Ways to adjust the heating system

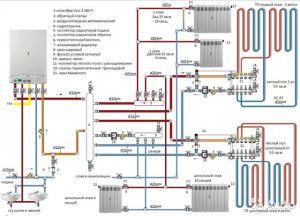

Heating system with control valves

There are several ways to change the characteristics of heat supply. Timely hydraulic adjustment of the heating system is necessary to stabilize the pressure in certain areas and the entire scheme as a whole. Temperature correction serves as a tool for changing the degree of air heating in a particular room. Most often, a tap is used to adjust the heating temperature.

All of the above characteristics largely depend on the operation of the boiler. However, to normalize the system parameters, it is necessary to install additional components. Depending on the function, they are divided into the following types:

- Temperature. Serve for partial or complete blocking of the coolant flow in radiators or in a separate circuit. With the help of taps, a thermostat or mixing units, the heating batteries in the apartment are adjusted;

- Pressure. Temperature differences between flow and return can cause pressure surges. This will unbalance the system, which will worsen its performance. To eliminate this problem, hydraulic arrows are mounted, as they do collector pipework.

In practice, timely adjustment of taps on heating radiators reduces energy costs. Also, with the help of control valves, you can change the degree of heating of the air in the room.

The actual performance of the heating system must match the calculated ones. In this way, the number of adjustment elements can be reduced.

Valve installation

Installation of valves on radiators is carried out in several stages:

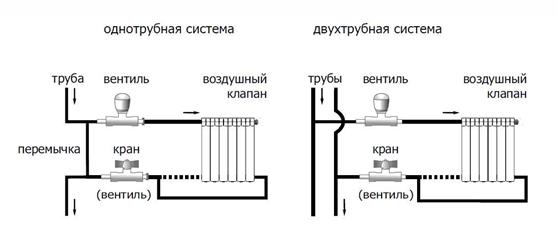

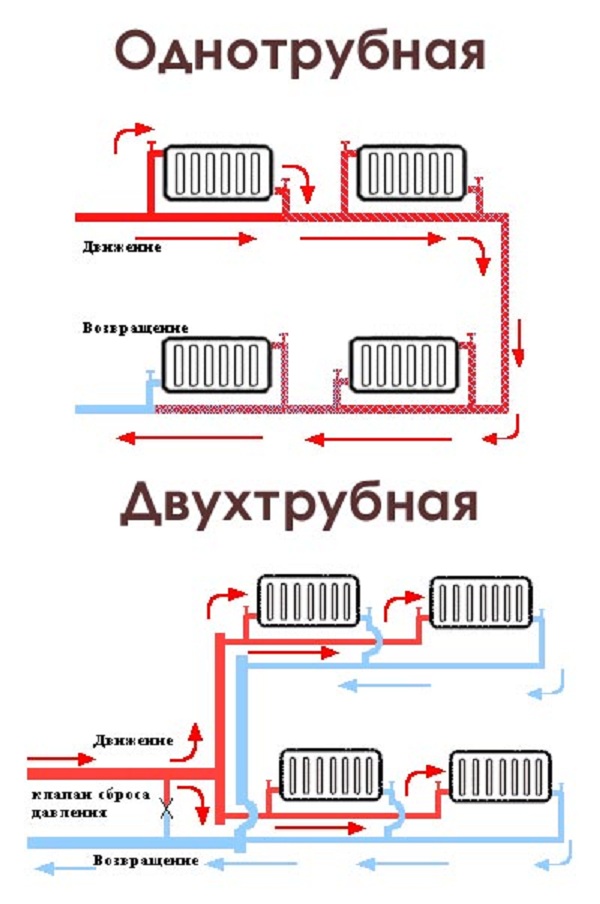

- selection of the device connection scheme. Specialists have developed standard schemes for heating systems with one and two pipes;

Standard Wiring Diagrams

- preparation of components and equipment. For installation you will need:

- stopcock;

- valve;

- a pipe cut for arranging a jumper (bypass), if a single-pipe system is installed in the apartment;

- bypass welding machine;

- tools for cutting threads on pipes;

- linen or FUM tape for sealing joints;

- wrench for tightening the thread;

- at the next stage, the liquid is completely drained from the heating system. If the installation of taps is carried out in a private house, then you can drain the system yourself. How to open the valve on the battery to drain the system? The valve is considered open if the control lever of the valve is located along the pipe. If the valves are tapped in an apartment building, then to drain the system, it is necessary to involve employees of the service organization;

Draining water from the heating system of a private house

- locations for the installation of valves are selected. It is recommended that valves be placed on pipes in such a way that they can be accessed as soon as possible. It is necessary to install a thermostatic valve at a distance of 0.7 - 0.9 m from the floor level;

- pipes are cut in selected sections;

The length of the section to be cut must match the length of the valve to be installed.

