How wind instruments work

A wind instrument is made up of certain types of resonators (usually in the form of tubes). They vibrate a column of air that the player blows into the wind instrument, and as a result, the sound is amplified.

The sound range of a wind instrument is determined by the size of its resonators. For example, the sound extracted from a thick tuba is low because the length of its air channel contributes to the low-frequency oscillation of the air flow. And the sound of a thin flute will be high due to the narrower shape of the instrument, and, accordingly, the smaller volume of the resonator: under such conditions, the air column oscillates against its walls more often, therefore, the sound becomes higher.

It is possible to increase the oscillation frequency of the column by accelerating the air injection, that is, if you create a faster and sharper air jet.

Device and principle of operation

The classic clamp has the same functions as a vice, and its design is very similar to the mechanism for attaching a Soviet meat grinder to a table.

The material used in the manufacture of this tool is metal, wood, durable plastic.

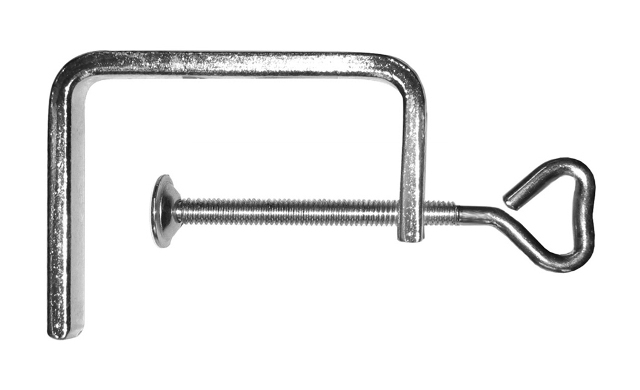

An ordinary manual clamp is a monolithic frame curved with the letter “P”, to which movable clamping elements are attached on one side.

As a rule, this is a long screw, equipped on one side with a handle for easy turning around the axis, and on the other side having a flat wide nickel.

By turning the screw, this nickel creates pressure on the opposite end of the frame.

If you place two, say, wooden bars between the nickel and the frame, and then tighten the screw, they will securely lock together.

According to the design, pressing auxiliary tools can be divided into:

Body clamps

Clamping force can be used to clamp workpieces on oblique and parallel planes.

Due to the fact that the clamp is carried out by the body elements, the tool got its name.

It consists of two metal rectangular beams connected to each other on one side by a strong bar. One of them is fixedly attached to the bar, and the second is equipped with a tightening screw and can move freely.

The opposite part of the bars is the pressing lips.

To clamp the parts, it is necessary to bring the metal bars together until it stops in the workpiece, and then tighten the screw (equipped with a convenient handle).

This version of the tool is the most common.

screw clamp

It is a popular auxiliary tool.

It can be made in several versions, but the main clamping force is provided by a screw with a handle and a penny.

It can be made in the form of a body clamp, where the clamping screw passes through the bar, and the nickel is a lip.

Another option is a body in the shape of the letter “G” or “P”, through one of the “legs” of which a clamping screw with a penny is passed.

Forged screw clamps made of tool steel are widely used.

The metal, after forging and hardening, has high strength, resulting in the reliability of the tool.

Magnetic clamp

It is most in demand by welders, as it serves for preliminary fixation of two metal blanks (tubes, profile corners, etc.) between each other.

It can be made in the form of an isosceles right triangle, five -, hexagon.

The edges of the clamp have magnetic inserts, which are responsible for fixing the metal elements to each other at an angle.

Ratchet Clamp

Outwardly, it is very similar to an ordinary clothespin, but larger.

It is clamped by the force of the hand, and the installed ratchet mechanism blocks the expansion of the jaws.

To loosen the clamp, a special pawl lever (button) is used.

Trigger clamp

Also called quick release.

It has an F-shaped design.

One sponge is fixedly fixed on a metal bar.

The second has a handle similar to a pistol, with a lever resembling a weapon trigger, and a special flag - a lock.

If the flag is in the “unlocked” position, the movable jaw moves freely along the bar.

In the “locked” position, the clamping is carried out by pressing the lever.

In this case, the movement of the sponge in the opposite direction is blocked by the same locking mechanism.

Simply put, the system resembles caulk guns.

hydraulic clamp

G-shaped body, as in the case of a screw tool, however, instead of a screw, a kind of jack is used, on the stem of which a penny is mounted.

