From the position of the location of the heater

This is an important aspect, because Each type of insulation has its own advantages and disadvantages. Pros and cons of thermal insulation from the outside (from the street) and from the inside (from the inside), a comparison of when which method is justified or appropriate.

Outside garage insulation

A method recommended by both masters and users based on practical experience.

Benefits of outdoor insulation:

- reduces the likelihood of freezing of the walls of the garage. The freezing point is shifted towards the insulation. Among other things, this increases the life of the walls themselves;

- the risk of condensation is reduced;

- a favorable environment for the development of fungi is eliminated;

- the area of the premises remains unchanged;

- there is no need to dismantle the shelves and take everything out for work;

- the harmful effects on humans of fumes from heaters are excluded;

- cost and labor intensity are reduced.

Garage insulation from the inside

This method is used when:

- there is no possibility to perform external (external) insulation. For example, a garage is located in a block, i.e. located between other garages and has walls in common with them;

- there is no possibility or desire to dismantle the shelves inside the room;

- sprayed heat-insulating material (polyurethane foam, polyurethane foam or penoizol) will be used as a heater. With a minimum thickness, sprayed thermal insulation does not affect the usable area and, due to excellent adhesion to the surface, prevents the appearance of condensation on walls and ceilings.

Disadvantages of internal insulation:

- reduction of the usable area of the garage;

- displacement of the freezing point inside the room, at the junction of the insulation to the wall. The result is the gradual destruction of the walls of the garage.

Thus, if possible, it is better to give preference to the external method of insulation.

Buying a finished product

If you decide to install a factory-made structure in your garage, then the problems of how to insulate the gate will end there. New lift-and-swivel and sectional devices already have a layer of polyurethane foam. Even roller shutter types of gates are sometimes insulated, but the possibility of using them for a garage is very doubtful. Narrow aluminum lamellas will not be reliable protection against burglary, and their high thermal conductivity makes them unsuitable for our climate. When ordering a gate, a swing system with a gate would be a good option. It will significantly reduce the percentage of heat loss.

Basic functions of garage doors

Some helpful tips on choosing a garage door design.

Before choosing, imagine how convenient it will be for you to use such a gate. Will it be convenient for you to drive into the garage, as well as leave it. Will they reduce space due to their design.

As for the dimensions of the doorway, the gate should in no case reduce it with its design.

It is important to remember that in most cases, garage door insulation is carried out quite easily and not very long.

https://youtube.com/watch?v=cmwotqAIMf8

The next function of garage doors should include the strength of the material from which the gates are made, and also the opening-closing mechanism must be anti-burglary

Pay attention to what material is used in the manufacture

It is important that it is not subject to corrosion and can last a long time. If the opening design is reinforced with reliable locks and has armored inserts, then the probability of breaking into such a garage will decrease to a negligible probability.

It is also worth considering that doors should not only protect against thieves, but also from adverse weather conditions.Phenomena such as snow, rain, hail should in no case touch the car in the garage.

If all parts of the garage door structure fit tightly enough to each other, but they are not insulated, then the only thing left is to insulate the garage door.

How to install automatic garage doors?

The manufacture and installation of automatic garage doors is most often made to order and in a certain company for the manufacture of such structures.

Experts in this field will offer you the most profitable option, which will be ideally matched specifically for your premises. The only thing is that you choose the gate model and pay for the order.

https://youtube.com/watch?v=olPnauvOgkk

When choosing a garage door, you should pay attention to the following characteristics:

- Anti-burglary system;

- Moisture resistance of the design of garage doors;

- The gate must not release heat from the room;

- And according to the requirements of some customers - soundproofing characteristics.

Usually, when ordering, garage doors are insulated directly at the enterprise, so customers are not very worried about this. The main material for insulation is polyurethane foam.

But since not everyone can afford to order a gate, a simple instruction for insulating garage doors at home will be given below.

A selection of video lessons on the topic

Insulation technology for old garage doors:

How to seal gaps in garage doors:

Heated garage door lining:

Self-insulation of the entrance opening and garage doors should not cause difficulties. You should not consider this an excess, it is safer to store a car in a warm room without condensation, rust will not touch it. To do this, it is enough to insulate the garage doors with foam or mineral wool, and also close the gaps with a rubber or silicone sealant. And as an additional barrier to cold air, you can hang a canvas curtain.