- if necessary, a bypass is installed;

Installing a jumper for the passage of water in the system

- a thread is cut on pipe sections, the size of which matches the size of the thread on the valve;

Thread preparation for connecting a pipe to a faucet

- the thread is sealed with linen thread or FUM tape;

- the control valve is fixed to the pipe with a key.

Fixing the valve to the heating pipe

For normal fixation of the valve on the pipe, it is enough to make 4.5 turns. Overtightening can lead to cracking, and undertightening can lead to poor sealing.

- the tightness of the heating system, threaded connections and welds is checked.

How to cut threads and correctly install the valve on the radiator is described in the video.

Experts recommend installing thermostatic valves in apartments that allow you to independently regulate the temperature of the radiator. Installation of the device does not cause difficulties and is carried out by hand.

Valve plumbing repair

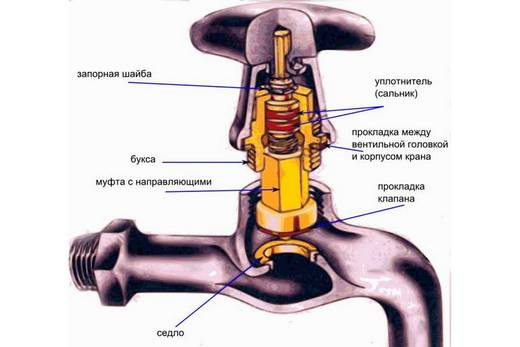

If the shut-off element of the valve is damaged, it is replaced with a similar, unworn or new assembly. To do this, the pipeline section is freed from liquid, blocking it from both sides. Then the valve-type shut-off element is dismantled. The ball valve is removed completely open-ended or On the flanges, the nuts are twisted in parallel and gradually - 3-4 turns on each.

First, you should check the serviceability of the seals, which are replaced when worn. Most leaks are due to deformation of gaskets and thread stripping due to improper installation. Then the body and seat are inspected. In the absence of cracks, the assembly is assembled again. The case cannot be repaired if mechanical damage appears on it. Growth to the pipeline requires its cutting and the need for further welding.

In this case, you will have to install a new or repaired water valve. An unprepared person should not undertake complex repairs because of ignorance of its features.

Shut-off valves create additional resistance, so blockages can form at the joints. It is not always necessary to remove the valves. Sometimes it is enough just to flush the pipelines by opening all the taps.

Replacing the oil seal can be done carefully with your own hands. To do this, turn off the water supply from the riser, disassemble the locking mechanism, replace the gaskets and lubricate the moving parts.

How to choose a valve

The thermostatic valve must be selected according to the following parameters:

- type of device;

- device characteristics;

- price and manufacturer.

Types of thermostatic valves

Adjustable valves for heating systems are divided according to the following features:

- according to the method of installing the valve on the heating pipe. Allocate:

Valve intended for installation on a pipe parallel to a wall

corner valve installed on pipes brought out of the floor;

Valve for installation on a pipe coming out of the floor

axial valve mounted on pipes coming out of the wall;

Valve for installation on a pipe coming out of the wall

- according to the type of heating system installed in the dwelling. Valves for one-pipe systems have a higher flow capacity than valves for two-pipe systems;

Varieties of heating systems in rooms

- according to the type of working substance in the thermoelement. The substances can be:

- gas;

- liquid;

- paraffin;

Valves that work by compressing gas are more accurate and reliable. Paraffin-based thermocouples are considered the most short-lived and less accurate. The fluid is in the middle.

- according to the type of adjustment of the thermoelement, there are:

- valves with pre-setting, which is carried out by specialists on the basis of average data from the home heating system;

- valves with open adjustment. Such devices can be configured by the user independently;

- according to the type of installed thermoelement. Distinguish:

thermostatic valve, manually adjustable

valves with a thermostatic head, which is controlled automatically according to the specified parameters;

Automatic heating valve

valves with a remote thermoelement, which is installed separately.

Thermal head with separate temperature sensor

Valve selection should be based on user requirements and convenience.

