Burner types

Any modern gas burner device according to the method of supplying air can belong to one of two groups. The first one is called injection. In this case, there is no ventilation unit, and the air supply is realized due to the special design of the burner in a natural way. It is this principle that is implemented in AGU-11.6. The second group is based on forced air supply, and a fan is included in the burner without fail.

As the operating experience of recent years has shown, it is no longer economically feasible to use injection systems for burning gaseous fuels. They have low efficiency and increased consumption of natural gas. Therefore, in most cases, when modernizing heating systems, it is those boilers that are equipped with forced ventilation burners and have improved technical and economic indicators that are recommended. At the same time, the cost between the first and second groups is not so much different.

Safe operation of the boiler calculation of its power

The power of the heating boiler is a key factor that affects the level of space heating, as well as the durability of the equipment and the safety of its operation. First of all, it is necessary to determine the heat loss through the ceiling, walls and windows. Part of the heat energy goes through the ventilation system, which should also be remembered. It is very difficult to perform such calculations with maximum accuracy on your own; you cannot do without the help of specialists.

However, there is a technique that allows you to approximately calculate the required power indicators. If the construction of the building was carried out in accordance with all safety and energy saving requirements, then about 100 W of heating equipment power is required to heat one square meter. Accordingly, it is necessary to buy a new gas boiler based on this ratio.

To choose a boiler, consider the features of your building. After all, the power will depend on many factors, whether it be the thickness of walls and ceilings, the presence of plastic or wooden windows, as well as their insulation. The difference between the outdoor temperature and the indoor temperature is significant. So, if inside the temperature changes slightly, then outside the amplitude reaches huge values. Even in winter, sharp transitions from plus 10 to minus 20 degrees are possible.

Give preference to modern units. And the reason is not only the quality of such equipment, but also the presence of additional functions, for example, LCD displays. Setting up the heating boiler in this case is not difficult, since the monitor shows the main parameters of the device - fan speed, actual and set water temperature, and much more.

One of the most common problems with equipment power is clocking. This phenomenon occurs when the unit you have chosen has too much power. In this case, there are only two ways out - either to purchase a new gas boiler, or to try to set it up with your own hands. The first option is preferable, but the second is also used very often.

Clocking is fraught with serious consequences. Unintentional switching on of the equipment causes excessive consumption of gas, in addition, excessive wear of the equipment is observed. However, the solution to the problem is very simple - adjust the level of gas supply to the burner to the minimum level. Regularly check the gas supply level and, if necessary, reset the gas boiler.

Each boiler comes with its own instructions, which describe in detail how to do this. Usually there are special screws on the gas valve that are responsible for the intensity of the fuel supply.On modern models, all settings can be made directly from the LCD display, which makes it even easier and faster.

Main characteristics

Automatic gas burner modification AGU-11.6 has the following main technical specifications:

- The nominal value of the thermal power corresponds to 11.6 kW.

- The type of gaseous fuel used is natural gas.

- The nominal pressure of the supplied fuel is 1.3 kPa.

- The optimal range for temperature control is 50-90 °C.

- The recommended dimensions of the furnace are 200 × 240 × 310 mm.

- The inner diameter of the fitting for connecting to the gas pipeline is 15 mm, and the thread on it is G1/2.

- The declared weight of the device is 6.3 kg.

- The recommended service life is 15 years.

- Warranty obligations are provided within 2 years from the date of purchase of the fuel combustion system.

Price

At the moment, such gas burner devices for boilers can be purchased for 5000-6000 rubles. Moreover, if you choose on the Internet, the price will be lower, and if you wish, you can purchase such a solution even for 4700-4800 rubles. Well, in specialized outlets AGU-11.6 with a guarantee can be bought for 5700-6000 rubles. Again, in the first case, shipping costs must be added to the cost of the burner. However, warranties may not always be guaranteed. Therefore, it is recommended that AGU-11.6 and other similar devices be purchased at specialized outlets.