Describe your question as detailed as possible and our expert will answer it

I want to share how I insulated the gate around the perimeter. I fixed a corner on the slopes and put a car door sealing gum on it.

How ALUTECH Classic sectional doors help to save heat

Due to the well-thought-out design, the doors of the Classic series are suitable for operation in conditions of high humidity, cold climates and are the best solution for heated rooms.

1. Panel thickness

Thermal insulation is one of the most important indicators for sectional doors. ALUTECH sandwich panels with a thickness of 45 mm have one of the best energy efficiency indicators on the European market. The heat transfer resistance coefficient is 1.0 m2°C/W. For comparison: a brick wall 60 cm thick has similar thermal insulation properties.

For each climatic region, the recommended heat transfer resistance coefficient is different. In warmer regions, it is R = 0.56 m2°C/W. For the regions of Siberia, this coefficient is 0.85 - 0.95 m2 ° C / W. ALUTECH Classic doors with R = 1 are suitable for installation in any latitude.

Required heat transfer resistance for doors in different regions

It is due to the large thickness of the door leaf that ALUTECH doors are distinguished not only by high thermal insulation properties, but also by excellent wind resistance indicators. Tests have shown that the canvas easily withstands loads up to 700 Pascals - this is comparable to gusts of wind up to 120 km / h.

ALUTECH doors effectively retain heat in the room

ALUTECH doors effectively retain heat in the room

2. Closed loop sandwich panels

Sandwich panels are made of steel with a thickness of 0.5 or 0.4 mm (smooth surface or WOODGRAIN embossing, respectively).External and internal steel sheets are connected in a lock and form a closed loop. At the bottom and top, the outer and inner steel sheets are connected by self-tapping screws in 4 layers. Thanks to a special connection system, the panels do not delaminate during sudden lowering, impacts, or heating by sunlight, which is especially important for gates painted in dark shades.

