What is styrofoam

What is expanded polystyrene and why is it used for floor insulation? This is a type of foam plastic obtained by combining hydrogen and carbon atoms. It is made by foaming granular extruded material with volatile petroleum products. To obtain the desired result, water vapor is used. The result is a durable substance with a cellular structure that retains heat and waterproofing properties for a long time. It does not rot and allows you to work with yourself at any temperature and even in rain and snow.

It is produced in the form of plates and panels of different sizes, which makes its installation simple and does not require special skills. Moreover, it simply fits and does not require special fastening. Easily cut with an ordinary knife to obtain the required size. With such work, the owner of the house can easily cope on his own, without involving a team of specialists for this.

The main thing when insulating the floor with polystyrene foam is to follow a certain scheme for laying it:

1. Before laying the insulation, it is necessary to carry out preparatory work - with the help of a cement screed, the floor surface is leveled.

2. In order to achieve the effect of sound insulation, spread a special thermo-acoustic film over the cement.

3. Then the styrofoam boards themselves are laid. They do not need to be fastened together or glued to the floor. Just dock the edges of the plates so that they lie freely.

4. To waterproof the floor, cover the styrofoam with a waterproofing film. For these purposes, it is not recommended to take too thin material, it will be of little use. Film thickness of 0.2 mm and above is best suited

Please note that in places where one piece of film is connected to another, the film should be overlapped so that the width of the overlap is at least 10 cm.

5. In order to strengthen the structure, another layer of cement screed is applied with a height of 5 cm or a little more.

6. The final stage is the laying of flooring: linoleum, laminate, parquet, tiles or any other.

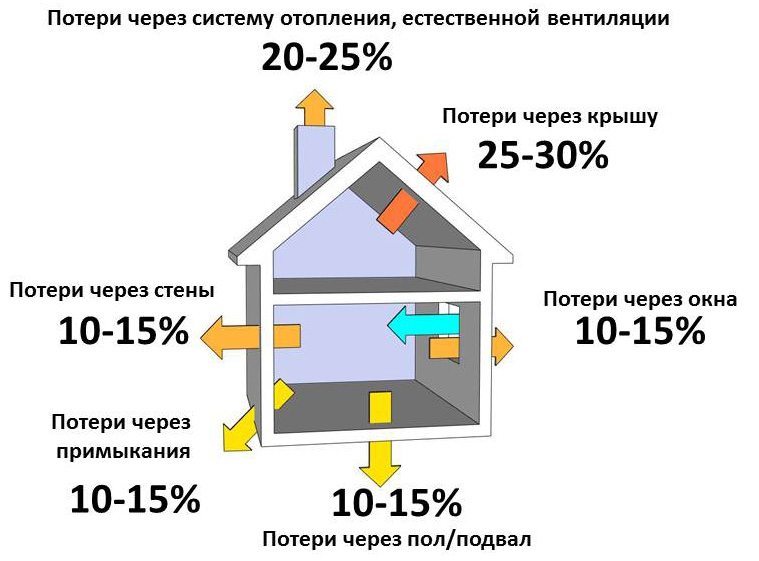

Why floor insulation is necessary

The floor is the only surface in the house that cannot be avoided.

Therefore, it is important to ensure its comfortable temperature. Warm air heated by radiator heating batteries rises, and if the floor is not sufficiently insulated, it is unpleasant to walk on it

When using a system of warm floors, insulation is also necessary. In its absence, the coolant will not rationally give off energy, heating not only the floor covering, but also the underlying cooled layers.

The lack of full-fledged floor insulation leads not only to overspending on heating, but also to damage to structures by mold and fungus. Condensation falls from the side of warm air, and a humid environment is beneficial for the development of dangerous microorganisms.

This is interesting: Characteristics of polystyrene foam - we know in general terms

Insulation of a wooden floor with mineral wool

The easiest and most reliable way to insulate a wooden floor is to use mineral wool. Usually, the floor structure contains logs, and it is precisely between them that this insulating material is laid.

