Range

Fitting

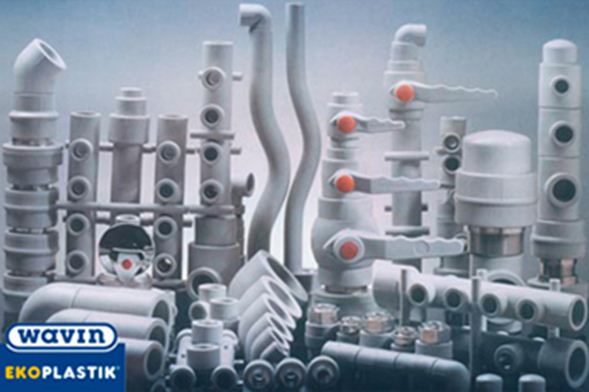

The company offers a full range of fittings for pipes of any size. Fittings are mounted traditionally - diffuse welding; without exception, all fittings are designed for pressure up to 20 atmospheres. Combination fittings combine PPR polypropylene with chrome plated brass.

A complete range of fittings of any type at your service

You will not find steel with its rust, or fragile silumin here.

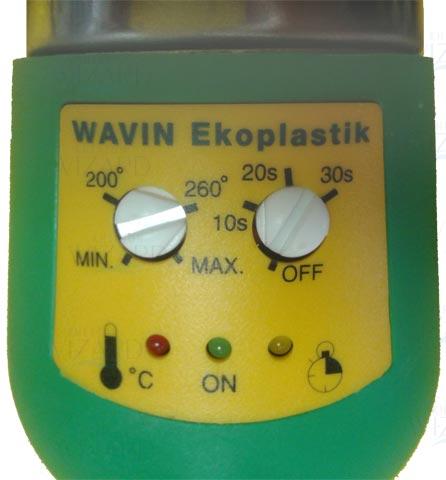

Welders

It is logical to offer a full range of products for the manufacture of plumbing. What we are seeing: soldering irons for plastic pipes with manual and electronic temperature control are offered to our attention. By the way, the term of the branded warranty for them is two years - twice as long as retailers usually give.

Solid devices with a simple but memorable design

Pipes

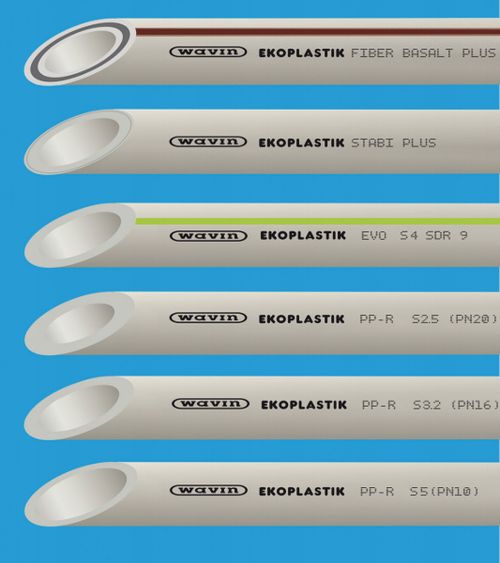

Ecoplastic pipe is produced:

- In the Ecoplastic PPR line - all-plastic strength PN 10, PN 16, PN 20. The maximum working pressure is 10.16 and 20 atmospheres, respectively;

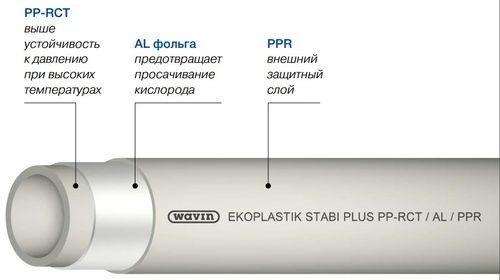

- In the line of Ecoplastic Staby - PN 20 with aluminum reinforcement. The reinforcing layer is under a thin layer of plastic closer to the outer surface of the pipe;

Aluminum reinforced pipes are recommended for heating systems

The Ecoplastic Fiber C and Basalt Plus lines offer glass-reinforced pipes designed for pressures of 16 and 20 atmospheres.

Basalt Plus, by the way - according to the manufacturer, the pipes are especially durable and stand out for their pressure resistance even against the background of reinforced PN 20.

