Vapor permeability is the most important factor

It is very important that it increases from layer to layer from the inner wall to the outer. This factor is very important because in the non-warm season, the humidity in residential premises is significantly higher than outside them.

All living in the house breathe, which means that the air is filled with moisture. Household processes from cleaning to cooking also play their role, as a result, the air is humidified, but does not go outside.

This factor is very important because in the non-warm season, the humidity in residential premises is significantly higher than outside them. All living in the house breathe, which means that the air is filled with moisture. Household processes from cleaning to cooking also play their role, as a result, the air is humidified, but does not go outside.

The warmer the air, the more moisture it can hold.

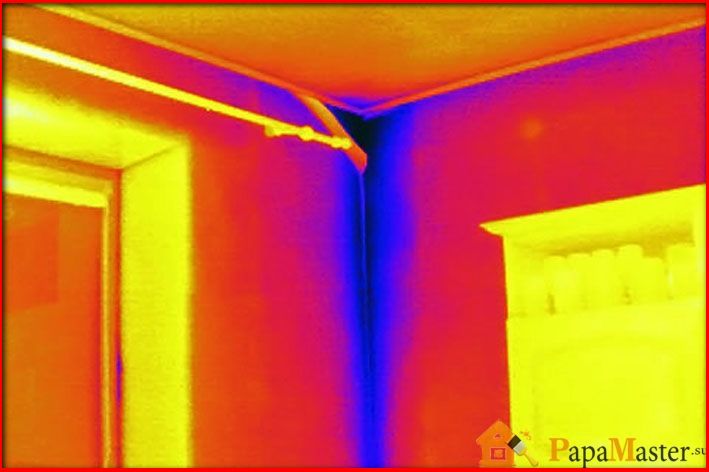

So that the walls do not sweat, there is no condensation and dampness in the corners, it is important to correctly resolve the issue of the vapor permeability of the materials used in the insulation. If the insulation of brick walls does not imply a vapor-permeable outer layer, the wall is guaranteed to be damp

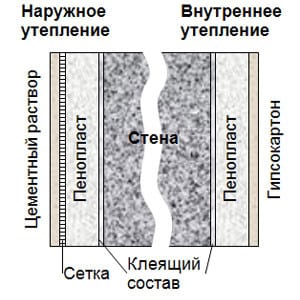

The location of the insulation of a wall-brick house from the inside is not the most effective type of insulation, since the ideal situation is when the house is insulated from the outside. If everything is not done correctly, the dew point will fall on the brick wall itself, which will accelerate the destruction of the structure, especially buildings made of silicate solid brick, which is most afraid of moisture. If your house is built from this, in addition to insulating a brick wall from the inside or outside, protect the walls with roof peaks, but do not forget about the outflow of steam, which in this case becomes even more important!

Insulation of brick walls from the inside leads to the fact that the dew point is located directly behind the insulation, a violation of the technology is fraught with dampness and mold. External insulation, of course, will ensure that the entire wall is warm, steam escapes to the outside, and there is no excess moisture.

But all of the above does not mean that it is impossible to insulate inside. There are many reasons why outdoor insulation may not be possible. For instance:

- We cannot insulate architectural monuments from the outside. A high-rise building is insulated, the upper floors are insulated, but there are no towers. The neighboring walls are so close that there is no place for the exterior thermal insulation to be done correctly.

These and other reasons make us accept the fact that external insulation is impossible. And if you have chosen the internal option to insulate your house, you just need to understand well how to properly insulate a brick wall from the inside in order to be sure to comply with the technology. The most important principle of which is as follows: we should separate the wall and its insulation from the room, make them airtight.

And there are two solutions here:

Internal insulation with a material whose vapor permeability will be extremely low.

These can be considered penofol, which is a heater with a layer of foil applied to polyethylene foam. Also, extruded polystyrene foam has low vapor permeability if its surface is denser on one side. Mandatory condition: both the foil side of the foam and that side of the extruded polystyrene foam, which is denser, must be laid towards the inside.