Closed Loop Sandwich Panels

Closed Loop Sandwich Panels

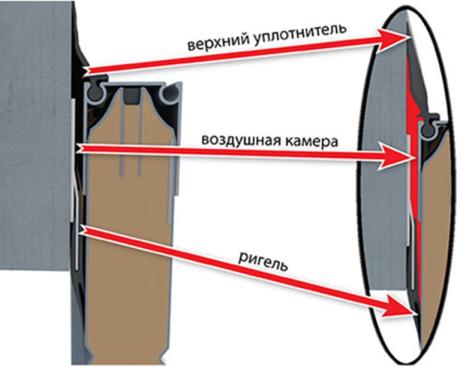

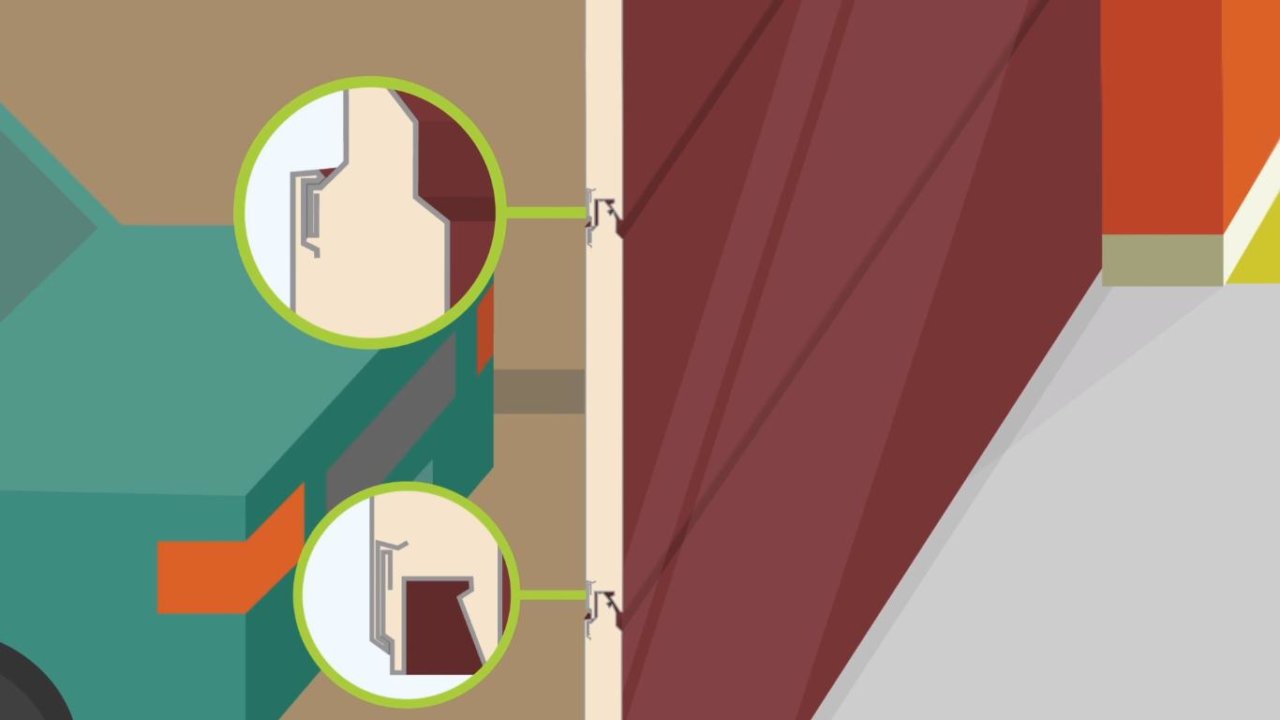

3. Frost-resistant EPDM seal

EPDM seals made of polymer rubber are used in the design of ALUTECH Classic doors. The material does not absorb moisture, is characterized by high frost resistance, resistance to sunlight and precipitation.

The side and top seals of the gate are two-petal: an air chamber is formed between the petals. This configuration of the seals improves the thermal insulation properties of the door. The tightness of the structure is supported by roller brackets, which tightly press the seal against the door leaf.

The tightness of the structure is supported by roller brackets

As a result, even when it is cold outside, a comfortable temperature with a “+” sign is maintained in the garage.

The use of modern seals in the design of garage doors is a reliable protection of the premises from drafts and a guarantee of maintaining an optimal microclimate in conditions of any geographical latitudes and in any weather.

4. Concealed rail mounting

If you look at the ALUTECH Classic door from the side of the street, you can see only the leaf, while the guides are absolutely invisible and, when the leaf is closed, do not come into contact with cold air from outside. Flashings and corner posts are also mounted behind the gate opening: this eliminates heat exchange with outdoor air, increases the thermal insulation properties of the gate and the energy efficiency of the garage.

All this increases the thermal insulation of the garage, provides wind resistance and tightness of the gate.

As a result, by equipping your garage with ALUTECH energy-efficient doors, you will significantly increase the level of personal comfort and be sure that the premises and property are protected from the influence of weather conditions. Due to the high thermal insulation properties, Classic doors allow you to save on space heating or completely abandon the installation of heating equipment. Provide yourself with comfort all year round by ordering ALUTECH garage doors.

How to insulate your garage door yourself

There are three methods for insulating garage doors:

- The use of sealants to close gaps.

- Installation of heat-insulating materials on the sash leaf.

- Hanging a curtain.

For thermal insulation of swing and up-and-over gates, all three methods can and should be used. And if a sectional or roll structure is installed at the entrance to the garage, then it will be possible to insulate it only with the help of the first and last trick.

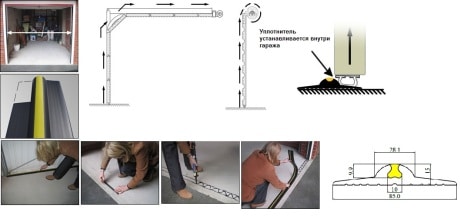

Sealers - fight against drafts

No matter how accurately the gate is adjusted in size, gaps still inevitably appear. To eliminate drafts, the gaps between the wings, as well as at the points of their connection with the floor, ceiling and walls, should be closed with a sealant. It fills the gap and prevents the exit of warm air from the room.

The sealing insert can be:

- silicone;

- rubber;

- in the form of a nylon brush with wax impregnation.