- Before starting work, you must lay the plastic wrap. It is advisable to do this before installing the lag. If this is not possible, you can try to push the vapor barrier under the lags, or cut it into strips a little more than the width of the lag. (Although this is not the best option).

- When the film is laid, you can lay mineral wool between the joists.There are several nuances here, firstly, you need to buy a heater so that its width is a little more wide between the lags, then you do not have to adjust the material in width. You can buy a heater, and then install the logs at the right distance. Further, the height of the laid insulation should be slightly less than the height of the log.

- From above you need to lay a plastic film that will protect your mineral wool from moisture penetration. If you do not have such a large film, you can cover everything from several parts, the film should overlap at least 10 cm.

- Sheet material, the so-called draft floor, is laid on top of the film on the logs. In the role of which sheets of chipboard should act.

As everyone knows, the main supplier of cold and dampness, and especially in private one-story houses, is the floor. The stores offer a huge selection of thermal insulation materials.

The most common and popular is foam. Today we will consider the characteristics, advantages and disadvantages of polystyrene foam. And we will also touch on where, when and how floor insulation is used with foam plastic.

Why do many people prefer this material

For thermal insulation of the floor, you can use different heaters, some people prefer the traditional method of insulation with expanded clay, others, on the contrary, use modern warm floors, but all of them have a number of disadvantages compared to polystyrene foam.

If we compare the insulation with expanded polystyrene and expanded clay, then there is a significant difference. If expanded clay does not allow cold air to enter the room, then expanded polystyrene, in addition, also reflects heat from the room and returns it back. At the same temperature in the room, the floor, which is insulated with expanded clay, will be colder.

If we compare these two materials, then a 2 cm polystyrene foam layer has the same thermal insulation characteristics as a 35 cm expanded clay layer.

It is especially good to use this material on a loggia or in a room where a heated floor is arranged, as it reflects that part of the heat that goes down and returns it to the room.

Gate protection

Many are faced with the problem of seasonal “walking” of the pillars (the base of the gate), which is why they do not close.

The best solution is to protect the base (pillars) from freezing when installing the gate. If you have already installed ordinary iron gates, then they must also be thermally insulated from the inside. If it is possible to attach the sheets to the dowels to the material from which the gate is made, it is worth doing it.

If not, the usual glue method will do. Already glued insulation is covered first with a vapor barrier film, then with outer skin. To enhance thermal protection, foil polyethylene can be used.

Thus, the right choice of heat-insulating material makes the insulation of the garage a fairly simple process, which everyone can do.

Hello, reader of the site about DIY repairs BabyRemont.ru.

One of the ways to insulate your home is to insulate the walls from the outside of the house. For this, extruded polystyrene foam or polystyrene is used. The installation of these panels is identical.

For insulation of brick and reinforced concrete walls, extruded polystyrene foam is used without a vapor barrier device. But, if you are going to insulate aerated concrete (foam concrete) walls from the outside, you must additionally make a vapor barrier on the warm side.

The thickness of the insulation panels for external walls should be, on average, 5 cm.But it directly depends on the insulated wall and on the climatic zone. Before buying extruded polystyrene foam or polystyrene, for the correct selection of thickness, first consult with specialists or the seller (perhaps he is also a specialist).

Extruded polystyrene foam, like polystyrene, protects against both cold and heat.

Thanks to this, comfortable living conditions are created. Before thermal insulation from the outside, level the surface of the walls using plaster mortars. Do not mount the heater on an uneven surface!

Fasten the thermal insulation boards to the walls only after the plaster mortar has hardened.

Styrofoam Processing Tools

Although it is obvious that foam is an easy-to-work material, you can find references to special thermal cutters or even machines for cutting this material. But they are rather required for those who constantly work with this material or are engaged in curly cutting. For a single use, it is hardly advisable to purchase an expensive device, and curly cutting for an insulated floor is not required.

