outdoor work

For more reliable protection of the premises from heat loss, it is necessary to insulate the window slopes from the outside. The best material for these purposes is penoplex. You will also need a special sealant for outdoor use. In a private house, you can do the work yourself, and in a multi-story house it is better to use the services of professionals.

The technological sequence of operations is as follows:

- Clean the surfaces of external slopes from dust, dirt, paint residues, finishing and building materials.

- Level with cement mortar, allow the layer to dry.

- Cut the insulation into pieces of the desired size.

- Lubricate the sheets with glue and install on the slopes. In addition, fix in several places with dowels.

- Mount corners. Do not neglect this step. As a result, you will get not only insulated, but also even slopes.

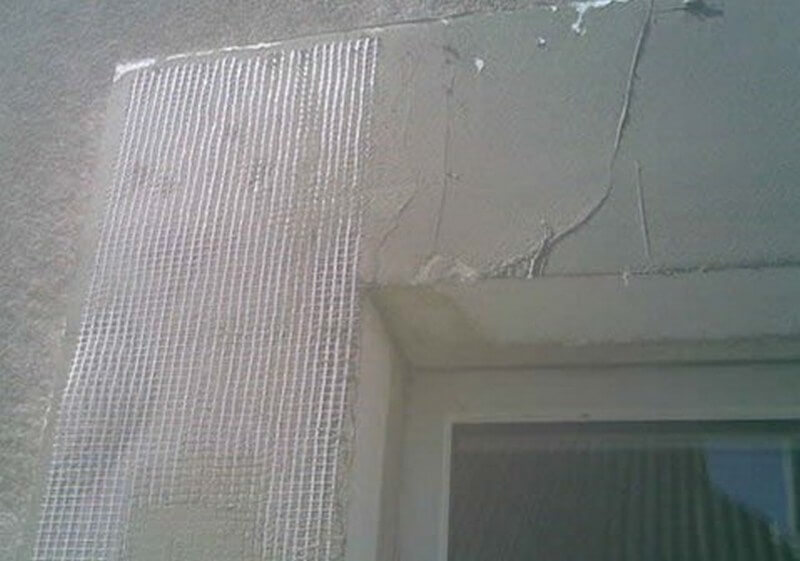

- Treat the front surface of the foam with special glue and fix the reinforcing mesh.

- Level with putty.

- After drying, apply water-based paint or other finishing materials.

Do not ignore the issue of slope insulation. The microclimate in the house and the size of electricity bills depend on how well and timely this will be done. Moreover, the whole process can be carried out independently.

How to make external slopes for foam windows step by step

Step 1: Preparing the Adhesive

Before proceeding with the installation, you need to prepare a suitable adhesive solution in advance. According to experts, Ceresit brand st-85 glue is most suitable. The adhesive composition is mixed very carefully - so that no lumps remain in the mixture. Stir until the mixture thickens: the glue should not flow down the spatula. Do not forget to prime the area around the window where the slopes will be installed.

Step 2: Installation of slopes

After that, we rub glue into the wall - this method will ensure the highest quality adhesion between the surface of the walls and the foam. Next, having already made a foam blank, we apply glue to the products, and for convenience it is best to use a notched trowel. Begin work on gluing from the bottom of the product, while checking the correct gluing of products. To do this, use the building level. It is desirable to glue the joints of the strips of our slopes with high quality. Having finished gluing around the entire perimeter, you need to coat the existing seams with glue again.

Do not forget to glue the place where the window sill will be installed. After that, we proceed to the installation of the side slopes in contact with the window frame. Glue should not be spared during work, otherwise voids may form between the frame and the slopes. Excess composition is carefully removed with a damp sponge. We coat all the joints between the material again - this completes the installation of the slopes.

Step 3: Material finishing

While the adhesive dries, we finish the foam to give it a good appearance. In this case, we once again process the slopes with an adhesive solution and mount the fiberglass

Do not forget about the importance of pasting the outer and inner corners with perforated corners. After the surface is completely dry, the foam is covered with facade paint in several layers.