The choice of gas equipment is the main criteria

You need to decide on the settings of a gas boiler even before buying it. We advise you to start with the power of the equipment. The features of your home matter a lot. The main condition for the normal and uninterrupted operation of such a unit is the presence of a centralized gas supply. Naturally, you can try to use imported gas cylinders, but this will significantly increase costs. In some cases, it is even cheaper to purchase electrical equipment for heating a building than to buy gas bottles.

Heating boilers are single-circuit and double-circuit. In the first case, we recommend purchasing an additional indirect heating boiler. Only then can the unit be used to heat domestic water. The best option is to buy a double-circuit boiler, which has all the necessary functions for heating the building and water. Its key feature is to transfer the priority of operating mode control to hot water supply. In other words, after opening the hot water supply system, the heat supply to the main circuit, which also includes the heating system, stops.

There are some features of choosing a floor and wall boiler. Wall-mounted equipment is less powerful, so it will not be enough to heat rooms with a total area of over 300 square meters. In this case, you will either need to purchase another boiler, or install a floor-standing gas boiler. In stores you can buy outdoor units of any capacity.

Automation 630 EUROSIT. Adjustment.

Today, the Rostov plant of boiler equipment CJSC Rostovgazoapparat produces Siberia boilers, widely known in our country. The author of these lines had the honor to install such a boiler in his own house. Everything would be fine, but in severe frosts problems with insufficient power of this device began to appear. At first, I sinned on power, since the area of \u200b\u200ba heated house is 95 square meters. m. and the declared power of the boiler is 11.6 kW. Naturally, the power reserve is not enough, since the recommended margin should be + 30% of the area of \u200b\u200bthe house. The boiler should be at least 12.5 kW. that is, for heating 125 sq.m. Now a brief background for buyers of Siberian boilers.

WARNING

Some versions of the multifunctional gas supply regulator are supplied without certain parts.Therefore, when installing the regulators, it is necessary to check the presence of the following components:

• minimum gas flow adjustment screw 3 (fig. A)

• adjustment screw for maximum gas flow 2 (fig. A) or, optionally, pressure regulator 2’ (fig. A*)

If not, install as follows:

• check that the accessory code is correct

• insert the minimum gas flow adjustment screw into hole 14 (fig. B), the maximum gas flow adjustment screw or pressure regulator into hole 15 (fig. B)

• insert the accessories and tighten completely.

Tight moments:

- adjustment screws 7Nm

- pressure regulator: 1Nm Gas connection

Use gas pipe with thread Rp 3/8 ISO 7. Tightening torque: 25 Nm. It is possible to connect a tube Ø 12 mm using a sealing ring and a nut (codes 0.958.025 and 0.957.007). Tightening torque 15 Nm. The valve has two inlet ports 10 and 12 (fig. D) and two outlet ports 11 and 13 (fig. D). Holes that have not been used must be closed with plugs (code 0.972.058). Tightening torque 7 Nm Pilot burner connection

terminal 8 (fig. D)

Tube diameters Ø 4 mm, Ø 6 mm or Ø 1/4″ can be used. Use nuts and cones of the correct size

Tightening torque 7 Nm.

After completing the work, check the connections for leaks.

Setting the maximum and minimum gas flow

These settings are made with a cold bulb.

Setting the maximum gas flow (version without pressure regulator) — (rice. A).

Turn the control knob 4 into position 7. Fully tighten the adjustment screw 2 and then gradually turn it out until the required gas flow is reached.WARNING

Once fully screwed in, do not unscrew the screw more than two turnover.

Disabling the maximum gas flow function

Fully tighten the adjustment screw 2 , and then unscrew it, unscrew it two turns and lock it. Disabling can also be done by replacing the adjustment screw 2 plug (code 0.972.057). In this case, the plug must be fully screwed on.

Setting the maximum gas flow (version with pressure regulator) — (rice. A*).

Turn the control knob to position 7. Turning the adjustment screw 2’ clockwise (VERSION WITH PRESSURE REGULATOR) - gas consumption increases.

Disabling the pressure regulator function

Fully tighten the adjustment screw 2’ clockwise.

