List the main types of insulation and their brief description

Insulators are divided according to their properties and method of application, but today the variety of materials is so large that it is very difficult to describe all the options, so only the most popular methods will be affected.

stone wool

Stone wool is a material that is used everywhere, it is preferred by many developers. The popularity of cotton wool is based on easy installation, since special skills are not required and you can get by with improvised tools.

Due to its distribution, cotton wool can be found in almost every major hardware store, while transportation is possible even in your own car. The main requirement for the installation of wool is its installation density - there should be no gaps.

Styrofoam

Styrofoam is a cheaper and moisture-resistant insulation, but at the same time it is quite fragile. Installation of foam plastic is somewhat more difficult and requires some experience in this area. Since the material does not absorb moisture, there is no need for moisture / vapor barrier membranes, which reduces the cost of the project.

The performance characteristics of polystyrene are somewhat repulsive to many people, which is why serious disputes flare up around the material. As negative points, they note that the material is not at all environmentally friendly and people complain about the deterioration of well-being after warming.

Mineral wool

Mineral wool is often used in construction due to its high thermal/sound insulating properties, and minerals are increasingly gaining popularity in private construction.

Cotton wool has the appearance of fibers, which are several times smaller than a hair, and all this is in a compressed form. The length of the fiber is 10-15cm.

Due to the presence of a huge number of air cavities in the material, heat is perfectly retained, and with it sound. Installation of wool is as simple as possible due to the flexibility and elasticity of the blocks, while there is no tendency to deformation. There is no risk of fire.

There are many other types of heaters, such as:

Additional insulation of the frame house

During the construction of a frame house, heat-insulating materials are placed between the racks of the frame, and then they are sewn up with slabs from the inside and outside. If this insulation is not enough, you can additionally equip external thermal insulation.

Warming the outside with mineral wool, a vapor barrier membrane is attached from the inside, which protects the thermal insulation from condensate, that is, air vapor from the room.

For this, aluminum foil, polyethylene film or a special vapor barrier film with a ventilation function is used. The latter option is more expensive than others, but from a technical point of view, this is the best solution.

To protect the insulation from blowing, a windproof layer is attached from the outside. OSB, chipboard or plywood can be used as the inner lining. The outer skin is made with eurolining, siding and other materials.

The walls of a frame house can be insulated from the inside. This method of thermal insulation has a lot of serious drawbacks. When the walls are insulated from the inside, condensation forms in the structure. The dew point for internal insulation will be in the supporting frame structure. If you cannot do without internal insulation, you can perform thermal insulation using liquid foam insulation.

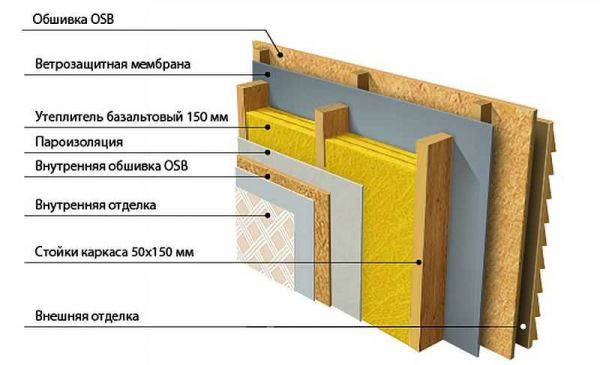

Frame wall insulation pie what elements it consists of

There are several basic options for building a frame house, the first is a factory one, when ready-made blocks are initially bought, it is called frame-panel. Another method is to arrange and assemble the panels on site, essentially by hand.

Both options should include several important layers, each of which has its own specific function. In fact, there are only 5 main layers:

- So the first, of course, is the facade cladding, this also includes the external insulation, so the function is an attractive design and protection from temperature changes;

- Further, the windproof membrane protects the house from drafts, removes moisture and thereby retains heat;

- The frame itself, it always contains some kind of insulation;

- The vapor barrier layer protects the insulation from the penetration of water vapor, which in turn ensures the durability of the building;

- Internal lining. There are no special standards here, you can use internal insulation, a variety of decor and everything that seems appropriate to the owner.

