees) K = 11.5.

- Let's apply the basic formula and get the heat transfer value Q = 11.5x0.0785x55=49.65 Kcal/h.

At first glance, the calculation is quite simple, but it is in theory.

To create a project for a real heating system, careful calculations are necessary taking into account the parameters of all elements that make up the system, including:

- Heating appliances.

- Fittings and valves.

- bypass lines.

- Insulated sections of the highway, etc.

By analogy with the calculation of the parameters of a steel pipe, the heat transfer of a copper pipe or any other is calculated; for this, we have placed several useful and informative drawings in this article.

The excellent heat transfer of a metal-plastic pipe and other advantages make it the most preferred option when creating modern heating systems, including alternative ones. Therefore, if you are just starting the construction of a country house, then you should opt for this modern material.

The required value of the heat output of the radiator

When calculating the heating battery, it is imperative to know the required heat output so that it is comfortable to live in the house. How to calculate the power of a heating radiator or other heating devices for heating an apartment or house is of interest to many consumers.

- The method according to SNiP assumes that 100 watts are required per "square" of area.

But in this case, a number of nuances should be taken into account: - heat loss depends on the quality of thermal insulation. For example, for heating an energy-efficient house equipped with a heat recovery system with walls made of sip panels, the heat output will be less than 2 times; - the creators of sanitary norms and rules in their development focused on a standard ceiling height of 2.5-2.7 meters, but this parameter can be equal to 3 or 3.5 meters; - this option, which allows you to calculate the power of the heating radiator and heat transfer, is correct only if the approximate temperature is 20 ° C in the apartment and 20 ° C outside. A similar picture is typical for settlements located in the European part of Russia. If the house is located in Yakutia, much more heat will be required.

The calculation method based on volume is not considered difficult. For each cubic meter of space, 40 watts of thermal power is required. If the dimensions of the room are 3x5 meters and the ceiling height is 3 meters, then 3x5x3x40 = 1800 watts of heat will be required. And although the errors associated with the height of the rooms in this calculation option are eliminated, it is still not accurate.

The refined way of calculating by volume, taking into account more variables, gives a more realistic result. The base value remains the same 40 watts per cubic meter of volume.

When a refined calculation of the heat output of the radiator and the required heat transfer value is made, it should be taken into account that: - one door outside takes 200 watts, and each window - 100 watts; - if the apartment is corner or end, a correction factor of 1.1 - 1.3 is applied depending on the type of wall material and their thickness; - for private households, the coefficient is 1.5; - for the southern regions, a coefficient of 0.7 - 0.9 is taken, and for Yakutia and Chukotka, an amendment from 1.5 to 2 is applied.

As an example, a corner room with one window and a door in a private brick house measuring 3x5 meters with a three-meter ceiling in the north of Russia was taken as an example for the calculation. The average temperature outside in winter in January is -30.4°C.

The calculation order is as follows:

- determine the volume of the room and the required power - 3x5x3x40 \u003d 1800 watts;

- a window and a door increase the result by 300 watts, for a total of 2100 watts;

- taking into account the angular location and the fact that the house will be private 2100x1.3x1.5 = 4095 watts;

- the previous result is multiplied by the regional coefficient 4095x1.7 and 6962 watts are obtained.

Video about choosing heating radiators with power calculation:

Heat loss through pipes

In a city apartment, everything is simple: both the risers, and the supply to the heating devices, and the devices themselves are located in a heated room. What's the point in worrying about how much heat the riser dissipates if it serves the same purpose - heating?

However, already in the entrances of apartment buildings, in the basements and in some warehouses, the situation is radically different. You need to heat one room, and bring the coolant to it through another. Hence - attempts to minimize the heat transfer of the pipes through which hot water enters the batteries.

thermal insulation

The most obvious way how the heat transfer of a steel pipe can be reduced is the thermal insulation of this pipe. Twenty years ago, there were two ways to do this: recommended by regulatory documents (insulation with glass wool wrapped with non-combustible fabric; even earlier, external insulation was generally made solid using gypsum or cement mortar) and realistic: pipes were simply wrapped with rags.