Setting the minimum gas flow

Slowly turn the control knob clockwise to the minimum power position (close to the main burner off position). Turning the adjustment screw 3 counterclockwise, the gas flow increases. It is also possible to use screws with calibrated holes instead of the screws for setting the maximum and minimum gas flow (optional). In this case, the screws must be tightened with a tightening torque of 7 Nm.

Setting the gas supply to the pilot burner

When turning the screw 5 clockwise - gas consumption decreases.

ATTENTION

After completing all adjustment and adjustment operations, check the tightness of the seals and the correct operation of the equipment. Separation or breakthrough of the flame is strictly not allowed at the maximum and minimum gas pressure, respectively.

After adjustment work, fix the seals and/or adjustment screws with paint.

I bring questions and answers from the old site, if you don’t find anything useful for yourself, write below in the comments.

Purpose

The AGU-11.6 gas burner device under consideration is intended for the repair and modernization of outdated individual household boilers. That is, if for some reason the gas combustion system is out of order and you need to urgently restore its performance, then you can install such a burner. Again, it is first necessary to clarify the compatibility of the boiler and AGU-11.6.

Also, such a gas combustion system is used by default in some models of modern household boilers. One of these is AOGV-11.6. Its key feature is that it is equipped with two coolant heating circuits.One of them is designed for heating and is used in the cold season, and the second is used for heating water all year round.

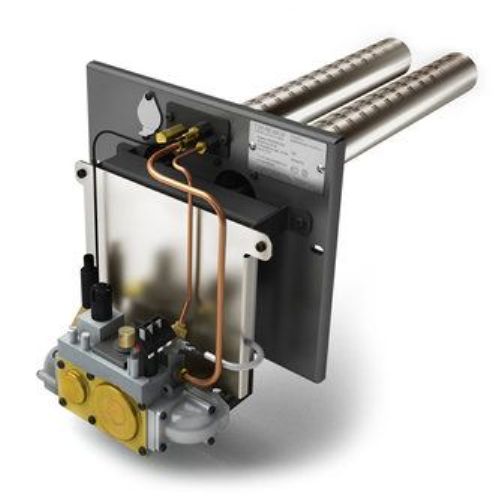

Gas burner VESTGAZKONTROL PG-16M with automatic equipment 630 EUROSIT Italy.

Gas burner device VESTGAZKONTROL PG-16M is used to upgrade or replace gas automation in old boilers, which allows to increase the efficiency of heating equipment by almost 20%. The gas burner device Westgazkontrol PG-16M is designed to heat the coolant and (or) structural elements of heating equipment. The device is designed for operation on natural gas in accordance with GOST 5542–87 with a pressure of 1274 + 100 Pa.

GGU Vestgazkontrol PG-16M provides economical combustion of natural gas with the possibility of automatic control of thermal power and shutting off the gas supply in the event of an emergency.

Automation Westgazkontrol PG-16M is equipped with an automatic control device - gas valve 630 EUROSIT (SIT, Italy).

The 630 EUROSIT gas valve does not require electrical power.

Gas valve 630 EUROSIT allows you to produce:

- ignition of the pilot burner using a piezoelectric element;

— regulation of heat carrier temperature from 40°С to 90°С;

— regulation of the maximum gas flow;

— regulation of the minimum gas flow;

- regulation of the gas flow to the pilot burner;

and provides:

— automatic maintenance of the specified coolant temperature;

- automatic shutdown of the device in case of a sudden shutdown of the gas;

- automatic shutdown of the device in the absence of traction and with reverse traction;

- the ability to operate the device at reduced gas pressure.

The use of stainless steel microtorch burners in Westgazkontrol PG-16 gas automation provides:

- gas savings up to 20% compared to conventional burners;

— reduction of CO emissions into the atmosphere;

- reducing the intensity of soot settling in the chimney;

- reliable operation of the burner throughout the entire period of operation.