Internal and external insulation features and nuances

Each insulation option deserves its right to exist, as in some situations it shows better results. The advantages and disadvantages of each method should be analyzed point by point.

Internal insulation has a higher heat retention coefficient, so energy costs will be minimal.

This is due to the fact that there is no need to warm up the walls, most of the air is retained directly in the room. The situation is twofold, since walls can also collapse due to a shift in the dew point. So the moisture from the cold air will be transformed into drops almost in the room itself.

Comparison of insulation methods

Also, the internal insulation option is easier to install; you can get to the wall using a simple stepladder.

In contrast to this advantage, there is a nuance - this is a decrease in the variety of wall decor, that is, the insulation is less durable and the fastening of some structures can be difficult. It is logical that the construction of an additional layer on the walls leads to an overall decrease in the area of \u200b\u200bthe house.

It is highly not recommended to use foam and its derivatives due to the synthetic origin of the material and the increased risk of fire. Releases toxins when burned

We recommend paying attention to eco-insulation

External insulation is a more standard and safer way to keep warm. This type of insulation has the following advantages:

- The walls are protected from destruction and are less affected by weather phenomena;

- Does not take up space in the room;

- Less requirements for the environmental component of the insulation;

Wall insulation technology with basalt wool

Basalt slabs are attached to the wall with glue. It is necessary to install the insulation on the treated area from the bottom up and from right to left.

Work on wall insulation with basalt wool begins with the installation of a special cornice made of metal. The cornice is placed in the area of \u200b\u200bthe base and attached to the wall from below. To install such a cornice, you can use dowels. The main function of this design is easy laying of thermal insulation material and protection from rats or mice, if any. Rodents simply will not be able to get inside.

Next, an adhesive polymer-cement composition is taken, which is unable to harm the heat-insulating material. Clay solves the second very important problem. It serves as a bonding mixture for directly insulating material and wall construction. On the surface of the insulation, the composition is distributed evenly.

A basalt wool slab smeared with glue is applied to the wall and pressed down a little to adhere to the wall surface. Installation of insulation should begin from the bottom of the treated area, gradually moving up. The laying is carried out from right to left.

Initially, solid slabs of heat-insulating material are installed.The remaining places are sealed with pieces, the size of which should correspond to the area of the raw surface.

Basalt wool as a heater for the walls of a frame house has a number of advantages, one of which is its low weight, so that the slabs are laid very quickly and without any problems.

After the insulation is laid, take a sanding trowel and level the surface so that a vertical plane is obtained without any protrusions. When carrying out such activities, it is necessary to check whether the thermal insulation system contains cracks at the joints, which, if found, must be eliminated.

Characteristics and types of material

Mineral wool is a special synthetic material, which includes inorganic fibers.

The production process of mineral wool is the melting of broken glass, basalt and dolomite, followed by a run through a centrifuge.

Under the action of centrifugal force, liquid substances are stretched into fibers, from which pressed plates or rolled materials are produced.

The technology for the production of insulating material creates a huge number of air chambers inside the finished mineral slab (up to 90% of the total volume), due to which the wool does not allow cold air from outside to enter the house and keeps it warm inside.

The advantages of mineral wool are its low cost, ease of working with the material and high thermal insulation performance.

In addition, mineral wool is a refractory and soundproof material with increased plasticity, which facilitates the process of installing insulation with your own hands.

The disadvantages of the material include low resistance to moisture and the presence of formaldehyde in the composition. All these disadvantages are successfully leveled in the course of construction work.

So that mineral wool is not afraid of moisture, it is covered with a waterproof material.

Before the process of insulating the walls of a frame house with mineral wool, you need to figure out what types of material actually exist.