- The following solution to the problem is also possible: wall insulation from the inside should assume the presence of a vapor-tight film, which will be located on the inside of the housing and hermetically cut off the insulation from the inner wall. If you go this route, you should not leave a single tiny gap for moisture, be sure to overlap the vapor barrier and carefully tape the seams

Ways to insulate an apartment

Insulation consists in installing a special material on the outer walls - a heat insulator. There are two types of insulation:

- External (external). Experts unanimously consider this technique the only true one. The heat insulator is installed on the outside of the walls, which are separated from contact with the outside cold air. As a result, the thermal circuit of the room begins to operate in the nominal mode, the surface temperature of the enclosing structures returns to normal, and the formation of condensate stops.

- Internal. Forced option, used when it is impossible to produce external insulation. The insulator is installed on the inside of the walls. The volume of the room decreases (slightly), it becomes necessary to install a durable protective layer over the heat insulator. The main disadvantage of the method is the exclusion of walls from the composition of the thermal circuit of the room. From now on, they perform only the functions of an external mechanical barrier, not participating in the heat saving of the apartment.

External insulation has a lot of advantages:

- Works are carried out outside, without creating inconvenience for living.

- The surface of the walls remains intact, the interior of the room does not change, there is no need for sheathing or decoration.

- The microclimate of the room improves, there is a feeling of coziness and comfort.

The disadvantage of external insulation is the complexity of the work outside, the reasons for which may be:

- The apartment is located on one of the upper floors;

- The facade of the building has an architectural value, as a result of which the installation of any materials is excluded;

- Any technical or decorative objects are installed on the wall;

- The building is located close to other buildings or structures;

- Work can only be carried out during the warm season.

Internal insulation is almost completely devoid of these shortcomings, no permit is required for work, you can work at any time of the year. And yet, experts prefer external insulation. The reason for this is the presence of water vapor in the internal air of the apartment. It is gradually absorbed into the outer walls, passes through them and evaporates from the outside. This process happens all the time in any living space. Mounting the insulator from the outside does not stop it, you just need to correctly organize the progress of work. With internal insulation, water vapor is locked inside the apartment, which has a sharp negative effect on the microclimate. There is a strong humidity, a feeling of stuffiness, lack of comfort.

The choice of internal insulation, as a rule, is due to the lack of the ability to work outside. Outdoor work requires a permit, which is not easy to obtain. In addition, to install a heat insulator, you will have to involve industrial climbers, which will be quite expensive.

Therefore, most apartment owners choose a more affordable and simple option - internal insulation.

The method allows you to get a positive result, it is only important to correctly understand the physical essence of the process and organize it in the right way.

Vapor permeability

In a residential building, the vapor permeability of the walls should increase in the direction of the street. The main reason lies in the different humidity in winter inside and outside the house. The reasons for high humidity in the house are as follows:

The house is inhabited by people who breathe, cook, wash floors and dishes, and do laundry.

All these habitual operations make the air more humid. And with closed windows, air exchange is difficult and is carried out only by the forces of the ventilation system. From the course of physics, we know that heated air is able to retain more moisture than cool air. For this reason, condensation occurs from the "excess" moisture during the cooling of the air.

Sweating windows and dampness in the corners of the building are a practical example of this. But water vapor leaves the house not only through ventilation, but also through the pores of the wall. If the wall outside is more permeable to steam, then it can easily pass through it. Otherwise, having met an obstacle, water vapor begins to condense right in the wall, which leads to its dampening.

Types of heaters

There are many insulation materials on the market. Consider the most popular heaters in detail.

Mineral wool

One of the most successful options is stone (basalt) wool. Usually, when it comes to mineral wool, they mean exactly stone, although the term denotes a wide group of materials, which include slag wool, glass wool and other types of similar insulators. Basalt wool is more convenient to use, has a good set of operational and technical characteristics. It does not burn, does not emit harmful substances and is not subject to decay. It is produced in different forms - from rolled to more rigid slab. The disadvantage of mineral wool is the ability to absorb water, which makes installation somewhat difficult and requires additional operations.