Now there are a lot of quite adequate ways to limit heat loss: here are foam linings for pipes, and split shells made of foamed polyethylene, and mineral wool.

In the construction of new houses, these materials are actively used; however, in the housing and communal system, the limited, politely speaking, budget leads to the fact that the pipes in the basements are still just wrapping ss ... um, torn rags.

Underfloor heating systems

If we are talking about a water-heated floor, unlike the electric counterpart, it uses metal pipes as a heating circuit, although they have been used less and less lately.

The main reason for the decline in demand for underfloor heating is the gradual wear of steel pipes, reducing the clearance in them. In addition, the method of installation also matters - far from everyone can perform welds, and a threaded connection threatens to leak coolant after a while. Naturally, no one will like the result of water leakage from the system in the floor with a screed - the ceiling of the lower floor or basement will be flooded, and the ceiling will gradually become unusable.

For these reasons, steel pipes in warm water floors were first replaced by metal-plastic coils, the fittings to which were attached outside the screed, and now reinforced polypropylene is preferred.

Such material is characterized by a slight thermal expansion, and with proper installation and operation, they can last for more than a dozen years. Alternatively, other polymeric materials are also used.

Heating appliances

- warm floor;

- registers (radiators);

- heated towel rails.

Warm floor

Pipes are used for a water-heated floor, but steel pipes are rarely used. They are not resistant to corrosion, tend to accumulate deposits (which reduces clearance), require welding. When using threaded connections, a leak invariably appears during operation. And this is not at all desirable when laying the system under the screed, as it will entail a wet ceiling from the neighbors below or the destruction of the ceiling. Based on this, metal-plastic products are most often used for underfloor heating.

Registers

The register is several large-diameter pipes with welded ends, which are connected in parallel. This is the cheapest heating device. But the registers can also include trunk lines, consisting of smooth-bore pipes, radiators, heated towel rails, tubular - radiators.The most primitive registers can still be seen in old warehouses and shops, where the heat is felt from a few thick pipes on the wall. The register can also be considered as a thick pipe, which is stretched along the perimeter of the room.

But a simple register is less efficient than, for example, an aluminum radiator equipped with metal plates. The aesthetic side of a simple steel register is not even worth talking about. But in Soviet times, such a heater was a simple and cheap solution, which also had the advantage of not needing to clean the inner surface, since it generated enough heat even after it was overgrown with corrosion products and other deposits.

You can increase the heat transfer of the register by attaching metal plates. In this case, it will also play a decorative role, turning into a design radiator that carries a certain load in the interior of the room.

The register can only be mounted by welding, which limits the scope of application. However, if the correct scheme is created and the welding work is carried out outdoors, the final assembly is possible without welding work.

Towel dryers

Towel rails made of steel pipes are still found in houses that were built in Soviet times. Then they were mounted using threaded connections and heated up only at a time when the residents used hot water. That is, they either heated up or cooled down, which led to leaks.

Later, heated towel rails were made part of the heating risers and mounted by welding. They began to heat up continuously, but the size of the devices decreased significantly.

How to calculate the consumed thermal energy

If for one reason or another there is no heat meter, then the following formula must be used to calculate the heat energy:

Let's take a look at what these conventions mean.

1. V denotes the amount of hot water consumed, which can be calculated either in cubic meters or in tons.

2. T1 is the temperature indicator of the hottest water (traditionally measured in the usual degrees Celsius). In this case, it is preferable to use exactly the temperature that is observed at a certain operating pressure. By the way, the indicator even has a special name - this is enthalpy. But if the required sensor is not available, then the temperature regime that is extremely close to this enthalpy can be taken as the basis. In most cases, the average is approximately 60-65 degrees.

3. T2 in the above formula also indicates the temperature, but already cold water. Due to the fact that it is rather difficult to get into the cold water main, constant values are used as this value, which can change depending on the climatic conditions on the street. So, in winter, when the heating season is in full swing, this figure is 5 degrees, and in summer, with the heating turned off, 15 degrees.

