High-quality insulation of a wooden house from the inside

Building science recommends doing external insulation of buildings, since in this case the dew point is outside the room in the insulation or in the outer layer of the walls. With such insulation in rooms, moisture will not condense on the walls.

But still, there are cases when warming a wooden house from the inside is the only right decision. For example, if the owner of the house wants to preserve the beautiful appearance characteristic of houses made of logs or laws prescribe to preserve the historical appearance of the building.

Modern building science allows you to make internal insulation of wooden houses, but for this you should use the right materials and follow the technology.

The technology of thermal insulation of walls with drywall from the inside

The technology of insulating the walls of a room with drywall from the inside does not require special training of workers and expensive equipment. Enough general construction skills and a universal tool.

Tools and materials

During the work you will need:

- guides (metal profile or wooden bars);

- drywall sheets;

- insulation in slabs or rolls;

- double sided tape;

- vapor barrier membrane;

- self-tapping screws, dowels and other fasteners;

- anti-mold agents;

- putty;

- drill;

- screwdriver;

- hand tool.

The floor in the room must be cleaned of debris and foreign objects.

Design

At this stage, the type of insulation, drywall and guides is selected.

If the kitchen or bathroom is insulated, you should choose moisture-resistant drywall. For a boiler room, it is recommended to use a fire-resistant one.

Wooden guides are cheaper, but they are at risk of drying out and deformation in case of temperature changes. The metal profile does not have such disadvantages. The number of guides is calculated based on a standard step of 60 cm.

When calculating the volume of purchases of materials, a 5% margin should be made in case of damage to drywall sheets and for cutting complex elements of walls and ceilings.

Stages of work

At the first stage, it is necessary to perform a number of preparatory work:

- clean the walls from dirt, streaks of mortar;

- dismantle all protruding objects: fasteners, remnants of fittings, sockets, lamps, etc.;

- putty all cracks and irregularities;

- treat with a composition against fungus and mold;

- dry the surface.

Next, proceed to the marking work. Use a plumb line or a laser rangefinder and a chopping cord

special attention should be paid to:

- parallel marking of the mounting points of the guides;

- marking in the corners and junctions of building structures: arches, window and door openings, columns, bay windows, ceiling beams.

After marking, they proceed to the installation of frame guides.

- a starting profile is glued to the floor on double-sided tape, adhesive tape will improve sound insulation and protect against drafts;

- vertical profiles are attached to the starting bar with metal screws, and to the wall with self-tapping screws on dowels.

The process of wall insulation with drywall

The process of wall insulation with drywall

A very important stage is the laying of the insulation in the guides. The quality of insulation will directly depend on the accuracy of the work:

- insulation sheets are laid in the guides from the bottom up;

- they must enter between the profiles without gaps, with some effort;

- sheets are additionally attached to the wall with adhesive or dish-shaped dowels;

- all cracks and gaps must be tightly hammered with scraps of material or sealed with mounting foam.

Now it's time to install the vapor barrier:

- penofol is mounted with foil inside the room;

- the vapor barrier membrane is fixed with the rough side inward; double-sided tape is used for installation.

And the final stage is the installation of drywall sheets. They are mounted horizontally, from the bottom up. Before screwing the sheet to the guides, it is necessary to use the markings and the level to make sure that it is located strictly horizontally. After the first layer is fixed along all the guides, the next one is placed on top of it. Here you also need to monitor the horizontal position and ensure that the gaps between the sheets are minimal.

As a rule, the dimensions of the room do not allow installing only whole sheets of drywall. In the corners and under the ceiling, you have to mount pieces. Drywall should be cut on the floor, in a horizontal position, on a flat base. It is enough to cut through the top layer of paper with a mounting knife. Now the cut piece can be broken off along the cut line.

At the end of the installation, all joints between the sheets should be carefully puttied. After the composition dries, it is leveled with fine sandpaper, achieving a completely even surface of the wall or ceiling.

Now the surface of the insulated wall is ready for final finishing. Two main types are used:

- wallpaper;

- water-based paint.