Styrofoam

This insulation is a confident leader among all other types in terms of popularity. The reason for this is the low price of the material, low weight, ease of installation and processing. The material is resistant to water, has stable dimensions and geometry of the plates, impervious to water vapor. For internal insulation, this is the most preferred option, budgetary and not time-consuming.

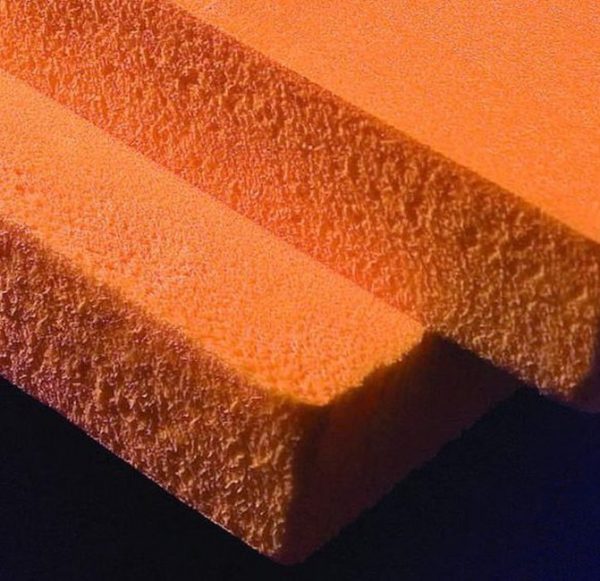

Penoplex

From a chemical point of view, this material is a complete analogue of polystyrene - both of them are variants of expanded polystyrene. But unlike polystyrene, which is expanded polystyrene granules connected during heat treatment, foam polystyrene (extruded polystyrene foam) is a monolithic material, hardened foam. It is stronger and heavier than foam, has a higher price.

polyurethane foam

A specific heat insulator, sold in liquid form and applied by spraying onto the surface to be treated. In air, the material foams and hardens, as a result, an airtight layer is formed, resembling mounting foam. Polyurethane foam is ideal for insulating walls with complex geometry, the presence of small defects or protruding parts. The price of the material is quite high, in addition, special equipment is used for application. These factors somewhat limit the use, although the performance of the insulator is very high. It is completely impervious to moisture, sealed and perfectly covers the surface without gaps or gaps.

There are other materials that can be used for internal insulation. It is not advisable to list them all, since they are noticeably inferior to the named species in terms of operational and technical characteristics or are expensive.

Permeable types of heat insulators require the installation of a vapor barrier film, which increases the number of installation operations and requires additional costs. Permeable types of insulation include mineral wool and polystyrene, foam or polyurethane foam are impervious to steam or water.

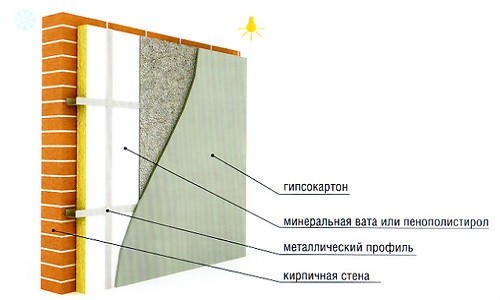

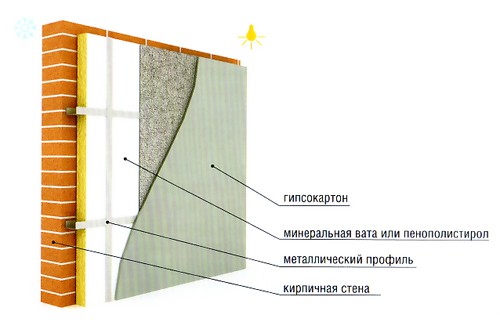

Creating a double wall

Another way to insulate is to create a double wall with underfloor heating elements. This method involves mounting the heating elements on the wall. In order to install such a design, it is necessary to create a second wall.This can be done using drywall, or you can build a full-fledged thin wall from brick halves. The presence of a false wall allows you to install insulation on its inside.

