Roof insulation

Before you begin to insulate the roof of the bath, it is necessary to treat the surface of the roof, rafters and beams with antiseptic flame retardants to protect structures from decay and high temperatures.

If poor quality, rotten elements are found in the process, they must be replaced.

Further, waterproofing material is strengthened over the entire surface of the roof. As such, a membrane film is usually used, but polyethylene can be used.

The film is spread before installing the crate, the rafters wrap around it along the entire length. The film is fastened without tension, with an overlap of 10 cm. The seams and joints are insulated with adhesive tape, preferably foil.

After that, the laying of the insulation begins. If you have chosen material in the form of plates, it is installed between the rafters by surprise. The best option would be to lay the slabs in two layers, so that the second layer overlaps the joints of the first. In this case, the likelihood of cold bridges between the joints will decrease.

https://youtube.com/watch?v=1oq77y9dl6M

Each layer should be at least 10 cm thick. If the width of the rafters does not allow laying a layer of such a thickness, they will have to be increased by nailing a timber of the required thickness to them from above. You can try to save on insulation by reducing the layer thickness to 5 cm. However, this will require laying an additional layer of vapor barrier.

The insulation is fixed with the help of a crate, which is stuffed onto the rafters every 30-40 cm. You can use a cord or fishing line as a fastening, which is pulled across the insulation.

This method of fastening will help, among other things, create the necessary air gap between the insulation and the next layer of the roofing pie - vapor barrier.

Vapor barrier materials

Foil, roofing felt, membrane coatings can act as a vapor barrier material. You can do without a vapor barrier if you use mineral wool foil boards as a heater.

The vapor barrier layer is attached to the rafters using a construction stapler. Laying is carried out without tension, overlapping, preferably in two layers. The joints must be taped with tape to protect them from damage.

Roof insulation is carried out if it is necessary to use the attic space. Therefore, to do without interior decoration will not work. Lining or any wall panels are well suited as a finishing material.

Warming technology

In order for the adoption of bath procedures to be comfortable, it is necessary to follow the technology of warming the roof of the bath:

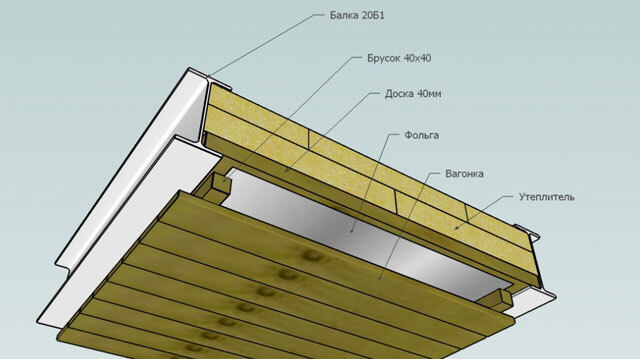

- A vapor barrier layer is being installed. To do this, you need to purchase special materials. The vapor barrier is fixed between the beams. Foil tape is glued to the knocks.

- A crate is nailed over the vapor barrier. As a rule, the distance between the bars of the crate is 60 cm. However, the dimensions of the selected insulation should be taken into account.

- Insulation is laid or filled up, while there should not be free space left. The thickness of the layer depends on the climatic conditions of the area where the bathhouse is located. Thermal insulation characteristics are directly dependent on the thickness of the layer, that is, the thicker it is, the better the thermal insulation. But there is no need to make the layer excessively thick. In most cases, 15-20 cm is enough.

- Slots should be filled with mounting foam.

- A thermal film or polyethylene is laid on top of the thermal insulation. A waterproofing layer is required, if it is absent, the insulation will quickly become unusable. The film is fixed with a construction stapler.

- The ceiling is sheathed with finishing material. The best option is eurolining, but you can use ordinary boards.

Here is a general action plan for warming the roof of the bath.The technology for performing insulation can be changed depending on the type of ceiling construction.