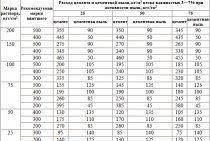

Specifications:

Recommendations for setting up automation Eurosit 630

The use of Eurosit 630 gas automation in complete deliveries of most modern domestic heating boilers requires knowledge of the features of connecting automation and the procedure for its adjustment. It is difficult to explain in a nutshell how to set up most automatic combustion and safety controls. It is only worth noting that the procedure for adjusting Eurosit 630 automation depends on several parameters, including gas supply parameters, features of the heating system, and operating mode. Use of additional devices.

In the basic version, the Eurosit 630 gas automation, the device of which is as unified as possible, but has a number of features that depend on the direct purpose of the model, has four possibilities for adjusting actions.

- adjustment of gas flow limitation;

- setting the gas flow rate of the pilot burner;

- control of gas supply to the main burner;

- regulation according to the temperature of the coolant.

Each of the adjustments allows you to set the temperature in the house, the average gas consumption and the operating mode of the boiler of almost any modification, where the Eurosit 630 automation is installed. It is set up and adjusted by specialists from gas supply organizations, but it is also possible with your own hands if you are familiar with the peculiarities of using natural gas, the main adjustments of the Eurosit 630 system and are not afraid to be left without heating in the middle of winter.

Features of connecting automation, the presence of adjusting screws (there are 2 of them), the use of gaskets, plugs and the tightening level of fasteners, leak test technology, require an invitation from a specialist who is not only familiar with this type of automation, but also has a certificate that allows you to work with it.

Anyone can buy Italian-made automation in our online store when paying in any form. But setting up and commissioning these devices requires a project and the services of qualified personnel. Self-activity in the operation of gas installations is sometimes very expensive.

Automation Eurosit 630, in addition to very high reliability, is also distinguished by special requirements for adjustment. But once properly installed, it can work for several years without requiring maintenance work and the purchase of spare parts.

AGU-P

Automation of the AGU series is the oldest and simplest modification of gas burners. It is used for installation on brick ovens, small boilers of thermoregulation bases. It has small dimensions, simple design, unpretentious and durable. Protection is only against the extinction of the flame. Modern modifications of this burner (AGU-P) are made from many parts with rivets and bolts. This complicates the design and reduces reliability.

AGU-P is equipped with a draft sensor. The method of attaching it and the drive to the button lever raises many questions. The bimetallic plate periodically burns out and requires adjustment. The plug valve must be lubricated during maintenance.

Setting.

Gas combustion is controlled by supplying primary air to the tubes of the main burner using gate valves. Set the gap so that the flame is stable, blue and no more than 80 cm high. The burning intensity of the main burner can be changed using the shut-off valve. The burning intensity of the igniter can be changed using the outlet on the igniter tube.

Gas consumption, service life of units, safety depend on the quality of automation settings.

Steel gas boiler AOGV

Boilers of old modification and completeness in Novosibirsk are extremely rare. During the first gasification of the private sector, they were widespread. Now AOGV is a rarity. Decades of operation speak about the reliability of this device. There are currently no spare parts and accessories for sale. Repair and maintenance specialists avoid working with them and recommend replacing the boiler. The reason is that if a part breaks during disassembly of automation, then it will be costly and time-consuming to restore it.

The boilers of the new modification are made using all the latest developments: a control unit with a solenoid valve, a thermocouple, an electric draft sensor, a modern burner and heat exchanger, a capillary temperature sensor. A distinctive detail is a mirror for monitoring the pilot burner and a long thermocouple.

The boilers have disadvantages inherent in this series: loss of electrical contact between the thermocouple and the coil, an unrepairable automation unit. In addition, an extended thermocouple is used.

Eurosit control automation.

The Eurosit burner control automation is used in many boilers. This is a modern, easy-to-use device, using new technologies. The elements are in one housing, all types of protection (against flame extinction, lack of traction), maintenance is minimal. Only the thermocouple, draft sensor, and rarely the solenoid valve should be replaced. Automation is easy to install and maintain. There is only one drawback - the automation unit is practically not repaired and if it breaks down, the use of the boiler is impossible.