However, this method has a number of disadvantages:

- First, it greatly reduces the area of \u200b\u200bthe living space.

- Secondly, the double wall does not provide the most powerful heating.

- Thirdly, this method involves a large consumption of electricity.

What it looks like in practice

Now let's look at how to insulate a brick house from the inside, in practice.

If you chose polystyrene foam, then your insulation is quite dense, 20-40 mm, and you can glue it directly to the wall. The denser part looks inside the house, as you remember, and it can then be finished with a finish: glue wallpaper, plaster. By the way, if you are insulating not a house, but, for example, a bathhouse, but also made of brick, extruded polystyrene foam, as well as other polymeric materials, will not work here, because when heated significantly, they will release toxic substances into the air.

Warming the walls from the inside, start with the treatment of the walls: they must be leveled and primed with an antiseptic composition, which will guarantee the absence of fungi on the wall.

Armed with a regular tile adhesive or a special foam adhesive, use a notched trowel to apply the adhesive to the slabs previously rolled with a spiked roller, which will greatly improve adhesion. Glue the plates tightly to each other, make a vertical run between the seams of the rows. Wait for the glue to dry, then fill all the resulting seams with a silicone-based sealant.

You must achieve maximum vapor tightness. You can paste over the resulting surface with wallpaper, for which an aqueous solution of PVA glue will suffice. But if you want structural plaster from the inside in the house, then you also need to reinforce the surface with a fiberglass mesh, for which the same glue is suitable, and after the mesh dries, proceed to the decorative finish.

The disadvantages of these materials for a brick house are high vapor permeability and low density. Therefore, proper installation is also very important here. And it is produced by crating.

Therefore, before insulating a brick wall from the inside, we first take bars of the same thickness as your insulation board.

With a step not much narrower than a plate of insulating material, we erect a crate on the wall. The resulting windows are filled with insulation, it must be laid in a spacer. If you decide to insulate the brick walls of the house from the inside with foam, then take such an additional measure of protection as foaming the seams.

When the insulation is laid, a vapor-tight insulating film is placed on top. However, the most ideal protection for internal walls would be if you instead use foam foam 2-3 mm thick, fastening it with an overlap stapler. Be sure to glue the seam with construction tape.

At the end of the process of insulating a brick house from the inside with your own hands, you need to attach a false plasterboard wall to the bars, you can also use lining or wall panels.

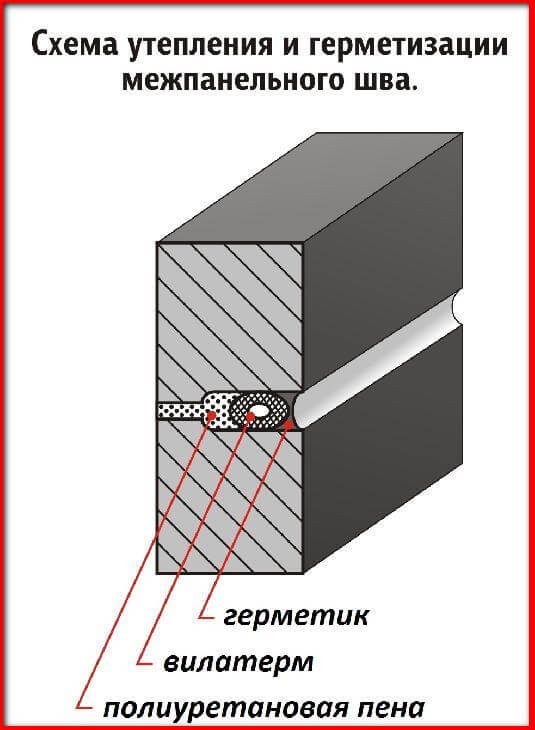

Seam insulation

The need for thermal insulation of joints in accordance with the technology will eliminate the appearance of drafts, fungus, and heat losses.