When insulating gypsum plasterboard rooms with high humidity, moisture-resistant grades of drywall with special hydrophobic and antifungal impregnations are used. Such panels are easy to distinguish: they are painted green. In damp rooms, it is also necessary to arrange supply and exhaust ventilation in order to prevent air stagnation and mold formation.

Types of drywall insulation

All drywall is produced in sheets of size: 2.6 - 3.0 m * 1.2 m. There are two options for thickness:

- 12.5 mm wall;

- 9 mm ceiling.

Depending on the purpose, the following types of drywall are distinguished:

- usual;

- waterproof for damp rooms;

- hardened;

- windproof for outdoor use;

- fire retardant.

Such methods of insulation with drywall are widely used, such as:

Sticker directly on the wall. Use an adhesive composition based on gypsum or polymer. In this case, the area of \u200b\u200bthe room is not “eaten up”, sound insulation improves. There is no need to talk about any noticeable warming. The method is applicable only in regions with a warm climate.

Mounting on frame rails. The rail system consists of vertical metal profiles or wooden blocks fixed to the wall. Drywall sheets are attached to them with self-tapping screws. This method leads to a decrease in the useful area of \u200b\u200bthe room, provides good sound insulation. The air gap between the drywall and the wall plays the role of thermal insulation. The return on such insulation depends on the wind insulation of the space under the sheets - if there are drafts in it, the efficiency will drop to zero. So you can insulate walls in regions with a temperate climate.

Laying a special heat-insulating material into the system of guides for drywall. Only this method is a real wall insulation with drywall, it will work in any region. The thickness of the plates of thermal insulation material is selected based on the depth of the frame in order to lay them with the highest possible density. In particularly cold regions, insulation is laid in two layers. In narrow places, for example, behind the radiators of the heating system, sheets of foamed plastics are attached.

The most widely used materials for the insulation of internal walls under drywall are:

- Styrofoam, or expanded polystyrene. Efficient, easy to install and cheap material. Its disadvantage is high brittleness and chipping. When smoldering and burning, it releases toxic gases and aerosols.

- Extruded polystyrene foam, PPE. Does not crumble, has high strength. Not subject to getting wet. It costs more than polystyrene, has better thermal insulation. Also, when smoldering, it releases harmful substances.

- Basalt wool.Good thermal insulation performance, easy installation. Does not burn, does not emit harmful substances. Needs vapor barrier.

- Glass wool. In terms of indicators, it is comparable to basalt. It has an important drawback: when wet, it loses its thermal insulation properties. Requires special attention to vapor and waterproofing. During installation work, it emits dust harmful to the respiratory organs and mucous membranes; it is necessary to work in protective clothing and a respirator.

- Penofol. Foamed polyethylene, sheets are flexible and ideal for installation in hard-to-reach places. On the one hand, it is laminated with a layer of foil that reflects heat back into the room. Does not require additional vapor barrier.

Basalt wool is used under drywall for wall insulation

Basalt wool is used under drywall for wall insulation

To protect the insulation layer from water vapor, synthetic membrane materials or thin foam sheets are used.

Mineral wool is supplied in 600*1200 mm slabs or in rolls. Plates are more convenient for laying in guides mounted with a standard step of 600 mm. Rolls are often used for thermal insulation of floors and for laying in guides with a non-standard step.

Vapor barrier in different rooms

In bathroom, in the bedroom or in the kitchen, different levels of evaporation of moisture. Therefore, you should consider how to install the vapor barrier material on the frame.

In the bathroom

Watch the video: waterproofing in the bathroom.

When working in the bathroom, the sequence of actions is as follows:

- First, the frame of the selected type is installed.

- Then a heat-insulating layer of material is mounted in the frame (if provided).

- After that, the moment comes for fixing the vapor barrier layer into the frame structure.

- Depending on the selected material (vapor barrier film or membrane film), the sheets are fixed either with a profile or immediately fixed with a drywall sheet. In the process of installing the vapor barrier material on the surface, you should be extremely careful. It is necessary to check that there are no cracks or gaps between the sheets.