To date, there are three types of mineral wool on the market:

glass wool. Durable and resilient material, which includes glass

When installing this type of insulation, you must be especially careful and wear overalls, as microscopic glass particles can damage the skin;

slag. The fibers of the material made from blast-furnace slag are thicker than that of glass mineral wool

A feature of slag wool is increased moisture absorption, therefore it is not recommended to insulate metal surfaces with it;

basalt wool. The fibers are made of basalt rock. The material does not require special precautions during operation. High temperature resistance of the material allows it to be used at extremely low and high temperatures (from -190⁰ C to +1000⁰ C).

All three types have high thermal insulation properties and are suitable for frame houses.

The cost of glass wool is lower than other varieties, but its density is lower than materials from slag and basalt.

Therefore, glass insulation retains heat worse, which means that its layer during installation should be thicker.

Mineral wool can also differ in the structure of the fibers. There are corrugated, spatial, vertically and horizontally layered. The structure depends on the material used in the production.

Specifics of house insulation from sandwich panels

Insulation of any building should be comprehensive - from the foundation to the roof. Canadian houses are no exception.

Only a comprehensive approach to insulation will give a real effect.

These are light houses that do not require a strong foundation, and if the project does not include a basement or ground floor, then in many cases they put the foundation on piles. And in order to reduce heat loss through it, a heat-insulated pick-up (base) is equipped.

In most cases, the floor insulation of a house from sandwich panels follows the classical scheme, in which wooden ceiling beams and transverse beams act as load-bearing components, and mineral wool is installed between them. So that the heat insulator does not “fall out”, a filing of boards holds it from below (a grid is used as a replacement). The base floor is laid on top, as the basis for the final coating.

Insulation of frame walls with mineral wool is carried out according to the following scheme: it is placed between racks and spacers, which are sewn up with sheet-type materials or a board. The cross section of the beam for the uprights determines the layer thickness min. wool, but this condition is not considered the main one when choosing the size of the bearing components. For the strength of the walls of a house made of sandwich panels, especially on one floor, a rack with a section of 50x150 millimeters is enough. For the southern regions with a "soft" in the winter period of such a thickness of min. cotton wool is absolutely enough. However, it is not enough for other regions.

Scheme of a frame wall with a beam 150 mm high

The use of a bar with a height of 200 mm is often redundant in terms of the bearing parameters of the frame, and in such cases it is more cost-effective to make additional insulation from the outside.

Important! What is the thickness of the layers min. wool is needed to insulate the house can only show a calculation carried out on the basis of the current standard, taking into account the specifics of the region and the parameters of all fencing surfaces. Insulation work of the roof depends on the nature of the operation of the attic space

Non-residential, or "cold", attic floors are insulated exclusively along the ceiling. For attics and used attic floors, in which engineering equipment is installed (for example, hydraulic accumulators, ventilation systems and cooling systems), the roof itself is insulated

Insulation work of the roof depends on the nature of the operation of the attic space. Non-residential, or "cold", attic floors are insulated exclusively along the ceiling. For attics and used attic floors, in which engineering equipment is installed (for example, hydraulic accumulators, ventilation systems and cooling systems), the roof itself is insulated.

From the point of view of heat engineering, the walls of a house made of sandwich panels are single-layer. In order for them to pass into the category of three-layer (structural material / heat insulator / structural material), the thickness of the outer layers of the enclosing surface must be more than 50 mm, in accordance with the thickness of the material for insulation, not less than 1 / 1.25 (clause 8.11 of SP 23-101- 2004). However, in reality, the structure of the walls of a house made of sandwich panels has 5 main layers, not counting the facade decoration and interior. A vapor barrier film (from the side of the room) and a hydromembrane (from the side of the street) are placed between the skins and thermal insulation. And such placement is dictated by the characteristics of min. cotton wool.

Use of other thermal insulation materials

Proper wall insulation provides for preparatory work performed according to the same algorithm. Otherwise, the procedure for thermal insulation of a frame house with any material is similar, the slight differences are only in the methods of laying the insulation, which will be discussed below.