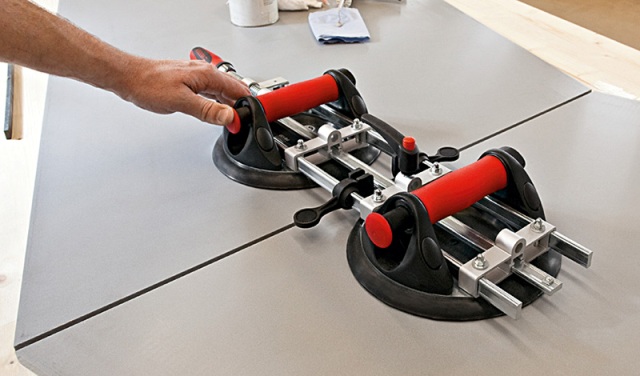

Vacuum clamps

Vacuum suction cups with built-in hand pumps are installed parallel to each other on the frame.

They are used for positioning two flat parts in the same plane, for example, MDF sheets, metal.

What is a clamp for?

Clamps are specialized carpentry clamps designed to fix individual elements.

Especially such a tool is relevant for carpentry and plumbing.

In practice, the tool is used in a variety of manipulations. You can’t do without it when gluing individual elements made of wood. Since for a quality connection, individual elements need to be compressed for 24 hours, which is simply impossible to do manually. For such situations, the purchase or independent manufacture of carpentry clamps will be the best way out.

Types of clamps

Today, such a tool can be made from various materials in several variations. Usually the manufacture of a clamp requires wood or metal. When installing the specified device in the right place, you can not hold individual parts, but work fully with other tools.

The simplest version of a carpentry clamp involves the presence of a pair of moving components and a frame for them. The work of the tool is carried out by means of additional clamps and levers. With the help of which the force is selected, the parts are compressed and they are fixed.

There are also quick-clamping structures representing the lever type. These are specialized clamps.

Their peculiarity is that the clamping occurs instantly, but this will require a certain force to be applied.

There are varieties of carpentry clamps. Depending on the mechanism installed in them and its features, they are:

- Corner structures.

- Screw installations.

- Quick release devices.

- Assembly structures.

- Hand clamps.

Wind instruments of the symphony orchestra

Flute, bassoon, oboe, tuba, horn, trombone, clarinet and trumpet are those wind instruments that are part of a symphony orchestra. Let's consider some of them.

Flute

Initially, the flute was indeed made of wood, but later, in the 19th century, silver became the main material for this instrument. The very word "flute" is rooted in ancient times; then this name applied to all wind instruments without exception. It is believed that the flute is one of the most ancient musical instruments in principle - the first ancestors of this instrument appeared already about 43 thousand years ago.

Previously, there was a longitudinal flute, which the musician holds in front of him like a pipe, but in the period after the Baroque era, it was supplanted by a transverse flute, which is held to the side, moving the arms to the side. It is the transverse version that most people imagine when they hear the concept of "flute". In a symphony orchestra, two flutes are mainly involved.The flute is used most often for classical pieces. Among other wind instruments, the flute is the best for most people, and learning sheet music for the flute is no more difficult than learning sheet music for the piano or guitar.

Trombone

The trombone is the only brass instrument that has not undergone any changes after centuries of its existence, and has remained the same as ancient musicians knew it. The trombone is the only instrument that does not transpose, that is, the pitch of the actual sound of which is the same as the pitch of the musical notation. The word "trombone" is usually understood as such a variety of it as a tenor trombone. There are also alto and bass trombones, but they are rarely used.

A symphony orchestra usually has three trombones. Trombone is most often found in such musical genres as jazz and ska-punk.

Oboe

The form that the oboe has now, he acquired in the XVIII century. Its predecessors since ancient times were such instruments as aulos, zurna, bagpipes and others. The oboe is characterized by a melodious timbre, similar to the human voice. He himself has a conical shape and a set of twenty-three cupronickel valves on the body.

The symphony orchestra has two oboes in its composition. Classical and Baroque pieces are the main repertoire of this instrument.

Pipe

Among the brass, it is the trumpet that can sound above all. It is made from materials such as brass, copper or silver. It is one of the most ancient instruments. Initially, it was used as a signal instrument, but since the 17th century it has become an element of a symphony orchestra.

A symphony orchestra uses three trumpets. This instrument is used in a wide variety of genres: classical, jazz, etc.

tuba

The tuba, unlike the trumpet, on the contrary, is the lowest-sounding element. In addition, the size and weight of the tuba also exceeds all other brass instruments. Because of this, it is often played standing up, which, among other things, implies the appropriate physical preparation of the musician. It is an invention of the 19th century Belgian Adolphe Sax. Like the trumpet, the tuba is a valve instrument.