Frost-resistant garage seals are available in the form of tubes and tapes with or without a self-adhesive backing. In the second case, you will need the appropriate glue to mount them. The brush option lasts the longest, but it also costs more.

It is not recommended to use polyurethane foam to seal gaps in garage doors. Of course, with its help you can create a reliable barrier to drafts. However, with the constant closing / opening of the doors, the foam layer will quickly collapse. Yes, and in the open air, it begins to crumble. But as an option for one winter, it will be enough.

In addition to factory products, a garage seal can be made from improvised means: a rubber hose or a piece of an automobile chamber. But the wear resistance of these options is obviously lower than the frost-resistant liners specially designed for this.

Insulation in garage doors - basic thermal insulation

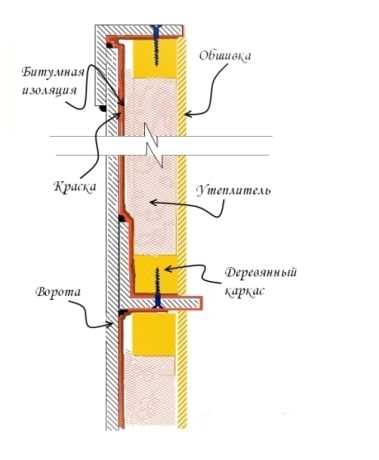

Seals alone for high-quality thermal insulation of garage doors are rarely enough. Often you have to fully insulate the sash. At the same time, it is necessary to prepare their metal parts by cleaning them from rust and painting, and then sheathe everything on top with decorative panels or wood.

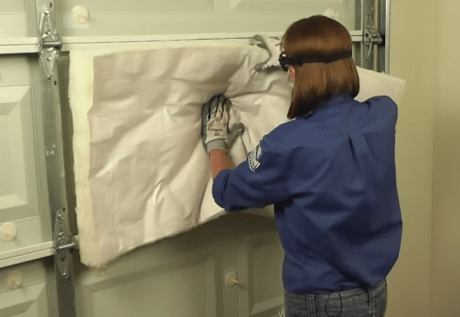

To insulate garage door leaves:

- To clean the rust on the metal of the door leaf, and then paint it for waterproofing with bituminous mastic.

- Fix a frame made of a bar with a section of 20–25 mm on the sashes with self-tapping screws.

- Fill the resulting honeycombs with insulation (foam polyurethane foam, cut and glue foam or insert cut-to-size mineral wool).

- Sheathe the OSB frame, clapboard or laminated MDF.

Wood boards for sheathing garage doors should only be used moisture resistant types. Ordinary fiberboard or plywood will swell and warp. It is better to take laminated sheets altogether. They cost more, but will last longer in a garage without heating.

Sheathing with foil will additionally insulate the garage doors. Just fix it with a layer of aluminum inside, then the heat will be reflected back into the room. Not much, but even keeping that heat energy inside will help keep the humidity down.

Curtain - additional protection

As an addition to the warm gate at the entrance to the garage, you can hang a curtain to increase its thermal insulation. For it, it is necessary to stretch the rope or fix a steel pipe with a diameter of 15–20 mm instead. The main thing is that the curtain should be made of a dense material (tarpaulin or PVC).

Instead of a tarp, you can hang vertical strips of polyethylene. Similar protection is used in car washes and workshops. Extremely simple, but quite reliable - much less heat will escape from the garage room.

Choosing the Right Material

There are no serious restrictions on the choice of thermal insulation material for garage doors.

At the same time, all heaters have some features that must be considered when choosing a material for such specific purposes.

- Mineral wool, felt, glass wool.

These materials have similar characteristics of thermal conductivity, vapor permeability and mass.

It is highly undesirable to use them in garage construction, because due to the small thickness of the main material of the gate, the dew point will fall into the thickness of the insulation, which will lead to its constant wetting in winter.

Peat, reed and cork slabs.

Suitable for use in a garage, but have a high cost and do not have great mechanical strength.

Elastic foam insulation. Inexpensive, effective, but sensitive to mechanical stress.

Various types of foam.

Foam insulation is most convenient for installation on iron garage doors. With a high degree of energy saving, the foam has a very small mass, is easy to cut and machine, and is easily fixed on any surface.