When cutting foam for thermal insulation of the floor, the following tools may be required:

- Ordinary knife. A sharply sharpened knife with a long blade is able to cut any kind of polystyrene foam. For thin slabs, even a kitchen knife with a serrated edge will do.

- Hacksaw. It may be more convenient for someone to cut the material with a hacksaw. It should be borne in mind that a hacksaw with fine teeth is better suited for cutting foam. A large tooth will form a more rough edge.

- String. For this purpose, you can use old guitar strings, mounted on two handles. Sawing with such a device as a two-handed saw.

Of course, these tools are not able to provide smooth cutting edges. But for joining foam boards for the floor, a perfectly even edge is not needed.

Useful advice. When cutting foam with any of these tools, it is recommended to provide a liquid lubricant to the cutting surface. This will make it easier to work with the tool and reduce the unpleasant sound that accompanies cutting.

Floor construction in a wooden house

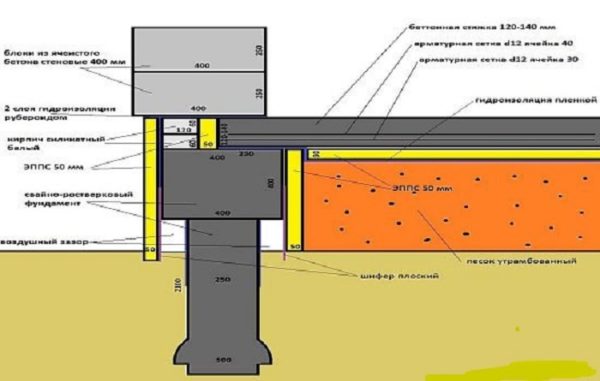

Regardless of the cottage construction technology and the wall material used, the following factors influence the choice of floor pie design:

- floor - the floor on the ground can only be made at the lower level;

- planned flooring - for tiles and most facing materials it is more convenient to floor on the ground, it is better to lay parquet on a black wooden floor;

- type of foundation - to reduce the construction budget, wooden buildings are erected on poles or MZLF, floating and insulated slabs are used on wet ground, pile-screw grillages remain the only option in swamps and steep slopes.

Floor decking on beams

In contrast to the floor on the ground and floor slabs, the wooden structure of the flooring on the beams is cheaper for the developer. Wooden floors can be made on any floor. However, wood protection, taking into account operational and structural loads, is much more complicated:

the wooden floor cake is closed with a vapor-tight film or membrane; however, the protection does not cope with humid air inside the house by 100%; some of the moisture penetrates the floors, is absorbed by the lumber; after which, with a decrease in humidity in the cottage, the wood tries to evaporate excess moisture; if the lumber is surrounded on all sides by a vapor-tight insulation, then this is impossible; elements of load-bearing structures darken and begin to rot, fungus and pathogenic microbes start and spread on their surfaces.

After foaming the cracks, the evaporation surface of the lumber is sharply reduced.

The vapor permeability of mineral wool insulation 0.45 is an order of magnitude higher than that of foam plastics (0.03) and 15 times higher than that of extruded polystyrene foam (0.013 Mg / m * h * Pa), and hygroscopicity is at least twice.

Advice! Experts recommend replacing the floor insulation in a wooden house made of polystyrene foam or extruded polystyrene foam with basalt wool insulation.

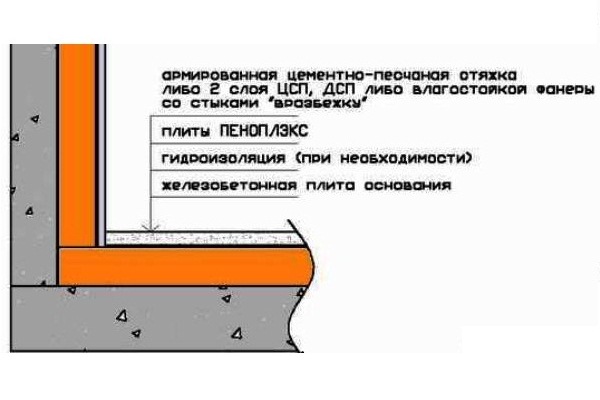

Ground floor

The reinforced concrete floor cast at the place of operation, which rests on the soil, is called the floor on the ground. The slab has a lower waterproofing, is cut off from the foundation by a damper layer, that is, it is floating.