The use of expanded polystyrene (styrofoam) and XPS

There is a lot of controversy between many builders and just owners of private houses about the use of polystyrene foam as a heater. And in fact, this material is far from an ideal option, although it is one of the best when compared with analogues in thickness. Insulation with foam plastic and extruded polystyrene foam differs little, therefore, the nuances of the work can be described in the same way.

Expanded polystyrene is a combustible material, therefore it is necessary to exclude its use near sources of fire.In addition, it is required to equip the ventilation of the room where it will be used, since polystyrene foam does not allow air to pass through. At the same time, it also does not allow liquids to pass through and does not absorb them, but it cannot be used as the only layer of waterproofing. Additional protection against moisture and steam is needed in order to protect the frame of the house. And it should also be borne in mind that rodents are very fond of the material, therefore their access to it should be excluded.

These are the main features of foam and materials based on it. Otherwise, working with the material resembles that with mineral wool.

Ecowool insulation

Ecowool is a novelty in the construction market and is used not only in private frame houses, but everywhere.

It is possible to make insulation using this material without the use of special equipment, but it is still not recommended to do this. This is due to several reasons. When using a special tool, ecowool can be applied evenly, filling all the voids. In addition, hand-prepared material will have poorer thermal insulation and shrinkage characteristics.

Since ecowool is exposed to moisture, the layers of vapor-waterproofing must be made with especially high quality. The material should be applied in excess, as shrinkage of up to 15 percent is possible in the future. When working with the material, be sure to use protective equipment.

Thermal insulation with expanded clay

This material is not commonly used these days as there are many alternatives with better properties, but it still needs to be mentioned.

Expanded clay in its dry form is used as thermal insulation for floors, ceilings and interfloor ceilings. Its use for insulating the walls of a frame house is problematic, although possible.

Often, expanded clay is mixed with sawdust, ash and similar materials. To apply the material, it is required to close the ceiling and the floor under the logs closely with boards or plywood sheets. It is recommended to use expanded clay of small fractions, this will reduce the number of voids.

Features of warming a frame house

Insulation of any building should be comprehensive - from the foundation to the roof. Frame houses are no exception.

Only an integrated approach to insulation will give a real effect.

Only an integrated approach to insulation will give a real effect.

These are light houses that do not need a strong foundation, and if the project does not include a basement or basement, then in most cases they put a pile foundation. And in order to reduce heat loss through it, they equip an insulated pick-up (basement).

Usually, the floor insulation of a frame house follows the traditional scheme, in which wooden floor beams and logs act as load-bearing elements, and mineral wool is mounted between them. So that the insulation does not “fall out”, a filing of boards holds it from below (a grid is used as an alternative). A rough floor is laid on top, as the basis for the topcoat.

Warming of frame walls with mineral wool occurs according to the following scheme: it is laid between racks and struts, which are sheathed with sheet materials or a board. The section of the beam for the racks determines the thickness of the mineral wool layer, but this condition is not the main one when choosing the size of the bearing elements. For the strength of the walls of a frame house, especially a one-story one, a rack with a section of 50x150 mm is enough. For southern regions with a "mild" winter, this thickness of mineral wool is enough. But for other regions it is not enough.

Scheme of a frame wall with a beam 150 mm high

Scheme of a frame wall with a beam 150 mm high

The use of a beam with a height of 200 mm is often excessive in terms of the load-bearing properties of the frame, and in such cases it is more cost-effective to perform additional external insulation.

Roof insulation depends on the nature of the operation of the attic. Non-residential, or "cold", attics are insulated only along the ceiling.For attics and operated attics, in which engineering equipment is installed (for example, hydraulic accumulators, ventilation and cooling systems), the roof itself is insulated.

From the point of view of thermal engineering, the walls of a frame house are single-layer. In order for them to pass into the category of three-layer (structural material / insulation / structural material), the thickness of the outer layers of the enclosing surface must be more than 50 mm at a ratio with the insulation thickness of at least 1 / 1.25 (clause 8.11 of SP 23-101-2004) . But in reality, the structure of the walls of a frame house contains 5 main layers, not counting the facade and interior decoration. A vapor barrier film (from the side of the room) and a waterproofing membrane (from the side of the street) are laid between the skins and the thermal insulation. And this arrangement is dictated by the properties of mineral wool.