In the same way, the vapor barrier material is installed in other rooms.

It is preferable to opt for waterproofing the bathroom with mastic.

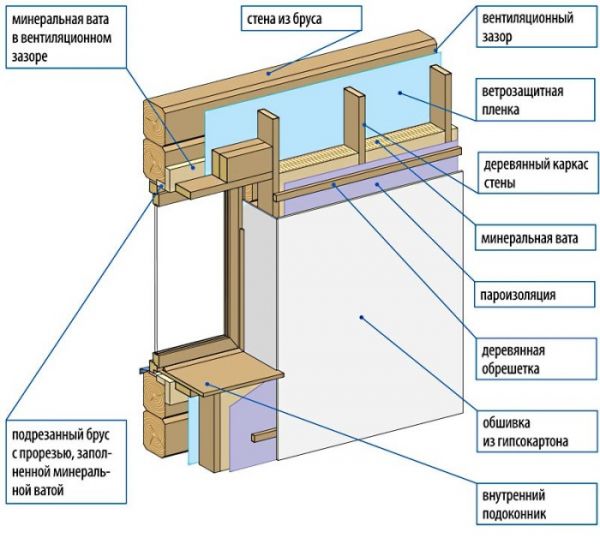

In wooden houses

There are some differences in the process when installing a vapor barrier layer in a wooden house. Plasterboard material coatings are popular in a wooden house. The main thing is to adhere to the technology of the process in order to do everything right.

The wooden facade of the house is prone to corrosion and fungi. Therefore, it is best to install a vapor barrier on both sides of the insulation so that moisture and dampness coming from the wood does not get on the surface of the drywall sheets. To do this, you can first, before installing the insulation in the frame, fix the vapor barrier sheets on both sides. This will remove excess moisture from the surface of drywall and wood.

It is not difficult to install a vapor barrier material under drywall ceilings. The main thing is to weigh the important nuances and decide what materials you need to buy, and which installation option is most relevant.

The choice of raw materials to provide vapor barrier properties is a fairly simple task.

The main thing is to decide what goals are set, and you also need to pay attention to the cost of the material. A narrow choice of vapor barrier materials makes it impossible to get lost in a multitude of ideas

See in the video: fixing the vapor barrier in the attic under a metal profile and to aerated concrete walls.

Insulation without frame

Insulation of walls with drywall from the inside is not always possible with the assembly of the frame. You can carry out insulation without a foundation.

Initially, the walls are prepared for fastening sheets of insulation. All fragile areas are restored, and the surfaces are treated with an antiseptic.

Styrofoam or cotton wool is fixed, as in the previous version, that is, an adhesive mixture and plastic dowel nails.

Drywall sheets are mounted using a gypsum mounting mixture of the Perlfix type. Glue is prepared with the addition of water and thorough mixing with a mixer. A mounting mixture is pointwise applied to the surface of the GKL, and the material is pressed against the insulated wall. Additionally, fixation is provided with self-tapping screws.

However, this method of plasterboard sheathing with insulation should be used only as a last resort. The presence of a frame base provides a higher level of structural reliability, despite various influences: humidity, tension and other loads.

Pros and cons

The main advantage of thermal insulation of the walls of the house under drywall is

- ease of installation;

- high efficiency of insulation;

- ideal wall and ceiling surface for finishing.

The disadvantages include:

- the system of frame guides takes up space and volume, this is especially noticeable in compact rooms;

- low mechanical strength of the coating, does not tolerate impacts;

- do not hang heavy objects without additional guides.

Wall insulation with drywall has a number of advantages and disadvantages.

Wall insulation with drywall has a number of advantages and disadvantages.

Nevertheless, more and more rooms are being trimmed with drywall. To work with it does not require high qualifications or expensive specialized equipment.

Drywall

Some types, due to their water-repellent properties, are used in the decoration of bathrooms and bathrooms.

Before using drywall, you need to understand its positive and negative characteristics in order to imagine the specifics of handling it.