4. As for 1000, this is the standard coefficient used in the formula in order to get the result already in gigacalories. It will be more accurate than if calories were used.

5. Finally, Q is the total amount of thermal energy.

As you can see, there is nothing complicated here, so we move on. If the heating circuit is of a closed type (and this is more convenient from an operational point of view), then the calculations must be made in a slightly different way. The formula that should be used for a building with a closed heating system should already look like this:

Now, respectively, to decryption.

1. V1 denotes the flow rate of the working fluid in the supply pipeline (not only water, but also steam can act as a source of thermal energy, which is typical).

2. V2 is the flow rate of the working fluid in the "return" pipeline.

3. T is an indicator of the temperature of the cold liquid.

4. T1 - water temperature in the supply pipeline.

5.T2 is the temperature indicator that is observed at the outlet.

6. And, finally, Q is all the same amount of thermal energy.

It is also worth noting that the calculation of Gcal for heating in this case is based on several designations:

- thermal energy that entered the system (measured in calories);

- temperature indicator during the removal of the working fluid through the "return" pipeline.

Consider the calculation method for rooms with high ceilings

However, the calculation of heating by area does not allow you to correctly determine the number of sections for rooms with ceilings above 3 meters. In this case, it is necessary to apply a formula that takes into account the volume of the room. According to the recommendations of SNIP, 41 W of heat is required to heat each cubic meter of volume. So, for a room with ceilings 3 m high and an area of 24 sq.m, the calculation will be as follows:

24 sq.m x 3 m = 72 cubic meters (room volume).

72 cubic meters x 41 W = 2952 W (battery power for space heating).

Now you should find out the number of sections. If the radiator documentation indicates that the heat transfer of one part of it per hour is 180 W, it is necessary to divide the found battery power by this number:

2952W / 180W = 16.4

This number is rounded up to a whole - it turns out, 17 sections to heat a room with a volume of 72 cubic meters.

By simple calculations, you can easily determine the data you need.

Other ways to calculate the amount of heat

It is possible to calculate the amount of heat entering the heating system in other ways.

The calculation formula for heating in this case may differ slightly from the above and have two options:

- Q = ((V1 * (T1 - T2)) + (V1 - V2) * (T2 - T)) / 1000.

- Q = ((V2 * (T1 - T2)) + (V1 - V2) * (T1 - T)) / 1000.

All values of the variables in these formulas are the same as before.

Based on this, it is safe to say that the calculation of kilowatts of heating can be done on your own. However, do not forget about consulting with special organizations responsible for supplying heat to dwellings, since their principles and calculation system can be completely different and consist of a completely different set of measures.

Having decided to design a so-called “warm floor” system in a private house, you need to be prepared for the fact that the procedure for calculating the volume of heat will be much more difficult, since in this case it is necessary to take into account not only the features of the heating circuit, but also provide for the parameters of the electrical network, from which and the floor will be heated. At the same time, the organizations responsible for monitoring such installation work will be completely different.

Many owners often face the problem of converting the required number of kilocalories into kilowatts, which is due to the use of many auxiliary aids of measuring units in the international system called "Ci". Here you need to remember that the coefficient that converts kilocalories to kilowatts will be 850, that is, in simpler terms, 1 kW is 850 kcal. This calculation procedure is much simpler, since it will not be difficult to calculate the required amount of gigacalories - the prefix "giga" means "million", therefore, 1 gigacalorie - 1 million calories.

In order to avoid errors in calculations, it is important to remember that absolutely all modern heat meters have some error, and often within acceptable limits. The calculation of such an error can also be done independently using the following formula: R = (V1 - V2) / (V1 + V2) * 100, where R is the error of the common house heating meter

V1 and V2 are the parameters of water consumption in the system already mentioned above, and 100 is the coefficient responsible for converting the obtained value into a percentage. In accordance with operating standards, the maximum allowable error can be 2%, but usually this figure in modern devices does not exceed 1%.