For drying

Hot air spoils the structure of the hair, they lose their shine and become brittle. Cold blown hair also dries, but does not change its structure. The scales that make up the outer layer of the hair are less injured. Cold air will make your hair shiny, prevent split ends, and make your hair easier to style.

Here are some lights for quality drying:

- Hold the hair dryer not at a straight line, but at an acute angle to the hair, this will help keep the scales closed;

- The foam must be applied from the ends to the roots, dried in the opposite direction;

- Use hair protection products;

- Blow damp hair at maximum speed, reducing it as it dries, especially if the main drying is with hot air.

- It is not necessary to use only the cold drying method, it takes a lot of time. Trichologists are sure that hair will not suffer from alternating cold and hot air, but it will be faster.

If there is only cold air in the hair dryer, this does not mean that it does not harm the hair at all. Continue to use your usual sprays and lotions, they are necessary, but they need less.

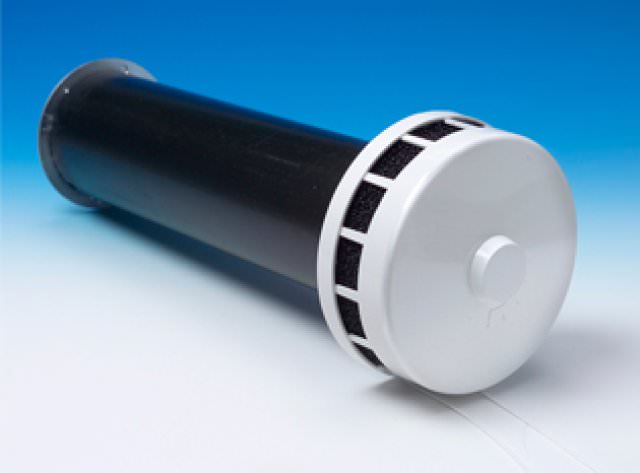

Design Description

- Air duct. An ordinary pipe that is inserted into a hole in the wall. Air will pass through it.

- Outer grille. Installed at the end of the pipe facing the street. Does not allow large insects, leaves, poplar fluff, precipitation to penetrate.

- Insulation. Prevents freezing of the pipe and at the same time serves as a noise suppressor.

- Internal headband. Valve body located indoors. Contains a filter.

The inlet body must also be able to completely close the valve: in winter, in severe frost (below -10º), it is better to cover the ventilator. Too cold air simply will not have time to heat up, even if the valve is next to the battery. As a result, the temperature in the room will drop, and there will be a draft.

In addition to these parts, the inlet valve can be additionally equipped with:

- Fan (operating both for supply and air removal).

- heater.

How to choose and where to install a supply valve

It would be ideal to provide for the presence of vents for the installation of supply valves at the construction stage. The second good moment for installing the valve is a major overhaul, when you can do all the necessary operations without fear of damaging the wallpaper or littering the room.

Before you buy a supply valve into the wall, you should compare its average cost of about 3-5 thousand rubles with a complete set. If you decide to equip all rooms with these devices, then it is better to take models from one company, this will not violate the overall interior of the house.

It is important to carefully follow the installation instructions, because if you do not install the inlet valve with your own hands, there is a high probability of it freezing in the winter months. Therefore, it is better to turn to professionals in this field.

If you live in regions with harsh climatic conditions, then the installation of forced ventilation should be abandoned altogether.

Conventional models that are not equipped with a forced ventilation system are capable of providing up to 30 m 3 / h of fresh air, which is quite enough for one adult.

Article

It is not necessary to keep the window open to provide fresh air to the room. Much more convenient is to install a supply valve in the room.

Thanks to its simple design, it is not necessary to buy a ventilator: if you wish, you can make such a device with your own hands.

Main design features

The system consists of several elements:

- Plastic grid. This decorative decoration of the structure filters out large debris that can enter along with air masses.

- valve or baffle. The function of the valve is to block the flow of air when the device is turned off.

- Filters. Filters trap small debris, dust. These filters must be replaced every few months.

- The heating element is a heater (water or electric).