Why it is worth insulating the roof of the bath interesting for dummies

so that the roof of the bath well protects the room from external adverse factors, becomes vapor-tight and has good ventilation, it should definitely be insulated. It is this solution that will keep the heat in the steam room for a long time, what will the process of staying in her comfortable. Of course, when choosing a method of insulation, it is worth considering how often visitors will be in the room. If the bath will be used only occasionally, then thinner and cheaper materials can be used for insulation, but for a room in which they will be constantly steamed, more serious insulation needs to be done.

It is possible to insulate the roof, both during the construction of a bath, and already finished premises, choosing for this purpose the appropriate high quality materials. To insulate the roof of the bath with your own hands, you will have to stock up on forces, materials and tools that will come in handy for the work.

Thermal insulation of the floor ceiling

The flooring method allows you to build a ceiling without the use of beams. In such a situation, the flooring of the boards is carried out on the strapping or on the upper crowns. Great for steam rooms with an attic space.

The most budgetary and easiest option for self-arrangement of the ceiling. With this method, the insulation from the side of the roof does not close, so you will not be able to use the attic in the future. In addition, any repair work related to the ceiling will require the replacement of insulation, which is not very convenient.

Directly thermal insulation work begins with the fact that first a rather thick layer of clay is laid on the ceiling boards. Next, you need to wait until the clay is completely dry, lay the selected insulation on top and cover it with a layer of loose vapor barrier. Before starting work, you need to place a box around the perimeter of the attic, which will serve as a fence for loose thermal insulation.

Warming can be done with wood chips mixed with cement. This material will allow you to fill all hard-to-reach places and get the highest quality thermal insulation.

Choice of materials

Regardless of whether the attic space will be used, it must be vapor-insulated. Click on the photo to enlarge.

If the attic of the bath is not used in any way, special roof insulation is not required. It will be enough to provide steam and thermal insulation of the ceiling of the bath and the floor of the attic.

If you want to use the attic as a place to relax, or to dry clothes and store bath equipment, capital insulation will be required.

To insulate the roof of the bath, almost any insulating material is suitable - polystyrene foam, glass wool, mineral wool, synthetic heaters such as "Ursa".

It will be good to use mineral wool with a foil side.

When choosing how to insulate the roof in the bath, pay attention to materials that are resistant to high temperatures and high humidity.

Steam and waterproofing

Before starting work on insulation, all roof elements must be treated with antiseptics and fire retardants.

Membrane coatings are usually used as a material for waterproofing.

The waterproofing film is laid on the rafters before the installation of the crate. The film, which serves as a vapor barrier, is mounted between the lining and the ceiling insulation.

The film is laid freely, without tension, with an overlap of strips of 10-15 cm. Seams and joints are glued with adhesive tape to seal and prevent stretching and tearing in case of temperature deformation of the film.

Ceiling insulation procedure

Insulation of the roof of the bath implies the obligatory installation of a vapor barrier layer. The vapor barrier is fixed between the beams. Special ready-made materials are available for sale, so you will not have any problems with the purchase.Joints must be glued with foil tape.

vapor barrier

A crate is mounted on the vapor barrier. The standard step between the bars of the crate is 60 cm. You also need to focus on the dimensions of the selected insulation.

When choosing the layer thickness, the determining parameter is the climatic conditions of the area in which the bath is located. The thicker the layer, the higher will be its thermal insulation characteristics. However, you don’t need to make it too thick, there will be no point in it. Usually a layer of 15-20 cm is sufficient.

The laid thermal insulation is covered with thermal film or polyethylene. This is a mandatory moisture-proof layer, without which the service life of thermal insulation will be significantly reduced. To fix the film, it is most convenient to use a construction stapler. In the end, it remains only to sheathe the ceiling with the selected finishing material. It is best to use eurolining for this, but simple wooden boards are also suitable.

Bath roof insulation

This is how the process of warming the roof of the bath looks like in general terms. Depending on the design features of the ceiling in your bath, the technology of the thermal insulation device may undergo certain changes.

Stages of work on roof insulation

First of all, it is necessary to treat all wooden elements of the roof structure with an antiseptic. This will increase the resistance of the rafters to moisture. You can also treat wooden structures with fire retardants. To save money, such processing can be done within a radius of several meters from the chimney.