To prevent the composition from getting on the glass (which will be very difficult to clean), paste over the perimeter of the double-glazed window with a wide piece of construction tape. But to carry out a fine (finish) finish, rely on your tastes, since modern manufacturers will be able to offer you a wide selection of goods. So, you can buy a color scheme that will change the color of the slopes, acrylic paint with small particles is also suitable - this will create an unusual effect.

Why is it worth insulating

First of all, it is worth noting that insulation is an essential part of a high-quality installation of a window system, which subsequently will not only last longer, but will be distinguished by high functionality. The main reasons for requiring insulation:

- The frame of the window does not adhere tightly to the surface of the slopes, leaving corresponding seams, which are often filled with mounting foam to seal. This material shows excellent thermal insulation properties, but often reacts to moisture and temperature changes, undergoing destruction and loss of basic functions.

- Window frames, devoid of additional decoration, are poorly protected from the influence of external factors. If insulation is not carried out, the joints will be subject to water ingress, which, under the influence of low temperature, leads to the destruction of the fasteners and the window to sag.

- After shrinkage of the structure, free spaces are formed between the window frame and openings, which lead to freezing and cold air inside the room.

- Insulated windows are not characterized by the accumulation of condensate from the inside, leading to the formation of fungus or mold.

In addition to functionality, the insulation of window slopes will give the structure a stylish appearance that will harmoniously merge with the interior of the room.

We warm the inside

Having decided how to insulate the slopes, we turn to practice. Sometimes it happens that with a plastic window installed, despite good foam processing, the windows get wet and it blows strongly from the slopes. This is often the result of careless installation, as a result of which the structure will have to be put in order on its own.

- Remove the remnants of mounting foam.

- Treat the surface with a primer with an antibacterial effect to prevent the appearance of mold in the future.

- We plaster the area of the window, achieving a flat surface, on which you can later glue the foam without any problems.

- We clean the plastered places well, go through the primer and begin to lay the insulation.

- In the case of foam, its surface must be scratched with an emery sheet to reduce smoothness. After that, the material can be safely glued to the slopes. When cutting out the desired pieces of foam, measure out slightly larger sizes, which can always be cut off instead of gluing the missing pieces.

Before gluing the foam, it is recommended to scratch its surface

Before gluing the foam, it is recommended to scratch its surface

Let the structure dry and putty the corner.

After laying the foam, we proceed to the finish coating, chosen to our own taste. This can be plasterboard sheathing or decorative plastering.

Having figured out in practice how to insulate the slopes of plastic windows inside, we turn to external work.

Applicable materials

The range of materials used for insulating slopes on their own is quite diverse. Each of them has its own advantages and differs in the features of installation and operation:

- Mineral wool (not to be confused with glass wool - this material is highly undesirable to use for interior work). The main advantages are excellent heat and sound insulation properties. The disadvantage is high moisture absorption. If you notice that the windows “sweat”, then it is better to abandon this type of insulation, as over time this can lead to the formation of mold and fungi.

Styrofoam. Inexpensive and easy to use material, which led to its popularity in various types of work.

Penoplex. It has improved performance compared to foam, but it is also more expensive.

Sandwich panels. Modern and most comfortable type of material. Already includes heat-insulating and protective layers.Harmoniously complements plastic windows, usually fits into any room design. Cons - relative high cost.

The choice of the preferred material is based on climatic conditions, the general condition of the walls of the house, the material capabilities of the owner, and the skill level of the workers.

Choose the required thickness of insulation.

Material selection

The modern building materials market is distinguished by a wealth of choice. Despite the wide variety of products presented, the most popular are polystyrene foam, polystyrene foam and mineral wool. Simply filling in existing gaps has little effect, as the mounting foam degrades over time, and the plaster cracks and falls off. Warming slopes only from the inside will not bring the desired results, as soon the cold will again pave the way to your home. There is only one way out - the use of high-quality thermal insulation materials for laying outside the building.