The advertisement is engine of the trade…

Pipe diameters are 20, 25, 32, 40, 50, 63, 75, 90, 110 and 125 millimeters; at the same time, pipes of the Basalt Plus series of maximum diameter are made to order with a delivery time of 30 days.

According to the manufacturer's recommendations, ecoplastic pipes (another common name) are recommended to be used:

- PN10 - for cold water supply systems and underfloor heating systems with low pressure;

- PN16 - cold water at high pressure and heating at low pressure;

- PN20 - pipes for all types of water supply and heating.

If you often see this in the mirror, it is possible that in winter your batteries have a temperature that is too high for polypropylene.

Polypropylene ease of installation and temperature limits

- Small weight, which greatly simplifies its installation on almost any surface.

- High resistance to corrosion, and due to the smooth inner surface, it practically does not overgrow with lime deposits.

- Resistance to low temperatures. When the coolant freezes in a polypropylene pipeline, it is guaranteed not to defrost (subject to proper installation and high-quality soldering).

- High aesthetics. The polypropylene heating circuit does not need to be painted and does not change color over time.

- The possibility of self-assembly by soldering with a special soldering iron.

Tip: The diameter of a polypropylene pipe for heating a private house, most often, is required to be large enough. Due to the low price and plasticity (when the coolant freezes), a polypropylene pipe is a good choice for summer cottages and country houses with irregular residence.

Despite the large number of advantages, polypropylene is not an ideal material.

- CO polypropylene elements do not bend, which means that additional fittings must be used for turns, which increases the estimated cost of CO.

- High thermal conductivity. When the temperature drops, the coolant in the circuit cools quickly. To maintain a comfortable temperature, it is necessary to increase the temperature of the coolant, which incurs an increase in fuel costs.

The most significant disadvantage of polypropylene is its high linear expansion.Under the influence of temperatures over 70°C, the already installed pipe may sag in the area between the fasteners!

Advice: Use polypropylene in CO production if the actual temperature of the coolant in the circuit does not exceed 60 ° C, and the pressure - at the maximum allowable temperature - 10 bar.

Features of Ecoplast products

Wavin has an impeccable reputation, its products are widely known all over the world, and it deserves to rest on its laurels.

And so, what can this company boast of:

- they hand over their ecoplastic polypropylene pipes only to official sellers. Wholesale within one country is strictly fixed, and the list of companies that have the right to do this can always be viewed on the company's main website. Such a policy completely cuts off the path for resellers, so the products are always of high quality, and the prices for them are acceptable.

- Unique production control systems, where all employees have the highest degree of qualification precisely when working with the equipment of this company. A person from the street will never be taken here. Each stage of production is transparent to the management, there is a constant improvement of the process.

Ekoplast pipes (often they are incorrectly called that way) from different batches correspond to each other, the possibility of marriage is excluded. Also, the quality composition of the plasticizer never limps in them, so pipes from different batches are perfectly welded together.

As you know, fakes are always made for the best goods. This once again proves the impeccable quality of Czech products. In general, this country has long become one of the best suppliers of sanitary materials to the world markets. Here it is appropriate to introduce such a term as "Czech quality". By purchasing this product, you completely deprive yourself of the problems of operating such a pipeline.

Ecoplastic: pipes and accessories

Ecoplastic pipes and accessories are always perfectly calibrated to each other. The variety of fittings is so great that there is absolutely no need to turn to parts from other manufacturers.

All fittings are designed for high pressure. Manufacturers guarantee that the nodes will withstand 20 atmospheres. Most of the connecting elements are made specifically for diffuse welding. There are also a variety of PPR material options that are combined with brass coated with an electroplated chromium film. It is impossible to find low-quality steel or grainy brittle silumin here. The aluminum used is very ductile.

Types and differences

Ecoplastic pipes (Czech Republic) are manufactured according to various standards. The product line of Czech manufacturers is wide and varied. You can satisfy your needs in any case.

To begin with, let's pay attention to the working diameters of the products. In general, the company works both according to personal standards and under the order.

Mass production is aimed at the formation of sanitary products with a diameter of 16 to 125 mm. The diameter step is uneven and approximately equal to 5-8 mm.

It is possible to order pipes for individual parameters, but then, of course, you will have to pay extra. The plant produces its products in billets 4 meters long. In some cases, the length of the workpiece is reduced to 3 meters.

Pressure levels

An important role is played by the nominal pressure that the pipes are able to withstand at a normal level. Polypropylene pipes are divided according to the level of pressure on products of brands:

- PN 10.