The main prerequisite for the work is a fairly long service life of the house - twenty years or more, resulting in shrinkage and shift of structural elements.

As a result:

- joint filler peeled off or cracked;

- there is a decrease in the temperature in the room during severe frosts;

- there is damage to the plaster layer, peeling of wallpaper and other finishing materials;

- constant humidity is fixed at the junction;

- the occurrence of mold;

- visual signs of the destruction of the seam from the outside.

The design of the interpanel seam

A panel seam is a junction of external enclosing structures, classified into a seam formed at the junction of two or three slabs.

The last type of seam needs an enhanced technological procedure, since it is the most vulnerable.

Today, the insulation of joints directly in houses from panels is made with polymeric materials, which significantly increased the life of the coating.

The following factors influence the choice of insulation:

- climatic zone;

- number of storeys;

- year of construction of the building and its purpose;

- a major overhaul.

Among the widely used heaters:

- polyurethane foam (sealant based on polyurethane);

- filler Vilaterm;

- mineral wool and other soft insulating fibers.

Also, complete sealing of the seam is a common method of thermal insulation. As a filler, plastic solutions are used that penetrate deeply into structural cavities, and sand, expanded clay, fine gravel are considered as fillers.

All work is carried out on a leveled and thoroughly cleaned surface, while the used plate-type insulation materials with a very high coefficient of strength.

What does corner apartment mean?

Corner apartments are located in the end sections of residential buildings. One or two rooms in such apartments have two adjacent walls bordering the street. The layout of such apartments is no different from the configuration of all the others in the house, only an additional window and a heating radiator appear, moreover, such an addition is not found in all corner rooms. To compensate for heat losses through enclosing structures resulting from an increase in the area of external walls, an increase in the internal temperature by 2 ° is provided, which is ensured by an increase in the standard number of radiator battery sections. In practice, this is achieved either by having a battery installed under an additional room window, or by installing a larger radiator (number of sections).

These measures rarely work as intended, as they are designed to solve the problems of the conventional premises and do not take into account many of the impacts that exist in reality:

- The outer wall is located on the windward side of the house;

- Worn-out heating networks, non-compliance of the heating regime with regulatory requirements;

- Mistakes and shortcomings made during the construction of the house.

These factors are often present all together, significantly changing the temperature in the apartment for the worse. The cold surface of the walls begins to get wet due to the active formation of condensate, the apartment becomes cold and uncomfortable. Such situations are quite common and require appropriate measures.

Getting rid of freezing corners

You can positively solve this problem if you know how to insulate a panel house from the outside and, in particular, an apartment.

Consider how and with what panel houses are insulated. There are several schemes and methods of insulation using various materials.

Particularly acute is the question of how to insulate the corners in a panel house. The corner room, due to its structural specifics, has not one in common with the street, but two, which significantly increases heat loss. In addition, such rooms contain two windows, one for each of the existing external walls. This fact is remarkable only in terms of illumination, but in terms of heat preservation - so-so.

Living in such apartments are trying to solve the problem by increasing the number of heating devices in the room. But, as everyday experience shows, often there are problems with freezing of the corners between the outer walls and, as a result, condensation appears on the wall and the consequences are not long in coming:

- wallpaper goes away;

- walls previously painted with water-based paint are covered with stains, and the enamel peels off in patches;

- the destruction of the plaster occurs, which will cause damage to the main wall;

- a fungus appears, which looks unaesthetic and is harmful to health.

The conclusion suggests itself - you need high-quality insulation of the corner room and it is better not to limit yourself to just improving the corners.

You can insulate a corner room:

- outside;

- from within.

If insulation is not available from the outside, consider the issue of internal thermal insulation. Condensation is a clear "bottleneck" of internal insulation, therefore, it is necessary to protect the main wall from water vapor.