Window insulation with polystyrene foam is recommended by most experts

Why is this particular building material recommended, which is not cheap compared to others? It is important not to confuse expanded polystyrene with polystyrene, because they differ in a number of significant properties:

- water absorption. The value for expanded polystyrene is 10 times less. What does it give in practice? If two plates are placed in water for 30 days, one will absorb 0.4% of its volume, the other - 4.0%. As you know, under the influence of moisture, the destruction of materials occurs, their weight increases, which means that the load on the fasteners increases. A wet surface gives off heat faster, so the value of the water absorption parameter should be as low as possible;

- thermal conductivity. This is the most important parameter that determines the effectiveness of the use of insulation. Expanded polystyrene has 27–46% less heat loss than polystyrene foam. In combination with low density and low weight, the thermal conductivity value of 0.028 W / (m.K) makes it an ideal heater;

- tensile strength. Everyone wants the funds invested in slope insulation to fully justify themselves, and the finished structure lasts as long as possible. That is why it is worth choosing polystyrene foam from two heaters, which is 5–7 times more reliable. This applies to both tensile strength and compression. The period of operation of both heaters differs by 2–5 times.

Expanded polystyrene is completely environmentally friendly. Its use will not have a negative impact either on the one who lays the insulation or on the environment during operation, despite temperature fluctuations and humidity. The advantages of expanded polystyrene over conventional foam are obvious. As for mineral wool, it has a much lower cost, and it may seem that the use of such a heater is more profitable. In fact, high thermal insulation characteristics are typical only for mineral wool boards, the price of which is higher than polystyrene foam.

How to make slopes on windows from polystyrene step by step diagram

Step 1: Preparing the surface for work

Before proceeding directly with the installation, you need to clean the place under the slopes from dust and dirt, and cover all the cracks with either cement or putty. The surface is primed for evenness, and while the composition dries, it will just be time to prepare the parts.

Step 2: Installing slopes

After cutting and preparing the slopes, we apply an adhesive mixture to their inner surface, after which we apply the material to the installation site. When pressing the parts, it is worth using the building level for reliability in order to be able to control the evenness of the work. Despite the high quality of modern glue, for reliability, you can fix the slopes with dowels by drilling several holes along the edges of the foam.By the way, experts do not recommend making holes for nails until the glue dries. If you make the slightest mistake during the work, this can lead to the fact that the set foam level will shift. It is better to drill holes either in advance or two to three hours after completion of work.

Step 3: Finishing the Material

The surface of the material is puttied, all joints and cracks are smeared with high quality, providing good insulation and protection against drafts. The entire surface of the products is covered with a starting putty, and a reinforced mesh is installed on top: gently press it with a spatula into the mixture. To prevent the corners from falling off during work, glue perforated corners to them. As soon as this layer dries, the material is once again covered with a finishing putty, after which the foam is painted or the slopes are plastered.

Stages of the laying process and their characteristics

Having decided on the key characteristics and advantages of the insulation, it is necessary to comply with the installation technology

It is important to know how to insulate windows with polystyrene foam in such a way as to create excellent conditions for tightness and long-term operation. To do this, it is worth doing the work step by step, paying great attention to each of the stages:

cut out strips of polystyrene foam of the required length and width. As a rule, a sufficient size is 5–8 cm. The thickness of the insulation must be at least 5 cm, otherwise the effect will be hardly noticeable;

clean outside windows. Expanded polystyrene is well attached to the brick, so it is advisable to clean the surface of foreign building materials, especially if they are weak

It is important to fill existing cracks with cement mortar and treat the places where mold or fungus has formed. You can additionally strengthen the facade by using a deep penetration primer;

installation of polystyrene slopes

As a fixer, special glue or dowels can be used. The combined use of fasteners ensures greater durability of the structure. It is important to know that for better drying of the glue, a temperature of at least +5 degrees is required - keep this in mind when planning insulation. When using polystyrene foam, it is recommended to play it safe and install both types of fasteners to significantly increase durability;

we blow out the cracks that have arisen with mounting foam, after which it dries, you can start applying the plaster. The process is mandatory, since even a material that is relatively inert to the influence of the external environment is subject to aging under the influence of environmental factors. It is important to use a mesh for reinforcement during the laying process - it will become an additional surface protection. Plaster will give the product greater strength and provide it with a long period of operation. After plastering, the surface is painted.

How to insulate window slopes with polystyrene foam in order to extend the period during which the material will maintain tightness? It is important not to rush in the process of equipping slopes - in order for the insulation to hold better, it is necessary to let both the glue and the mounting foam dry well. In general, we can say that having an understanding of how to insulate slopes with polystyrene foam, even a non-specialist can cope with the task.