The orchestra mostly uses a single tuba.

A more or less serious level of playing any wind instrument can be achieved in three or four years of systematic practice. Developing an ear for music will help accelerate progress. Woodwinds are said to be slightly easier to learn than brass ones; and the most difficult for students are the horn and trombone.

It will be easier to explain to young children what brass instruments are with the help of a video. We invite you to watch the following video:

https://youtube.com/watch?v=46UcdV76tuU

Homemade clamps

Making a wooden fixture

This is the easiest way to meet the need for a clamping tool. Convenience and quality will suit any master. Prepare for production you need simple materials and equipment:

- Rectangular pieces of wood or plywood.

- Threaded studs and nuts corresponding to it: two 20 centimeters long and the same number 12 centimeters long. The diameter must be the same.

- Reiki from oak, beech, birch. They need to be brought to an equal size and polished.

Holes are drilled in them according to the diameter of the studs and symmetrically relative to each other.Plywood blanks are glued on top and cut to the size of the rails. These will be the jaws of the clamp. Holes are also made in them according to the pattern from the rails.

Fastening to the workbench will provide short studs. To do this, in the bar, which will play the role of a fixed part in another plane, two more holes for the studs are needed. One of their ends must be riveted. On the other hand, they are locked with nuts. For convenience, lamb-shaped bars can be welded onto the fixing nuts.

Such a wood clip will be useful for gluing small parts in a garage or workshop

Screw metal tool

A nut of the appropriate diameter is welded to the second. A bolt is screwed in it with the head to the fixed side. On the other side, a perpendicular bar is welded, which will play the role of a crank.

Varieties of clamps

Not everyone can afford to equip their working workshop with a complete set of carpentry clamps. There are many types and sizes of them. Therefore, it is worth considering only their most common types.

F clamps

Clamps are divided into two types:

Light duty (for light use). Such rather thin and narrow devices do not weigh very much and do not take up much space.

Heavy duty (for heavier work).

F-shaped clamps are simple, so they are quite cheap. However, working with them is not very convenient, since you have to hold them with both hands and then twist them.

Tape clamps

Tape clips will provide a uniform pressing force and a strong hold on any workpiece. They can be used to make or repair frames, wooden chairs, countertops, aquariums and more. With this universal fixture, it is convenient to connect, drill and glue fixed parts of the structure at a precisely given angle.

The length of the tape in the belt clips is such that it can be wrapped around the body of any multi-dimensional design, while tightening all the connections at the same time. There is no risk of damaging the tightened parts, since the metal parts of the band clamp will not touch them.

However, in some cases it is not very convenient to work with this type of clamps. This is due to the fact that when installing a corner on one side, on the other, it may fall. In addition, it is impossible to increase or decrease the pressure on one specific plane or axis.

When using tape without corners, it is easy to damage the edge of the edge of the workpiece. Therefore, in addition to the tape clamp, it is recommended to purchase special corners that will significantly expand the functionality of the clamp.

Pipe clamps

You can buy threaded pipes at any hardware store. At the same time, you can purchase not only ordinary pipes, but also galvanized elements. The movable jaw of the clamp will slide best over black pipes, which are also quite cheap. The advantage of galvanized pipes is that they are protected from corrosion. In addition, in contact with glue, unlike simple pipes, elements with such a coating do not leave dark spots on the workpiece.

To protect the protruding threads, you can use special removable caps. To prevent long clamps from bending when tightening, it is recommended to use more rigid elements with a diameter of ? inches.

If, when gluing a large structure and there is no clamp of the required length at hand, you can use two short fixtures.To do this, they will need to be connected by a coupling.

