Troubleshooting

coolant hoses

There are three possible options for removing an air lock from the cooling system:

- Through the expansion tank with the removal of the pipe.

- Without disassembly, by tilting the car and adding fluid.

- With the help of heating.

Let's take a closer look.

First option

The first option on how to remove the airlock from the cooling system is suitable for most owners of domestic vehicles. In these cars, it is possible to disconnect the carburetor heating hose or the throttle assembly. To remove the hose, you will need to remove all parts that interfere with this procedure. Then you need to get this hose and remove it from the fitting. After that, unscrew the plug at the expansion tank and start blowing into it. As soon as the coolant began to flow out of the hose, you must quickly return it to its place and secure the pipe with a clamp. We return all the details to their place and enjoy the working stove.

Second option

Coolant filling

In the implementation of the following method of self-bleeding, you will need to drive into the inspection hole and set the car to the handbrake. Using a jack or other suitable tool, raise the front of the vehicle at a slight angle. You can achieve the same effect without a jack by setting the car on a steep slope. How to break an air lock in the cooling system in this way? Everything is simple. We unscrew the caps at the expansion tank and at the radiator (if any). We start the engine and bring it to the optimum operating temperature. We are waiting for the damper to open and the fluid to move in a large circle. The switches on the stove should be at the maximum heating level.

While the engine is warming up, it is important to monitor the fluid level in the tank - it should fall. Gradually add the outgoing antifreeze (antifreeze)

To increase circulation and outflow of antifreeze, it may be necessary to increase engine speed. A sharp drop in the liquid level can occur, and here it is important to add it to the correct level very quickly. You need to continue the procedure throughout the entire moment of the release of air bubbles. After completion, you will need to lower the car and add antifreeze to the required level.

Third way

The third method will also tell you how to remove the air lock from the cooling system. For its successful implementation, it will be necessary to start the engine and not turn it off until the optimum operating temperature is reached. After turning off the engine, remove the protective parts from it in order to get to the heating hose of the union assembly. The coolant is very hot, as are the hoses through which it flows, so you must protect your hands to avoid burns. You can put on two pairs of gloves - working and on top of them - rubber. We disconnect the hose and wait for the liquid (antifreeze, antifreeze) to flow out of it. When this happened, we return everything to its place. It may happen that the antifreeze has not begun to flow out. In this case, we return the hose to its place, unscrew the cap at the expansion tank and screw it back on. Then try again with the hose disconnected.

After considering three possible options for removing an airlock from a vehicle cooling system, you only need to choose the right one. One thing is for sure - it is better not to delay the solution of this breakdown, because the air in the system causes a malfunction of the stove and serious problems with the engine, up to its complete failure.

Causes of air pockets

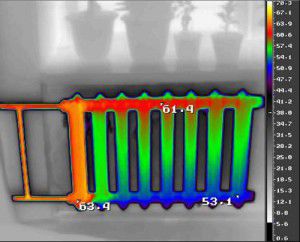

Thermogram as one of the ways to detect air pockets

The formed air plug in the heating battery can occur for a number of reasons. The main one is coolant leakage. Even a slight decrease in the volume of water in the system entails the formation of air gaps in pipes and radiators.

In addition, we must not forget that water is characterized by the degree of oxygen saturation. During heating, not only expansion occurs, but also steam is released. It can be concentrated in the upper points of the highway. Most often, an air lock in a heating radiator is formed precisely because of this. After the coolant cools, its volume decreases, the resulting space is occupied by air. During operation of the system, in order to avoid the occurrence of these phenomena, the following recommendations should be followed:

- Compliance with the level of the location of pipes and heating appliances. Even a slight skew of the battery will pose a question to the owner - how to expel an airlock from the heating system;

- The use of system elements, the material of which does not allow oxygen molecules to pass through. The most common mistake is the installation of XLPE pipes without a protective sheath;

- Compliance with the operating modes of heating. This applies to both the temperature curve of operation and the pressure. To do this, manometers and thermometers should be mounted on critical sections of the highway;

- For closed systems, it is recommended to install automatic replenishment with coolant. In the event that even a small amount of water decreases due to leakage or evaporation, this mechanism will automatically add the required amount of coolant.