Do you have the skills to work with the necessary building materials? Can you accurately and accurately carry out each of the stages of work? The procedure does not require the use of special equipment, so feel free to proceed with the insulation of window slopes.

Insulation of slopes inside with foam plastic or foam plastic

Styrofoam or foam sheets are the most common types of materials for slope insulation. Work with their use is carried out after the installation of a double-glazed window in the following sequence:

- Slopes and areas between the frame and the wall, filled with mounting foam, must be plastered with cement mortar.

- After drying, treat the surface with an antibacterial compound.

- Cut the insulation to the required size. It is better to cut off a larger piece - the excess can be easily trimmed after installation.

- Sand the surface with sandpaper. Lubricate with special glue for foam. If you're using foam, don't apply too much adhesive. This type of insulation expands when heated - in the hot summer time, an abundant layer of glue can crack, and the coating will lose its thermal insulation properties. Attach the prepared insulation to the slope, partially overlapping the window frame.

- After the insulation has been glued, we fix it with plastic umbrellas.

- The next step will be mesh reinforcement.

- Then, we put the perforated corner on the putty, set it right on the level.

- Apply a decorative coating to the front part of the insulation in accordance with the repair concept. It can be drywall with subsequent painting, plastic panels, colored plaster.

How to insulate plastic windows for the winter

The material is selected depending on the area that needs to be insulated.

| insulation | Mode of application |

| Mounting foam | The voids between the window opening and the frame (mounting seam) are filled along the entire perimeter |

| Mineral wool (for interior work) | Insulation of the window sill and internal slopes with a mounting joint width of 30 mm or more |

| Styrofoam, expanded polystyrene | Insulation of external and internal slopes with a mounting joint width of less than 30 mm |

| Dry building mixtures (plaster, putty for outdoor use) | Insulation of slopes, protection of the insulation from the external environment outside |

| silicone sealant | Sealing gaps between plastic window elements |

| Scotch construction | Adhesive on top of sealant or instead of it |

| Energy saving film | Adheres to the inner surface of the double-glazed window |

| Rubber compressor | Replacing a dry or damaged seal on the sash and frame |

To protect the insulation from mechanical damage and as decorative coatings for slopes indoors, plastic panels and drywall are mainly used. The latter requires additional puttying and painting.

Technology of work on the internal slope

To begin, prepare the slopes themselves. They need to be cleaned of debris, cover the gaps with cement mortar. Next - apply a primer to the entire surface with a brush. While the primed surface dries, prepare the blanks (cut to size).

Then, an adhesive solution is applied to the surface of the foam with a notched trowel, and the workpiece is pressed against the slope. You can immediately pick up the building level, checking how smoothly the installation is carried out, because if the surface is uneven, this will greatly complicate the installation of windows. For a clearer installation, we advise you to fix the foam on the dowels at several points, then the plate will definitely not move away from the slope.

Next - all foam plates are installed, with careful docking. If possible, you can additionally putty the joints so that there are definitely no gaps.

Now we apply the starting putty to the surface, fasten the reinforced mesh, and on top - we apply the finishing layer of putty. So the internal slopes are ready with their own hands from foam. But what about the outside? Let's take a look now!

Internal and external slope insulation

In order for the installed plastic window to serve you for many years and meet all the requirements, many experts strongly recommend that the slopes be insulated both indoors and outdoors.

After you have installed a new plastic window, you should not immediately start doing wall decoration, you should first take care of the insulation of the slopes and install thermal breaks in the gap between the window and the wall.

When choosing a material for internal insulation of slopes, one should not forget that the quality of window opening insulation depends on how tightly the heat insulator will be in contact with the surface.

When using the soft heaters discussed above, the gap between the window and the wall should be completely closed, solid materials are placed end-to-end over the thermal insert.

Insulation of slopes with foam

These works are best done immediately after installing a new window. In this case, all the slopes should be plastered with a special solution and create a flat plane at a certain angle.

After preparing the surface for mounting the foam, it should be treated with special antifungal compounds to create a protective barrier against mold between the surface and the foam.

To ensure better adhesion of the material to the surface, the side of the foam on which the adhesive will be applied should be treated with sandpaper, roughening the surface of the foam.