Device selection according to performance

After the type of thermostatic valve has been selected, it is necessary to determine the operating parameters of the device.The valve installed in the heating system must:

- withstand temperatures up to 200ºС;

- withstand pressure within 16 - 40 bar;

- be made of materials that are not susceptible to corrosion and mechanical stress. The most durable valves are made of bronze. You can also install devices made of steel or brass;

- match in diameter with the diameter of the heating pipes;

- be able to install on a specific system. If a threaded valve is mounted, then the thread parameters on the pipe and device must match.

Popular manufacturers and cost of valves

The cost of thermostatic valves depends not only on the type of device, but also on the manufacturer. The most durable and reliable are valves made:

Choosing a thermostatic expansion valve for an air conditioner

The thermostatic expansion valve (TRV) in the room air conditioning system controls the level of refrigerant entering the evaporator and prevents liquid from entering the compressor.

Valves for the air conditioning system are divided into two types:

devices with external equalization. The pressure is determined at the outlet of the evaporator. The system has an additional tube that supports the specified parameters;

Thermoregulation device with external pressure equalization

devices with internal equalization. The pressure in the system is determined directly in the evaporator itself.

thermostatic expansion valve

Valves with internal equalization are installed exclusively on single pass evaporators.

Pipe connection methods

According to the method of installation, water valves are divided into two positions.

- Coupling or threaded. At the heart of the connecting element is a thread, which can be internal or external. In domestic networks, valves of this particular type are used, especially for internal wiring. Fittings with such a connection are mainly installed in pipelines through which water moves with a pressure of no more than 1.6 MPa.

- Flanged. These are either cast-iron or steel devices, on the ends of the nozzles of which there are flanges. These are more powerful devices with greater weight and overall dimensions. They are mounted only on main or industrial pipelines in which water moves under a pressure of more than 10 MPa.

Socket valves are installed in the water supply system by means of a thread, which must be cut at the ends of the pipes to be connected. This can be done with a special tool - a die. Its size is selected according to the diameter of the valve and the size of the thread. The second option is to weld spurs of the same diameter as the valve to the pipes, taking into account the thread number. When connecting the device to pipes, in order to create a complete tightness of the joint, use an FUM tape or thread.

Valves with external threads are attached to pipes using a fastener, which is popularly called an American. It's basically a nut with a rubber seal. To do this, an American is first put on the pipe, and then a branch pipe with a side at the end is welded to the first one. It is on him that the union nut will rest in the process of screwing onto the thread of the valve.

Flanged models cut into the pipeline by installing flanges of identical size at the ends of the cut pipes. The connection of the latter with pipes is carried out by welding (gas or electric).

Method of fixing plastic valves

For this, welding technology and a special welding machine are used. Since a plastic device is used when installed in a water supply system assembled from plastic pipes, the welding technology lies in the fact that the pipe and valve nozzle are heated to a certain temperature.

The pipe is heated along the outer contour, the valve along the inner hole of the pipe. The plastic softens, the pipe is inserted into the pipe and allowed to cool.The material of the pipe and the valve are soldered at the molecular level, resulting in a single non-separable structure, one hundred percent sealed.

Replacing a valve on a gas pipeline

Replacement scheme

Replacing valves in an apartment on a gas supply pipe is carried out in the following way:

- preparation of materials. To carry out the work you will need:

- a new valve, selected in all respects;

- two wrenches;

- means for sealing joints (linen thread and graphite grease);

- plug (required if the work is performed by one person);

- before replacing, it is necessary to shut off the gas supply to the room. To do this, the old valve must be transferred to the “closed” position, that is, perpendicular to the pipe. Then you need to remove the remaining gas from the pipeline (for example, burn it with a stove burner);

- dismantling of the old valve:

- if the valve is installed on the thread, then the fixing elements are unscrewed;

- if the valve is installed by welding, then the device is cut out of the gas pipeline;

How to cut a thread on a pipe yourself

- a plug is installed at the end of the pipeline. If the work is done together, then the pipe can be drowned out with a finger;

- the thread is treated with sealing materials. For the strength of the connection and the smooth running of the valve, graphite grease is applied over the linen thread;

Threading with graphite lubricant

- new faucet installed.

Installing a new valve on a gas pipe

Leak test

After installing the valve on the gas pipe, it is necessary to check the tightness of the connections obtained and the device itself. You can determine the presence of a gas leak as follows:

- a saturated soapy solution is introduced. To do this, the maximum amount of any soap must be diluted in water;

- with the resulting solution, with the help of a sponge, the joints and the valve are coated.