Insulation installation

After processing the rafters with the appropriate compounds, you can start warming the roof of the bath. In the process, you must follow the following sequence of work:

- For laying between the beams, if necessary, the insulation is cut with your own hands to the appropriate size.

- In this case, the width of the sheet must be made 2-3 mm more than the distance between the rafters. This is done for a tighter fit of the material to the beams.

- After that, a vapor barrier membrane is laid on the insulation.

- On top of the rafters, the insulation is sewn up with boards. It is possible to use other sheet materials: chipboard or plywood.

Particular attention is paid to do-it-yourself insulation around the chimney. In this place it is better to do the following:

- Build a frame around the chimney pipe from a galvanized iron plate 25–30 cm wide.

- The resulting space between the chimney and the frame must be filled with non-combustible and refractory material. For these purposes, asbestos inserts of a suitable size are used.

- The same manipulations must be performed at the place where the pipe passes through the ceiling of the bath.

On this, the roof itself is considered insulated, but there are still some nuances.

Don't forget the ceiling

In order for the insulation of the roof of the bath to be really done correctly, it is necessary to take care of the waterproofing and insulation of the ceiling of the bath. To do this, there are several methods that differ from each other in the way they solve the problem.

- A layer of vapor barrier is laid on the ceiling of the bathhouse, which was previously hemmed with boards, from the side of the attic. The use of foil material is recommended. In this case, the foil layer is laid on the boards (face down).

- Then, a heater is placed in the inter-beam space. Optimally suitable for this is pressed basalt wool, as the most natural material.

- Then boards or plywood are laid on the beams, thus forming the floor of the attic.

- Ordinary clay is mixed with water until a homogeneous greasy mass without lumps is formed.

- Sawdust is added to this mass and thoroughly mixed to a state of viscous mastic.

- This mass fills the draft ceiling from the side of the attic. The minimum required layer is at least 15 cm.

- The joints and seams between the walls and the ceiling are especially carefully sealed.

- After applying this mass, it is covered with a layer of sawdust, shavings or straw from above.

Arrangement of ventilation

Having dealt with the question of how to insulate the roof of the bath, do not forget about the need to equip the ventilation of the attic of the bath. Proper ventilation with your own hands can be done in several ways:

- Equipment of several dormer windows (at least two).

- Install two ventilation pipes. Their installation should be carried out on different sides of the attic.

- You can also increase the ventilation gaps by installing the roof ridge a little higher.

How to choose a heater

If the construction time is not running out, and you want to save money, you can use folk methods of insulation. For example, coat the ceiling with a mixture of sawdust and clay.

Or lay out the floor of the attic with moss and sprinkle wood ash on top. The reliability of such methods of insulation has been tested for centuries.

However, today there are modern materials that are more convenient to install. Unfortunately, not every one of them is suitable for warming a bath.

When deciding how to insulate the roof in the bath, take into account the following material properties:

- thermal insulation characteristics.

- Resistant to high temperatures.

- Susceptibility to moisture.

- Environmental friendliness of the material.

The last point is especially important. Synthetic materials under the influence of high temperatures can begin to release toxic substances, which will adversely affect the health of bath users.

For roof insulation, it is most often recommended to use mineral wool (preferably foil-coated), Penoplex boards, extruded polystyrene foam, basalt boards, and felt. Expanded clay chips are suitable for warming the attic floor.

Steam and waterproofing

The first stage in the work on roof insulation is the treatment of structures with antiseptic preparations that prevent wood decay. To prevent fires, the roof is treated with flame retardant compounds. For waterproofing, membrane films are often used that protect against moisture, the film is laid on the rafters before the installation of the crate, and is intended for vapor barrier between the ceiling insulation material and the ceiling filing. The film material is laid without tension, overlapping with an allowance of 20-25 cm. The film sheets are connected with strips of adhesive tape, due to which there are no stretching, tearing, no deformation when the temperature rises.