There are currently two known solutions:

- the use of a heater characterized by low vapor permeability;

- protection of the insulation directly with a vapor barrier film;

When it is not possible to insulate outside

Ideally, place a layer of insulation outside the building along its facade. But not always the owners manage to implement this option. There may be several reasons for this:

- it is forbidden to change the facade of the house because of its historical value (the situation is typical for old brick apartment buildings); insulation work must be carried out at high altitude, and the owners do not have the opportunity to turn to professional builders; there is too little distance between neighboring houses, which does not allow work with outside walls.

In all of these cases, you will have to resort to internal insulation. The main task in such a situation is to avoid the harmful effects of condensate on the insulation.

It can be solved in two common ways:

- When using mineral (basalt) wool, the vapor barrier film is overlapped and all seams are carefully glued. As such a material, you can choose polystyrene foam or penofol with a foil layer.

How to insulate walls in a panel and monolithic house

How to insulate walls from the inside? How to insulate a concrete wall from the inside? How to do it right? To insulate a wall from the inside, consider a step-by-step instruction for insulating walls and partitions in a panel house from the inside.

Action algorithm:

- First you need to prepare the walls. To do this, remove the furniture, clean the walls from the finishing material to the plaster. Therefore, this procedure should be combined with the repair work in your apartment;

- next to be done. It is best to use special polymers, but you can also use ordinary plastic wrap. It is applied directly to the walls, the bonding points of the strips are glued. To do this, use construction tape;

- then we mount the crate, you can use both wooden and metal rails. In the first case, the tree must be treated with antiseptics and fire-fighting solutions. When installing the crate, the step size must be selected depending on the insulation so as not to form gaps and voids;

- then we directly lay the heat insulator, that is, we insulate the walls. It should fit into the openings between the crate. Many materials are designed in such a way that when installed they straighten and fill the entire form, this significantly reduces installation time;

- installation . By installing it, we protect our insulation from wet steam, which is always present in the apartment. In no case should these measures be neglected, since moisture will begin to accumulate in the insulation. As a result, the product will lose its properties, and all your work will be lost.

How to insulate the walls of the apartment from the inside? You can insulate a corner apartment in a panel or monolithic house by following these six steps.

Advantages of expanded polystyrene

Scheme of insulation of a brick wall from the inside with foam.

In other words, this is a well-known foam.

Easy to install, lightweight and budget option, available to anyone who wants to insulate their home from the inside. For greater fire resistance and less brittleness, we advise you to choose extruded polystyrene foam. Choose the thickness and density of the sheets depending on the purpose of insulation.

Necessary materials: expanded polystyrene, polyurethane foam, glue for expanded polystyrene, mounting dish-shaped dowels-“fungi”, metal profile for drywall, drywall, drywall screws.

Necessary equipment: a knife, metal scissors, a wide spatula-comb for applying glue and a small handy spatula, a bucket for diluting glue, metal scissors, a puncher with a drill suitable for "fungi" and self-tapping screws, a nozzle for mixing glue or just a rod.

Apartment insulation methods

Before mounting the walls, you need to change the wooden windows to metal-plastic ones, preferably three-chamber ones, they will act as a vacuum. If this is not possible, then you can treat the window joints with silicone and put rubber seals in the places of contact. Do the same work with the balcony. Of the most practical options for warming a corner apartment, it is customary to distinguish the following:

To perform the work, polyurethane foam can be used.

To perform the work, polyurethane foam can be used.

- Mineral wool - due to its plasticity, it is easy to install, easy to process, made of refractory material, non-toxic. The disadvantages include the fact that it is a moisture permeable, rather heavy and deformable.

- Expanded polystyrene - is able to withstand temperature extremes and retains its properties for up to 35 years. But at the same time flammable.

- Polyurethane foam - has excellent soundproofing properties, non-flammable, durable. Requires high costs, requires the assistance of specialists and additional equipment in operation.

- Plaster - acts as a barrier to heat transfer.

- Thermal paint - is able to eliminate cold bridges and maintain the optimal microclimate of a corner apartment.