It does not perceive structural loads, it distributes only operational loads from the weight of furniture and people inside the room to the ground. However, even with a minimum thickness of 7 - 10 cm, the own weight of the structure is much higher than that of a beamed ceiling.

Therefore, the heater must have the following qualities:

- high density - so that the floor slab does not sink on the ground over time;

- low hygroscopicity - despite waterproofing, concrete can absorb soil moisture, so thermal insulation must retain its properties when wet.

These properties are possessed by foam glass and extruded high-density polystyrene foam.

Due to the large loads and the possibility of subsidence in the floors on the ground, high-density EPS is used, and not PSB foam.

Styrofoam breaks under the floor's own weight on the ground, mineral wool loses its thermal insulation characteristics when wet. Therefore, these two materials for flooring on the ground are not suitable.

The finished floor on the ground is a slab foundation, the easiest way is to make a 10 cm reinforced screed inside the MZLF. It is much more difficult to implement a floor on the ground inside the grillage:

- grillage beams must necessarily be separated from the ground;

- in high (hanging) grillages, this happens automatically;

- in low (ground, underground) air gaps are protected on the sides with sheet materials so that soil does not crumble inside it;

- the base inside the grillage must be compacted with a vibrating plate or vibrating roller to ensure normal bearing capacity.

Since it is difficult to make a floor on the ground in a hanging grillage, a slab floor is poured with support on the foundation beams.

In a hanging grillage, the soil will fall out from under the beams; when the base is compacted inside a low grillage, the probability of destruction of sheet materials increases, which closes access to the air gap when soil pressure increases on them.

How to make the right choice

This is an artificial material, it is obtained by swelling polystyrene granules with a blowing agent, which are sintered at a high temperature. Extruded polystyrene foam has higher strength and compressive strength, so it is better suited for thermal insulation of the floor, both on the loggia and in the garage.

This material is available in the form of plates, they can be of different colors, they have a smooth surface. When the plate breaks, its inside will look like foam rubber. The color of said material does not affect its quality, just the way manufacturers distinguish their products.

There is a large selection of this material, which is used for thermal insulation of the floor in residential premises, garages, as well as on the loggia. If we talk about the brands of this material, then the most common are such as Penoplex 35 and Penoplex 35 Standard, Penoplex 31 Standard and Penoplex 31 and others.

If the insulation is supposed to work in a wide temperature range, then preference should be given to Technoplex, since it retains its qualities at temperatures from -50 to +75 degrees. It is he who is suitable for thermal insulation of a balcony or loggia, as well as the roof of a building.

For thermal insulation of the foundation in a swampy area, it is necessary to use "Termite", as it has the lowest moisture absorption coefficient.

Insulation of a wooden floor with expanded clay

Expanded clay is a fairly well-known material that is used to insulate houses. It has been used for several decades, and thanks to its high operational data, its popularity does not decrease.

It is made from clay of special grades, which is processed at high temperatures. As a result, balls of a certain size and a certain density are formed.

Before work, the surface must be cleaned of debris. A good helper in this matter will be a broom and a scoop.

If there are gaps between the floor and walls, they must be sealed with sand-cement mortar or mounting foam.

Now, so that when the dry screed expands, the floor does not bend, you need to leave a gap between the floor and the wall. To do this, you can lay a polyethylene foam tape along the wall around the entire perimeter. Its thickness should be sufficient so that the floor can expand freely.