For small rooms or houses, it is better to use an electric heating element, and for large areas - water.

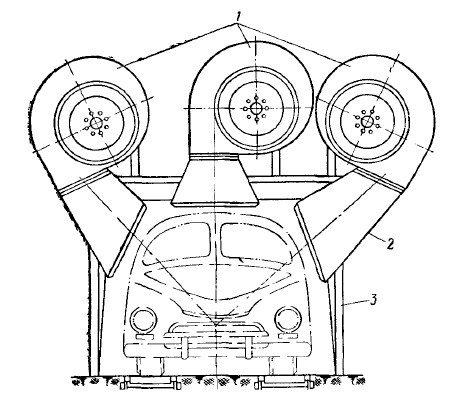

Vehicle airflow

To speed up the drying of cars, blowing with cold or heated air is used.

After washing, cold air is blown with the help of a powerful blower installation of fans of the "Sirocco" type, forcing air into the air distribution pipes with slotted nozzles at an angle of 60 ° to the surface being blown.

The installation for blowing air after washing cars consists of three fans 1 of the EVR-6 brand, driven by electric motors with a power of 20 kW. To direct the air jet, each fan is equipped with a figured nozzle 2 of a rectangular shape. The unit is mounted on frame 3 and enclosed in a casing.

The disadvantage of drying with cold air is a significant consumption of electricity (the power of the electric motors of the fans reaches 60 kW). However, the use of warm air due to its low thermal conductivity (250 times less than the thermal conductivity of iron) is also not effective enough due to the too low heat utilization factor.

A promising method of drying a car can be considered the use of lamps with infrared rays, as well as thermoradiation drying with dark infrared radiation panels with high efficiency. and little heat loss.

Function and application

The main function is the intake of air from the street to remove the negative phenomena that have arisen due to the lack of organization of natural ventilation in the apartment, as well as the deterioration of its effect when installing plastic windows.

The latter also require significant air exchange with the street.

Otherwise, there will be a constant problem with condensate on their surface and the formation of fungus at the joints, where the flowing water from the double-glazed window will constantly flow. The supply valve, together with the main ventilation, will create the necessary air circulation in the room and remove all of the above negative phenomena.

If we talk about other negative phenomena with windows, then they require constant ventilation.

In winter, an open window can quickly cool the room, which will again affect the health of residents. The supply system does not have such a large opening, the air entering the room has time to warm up.

Bad odors and carbon dioxide are also removed, but only through the exhaust system of house ventilation. This is true for kitchens without an exhaust system installed above the stove. Also in the pantry, where there is no ventilation at all.

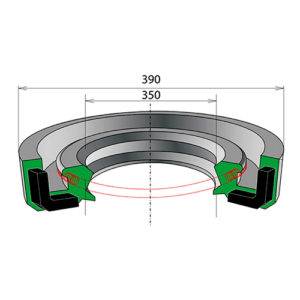

The cold period of the year HP.

1. When air conditioning in the cold season - HP, the optimal parameters of indoor air in the working area of the room are initially taken:

tV = 20 ÷ 22ºC; φV = 30 ÷ 55%.

2. Initially, we put points on the J-d diagram for two known parameters of moist air (see Figure 8):

- outside air (•) N tH = - 28ºC; JH = - 27.3 kJ/kg;

- indoor air (•) V tV = 22ºC; φV = 30% with minimum relative humidity;

- indoor air (•) B1 tIN 1 = 22ºC; φIN 1 = 55% with maximum relative humidity.

In the presence of heat excesses in the room, it is advisable to take the upper temperature parameter of the indoor air in the room from the zone of optimal parameters.

3. We draw up the heat balance of the room for the cold season - HP:

sensible heat ∑QHHH

by total heat ∑QHPP

4. Calculate the flow of moisture into the room

∑W

5. We determine the thermal tension of the room according to the formula:

where: V is the volume of the room, m3.

6.Based on the magnitude of the thermal stress, we find the gradient of temperature rise along the height of the room.