Always use a level when leveling surfaces. You can also make "warm walls" by analogy with the "warm floor". In this case, the electric insulation is mounted in the walls, this will allow them to warm up so much that the formation of condensate drops to zero. It is customary to distinguish two main methods of insulation:

- Interior.

- External.

How to insulate the corner wall of a brick house from the inside?

At the beginning of work, the surface is cleaned, a primer with antifungal properties is applied on top. When insulating with mineral wool, a frame is built from wooden slats, between which cotton wool cuts are laid on glue. Glue is applied to the wall. The seams are smeared and overwritten, drywall, primer and paint or wallpaper are applied. When working with expanded polystyrene, glue is applied to the sheet with a spatula and glued.

There should be no gaps, the seams are covered with sealant. Finishing is done with fiberglass plaster mesh, which is smoothed with a layer of glue, drywall is attached to it. When plastering, the material is applied in three layers, and after each it dries, then primed and leveled. The wall is painted or pasted over. To insulate a corner room with thermal paint, the base is prepared, paint is applied with a brush or roller. After drying, you can paste over the walls with wallpaper.

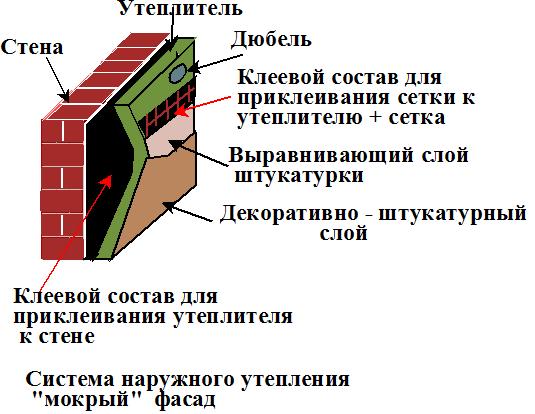

External insulation

For external sheathing of surfaces, mineral wool, expanded polystyrene and polyurethane foam are used. Mineral wool sits on glue and is fixed with anchors. The seams are rubbed and leveled with sealed materials. A reinforcing mesh is applied on top, and a layer of facade paint is applied on top of it. The technology of insulation with expanded polystyrene begins with the installation of a metal frame. The walls are treated with a special solution and expanded polystyrene plates are placed on the glue.The corners are rubbed, a layer of plaster and paint is applied. When insulating with polyurethane foam, a metal mesh is installed. The material is applied using a spray gun. From above, you need to apply a layer of glue and a reinforcing mesh, and then plaster and paint with facade paints.

One of the frequently asked questions by most of us, especially the owners of an apartment in a panel house, is how to insulate a corner room in a panel house.

Warming a panel house from the outside is a necessary measure, since living in a cold apartment does not add comfort and is fraught with health problems. And, most of all, this applies to end (corner) apartments in panel high-rise buildings. At the interfloor joints, cracks are formed over time, through which water easily penetrates into the wall and is absorbed. In winter, the water accumulated in the walls freezes and begins to hit the wall from the inside, making the living space both cold and, moreover, damp.

Requirements for insulation for interior work

It has been proven that approximately 40% of heat loss in a private house occurs through walls. Therefore, it is necessary to start thermal insulation work from the walls. When choosing a heater, you need to consider that it must have a certain set of technical characteristics, namely:

Wall insulation with foam.

- Low thermal conductivity. The selected material should not only keep warm inside the house in winter, but also not let warm air in from the street in summer. Only in this case, accommodation will be comfortable all year round.

- Little vapor permeability. The insulation should have less vapor permeability than the building material from which the house is built.

- Incombustibility. High resistance to open fire is the main condition in terms of fire safety.

- Environmental friendliness. The material used during operation should not emit harmful substances that adversely affect the human body.

- Moisture protection. The selected insulation should not have high absorbency, since with an increase in humidity, thermal insulation properties decrease.

- Small thickness. The thickness of the insulation will determine how much free space its installation will take.