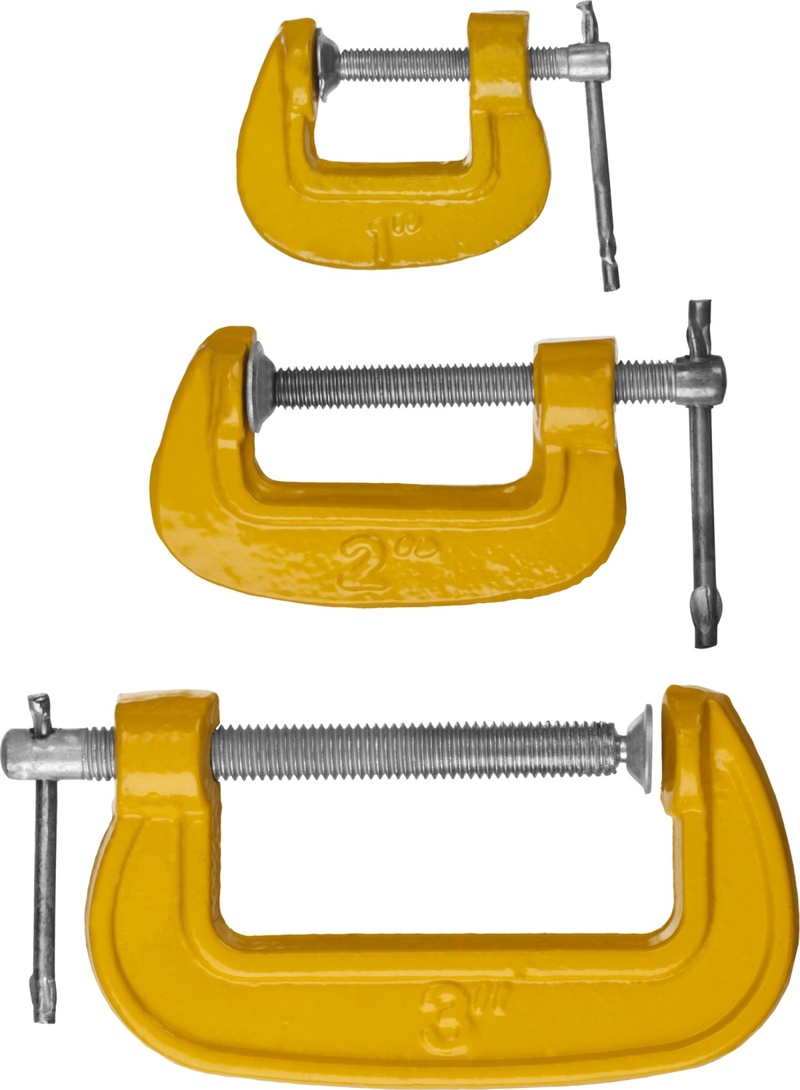

G clamps

G-clamps must be of good quality, as the brackets of cheap clamps bend and are difficult to work with. However, quite cheap lightweight clamps of excellent quality are found on sale.

There are specialized G-clamps with increased grip depth. With their help, you can reach places inaccessible to ordinary clamps. To fix the overlays, edge clamps are produced that can press the workpiece in two directions at once.

Devices are divided according to the type of material of manufacture:

Forged steel clamps allow high clamping forces. Therefore, they can be used even during welding to fix steel beams.

Cast iron clamps are less durable, since brittle cast iron can burst from excessive force.

When choosing a G-clamp, you need to make sure that the screws are large, the surfaces are flat, and the knob is thick and has a rounded end.

Carpentry clamps should be maintained in the same way as the rest of the tool. Stops, rods and jaws of fixtures must be cleaned immediately after gluing. Dried glue is difficult to remove and leaves notches on the wooden parts. In order for the screws of the clamps to rotate smoothly, it is recommended to lubricate them with wax. It is better not to use oil and silicone lubricants, as they can stain the product.

Being practically another "one hand" of the master, clamps can help out if any part needs to be fixed for processing, "hold", and both hands are busy. It is difficult to do without them when assembling home-made furniture or gluing any wooden parts that need to be pressed tightly against each other and connected. Therefore, for carpentry and other work, it is recommended to have carpentry clamps of various sizes and types, while not forgetting to properly care for them.

Classification of wind instruments

Wind instruments are divided into two groups:

- brass wind instruments;

- woodwind instruments;

- keyboard wind instruments.

Initially, this distribution arose due to the materials used to make this or that instrument, but later it became more related to the way the sound was extracted from it. The material of tools made in our time is not limited to copper and wood and can be very diverse - from metal to plastic, from brass to glass, but these tools will still belong to one of the above groups.

woodwind instruments

When playing them, the sound is extracted due to the change in the length of the air column. This can be achieved by opening special holes that are on the tool, and which ones - depends on the distance at which these holes are from each other.

Woodwind instruments are divided into two subgroups: labial and reed. The distribution depends on how the air is blown into the tool.

In labials, air is blown through a transverse slot located on the head of the instrument itself: due to this, the air stream is dissected and promotes internal air oscillation.

The labial wind instruments include the pipe, as well as the flute and its varieties.