Garage door insulation does not take much time. The video below shows the entire insulation process from getting rid of the old skin, to the final result in just one weekend:

Types of gates and features of their thermal insulation

There are several types of “doors” for entering a car garage.In some cases, it is easier to buy ready-made insulated garage doors, while in others you can make them warm with your own hands after installation. However, the desire to make something on your own is not always prudent. There are gate structures that are quite problematic to insulate with high quality.

The garage entrance can be closed with the following types of gates:

- swing;

- lifting and turning;

- sectional;

- rolled.

The swing design is the most common and is one or a pair of wings that open outward. These classic doors are in demand due to ease of installation, reliability and anti-vandal security. They are made of metal sheets 2-3 mm thick and reinforced with a corner. It is easier to make them and then insulate them with your own hands.

In the lift-and-turn model, the sash rises to the ceiling. In most cases, these are products that are manufactured and insulated inside with various materials at the factory. These one-piece sandwich panels are made from two sheets of metal and polyurethane foam between them. It is not necessary to insulate them additionally, it is enough just to carry out the installation correctly according to the instructions and install the seals.

Sectional doors are an improved version of the overhead door. Only they do not consist of a single canvas, but of several horizontally connected sections, which, when opened, fold like an accordion or move along the guides to the ceiling.

Roller blinds are a descending/rising canvas, consisting of individual narrow plates, which, when closed, are wound on a shaft under the ceiling. Like the sectional version, rolling shutters already come with insulation inside the slats. If a structure without heat-insulating material is purchased, then it is difficult to insulate it on your own. It will be necessary to inject polyurethane foam into the sections.

Ready-made, already warm, industrial-made rolling and sectional doors are not able to keep heat in severe frosts. However, it is rather problematic to additionally produce their thermal insulation. For the southern regions, they are quite suitable, and in Siberia it is better to install a hinged insulated alternative.

FakeHeader

Comments 51

I chose the day there was not a big thaw and foamed the gap between the threshold and the gate, it got better) During the time I had time, now the frosts have risen over -30.

The bottom can be made with felt

Will freeze to the gate.

Then from the fire sleeve

Hang a curtain made of dornite, we have this hanging in every garage and you will be happy

You can do stuffing with felt on the gate, but I also saw that in the neighborhood in the garages people wrap a board with a tarpaulin and just lie down with their hands every time.

Thank you! I also tend to this design, make staples on the threshold and insert a board with felt there.

I was also puzzled by the question, until I saw that people just use the boards, and not just one person, but directly en masse.

such a good corner for a sealant ... my toad says that a drywall profile would be enough, it is noticeably cheaper!

The threshold is coated with working off and on the closed door directly into the slot with mounting foam, after hardening the foam will remain on the door itself, creating a seal and will not stick to the threshold

I support! I did exactly the same, around the entire perimeter, everything was fine and it turned out hermetically. Only I didn’t smear with working off, but with a thin layer of lithol. Three years have passed, no complaints.

The threshold is coated with working off and on the closed door directly into the slot with mounting foam, after hardening the foam will remain on the door itself, creating a seal and will not stick to the threshold

Can be glued with adhesive tape, polyurethane foam also does not stick to it

I screwed a double-folded fire hose around the perimeter. Outward bend. Previously, you put a galvanized metal strip with holes into the sleeve. Self-tapping screws after about 200 mm.

And I got frost around the perimeter. Neatly so.

Nope)) I don’t like such a heater, I also used it for a while)

I sewed up the gate first with a wooden crate around the perimeter, then with foam plastic and from above the whole OSB-3 thing. So the OSB tried to adjust it so that it was right close to the frame. But still, such a neat frost around the perimeter. , does not melt, but falls off in pieces. It will be necessary to hang the curtain.

it was necessary to take a picture of the gap below, the options depend on its size

I cut the rubber chambers from Kamaz into strips. I fixed these rubber strips in two layers - on one and on the other side of the rail (double shutter turned out). I did this around the entire perimeter of the collar. Then I cut these strips in place (in width, so as not to interfere with the closing of the gate).

Mounting foam. I did this to myself, everything is tight in a circle. There are many videos on YouTube.

Now on sale there are a lot of rubber profiles for sealing the joints of doors, windows and gates. Why reinvent the wheel?