- PN 16.

- PN 20.

The PN marking means the working pressure inside the pipes. It is measured in bars. For example, a PN 10 pipe can withstand an average of up to 10 bar. This does not mean that at a pressure of 12 bar the pipe will burst. This means that initially the material was calculated for the corresponding level of pressure.

Reinforced polypropylene pipe

Increasing it increases the likelihood of a breakthrough and the rate of product wear. In the event of a premature breakthrough, it will no longer be possible to present any requirements or claims against the manufacturer, since the warranty period due to incorrect operating conditions is automatically canceled.

Pipes of the first group are cheap and easy to manufacture. They have thin walls, withstand little pressure. For the formation of hot water supply systems, they are not suitable in the best way, since they deform when the temperature rises.

The deformation of polypropylene is slightly different from what we are used to seeing. Plastic reacts differently when it comes into contact with hot water. At first it gets very hot, then it becomes soft and pliable.

Polypropylene products of the PN 16 sample are already stronger. This is a kind of budget option for those who want to equip themselves with not only cold water supply, but also hot water. Just keep in mind that it is reasonable to use PN 16 polypropylene for low pressure hot water pipelines.

But PN 20 pipes have no restrictions at all. The model under consideration was originally designed as a working element of pipelines for hot water supply and permanent heating.

Pipes Ecoplastic Reinforced

Polypropylene is known not only for its basic characteristics, such as strength, operating temperatures, etc. After all, almost all plastic products have similar properties.

Where polypropylene is unique is in its ability to be effectively combined with foreign materials. For example, with aluminum foil, fiberglass, etc.

Reinforced products are much stronger, more durable and more stable than conventional polypropylene pipes. It is not surprising that several variations of reinforced pipes are produced under the Ecoplastic brand at once.

Ecoplastic Fiber

The Fiber line is a sample of Ecoplastic pipe with an inner layer of fused fiberglass. The outer and inner layers of the pipes are made of high-strength polypropylene.

The insides are formed from good quality fiberglass with special additives.

The result is a product, on the one hand, quite cheap (because it is easy to work with fiberglass, especially if it is fused into polypropylene), and on the other hand, it is of sufficient quality so that it can be safely installed in heating systems, hot water supply, external pipelines, etc. d.

Fiberglass does not allow the pipe to float, increases its strength, stability, while the wall thickness and weight of the product almost does not change.

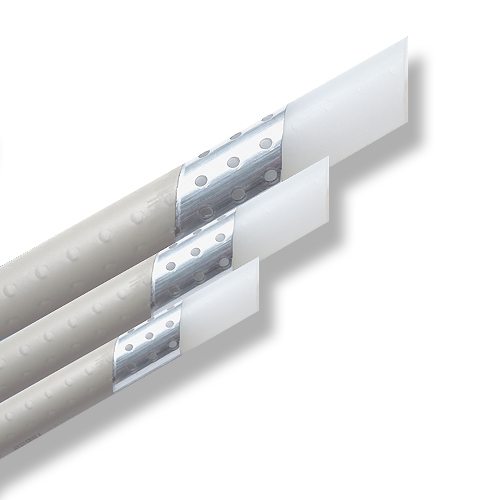

Ecoplastic STABI

Polypropylene pipes Ecoplastic STABI are in many ways similar to the previous option under consideration. Only now they are reinforced not with fiberglass, but with several layers of high-quality aluminum foil.

The integration of foil into polypropylene is somewhat more complicated and expensive, but the result is excellent.

Due to their price and performance characteristics, STABI Ecoplastic pipes are bought mainly for organizing heating in private homes.

However, if the budget allows you, then no one forbids you to purchase materials for less serious tasks. In any case, the choice is yours.

Metal-plastic pipes

Pipes made of metal-plastic have a structure of 5 layers: plastic, aluminum glue, glue, plastic. Due to the multi-layer, pipes easily tolerate temperature changes, are resistant to corrosion, chemical attack, do not oxidize, do not deposit salts.

Metal-plastic pipes are used for cold and hot water supply, heating.

- maximum temperature - 95 degrees;

- maximum pressure at the highest temperature - 10 bar;

- maximum pressure at a temperature of 0−25 degrees - 25 bar;

- the maximum allowable short-term temperature is 130 degrees.

If all operating conditions are met, the pipes will last at least 50 years.