In reeds, blowing occurs with the help of a tongue - a thin plate at the top of the instrument, as a result of which the air column begins to oscillate.

Reed wind instruments include: saxophone, clarinet, bassoon and their varieties, as well as instruments such as balaban and zurna.

brass instruments

From the method of sound extraction, caused by a certain position of the lips on the instrument and the force of blowing in an air stream, the instrument's belonging to the brass depends.These wind instruments used to be copper, later brass, and sometimes silver.

Brass wind instruments are also divided into subgroups.

The peculiarity of valve instruments is that they are actually equipped with three or four valves, which are controlled by the player with his fingers. They are needed in order to increase the length of the air jet by increasing the length of the instrument itself and thus lower the sound. This happens when the valve is pressed, when an additional crown is included in the tube and the tool is additionally lengthened.

Valve instruments include: trumpet, horn, tuba, saxhorn and others.

But natural wind instruments do not have additional pipes at all: they extract sounds only from the natural scale and are not able to play melodic lines, so they practically ceased to be used at the beginning of the 19th century. This subgroup includes the bugle, fanfare, hunting horn and similar instruments.

An additional retractable tube in the shape of the letter U, which is called the wings, characterizes a type of brass trombone. The movement of this tube affects the length of the air stream, respectively, and the tone of the sound.

Keyboard wind instruments

Keyboard wind instruments are distinguished separately in this classification. Their peculiarity is that in their structure there are reed and movable tubes - air is pumped into them through special furs.

Among them there are two subgroups:

- reed - harmonium, accordion, melody, button accordion;

- pneumatic - an organ and some of its types.

Types of clamps

There are a lot of such tools in trade organizations. All of them are of different shapes and made of various materials. Each device has its own purpose and design features. Like other equipment and accessories, clamping mechanisms have their own classification:

- For uniform distribution along the entire length of the pressed, coaxially located surfaces, a G- or C-type tool is used. Especially widely they are applied to pasting of joiner's products. It is a versatile, lightweight and comfortable design with high clamping force. Sponges are fixed rigidly, without swaying. They are cast in one piece or produced by forging steel. Used for narrow parts.

- F-shaped products are characterized by a large capture depth. They consist of an axle rod with two jaws. On the displaced one there is a locking lever with an eccentric for determining the desired clamping zone and preventing the workpiece from slipping out. For products of various dimensions, there are F-shaped clamps of two varieties: light duty for light and heavy duty for heavy ones. It is not very convenient to work with such a device alone, because at the same time you have to hold the workpiece and fasten it in the jaws.

- Three fixing elements became a characteristic difference of the end clamp. This is the main inconvenience in use. When you hold the workpiece with one hand, it is problematic to tighten all the stoppers at once. However, with its help, carpenters solve the issue of clamping edge and end planes.

- There are many design options for angle clamps. At the heart of its body with one or more patches on a screw stud. For fixing at an angle of 90 degrees, this is the most indispensable thing. However, use with large parts is difficult.

- In carpentry and locksmith production, quick-clamping automatic clamps will help with fastening parts of any size. The size depends only on the number of clamps themselves. These are light and durable tools with reinforced plastic jaws. Their design does not scratch the surface when clamped. Fixation occurs due to the spring mechanism, which allows you to cope with the work alone.However, a quality tool is expensive, and cheap analogues quickly fail.

- Spring-loaded strings work on the principle of clothespins. Their clamping force is constant, with a small depth. The optimal area of application will be working with small fragile workpieces without assistance.

- For accurate clamping of rounded and corner parts, tape clamps are used. Their design allows you to work with products of any size. The kit includes a tape made of synthetic materials of increased strength and a tensioner. For gentle impact, plastic corners are added to it.

- For large products and panel structures, pipe clamps are used. They include a half-inch or three-quarter pipe, an emphasis and a mobile jaw with a lock. This is an inexpensive product with a lot of clamping force. If necessary, such a device is made independently.

Purpose and design

The simplest clamping device consists of two parts: a movable and a main one, standing still. With the help of a screw, the first part moves to the second and is locked in the desired position by the clamping part. This function is performed by screws, levers or ordinary rods. The device of a vice and fixing elements of meat grinders is also conventionally referred to this type of auxiliary tool.

The scope of use of clamps is extensive. The first thing that comes to mind at the mention of this tool is gluing, when the halves must be kept clamped for a long time. It is unrealistic to do this with your hands, so the simplest carpentry clamps are purchased.