I didn't see the threshold.

on the thresholds you can use the same. Or too small?

Lepi antithreshold! ))))) www.antiporog.ru/ustanovka-antiporoga.html

Cool thing! I'm afraid to freeze and frost will clog the mechanism.

to close up the gaps at the gate, the first thing to look at is that at the exit from the garage it’s just the earth that raises in winter or thoughtfully poured concrete ... and so that it’s right on Feng Shui, or the second light doors should be made so that the vestibule is to play the role of an “air cushion” or a more budget option for felt curtains and there will be a song

The problem is only with the threshold. I got confused with rubber bands because I didn’t want a curtain.

A huge canvas curtain! On the entire wall, it will be a very cool effect.

I have the 50th corner welded to the program without insulation and there are no problems.

a dozen mops with bristles down. just leave it, ventilation has never harmed anyone.

ventilation and draft are very different things ... and where there are gaps, then in winter there will be frost and there will be a lot of it, which then melts and moisture, one asks where are the advantages of such “ventilation” ...

moisture where the humid air of the garage comes into contact with cold objects, if it blows into the gap under the gate, then there will be no frost, and if there is frost, what is the problem at the threshold of frost? this is not a ceiling. besides, the more ventilation, the less likely it is to catch the dew point. and I probably won’t list the pluses from ventilation.

Preparatory stage

It must be carried out before insulating the garage door from the inside, since the metal, although reliable, requires certain conditions in order to remain so for a long time. The gate is a structure not designed for loads, therefore, super-strong steel grades are not used for their production. This has advantages: lower price and ease of working with such metal. However, the gate is strongly affected by the environment, so corrosion is inevitable. So that the metal does not rust in just a couple of years, the simplest algorithm is used:

- The surface is carefully cleaned from old paint, rust and other debris. Instead of traditional sandpaper or a manual metal brush, you can work with a metal core brush attachment.

- The cleaned iron is degreased with acetone or another alcohol-containing solution.

- Primer. It is better to buy a special tool. The cheapest, but not the best way is to paint with oil paint.

High-quality durable paints and varnishes are expensive, and knowledgeable people advise using any bitumen-based composition if there is a shortage of funds. They are not particularly aesthetic, but this is not necessary, because the surface will subsequently not be visible.

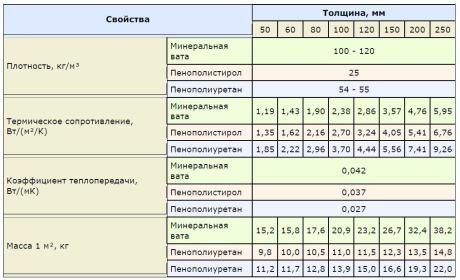

The choice of insulation

To carry out the work, it is necessary to find a material with a minimum thermal conductivity. In construction, a special coefficient is used for this, and the smaller it is, the more effective the insulation for the garage door will be. Admittedly, there are quite a lot of such materials.

In this video, we will look at how the garage door is insulated with our own hands:

Mineral wool

It is a good insulation widely used in construction. At the same time, the cost of the material is low, and finding it in retail chains will not be a problem. However, this common name hides three subspecies at once:

Glass wool is made from thin glass fibers. With low thermal conductivity and moderate hygroscopicity, it can be a good choice

However, when working with glass wool, precautions must be taken.

Slag wool is made from blast-furnace slag and has a higher thermal conductivity compared to glass wool. Due to the strong hygroscopicity and acidity, it is better not to use it for warming metal doors.

Stone wool - due to its low thermal conductivity, it could be a good insulation, but when heated, it can release phenols - substances harmful to the human body.

Various types of foam

A large number of materials of synthetic origin belong to this class. Common to them is a polymer base and a foamed gas-filled structure. To classify the foam, the type of base polymer is used:

- Polystyrene - to insulate the garage door from the inside with your own hands, it is better to use extruded polystyrene foam of the EPPS brand.

- Polyvinyl chloride - in construction is actively used for sound and heat insulation. It differs from the previous material in high fire resistance.

- Urea-formaldehyde is a popular type of foam. It is most often used in liquid form, since after drying its size does not increase.