The air temperature gradient along the height of the premises of public and civil buildings.

| Thermal tension of the room QI AM/Vpom. | gradt, °C | |

|---|---|---|

| kJ/m3 | W/m3 | |

| Over 80 | Over 23 | 0,8 ÷ 1,5 |

| 40 ÷ 80 | 10 ÷ 23 | 0,3 ÷ 1,2 |

| Less than 40 | Less than 10 | 0 ÷ 0,5 |

and calculate the temperature of the exhaust air

tY = tB + grad t(H – hr.z.), ºС

where: H is the height of the room, m; hr.z. — height of the working area, m.

7. To assimilate excess heat and moisture in the room, the supply air temperature is tP, we accept 4 ÷ 5ºС below the temperature of the internal air - tV, in the working area of the room.

8. Determine the numerical value of the heat-humidity ratio

9. On the J-d diagram, we connect the 0.0 ° C point of the temperature scale with a straight line with the numerical value of the heat-humidity ratio (for our example, the numerical value of the heat-humidity ratio is 5,800).

10. On the J-d diagram, we draw the supply isotherm - tP, with numerical value

tP = tV - 5, ° С.

11. On the J-d diagram, we draw an isotherm of the outgoing air with the numerical value of the outgoing air - tAtfound in point 6.

12. Through the points of internal air - (•) B, (•) B1, we draw lines that are parallel to the line of heat-humidity ratio.

13. The intersection of these lines, which will be called - the rays of the process

with isotherms of supply and exhaust air - tP and tAt determines the supply air points on the J-d diagram - (•) P, (•) P1 and outlet air points - (•) Y, (•) Y1.

14. Determine the air exchange by total heat

and air exchange for the assimilation of excess moisture

Do-it-yourself installation of the inlet valve in the wall

If you provide for the presence of a hole for installation at the design stage, you can save on their further drilling

Well, for already built houses, you will have to resort to installing the valve in compliance with all precautions

| Drawing | Actions |

|---|---|

|

Markup. Having chosen a place for a hole in the wall, you should measure the distance between the fixing anchor of the bed and the drill bit. |

|

Drilling a technological hole. Using a perforator, having selected a drill corresponding to the diameter of the anchor, it is necessary to drill a hole in the wall. To collect dust during drilling, keep the bell of the switched-on vacuum cleaner directly near the drill. |

|

Fixing the bed. An anchor is driven into the drilled hole; for greater density, use the adapter. Before installing the frame, a sheet of cardboard or other softening material should be placed under it to avoid damage to the wall surface. When the bed is installed, it must be securely pressed against the wall with a hairpin, tightened with a nut with a wrench. |

|

Protection of the wall from the flow of dirty water. To do this, a strip of film is glued to the adhesive tape, under the place where the rubber cuff will be installed. The film must be at least 30 cm wide, and the length must be enough to the floor. The bottom edge of the film must be placed in a container for draining water (a bucket will do). |

|

Cuff attachment. It is inserted into special adjustable arms, on the body of the drill. A hose is connected to the cuff for the outflow of water, which provides cooling of the bit during drilling. The hose fits tightly on the pipe and is fixed with a clamp. |

|

Drill assembly. Professional drilling rigs are very heavy, therefore, to simplify their installation, they are assembled on a fixed frame in stages. When the assembly is completed, a crown of the appropriate diameter is put on. A hose is connected to the drill handle, through which coolant will be supplied, it must also be secured with a clamp. Next, the pump is inflated with a manual pump, when the operating pressure is reached, you can start drilling. |

|

Drilling. Turning on the drilling machine, you should bring the crown to the wall.When it comes into contact, and the process begins, do not exert strong pressure on the adjustment knob. Otherwise, the victorious diamond-coated teeth on the crown may break and the crown will be damaged. |

|

Removing the rod. The length of the bit rarely exceeds 500 mm, and the wall being drilled is usually thicker. Therefore, drilling is carried out in two stages. After the first, the concrete rod is knocked out of the bit, and an extension for the bit is installed in the drill machine. |

|

End of drilling. When the hole is ready, you should disassemble the installation in the reverse order, and wipe the place under the cuff with a damp cloth or rag from wet concrete dust. |