In order to connect metal-plastic pipes to each other, brass fittings are used, which ensure the reliability and strength of the structure. The disadvantage of this connection is a decrease in the diameter of the flow section of the fitting.

About the various elements of the heating system

All used components for heating systems can be divided into several different groups.

Boiler equipment

It can be attributed to:

- hot water boiler;

- expansion tank;

- pump;

- burner;

- automation of work control and boiler piping.

So, the boiler is determined by the available type of fuel, the expansion tank, depending on the type of system, can be open or closed, which is again determined by the heating system. All these questions - what kind of home heating equipment will be used, must be resolved at the design stage.

Safety valve for heating and other control equipment

Suffice it to say that when choosing a heating system that uses natural circulation, an additional pump is not required, so the correct formulation of the problem, what it should be, will significantly reduce the cost of its creation. At the same time, components for heating a private house should be selected according to the parameters of specific working conditions at the design stage.

Heating appliances

They are no less important part of the heating system than the boiler. Suffice it to say that they directly heat the premises. To date, the heaters used for heating are usually divided according to the type of materials used in the manufacture. As a rule, these are radiators:

- aluminum;

- bimetallic;

- steel;

- cast iron.

|

Equipment for flushing heating systems |

|

|

|

Cast iron radiators |

Sources

- http://trubypro.ru/materialy/polymer/ecoplastic.html

- http://ventilationpro.ru/sistemy-otopleniya/material-dlya-sistemy-otopleniya/truby-dlya-sistem-otopleniya-chto-neobkhodimo-znat-pri-vybore-materiala.html

- https://o-trubah.ru/materialy/plastikovie/truby-ekoplastik-329

- https://teplo.guru/elementy/truby/vybor-trub-dlya-otopleniya.html

- http://vse-o-trubah.ru/kakie-truby-dlya-otopleniya-vybrat.html

- http://otoplenie-doma.org/oborudovanie-dlya-otopleniya.html

Features and purpose

Each country is trying to organize its production facilities and establish the production of sanitary ware from polymers, and the Czech Republic is no exception. Here, the leading position is occupied by the Ecoplastic brand, which is very popular not only within its homeland, but throughout Europe.

Under the brand, plastic pipes of various designs are produced. The main direction is the casting of pipes from polypropylene.

The choice of polypropylene as the base working material was made for a reason. Polypropylene stands out from building plastics and is, without exaggeration, the most successful solution.

Unlike polyvinyl chloride or polyethylene, polypropylene products can easily withstand physical pressure, a serious increase in the temperature of the liquid being carried, freeze cycles, etc.

Polypropylene is easily processed, it is quite easy to form tubular products from it, it is capable of diffusion with foil or fiberglass (which allows the production of full-fledged reinforced pipes), etc.

It also makes excellent components, such as fittings, connectors, adapters, decorative inserts, etc.

It is not surprising that the Ecoplastic company appreciated all the advantages of polypropylene, and began to produce its own developments.

Product properties Ecoplastic

The manufacturer Ekoplast (Czech Republic) has been a leader in the market for decades. The history of the company contains both moments of ups and downs.

Over the entire period of its existence, Ekoplast specialists have managed to develop an improved formula for polypropylene, as well as significantly optimize the entire production process.

Fittings for polypropylene pipes Ecoplastic

This, in turn, not only increased the already enviable production capacity for the creation of polypropylene pipes, but also affected the price at which components are sold.

In many positions, Ecoplastic pipes are in an economically advantageous position, and in some positions they are significantly ahead of their competitors.A good price with excellent quality is another important plus in the treasury of Ekoplast polypropylene products.

But Ecoplastic products are not known for their price alone. In addition to the excellent cost, it also has many other advantages.

Main characteristics:

- durability;

- chemical inertness;

- increased density;

- operating temperature up to + 70 degrees Celsius (for reinforced models even more);

- cardinal simplification of the installation process;

- low hydraulic resistance;

- not afraid of aggressive environmental influences;

- high quality standards;

- environmental friendliness.

From the above list of characteristics, we single out durability. Experts from Ecoplastic managed to establish the production of pipes that, under normal operating conditions, are safely operated for at least 50 years.

The manufacturer himself gives a guarantee of 10 years for ordinary products and up to 25 years for products with increased strength.

The operating temperature of PP pipes varies, and each brand has its own. For the simplest products with thin walls, the permissible carrier temperature is + 50-60 degrees Celsius. For thick-walled samples, this figure is + 70-75 degrees.