Using Soap Solution to Detect Gas Leaks

If the junction of the valve with the pipes is not tight, soap bubbles will form.

The formation of a bubble indicates a violation of tightness

If a leak is detected, it is recommended to perform all work again and increase the sealing.

You can replace all the valves in the living room yourself. To carry out the work requires minimal knowledge and a small set of tools.

The water valve belongs to the group of valves for special purposes. It is used both in internal and external water supply networks, as an element with which you can completely shut off the water supply or regulate its volume and pressure. In the internal water supply system, the valve must be installed at the entrance of the route to the house (apartment) and near each plumbing fixture.

Installation of air vents

A typical faucet for a heating battery is Mayevsky's product. The valve is a simple design of a brass rod, in the closed position, blocking the hole in the seat, and threads to install it in the radiator plug.

Such taps for heating radiators are reliable and rarely need repair or replacement, but:

- their permeability is small. If you put the tap on the riser and wait about 10 minutes once a year until the air comes out easily, then it is hardly worth installing such an air vent on the expansion tank of an apartment building with a top filling. It is better to give preference to a conventional valve;

- when buying a Mayevsky faucet, you need to choose a product for a screwdriver, and not for a special key, which is not always easy to find before starting the heating;

- part of this type of product allows you to unscrew the stem completely, unfortunately, such cases are not uncommon. No one has yet succeeded in screwing the rod into place, while overcoming the resistance of the hot coolant.

An alternative to the Mayevsky faucet is a drilled radiator plug or an adapter with a screwed plug valve. Sometimes, for this purpose, a conventional water tap is used, which is placed upside down - with the spout up.

When such a tap is installed on a heating radiator, you need to remove the handle and lamb from the valve, as a small child in the house will be attracted to a bright object, and he will eventually try to turn it. The consequences will be bad.

valve material

Here it is necessary to divide the valves into those that will be used in internal water supply networks, and those installed outside.

For internal networks, devices are made of bronze, brass, stainless steel and plastic. For outdoor use models from all of the above materials, as well as from steel and cast iron.

- Devices made of brass and bronze are the most expensive, but at the same time, the most durable. They have a small specific gravity, small dimensions, they can be installed both on a water supply system with cold water and hot water. More recently, only they were used in the heating system, because scale does not settle on the surfaces of brass and bronze appliances.

- Stainless steel valves also boast a long service life. But they are much cheaper than the first two models.

- Plastic valves are the cheapest with good technical characteristics. It is now used in all types of plumbing and heating networks.

Valve types

It is classified according to three criteria:

- body shape;

- type of locking part;

- installation method in the system.

Valves are classified according to their body shape as follows:

- direct-flow - the flow is blocked by the valve seat in the transverse direction;

- angular - the locking element moves towards the movement of the medium;

- mixing - to obtain a given water temperature.

The locking element differs in design:

- Ball - a through sphere in a straight-through body. When the longitudinal axes of the hole and the body are aligned, the flow movement is completely opened. Turning in the perpendicular direction 100% shuts off the flow of fluid. The valve performs the function of only a locking element, and it is not suitable for regulation. The use of the device is associated with its high reliability, speed of shutting off the flow and compactness. Almost nothing breaks in it, since there are very few parts.

- Valve - with a constipation associated with a threaded rod screwed into the seat nut. The unit is used to control the flow and to completely shut off the flow (in the lowest position).

- Needle - conical piston with high pressure fluid flow regulation (about 220 bar).

Valve materials:

- ball: brass, stainless or;

- valves: cast iron, brass.

New materials are also being used to make valves. The polypropylene body makes the device durable and cheap at the same time. Fluoroplastic coatings improve resistance to corrosion and aggressive environments.

Ball valve and valve difference and product features

What is better to buy: a faucet or a device such as a valve? It is really impossible to give a precise answer to this question. Indeed, in some situations it is necessary to use a ball valve, but in others - a special valve. Additionally, it is recommended to note here the fact that the crane is considered a more convenient device to use. In this situation, the handle can be rotated all 90 degrees. Due to this, the incoming water is blocked. But the shut-off valve present in the valve must be wrapped in order to close or open the water supply.

Additionally, there are special valves with gaskets on the valve. When worn out, it is enough to simply replace them with a new version.It is also recommended to periodically replace the seal itself. But with a ball valve variety, such problems do not really exist. Only constant and thorough care of the surface itself is recommended here. It should always be in the most ideal condition.