Advantages of drywall:

- Flexibility and lightness. The use of this material allows you to implement the most daring design decisions. It is easy to make various geometric shapes from it - from banal rectangular to complex semicircles, arches, columns;

- Thermal insulation properties;

- Fire resistance. Drywall does not burn. When exposed to fire, only the top paper layer suffers.

- Water resistance. Special types of GKL have been developed, recommended for use in rooms characterized by high humidity.

Disadvantages of drywall:

- The main disadvantage is its fragility. A drywall sheet can easily be damaged during transportation, installation, subsequent operation;

- soundproof characteristics. Drywall does not have soundproofing properties. Behind a simple partition made of plasterboard, all sounds will be heard.

Drywall

The use of drywall as insulation

Drywall, or drywall, is a sheet of thin sheet of gypsum, lined on both sides with layers of thick paper. Drywall has good strength and a perfectly flat surface, which is convenient to paint or wallpaper. It is easily mounted on prepared guides; it is possible to cut the sheet into pieces of the required size and shape with an ordinary mounting knife.

All this makes drywall one of the most popular finishing materials. Can it also serve as a heater? By itself, no. Its thermal conductivity is determined by the thermal conductivity of gypsum, which is only half that of brick and ten times higher than that of mineral wool or other thermal insulation materials. In order for drywall to effectively retain heat, its layer must be several tens of centimeters.

However, the structure of the guides, which are mounted to install drywall on walls or ceilings, can be effectively used to accommodate real insulation - mineral wool sheets or foamed plastics. The surface of the drywall sheet will cover the thermal insulation from mechanical stress.

Wall insulation from the inside with mineral wool plus drywall

IMPORTANT! Any thermal insulation work should begin with surface preparation. All irregularities and depressions must be plastered and puttied

Walls that are subject to insulation are treated with anti-mold preparations and primed

All irregularities and cavities must be plastered and puttied. Walls that are subject to insulation are treated with anti-mold preparations and primed.

Insulation of a brick wall from the inside with mineral wool:

- The method discussed above creates a crate in addition to fixing the bearing racks;

- insulation is being prepared. The method of its fastening depends on what kind of mineral wool you have to deal with. It is convenient to string cotton wool in the form of mats on brackets installed in the wall. Laying should be carried out so that there are no gaps between the mats. ;

- after filling the walls with insulation, load-bearing racks are mounted;

- if mineral wool is purchased in rolls, its laying can be carried out after mounting the racks. It is easy to fill the space between the racks and the wall;

- the surface of the insulation and the crate is covered with rolls of an overlapping vapor barrier membrane. The joints of the membrane are glued with mounting or plumbing tape.

Warming scheme

Material laying

Thus, there is a prepared surface for the installation of drywall sheets.

Types of mineral wool

There are many legends about a simple question: can it be used indoors? We have all heard about the harmful environmental and physical properties of mineral wool. But let's see what is true and what is not.

There are three types of cotton wool, depending on the raw materials of production:

- Glass. This type is made from molten glass. Differs in high fragility and causticity. In case of contact with the skin and eyes during the laying process, it causes severe itching. Not subject to decay. It has a low degree of flammability. This type is not recommended for internal insulation work.

- Stone. The raw materials for its production are igneous rocks, mainly basalt is the most durable. Does not cause reactions on contact with the skin, does not support combustion. Also a plus is the release form - slabs or mats are extremely easy to install. For interior work, this type is recommended.

- Slag. This type is made from waste from the metallurgical industry. The main disadvantage is the increased ability to absorb moisture. For this reason, it sags, deforms. The moisture inside the cotton wool favorably affects the formation of fungi and microorganisms. Just like glass wool, it is characterized by causticity and brittleness, and is not recommended for internal insulation.

Formaldehydes are used in the production process, which are harmful to health, but they are used in such small quantities that they do not affect health in any way. And modern technologies have left their mark on this issue. Some manufacturers have replaced formaldehyde with bitumen in the process. At the same time, we still recommend that you observe some preventive safety measures during insulation. The main one is to separate the room with a partition. We recommend using drywall or chipboard, OSB sheets.