For the decor of the foam, it is customary to use the following materials:

- decorative plaster;

- moisture resistant drywall;

- decorative plastic panels.

The main parameter for choosing a material is to match the product with the interior decor of the room. For more information about the stages of work, see this video:

External insulation

As mentioned above, insulation is best done for slopes outside and inside. To level the insulated outer surface, a cement mortar or a special mixture is used; further work is not recommended without waiting for complete drying.

For outdoor work, it is recommended to use penoplex (expanded polystyrene), since the density of this material is greater than that of polystyrene. Penoplex is installed using an adhesive solution, as well as the additional use of 2-5 dowels, depending on the size of the slope.

After the adhesive has hardened, another layer is applied to the surface, into which a reinforcing plaster plastic mesh is pressed. When the top layer of the coating hardens, you can start decorating. For more information on slope insulation, see this video:

Summing up the written material, it is safe to say that work on the insulation of slopes is within the power of every owner. There is no doubt about the significance of this process, “the result will speak for itself”, and you can decorate the appearance of insulated surfaces with any of the above options.

Sometimes the owners of windows made of metal-plastic profiles are faced with a situation that in winter cold air enters the room through the window opening (through, “pulls”). To decide how to insulate plastic windows, you need to find places and identify the reasons for the violation of thermal insulation.

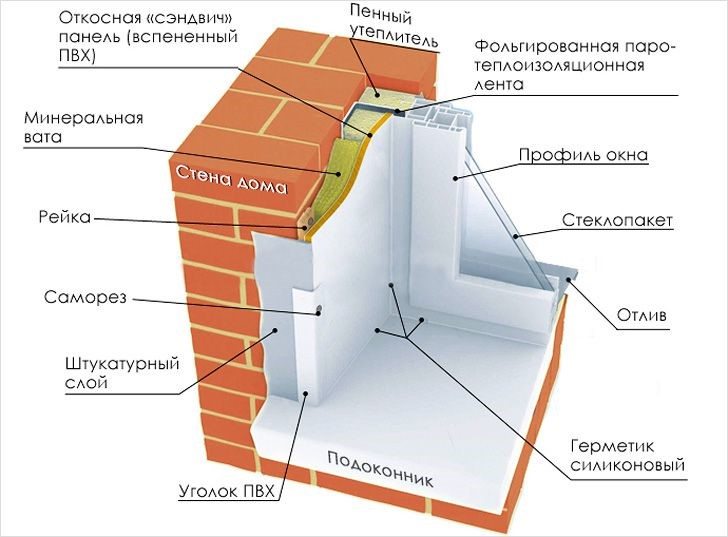

Insulation with sandwich panels

One of the simplest and fastest ways to insulate window structures using sandwich panels.

In addition to the main material, you will need a U-shaped profile, mineral wool, an F-shaped profile, self-tapping screws to complete the work.

Work process:

- fix the U-shaped profile around the perimeter of the window structure with self-tapping screws;

- prepare appropriately sized slopes from the specified building material;

- insert the panels into the mounted profile;

- the gap between the sandwich material and the wall can be sealed with mineral wool or other similar heat insulator;

- “transform” the outer side of the slopes with a finishing F-shaped profile.

How to determine which way it is blowing

Possible cold air entry points are:

- Adjacency of the window block to the wall panel along the entire perimeter (ceiling part, slopes, window sill);

- Sealing between sashes and window frame;

- Accessories (worn or loose hinges, handle);

- Plastic glazing bead that secures the double-glazed window in the profile.

The main reasons for the formation of cracks in these places are:

- Violation of the rules for the installation of plastic windows;

- Skewed window frame during natural shrinkage of a new building or a wooden house;

- The use of low-quality materials by the manufacturer in the manufacture of the PVC profile and by installers when installing the window in order to save money;

- Drying and cracking of the rubber seal;

- Depreciation of window fittings, leading to a weakening of the clamping force;

- Non-compliance with the rules for operating windows (regular wet cleaning and glycerin treatment of the rubber seal, cleaning and lubrication of the clamping mechanism and hinges).

To determine the place of inflating, it is enough to hold the back of the hand along the listed elements. In the place of broken thermal insulation, the flow of cold air rushes into the room. For greater effectiveness, the palm can be wetted.