In general, if enough hard water is supplied to the room, then the installation of a valve is recommended. After all, such a product is subject to, albeit partial, but still repair. In a situation where the crane is damaged for some reason, then you can not do without its full replacement.

With all this, the valve can most often be purchased at a lower cost, if taken in comparison with the second type of product. Such a not too high price is primarily due precisely to the fact that the device has a simple design of such an element as a shut-off valve.

In any situation, the shut-off type of valves in modern times is used to create a variety of sewer and gas pipeline systems. It is also often found in pipelines with a general purpose. The device is intended to block the gas or water flow. For this purpose, it is possible to install not only valves and gate valves, but also devices such as taps and valves. All of them have a huge number of advantages, and some negative characteristics. Everything depends on the situation.

Thus, the difference between a valve and a tap initially lies in the fact that with the use of a tap it is impossible to regulate the pressure of the working flow. But the second product allows such an action.

Add site to bookmarks

- Kinds

- Choice

- Installation

- Finishing

- Repair

- Installation

- Device

- Cleaning

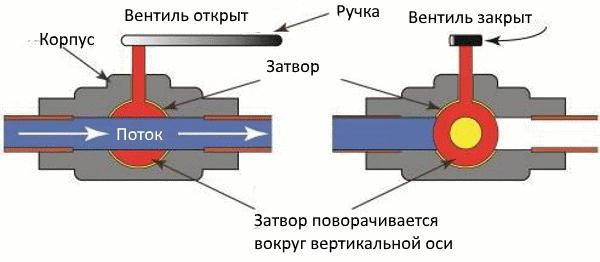

The device and principle of operation of the ball valve

The main working body of the valve is a ball with a through hole. When the handle is positioned along the pipe, the valve is open. If it is turned perpendicular to the pipe, it will close. The hole in the ball can be round, square, in the form of a trapezoid or an oval. In valves of small diameter, the valve is made floating, and for large-sized devices it is made on special supports. High tightness of the shutter is provided by an elastic seal. This allows you to install this type of models on gas pipelines.

The water ball valve operates in two extreme positions when rotated 90 degrees, when it is fully open or closed. Attempting to control flow will result in rapid seal wear.

They have wider possibilities for connecting pipes during the installation of water supply systems:

- walk-throughs;

- corner;

- with three or more outlets in order to redirect transported flows.

Connections with pipes are made by fitting, flanged and welded. The latter option allows you to permanently install a water valve in the system.

Comparative characteristics of a faucet and a valve

The main difference between a faucet and a valve is the adjustment of the pressure of the working medium. A valve can make this adjustment, but a tap cannot. Moreover, given the rules for the operation of cranes, it is strictly forbidden to regulate the pressure with their help. The crane has only two functions: to open and close the flow of the medium. But the valve can easily regulate the pressure of a liquid or gas.

This difference is due to the design. The locking element in this device moves in the direction of flow and eventually sits on the saddle. In cranes, it rotates around its axis. In addition, there are ball valves. In their design, the locking element is a ball that rotates perpendicular to the flow, as a result of which the diameter of the pipe changes. But the valves are equipped with a grun-box. This constructive solution implies that, by moving the stem of the bushing, the valve, which is attached to the stem, is raised or lowered.Thus, the opening or closing of the hole, which is located in the saddle, occurs.

Visually, it is easy to distinguish a valve from a faucet. If the shutoff valve has a simple handle, and the end of this handle is attached to the stem, then this is a tap. If there is a lamb in place of the handle on the stem, this is a valve.

Add to bookmarks

They are used on pipelines larger than 50mm in diameter where slow flow shutoff is required to prevent water hammer.

At the valve, the shutter moves perpendicularly, and at the moment of closing, the sealing surfaces do not experience friction, which significantly reduces the occurrence of scoring.

Due to the fact that inside the valve body the direction of flow changes twice, and the flow area is smaller than that of gate valves, the valve has an increased hydraulic resistance, which is its main disadvantage.

The valve cannot be operated in different directions relative to the flow direction. Its working position is the direction of flow when it presses against the plate in the closed state from the seat side, and not from the stem side. In this position, the flow pressure as the valve opens even helps lift the poppet off the seat. If the valve is not installed correctly, the flow pressure in the closed position presses the poppet, and when the valve is opened, a very significant force will have to be applied to move the stem, since it will be necessary to overcome the flow pressure. This can lead to its failure, since the valve disc can be torn off the stem, which will require a lot of labor for repair.