- Polyurethane foam - elastic foam is known to everyone under the name foam rubber, and liquid polyurethane foam is familiar to many. As a heater, it is better to use the first type of material.

Choosing a heater

A material with a minimum of thermal conductivity is a heater. In building codes and regulations (SNiP), thermal conductivity is calculated by special indicators. The lower the indicator, the material and it is worth insulating the gate

In this table, from the first to the sixteenth line, the types of insulation are described. With the sixteenth - build materials to which insulation is applied. It is quite logical - the thicker the insulation layer, the warmer. But from a practical point of view, it is advisable to make a layer of thermal insulation of 50 mm.

Mineral wool

The well-known glass wool, now it is called - mineral wool. This material has amazing thermal insulation, which has proven itself in the production of construction work. Glass wool consists of very thin glass microfibers with a thickness of 3-15 microns and a length of up to fifty millimeters. In terms of its construction qualities, this material is distinguished by low thermal conductivity (0.002-0.055 W / m). As well as the breadth of the temperature range from -65 to -450˚С, elasticity. Choosing this material for insulation, you need to take care of personal protective equipment. The fact is that glass microfibers are very fragile and brittle. They can dig into the skin and get into the respiratory system.

A type of glass wool is slag wool. It is made on the basis of slag or waste in metallurgical production. The fiber is thin - from 4 to 12 microns, and the length of the fibers is less, compared to glass wool, from fifteen to sixteen millimeters. But experts advise avoiding the use of this material, as it has an increased acidity, which causes premature corrosion of the metal.

Another "relative" of glass wool is stone wool. It is made by melting volcanic rocks. In its structuring, it is similar to slag, but it is noted for greater heat resistance and it is acid-neutral.In the production of insulation, phenol-formaldehyde resin is used, which, later, can release phenol, a very dangerous substance for human life and health.

Styrofoam

Styrofoam is a synthetic material that is foamed polymers. According to the type of foam can be divided into:

Polystyrene foam is the most popular material of its class, used much more often than other heaters. This type of foam is characterized by low hygroscopicity and practically does not ignite.

- Polyvinyl chloride foam - widely used in construction. It has excellent heat and sound insulation properties.

- Polyurethane foam is divided into two types:

- flexible polyurethane foam or, well-known, foam rubber;

- hard - hardened polyurethane foam.

Rigid polyvinyl chloride is usually used for insulation, because it “sticks” perfectly to any surface and is an excellent protection against moisture. Thus, with the help of PPP, you can not only insulate the garage door, but also protect them from moisture.

What thermal insulation material to choose

Before you start insulating the gates in the garage with your own hands, you need to correctly select the thermal insulation. The assortment line of insulating materials is huge, but not all of them will fit for insulating an automobile “house”. For independent thermal insulation of garage doors are suitable:

- Slab foam or polystyrene.

- Sprayed polyurethane foam or penoizol.

- Minvata.

The latter option will give odds to the rest in fire resistance, but it is much inferior to them in moisture resistance. Mineral wool is cheaper, but with equal thermal conductivity, its layer will be thicker and heavier than that of expanded polystyrene and polyurethane foam.

To insulate garage doors, it is best to take one of the varieties of mineral wool. This roll material is easier to mount, but the main thing is that it is not afraid of fire. The same cannot be said for foamed and sprayed polymer-based alternatives. They, despite all the impregnations and additives, still remain fire hazardous.

You can also use heat-insulating paint. To apply it, a regular brush is enough. After the thermal paint dries, a polymer-ceramic film with high thermal insulation characteristics is formed on the door leaf. But it will have to be applied to the gate in several layers, forming a coating of the desired thickness and insulating properties.

After the door is insulated, the temperature in the garage will no longer fluctuate constantly, which will reduce the risk of condensation. Most heaters are mounted on the front side of buildings. But it is impractical and simply unreasonable to insulate garage doors from the outside. It is not for nothing that they are made of durable iron, protection from vandals and thieves will not interfere with the car.

If the insulation is fixed on the garage door from the outside, then it will not be possible to open it completely. The design of the swing doors will not allow them to be opened wide in this case, and the sectional models are simply not designed for such changes, they cannot even fold in half. Plus, the heat-insulating material from the outside can be set on fire. It remains only the option with installation from the inside.