Setting.

Gas combustion is controlled by supplying primary air to the tubes of the main burner using gate valves. Set the gap so that the flame is stable, blue and up to 80 mm high. The temperature of the coolant in the boiler is set by turning the knob on the thermostat of the automation unit. The temperature value is shown by a built-in or overhead thermometer. At the maximum value, the main burner goes out. At the minimum value - enable. The burning intensity of the igniter can be changed using the outlet on the igniter tube.

Conclusion

Within the framework of this review, a gas burner device of the AGU-11.6 model was considered.Although such a fuel combustion system is used in modern boilers, from an economic point of view, its use is currently impractical due to the fact that the gas consumption is too high. Otherwise, this is a reliable and time-tested solution.

A comfortable cottage, a spacious garage, a private cottage, a multi-level apartment - gas boilers warm the lives of millions of people. The heat of powerful units is constant, habitual, and you don’t think about it until the temperature in your home or workroom suddenly drops. Adjustment and adjustment of gas boilers carried out from time to time will help to avoid accidents and breakdowns.

What is good for a Russian is 20 mbar for a European

In the countries of Russia and Europe, the main gas pressure standards differ. Abroad, this value is constant and is defined as 20 mbar. However, keeping the same level of heating in Russia both in summer and in winter is a utopia. So, in the warm season, the indicator drops to about 13 mbar, and with the advent of frost, pressure surges and interruptions in the supply of gas fuel are observed in the network.

Foreign manufacturers of gas boilers could not turn a blind eye to the climatic conditions of their neighbors and adjust imported boilers to certain sensitivity ranges. This operation is performed at the factory during the assembly of the movement. In addition, a special gas valve has been created that allows you to adjust the pressure if necessary. Initially, it was conceived as a way to save fuel consumption, but Russian citizens use it as a means of preventing an emergency shutdown of a gas boiler due to a pressure drop in the line.

Your own controller

The main actions for setting up and adjusting the operation of a gas boiler of any configuration must be carried out by a specially trained person. But there are a number of operations that the consumer of thermal energy can also handle - for example, while waiting for the arrival of the master.

- Problem: burner power too high. Description: A "dancing" flame smoking a chimney. Solution: close the gas valve on the descent.

- Problem: low boiler draft. Description: air does not enter the boiler, the processed gas does not go outside. Solution: close the gas cock on the downstream, thereby reducing the power of the burner.

- Problem: lack of air to support combustion. Description: yellow flame, soot accumulation. Solution: reduce the burner power in the manner suggested above.

- Problem: high gas pressure. Description: soot settles on the walls of the chimney and furnace, gas consumption increases. Solution: install a pressure regulator, close the gas cock.

The actions that are collectively called the adjustment and adjustment of gas boilers also include heating the boiler, opening the chimney damper, checking the safety automation, and transferring the dial gauge installed on the gas pipeline.

Note to the owner

Start-up and adjustment works of a gas boiler are inconceivable without an analysis of the waste and gas flows going to the supply. The adjustment cannot be considered completed if the optimum balance of air and gas has not been found. Who wants to pay for fuel that escapes into the atmosphere without a trace? Who will be warmed by inefficient heat? Are there citizens interested in deliberately reducing the life of the heater?

In order to divert an accident from your home or office, you need to make adjustment work a routine matter. Make it a rule: once in a certain period to carry out a thorough comprehensive inspection of the gas boiler, its parts and components. The maximum achievable efficiency of the boiler will be maintained with an acceptable quality of operation of the device. When setting up a wall-mounted or floor-standing heating boiler, make sure that no additional thermal insulation is required in the furnace room, and that the heat losses inevitable during the operation of the boiler are at an acceptable level.

With the beginning of the heating season, the owner of a private house must put the heating boiler into operation. The operation is not the most difficult, since all instructions for setting up the unit are necessarily indicated in the technical documents

In our article, we will tell you what to look for when setting up the equipment and how to make the boiler work with maximum efficiency.