It will not be superfluous to lay a plastic film on the base, it will serve us as a steam and hydro insulator. The film should rise along the edges of the walls just above the level of our future floor. The edges of the film are best secured with masking tape or tape to the wall.

Now that the preliminary work has been completed, we can lay the expanded clay layer.

It should be borne in mind that for insulation it is better to buy expanded clay in which the granules have different sizes, then the material will be distributed more evenly. The expanded clay layer should be at least 3 cm and not more than 7. Given this, you can pick up beacons, these can be wooden slats or a metal profile of the right size. It can be fixed to the floor with both cement-sand mortar and self-tapping screws. Beacons must be perfectly level and securely fastened.

Now you can sprinkle expanded clay and level its layer with a rule made from improvised materials.

You can not use beacons, but then you will need to align the layer with a rule that has a level indicator. It is much more difficult and not for everyone.

It is best to cover such a heater with sheet material. Chipboard, OSB, GVL and even sheets of plywood are suitable for this. But it is most practical to use (GVL) - gypsum fiber sheets.

Some, so that expanded clay is not loose, but turned into a solid surface, pour it with cement diluted with water. Such a solution is prepared using a construction mixer.

Filling them with expanded clay, you will strengthen the surface with a depth of more than three centimeters.

After the plates are laid, the top coat is already mounted on top. It can be boards, parquet, linoleum and much more, even ceramic tiles.

The use of expanded clay for insulation has a number of advantages, it is not combustible, it is light in weight, holds heat well and does not conduct sound. It is convenient to work with him, because he gives minimal shrinkage.

Insulation of interfloor floors

Scheme of floor insulation with foam.

This foam installation technology is used for apartments in multi-storey buildings or for private cottages with more than one floor. An interfloor floor is a ceiling that is both the floor of one room and the ceiling of another. To carry out the insulation of the interfloor floor with extruded polystyrene foam, you will need:

- penoplex;

- polyethylene film;

- mounting foam or putty;

- Scotch;

- cement-sand mixture;

- reinforced mesh.

Thermal insulation of the interfloor floor with foam plastic is carried out in several stages.

At the first stage, it is necessary to prepare the floor surface by cleaning it from the old floor covering, the resulting construction debris and dust. After that, all floor irregularities must be eliminated with a special putty or mounting foam.If the unevenness of the floor is significant, then a rough layer of screed from a cement-sand mixture should be poured.

Insulation of the floor with penoplex - floor pie scheme.

The second stage of work includes laying waterproofing, which will protect the insulation material from moisture that forms inside the entire thermal insulation structure. A plastic film is laid on the ceiling with an overlap on the walls of 10-15 cm. If the film is not solid, then at the joints it is necessary to make a ten-centimeter overlap and glue this place with adhesive tape, thereby achieving an airtight flooring.

At the third stage of work, extruded polystyrene foam is laid on the waterproofing layer. There are several materials for attaching foam plastic, for example, special dry mixes, mastics, foams and dowels. You can lay plates of extruded polystyrene foam:

- parallel to the walls, that is, when all sides and corners of the plates coincide;

- in a run, when the angles of individual elements do not coincide with each other (this type of laying resembles the technology of laying bricks).

Which of these two methods to choose, decide for yourself.

The fourth stage includes work to provide a waterproofing barrier on the outside. For this, the same polyethylene film is used.

The fifth stage of work is the pouring of a cement-sand screed. To do this, a reinforced mesh is laid on the waterproofing layer, and a cement-sand mixture is poured over it. The thickness of the screed layer must be at least 5 cm, and its complete drying time is 30 days.

Disadvantages of foam

Styrofoam - the material is far from ideal, it also has its own drawbacks, which you need to know about in order to draw your own conclusion - whether or not to buy such material for floor insulation. The main ones are as follows.

- Low strength indicators. The material is easily damaged or broken. But it is also easy to cut.

- The material is afraid of the effects of varnish or paint - it collapses because of them.