|

Installation of PVC pipes. The length of the plastic pipe should be equal to the thickness of the wall of the house. Further, the infiltration channel is tightly driven into the hole. |

|

Installing thermal and noise insulation in the pipe is done with a simple touch of the hand. |

|

Lattice installation. The landing site on the outer part of the wall should be covered with silicone sealant, the same should be done with the seat on the grate, and then firmly inserted into the socket of the duct. |

|

Installing the inside of the valve. The seats are also treated with silicone, after which the filter washer is fixed to the inner wall. The ventilation valve is installed in the wall. |

For extended hair

If the strands are fixed with hairpins, then they must be removed and. Hair extensions are usually a bit shinier, add shine to your hair with a blow dryer. Drying with a hot air dryer will heat the hairpins and cause discomfort.

If the hair is glued on, then hot air can destroy it, especially if you style or dry your hair more than three times a week. Dried glue slides off the hair, and the extended strands fly off.

You can not dry your hair with warm air to the end, it is very harmful to them. With false wet hair, you can not go to bed, so you need to use cold air blowing. If possible, do not dry your hair completely, leave it slightly damp. Also, hair extensions should not be combed wet.

Before drying, the hair must be blotted with a towel and straightened a little, and after drying, first check with your hands for no knots, and then comb it with a comb.

In what cases does it apply

The carefully thought-out design of the device does not allow mixing of fresh air, enriched with oxygen and heated to the desired temperature, with the already exhausted one. This ensures a regular flow of oxygen into the enclosed space.

Attention

Such a ventilation system is in demand in rooms where plastic windows are installed that are hermetically sealed and prevent the flow of fresh air, and in those where it is impossible to regularly ventilate the space: in basements, boiler rooms without windows

How to choose where to stay

When choosing, you should pay attention to the length and diameter of the pipe, so that its first indicator is enough to install into the thickness of your walls, and the second measurement is enough to access the right amount of air. A significant role is played by the presence of air flow regulation, the presence of several stages of its switching to create a comfortable movement of atmospheric masses into the room

Of particular note is the outlet of the valve, which must be protected from moisture and a grate with a mosquito net from insects entering through it.

A significant role is played by the presence of air flow regulation, the presence of several stages of its switching to create a comfortable movement of atmospheric masses into the room. Of particular note is the outlet of the valve, which must be protected from moisture and a grate with a mosquito net from insects entering through it.

Type and class of sound insulation to remove street noise, especially for buildings located along the red line and near the carriageway of major streets, highways and any other roads

The presence of thermal insulation is also important, without it the main cylinder, walls will freeze, supercooled air, excessive moisture and other troubles will penetrate into the room

The filter occupies an equally important role, its ability to purify the incoming air masses from various pollutants improves the quality of the indoor microclimate.

Wall supply valve KIV 125

Heated ventilation design

Regardless of the size and performance characteristics, supply ventilation with air heating consists of the main elements:

- the air intake grille is installed at the entrance from the street and carries not only a decorative load, but also protects the ventilation system from large debris, fallen leaves, insects, small animals or birds;

- valve - a protective barrier that, when the ventilation is turned off, blocks the access of cold air from the street or reduces the amount of its supply. If automation is required, the valve is connected to an electric drive connected to the control unit of the system;

- filters of varying degrees of purification retain soot, street dust, pollen and allergens. For high-quality air purification, filters must be regularly serviced during operation;

- heater - a water or electric heating element that brings the supplied air to a comfortable temperature. In small ventilation systems, it is easier to use an electrician for heating, a large-scale system can be connected to the heating of a building so as not to install additional equipment.

Additionally, supply ventilation with air heating may include diffusers for even distribution of flows, fans for pressurizing the system, silencers for operating appliances and a heat exchanger that uses the heat of the exhaust air to heat fresh air.