What mineral wool is used for thermal insulation of a house made of sandwich panels

The term "mineral" refers to three different materials: fiberglass wool, slag wool and basalt wool. For thermal insulation of houses for housing, including frame houses, the final version is used.

Fiberglass-based wadding is fragile, and when laid, a small “dust” of faulty fibers is formed, which is dangerous not only for workers, but also for residents. Slag wool has low ecological qualities.

Mineral wool for a house made of sandwich panels can have very different densities depending on the type of insulated surface and the method of thermal insulation.

Select min. wool is so large that it can be used to insulate any surface of the fence and structures

Important! Basalt wool is a special material. Its heat conductivity does not directly depend on density - the structure and production technology are important

Due to this, rigid boards or mats can have better thermal insulation properties than soft materials in a roll.

According to the type of enclosing surface, the following types of materials are used:

- rigid slabs - concrete ground floor, reinforced concrete floor on a tape-type foundation above the basement or lower floor (for laying floor tiles);

- semi-rigid slabs and mats - frame-type walls, attic or roof of an exploited attic floor;

- mats and rolls - wooden floors on wooden bars and ceilings.

Note. When choosing a density of min. wool for the walls of the house of sandwich panels have specific limitations. For "internal" insulation, materials with a density of 35-50 kg / m 3 are recommended, for external (according to the hinged facade technology) - not less than 80-90 kg / m 3. There are no such contraindications for wooden floors and ceilings, mineral wool of any density can be used, and the main criterion is how much such a heat insulator costs.

Insulation of the walls of the frame house from the outside

In order for the insulation of the house outside to be effective, the layer of mineral wool must be at least 15 centimeters.

To calculate the amount of material that will be needed for work, you need to know the height of the external walls of the building and its perimeter.

To get the number of cubic meters of mineral material that will be needed for work, you need to multiply the surface area by the thickness of the cotton wool layer, for example, if the thickness of the plates is 20 centimeters, then multiply by 0.2.

To understand how to properly insulate a frame house from the outside, you should know the technology for performing work.

There are two ways to externally insulate a building with mineral wool:

- the first method, suspended installation, assumes that a frame will be built on the outer surface of the walls of the house, between the racks of which mineral wool will be inserted;

- the second method is called wet - in this case, the insulation boards are attached to the walls using a special adhesive.

To prepare the wall surfaces for the installation of mineral wool in a hinged way, they are thoroughly cleaned of dust and dirt, metal elements are removed to avoid corrosion.

If the walls are wooden, then they need to be treated with an antiseptic.

After the preparatory work, a layer of vapor barrier is laid on the surface, hinged structures are attached at an equal distance on top - wooden beams, which will serve as a frame for mineral wool.

Mineral wool is laid in the grooves between the posts, the plates at the joints are fastened with glue. A waterproofing is attached on top of the laid insulation; on top, the structure can be sheathed with decorative materials.

To insulate a frame house in a wet way, you need to properly prepare the surface of the walls: prime them or plaster them.

When the walls are prepared, a metal frame is mounted along their bottom, which will serve as a support for the mineral wool slabs.

Mineral wool is laid in the likeness of brickwork, sparsely lubricating the joints with an adhesive.

Video:

After the laying is completed, the insulation layer is left to dry for a day, after which the structure is attached with dowels to the wall of the building.

Fasteners with wide caps are driven through mineral wool slabs into the wall so that their caps do not stick out over the insulation.

A reinforcing mesh is attached on top of everything, and after a day you can cover the insulating layer with plaster

Important: the plaster layer should not be thicker than the insulation layer

Mineral wool guarantees high-quality insulation of the frame house, subject to all the rules for installing the material.

If the laying work is done correctly, then inside the building it will always be warm and comfortable.