- It is not a breathable coating, although it is full of air in itself.

- If mice or rats start up in the house, they can greatly spoil this type of insulation. Therefore, it is best to cover the foam blocks with plaster.

- This is not an environmentally friendly material, and if set on fire, it releases a huge amount of toxic fumes into the air. But the foam itself is absolutely safe for humans.

- You still need to create a frame for foam, but in the case of this material, it can be made not as powerful as when using the same mineral wool.

The use of foam for floor insulation has its drawbacks.

Expanded clay

This material is quite popular for screeding in private houses on a pre-prepared soil base.

This option has a number of advantages:

- Fire resistance. The material does not burn, does not support combustion and does not emit toxic substances under the influence of temperature.

- The created layer of thermal insulation does not contribute to the appearance of mold and fungus. When water enters, rotting does not occur.

- Excellent soundproofing effect.

- Ability to withstand large temperature differences without changing characteristics.

- Affordable price making it affordable.

Expanded clay is clay boiled at a high temperature, respectively, the material is absolutely harmless

Expanded clay is clay boiled at a high temperature, respectively, the material is absolutely harmless

The material is laid according to the scheme:

- The base is being prepared. If the work is carried out on a foundation of soil, then a foundation pit is laid with a layer of sand, everything is carefully rammed.

- Depending on the necessary requirements for thermal insulation, a layer of expanded clay is poured.

- Additionally, a reinforcing layer is made.

- The prepared solution is poured over the structure.

Thus, the screed is created quite quickly, and the result is of high quality.

Loose heaters are more suitable for arranging a dry screed, with a wet version, expanded clay is best used as a solution filler (expanded concrete)

Loose heaters are more suitable for arranging a dry screed, with a wet version, expanded clay is best used as a solution filler (expanded concrete)

An example of floor insulation with foam

Consider step by step floor insulation in the house with foam. This is a fairly simple option, and any person can perform such insulation.

Step 1. First of all, the rough base must be cleaned of debris and all irregularities removed. If necessary, cracks are sealed, and the protrusions are polished

It is important to remember that the foam does not tolerate a curved base. Next, a waterproofing layer is laid

In this case, rolled material is used, which is laid in separate strips overlapping each other. In this case, the individual strips are fixed to each other by heating with a blowtorch. Waterproofing should be brought to the walls by about 10-15 cm.

Roll waterproofing

The material is brought to the walls by 10-15 cm

Step 2. Next, you need to install logs for the floor. In this case, they are wooden bars, on which the floor will subsequently rest under their feet. Logs should be used only from dry wood. Fixing the lag on the base can be done using dowels. The step between the lags can be equal to the width of the foam sheet.

Lags are installed

Lags are fixed with dowels

Step 3. After installing the lag, all communications should be laid that will be inside the floor pie. It can be wiring, pipes and so on. Laying should be done in accordance with the project of the house or repair. As for the water supply, especially in a private house on the ground floor, it is best to put it on the heat-insulating material.

Further communications are laid

Laying communications

Step 4. Next, foam must be laid on the surface of the waterproofing layer between the lags. It is laid consistently and tightly so that no gaps form. But if they appear, it is best to cover them with mounting foam. The logs should be of such a height that they are approximately 5-10 mm above the level of the laid foam.

Styrofoam plates are laid between the lags

The process of laying insulation

Styrofoam laid

Step 5. Then you need to “sew up” the floor cake with plywood sheets, OSB sheets, or an ordinary board. Everything, the floor is ready, you can equip the finishing floor covering.

The floor pie is sewn up with plywood

Video - Insulation of the floor with foam

https://youtube.com/watch?v=6eSa8gPCLsM

Styrofoam is really convenient and practical, and most importantly, an inexpensive material that is great for insulating floors in a house, as well as in any building. It is easy to work with it, and the material performs its functions properly. So the main thing is to work without violating the technology, and then in the house after installing such a heater it will be comfortable and cozy.