Types of recuperators

In modern construction, two types of recuperators are used, which have a number of features:

- rotary models are powered by electricity - a rotor rotates in their body, opening in turn the valves for the inflow and exhaust of air masses. Such devices are rather bulky, therefore they are suitable for installation in large ventilation systems;

- plate heat exchangers mean a stack of plates through which warm and cold air passes in different directions. In this case, the flows do not mix, and the inflow heats up due to the cooling of the discharged volume. Plate models are produced in a small size and do not require increased attention in operation.

Air heating automation

Supply ventilation with a heat exchanger or a heater can be automated so that it does not need to be constantly monitored and adjusted. In such cases, additional elements and automation are used during installation:

- the entire system is connected to a common control panel, on which the user can set the necessary settings;

- the system provides a timer, which turns on and off the heating of the incoming air masses;

- the heater can be connected to an exhaust fan to start heating immediately when the air outlet is turned on;

- pressure gauges are installed in the air ducts to monitor pressure drops in the system;

- at the inlet, a valve is installed that cuts off the supply air masses if necessary.

Automated heated supply ventilation is a very convenient solution, but it is very expensive, so it can not be used in every residential building.

Do-it-yourself supply ventilation system and its installation

Supply valve installation

It is quite difficult to make such a system with your own hands, but it is possible. Here it is worth having some engineering skills to organize all the work.

The basis is a simple pipe made of metal or plastic, a simpler version of the exhaust duct, from the air conditioner ducts and the like.

It is made of metal and painted, completely ready for use. We select the length according to the thickness of the wall.

From the street, we install a ventilation grill with a grid installed, we insulate the internal walls of a home-made valve, at the entrance to the room you can make the damper itself with adjustment, if you wish, install a fan for forced air movement.

Cons in this system will be obvious. Poor isolation from extraneous sounds, the absence of a filter reduces the quality of the incoming air and other negative phenomena that have already been discussed more than once.

Buying it will allow you to install it yourself. To do this, you need a puncher to make the necessary hole in the wall. Screwdriver for fixing individual elements to the wall. Mounting foam and sealant for sealing the resulting cracks. For wooden walls, a tool and other material is used that is focused on working with it.

The general course of work looks like this.

A place is marked for a hole under the valve, while making it, you need to take a slight slope from the street, this will help protect it from condensation inside the cylinder. Next, install the pipe, on the outside, the grate with all the additions. The next step is to fix the valve itself to the pipe and the wall of the room, and then the filter with the regulator. The last move is to seal the cracks formed with a drop, foam or sealant.

But do not refuse the services of installers of such forced ventilation systems. Specialists will come to you who will quickly install your purchase for you with maximum aesthetics and accuracy. And they don't charge much for their work. It is estimated at about one thousand and a half.

How to choose a hair dryer

Why you need cold air in a hair dryer is clear, but what to buy? Prices for a cold air dryer can vary greatly, but how to choose the quality and what to look for when buying?

Air flow rate. In a good hair dryer, the cold air supply speed is instantaneous, that is, it turns on immediately by pressing the button, hot air turns off immediately

This is important when styling, otherwise you can dry your hair. Do not use a slow blow dryer in the hope that you will learn to guess the moment: such hair dryers work even worse over time.

Pay attention to how the buttons are located. The most convenient option is fixed buttons, that is, you do not need to constantly press them to supply air

If possible, take the hair dryer in your hand and check whether the handle fits comfortably in your hand and whether it is convenient to press the buttons.

Additional elements. Various nozzles, brushes, combs can be attached to the hair dryer, but not everyone needs them. If there is a choice of equipment, take the minimum one, with a diffuser nozzle and additional blades. Blades often get clogged with dust or wear out.

Availability of speed modes. This is true not only for hot blowing: someone likes fast, and someone likes leisurely drying.

Pay attention to the switch, it should be tight and without obvious plastic joints. For high-quality styling, 3 speeds are enough

If possible, get it, it makes your hair shine even better.

Read reviews! A cold blow dryer is more expensive, especially professional hair dryers. Despite the price tag, the quality may vary.Read what other people write about the model, perhaps everything is fine, but some trifle will not please you (color mismatch, too strong or weak air, dishonest supplier, etc.).