Manufacturing technology and materials

Manufacture of coupling shut-off and control valves is carried out by casting or stamping. At the same time, the material undergoes a preliminary check for compliance with the standards of operation in a particular environment.

For production, stainless steel, cast iron and brass are used, which are characterized by high performance, long service life and acceptable cost to meet the needs of the buyer.

brass valves

Brass coupling faucet is most often used in cold water supply systems of vertical or horizontal type. The design of the mechanism can be:

- Direct-flow. It has no internal metal parts that need protection. The spindle axis in them is located at an angle to the flow line. In this case, low hydraulic resistance is observed. The body of such a valve is long and heavy.

- Angular. Is established on places of turn or a bend of the highway.

- Direct flow. Its installation is carried out on any section of the pipe. The device is characterized by a high level of hydraulic resistance.

Brass products are distinguished by high corrosion resistance, resistance to temperature extremes, resistance to increased pressure inside the system.

Cast iron valves

The cast-iron coupling valve is distinguished by a powerful body and a spindle-based control unit. It is designed for pipes with a diameter of 10-300 mm. The body of the part is able to withstand pressure up to 15 MPa and heating up to +225°C. In practice, the products are operated in low-pressure water pipelines with a liquid temperature of about +50°C. Less often - for the transportation of steam and gas with prescribed maximum characteristics.

Due to the strength of the body and the control mechanism, cast iron faucets are widely used not only in everyday life, but also in industry. The relatively low cost makes them almost indispensable. The body of the product is made of gray or malleable cast iron. All parts of the locking unit are made of steel. A rubber or leather gasket is used as a sealing element.

Steel devices

The steel coupling valve has excellent strength, significantly exceeding the index of cast iron and brass, but inferior to them in hardness.To improve performance, alloying elements such as manganese, cobalt, vanadium, chromium, etc. are introduced into the composition.

One of the varieties of modified metal is stainless and heat-resistant steel. Cranes have proven themselves in highways with high temperatures and aggressive environments.

Union valves with an American mechanism are made of steel, in which union nuts are used instead of hexagonal ends. This design greatly simplifies the installation process, since there is no need to scroll through the entire armature. Fixing is carried out by screwing the nuts separately on each side.

What is a valve

Shut-off, or control, coupling valve is installed to stop the flow of fluid or control its power. Due to the peculiarities of the installation, the design has been widely used in water supply systems, heating systems, in gas household mains with a small pipe cross section.

Main characteristics

Shut-off and control valves with coupling fastening are a piece of pipe with a slight thickening in the middle, where the mechanism of action is located. There are threaded flanges on both sides, and a mechanical or electronic control element is attached to the mechanism.

The installation of devices involves screwing onto the opposite thread of the pipeline, therefore, in systems with large diameters, they are not used, giving preference to flange structures.

The technical characteristics of the valves vary depending on the material of manufacture, the main ones are presented in the table:

| Specifications | Cast iron | Steel | Brass |

| passage diameter | 15-50 mm | 15-50 mm | 15-50 mm |

| Pressure | 16 MPa | 16 MPa | 16 MPa |

| Operating environment temperature | +225ºС | +425ºС | +225ºС |

| Temperature outside | -40…+40ºС | -40…+45ºС | -40…+40ºС |

| Length | 90-200 mm | 60-200 mm | 55-132 mm |

The service life of all valves is about 50 years under conditions of proper installation, maintenance and care.

Advantages and disadvantages

Metal coupling valves have a number of advantages, which include:

- the ability to effectively perform their functions in systems with high pressure and its drops;

- ease of installation, repair and replacement;

- long service life;

- small stroke of the control lever, which allows you to quickly adjust the flow;

- small size and weight, due to which the parts can be installed at any point of the pipeline both horizontally and vertically.

A significant disadvantage is the high hydraulic resistance, due to which it is not possible to install structures in systems that carry viscous substances.

Conclusion

The water valve is easy to operate and does not require special maintenance. Each model should be used for its intended purpose. A simple repair of the valve can be done by hand, if you act carefully and correctly.

How is a faucet different from a valve? This question is of concern to a large number of buyers today. Initially, it must be understood that all existing pipelines are equipped with a certain type of fittings. Its main purpose is to block, as well as to open the flow of liquid, both in regulating the temperature regime and in protecting equipment.