Well, fiberglass or foil reinforced polypropylene pipes in the short term can even work with water at the boiling point.

However, in the long term, it is still recommended to refrain from such decisions. For carriers with a temperature above the boiling point of water, you should buy metal pipes, plastic, even if very high quality, will not help here.

Steel follow tradition or make smart choices

- Resistant to pressure surges in the circuit.

- Durability.

- Relatively low cost.

- When the coolant freezes in the circuit, it is possible to warm it up with an open flame.

In addition, steel has a low coefficient of expansion when exposed to high temperatures. In other words: steel products do not deform if the temperature of the coolant in CO approaches the boiling point.

Despite a lot of obvious advantages, the steel contour has its drawbacks, namely:

- Corrosion resistance.

- Difficulty of installation.

- Demanding for thermal insulation when running a pipeline through unheated rooms.

- Short service life (up to 15 years).

In addition, it is difficult to give the required geometry to the steel pipeline without heating or special equipment, which dramatically increases the estimated cost of CO. The circuit is mounted by welding or by twisting, which is accompanied by the purchase of fittings and labor-intensive threading.

Today, to increase corrosion resistance, some manufacturers galvanize steel elements that are used to organize CO and DHW.

Tip: Always create a metal circuit if there are difficulties with controlling the heating of the coolant.

Ecoplastic pipes and accessories

Each individual instance has an ideal calibration relative to each other. Since the range of fittings is at a high level, Ecoplastic pipes from the Czech Republic can be considered an ideal option.

Ecoplastic pipe

The manufacturer guarantees the consumer the high quality of the product. It is proved that the nodes will withstand a pressure of 20 atmospheres. The connecting elements are predominantly made for diffuse welding. In addition, PPR material is used together with brass and is used in various variations. In production, low-quality materials are categorically not used.

Polypropylene is a type of plastic that is characterized by a high rate of thermal expansion. Therefore, when the pressure rises or the temperature rises, damage to the structure will occur. Therefore, reinforced pipes with fiberglass or aluminum are used for use in certain areas.

Polypropylene Pipes have differences, so the manufacturer divided them into several categories, each of which has its own advantages:

Ecoplastic PPR. Monolithic plastic pipe without reinforcement and shielding.The letters PN are affixed to the products, and then atmospheric pressure is indicated. 10, 16 or 20 are numbers that indicate how much pressure the pipe can withstand. This type is available in all possible diameters. Accordingly, the more the product can withstand, the thicker its walls will be.

Ecoplastic PPR

Pipes Ecoplastic Staby. Maintain the maximum pressure of 20 atmospheres. At the same time, the wall thickness is reduced due to the use of aluminum fittings. Reinforcement is located closer to the plastic walls. Before installation, the surface must be cleaned.

Pipes Ecoplastic Staby

Ecoplastic Fiber and Basalt + are reinforced with basalt fiber. The fiber layout separates the views. Depending on the subspecies, there are variations in resistance - from 16 to 20 atmospheres. The maximum indicators of pipes on the official website are marked with high resistance to internal and external loads.

Special purpose

The grid of varieties of pipes made of ecoplastic produced in the Czech Republic includes specimens from 20 mm to 125 mm. Extra strong Basalt+ models of increased thickness are made to order. The waiting time can be more than a month.

The manufacturer associates the purpose of polypropylene pipes with the marking:

- PN 10 - used in the supply of cold tap water, or for sewer drains at an angle. Maintains work in heating system of the minimum pressure.

- PN 16 - copes with high pressure water supply or pressure sewerage.

- PN 20 - has no restrictions, is used everywhere in home improvement.

Features of ecoplastic pipes

All types of polypropylene pipes have individual performance characteristics, so it is recommended that you familiarize yourself with the nuances before installation. So, non-reinforced pipes of their ecoplastic tend to expand or contract. Perspiration will not appear on the surface, as the thermal conductivity is reduced. When hot water is supplied, heat loss is significantly reduced.

Wavin Ecoplastic provides customers with a guarantee for adequate operation without deformation for 10 years. At the same time, the possible period of use is 50 years, which has not been proven, since the products are not produced for such a long time.

The company's pricing policy may seem high, but if we take into account the absence of marriage and a long service life, we can say that the price justifies itself. Replacing regularly bursting specimens can be much more expensive.

Detailed information about the range can be found on the official website of the manufacturer. The catalog contains complete information about ecoplastic polypropylene pipes and accessories.