If in doubt, you can use a lit match, a lighter, a candle. They are carried out at a safe distance from the profile (2-3 cm) around the entire perimeter of the window. The deviation of the flame to the side indicates the presence of a draft from the gap.

The tightness of the seal can be checked with a sheet of writing paper. It is placed between the open sash and the frame. The sash is closed by turning the handle until it stops. If the paper can be pulled out, then the seal is loose and there is a gap.

Detected places of penetration of cold and cracks are marked on the drawing or with a pencil on the window profile

In the process of insulation work, special attention should be paid to these areas.

It is recommended to call the wizard if:

- The warranty period has not expired;

- Requires insulation from the outside on high floors;

- The cause of the gap is a factory marriage;

- Replacement of worn elements of the clamping mechanism is required;

- The work must be done with high quality and in a short time.

In other cases, it is more economical and more expedient to perform the insulation of plastic windows on your own.

Why insulate slopes and options for materials used

The most common reason for slope insulation is the replacement of obsolete wooden windows with plastic ones, but this process does not always lead to the desired result, and dismantling work may not be carried out properly, which will lead to large destruction of the window opening.

A guaranteed increase in thermal insulation properties, regulated by manufacturing plants, is possible if certain requirements are met, one of which is the installation of isolated slopes.

The reason for the need for this warming or insulation is that, if this process is not done, the window itself will be a direct barrier between warm or cold space.

In order to reduce such heat losses and move the barrier (neutral) zone slightly towards the apartment (this process will eradicate the cause of mold on the slopes near the windows), the slopes are insulated.

You can see a visual view of the insulated "pie" in the diagram below.

Materials for slope insulation

Before you insulate the slopes, you should decide on the option of insulation. To date, there is a large selection of material with which you can qualitatively isolate the slope, make it airtight and reliable. Such materials may include:

- mineral wool;

- glass wool;

- Styrofoam;

- expanded polystyrene;

- mounting foam;

- basalt wool;

- foil fiberglass roll type;

- sandwich panels.

The choice of a suitable material is made depending on what raw materials the wall is made of, and how the interior decoration of the rooms where the windows are installed is made.

Insulation of openings with soft materials is an effective method, but the parameters of slopes and openings do not always allow resorting to this type of insulation.

Since mineral, basalt and fiberglass wool are at least 5 cm thick, even when compressed, they may not fit the dimensions.

In addition, these types of insulation require external cladding with a separate material, in particular, plastic panels or drywall.

One of the most popular methods of slope insulation are options using polystyrene foam and polystyrene foam. These materials are dense and perfectly placed with adhesive solutions on any surface.

To give a decorative appearance to slopes insulated with foam or foam, the surface should be plastered and painted.

Sandwich panels are also considered a modern, but expensive option for finishing and insulating slopes. They can be mounted using the adhesive "liquid nails". The material is very reliable and does not require additional cladding.

Preparatory process and cutting of finishing material

Before insulating the slopes with foam, you need to properly cut the sheets. The size of the slope is closely related to the dimensions of the window, so you need to understand that they will have to be “planted” as deep as possible.

After cutting the parts, they are connected to each other with glue, which is applied to the seams. Then the glued product is left a little. Next, the prepared fragments are connected, strongly pressing, and left for 60 minutes to dry completely.

To achieve maximum strength, fiberglass reinforcement can be done. To do this, fiberglass is cut into strips, the width of which corresponds to the width of the slope. Fix the tape with a stapler, and then fix it with glue. When the glue dries, it is customary to putty the reinforcement, as shown in the photo above.

High-quality insulation of slopes of plastic windows is the key to maintaining heat in the apartment

Preservation of heat is one of the key conditions for comfortable living in an apartment during a cold period of time. Most often, an effective way to protect a home is to replace an old window with a modern metal-plastic one.

But choosing a high-quality design from a 5-6-chamber profile and a two-chamber double-glazed window is not enough, the window itself, of course, will not let the cold into the apartment, but the places where it adjoins the opening, if they are not properly insulated, may well cause penetration cold air into the room. dampness and mold.

Therefore, the insulation of slopes of plastic windows is a task of paramount importance. The opening is insulated from the outside and inside of the window, using various types of materials.