But how to break a cork in the heating if it has already formed? First you need to find. A clear sign of its appearance will be a sharp drop in temperature at a certain point in the pipeline or radiator. There will also be characteristic sounds - gurgling and fluid flow. Gentle tapping will help to find the exact location of the defect. At this point, the metal will create slightly higher sounds than when completely filled with water.

If it is necessary to avoid a situation in which it is difficult to remove the formed air lock from the heating pipes, it is recommended to install a separator after the boiler. This device reduces the amount of gas in the water.

Reasons for the formation of air pockets

The finished closed-type heating system is airtight, but this does not guarantee the absence of air bubbles. Where does the gas in pipes and radiators come from?

Air in the heating system appears for the following reasons :

- The coolant is tap water, which has not undergone special training - when heated, the air dissolved in water begins to be released, and plugs form from small bubbles.

- The tightness of the system is broken, and air is gradually sucked in through loose connections.

- During the repair work, a part of the circuit was disconnected by cut-off valves, any elements were replaced or cleaned, and then the coolant was again fed into the repaired circuit.

- The pipeline was laid in violation of the standards - a small angle of slope of the pipes and improper installation of the kinks prevent gas bubbles from entering special devices - air vents. As a result, gas accumulates in problem areas and interferes with the normal circulation of the coolant.

- If the heating system of a private house fills up very quickly (or when the coolant is not supplied at the lowest point), the liquid is not able to completely displace air from pipelines and radiators with complex configurations.

- Air vents are missing or incorrectly located. Also, the reason for the incorrect operation of the air bleed device is its contamination with mechanical inclusions in the unfiltered coolant.

Separately, it is worth considering gas formation in aluminum radiators.When metal comes into contact with a slightly alkaline coolant, hydrogen is released, which accumulates at the highest point of the heater. If the radiator is not equipped with an air vent, over time the gas plug will not allow the coolant to freely pass through the internal channels of the heater.

How to remove air from the cooling system

Make sure the cooling system is sealed. Obviously, air cannot appear in it just like that: this is either a consequence of the fact that the coolant was not filled during the replacement according to the rules for operating your car, or a sure sign that a hole has appeared in the system through which the coolant flows out, giving way to air .

To begin with, it is worth checking whether the drain plug of the cooling system is tightened tightly enough. If everything is in order with it, you should carefully examine the body of the expansion tank and look for cracks in the plastic.

In the worst case scenario, you may find that air is getting into the system due to a leaky radiator or head gasket.

When you are convinced that the system is airtight, and your work will not be wasted, get to work.

- Raise the front of the car. You can try to safely park it with the front wheels on any hill, or raise the front of the car with a couple of jacks.

- This must be done so that the air bleed screw located on the radiator becomes the highest point of the cooling system, and the air freely exits there.

- Open the valve of the interior heater. In order to do this, you just need to turn the heater controls to the extreme position, as if you wanted to warm up the interior.

- Also set the airflow intensity, if your stove model provides for it, to the middle position.

Turn off a cover of a broad tank and unscrew the screw for removal of air from the cooling system.

Start the engine and let the vehicle idle for a while until the engine warms up and the thermostat and engine RPMs reach operating values. Have a helper get behind the wheel of your vehicle.

In order to get rid of unwanted air in the cooling system, it is necessary to periodically press the gas pedal and increase the engine speed several times, to allow the coolant to ply throughout the system.

Also ask your partner to observe the operation of the stove: if, after a few clicks on the gas pedal at idle, it begins to perform its functions stably, that is, to supply hot air to the passenger compartment, consider that your mission is completed.

Reinstall the bleeder screw and let the vehicle run quietly at idle for a few more minutes.

Pour coolant into the expansion tank until it reaches the maximum level, and then close the tank cap tightly.

Let the car run for another minute. Make sure all caps and plugs are tight and stop the engine.

Signs and consequences of system airiness

If the boiler unit is working properly, the temperature of the coolant at the supply is normal, and the battery cannot cope with heating the room, check the presence of air in the heating system. Air locks in radiators are a common occurrence, and their presence is indicated by uneven heating of the device when the upper part remains cold. The airiness of the battery at first slightly reduces its heat transfer, but if the problem is not solved in time, the accumulated gas will block the path of the coolant and the room will not receive full heating.

Air bubbles interfere with the free movement of the coolant due to the narrowing of the channel, and this provokes the appearance of specific sound effects.Signs of a blockage include noise in the pipes, gurgling, seething. In difficult cases, pipe vibration is also added.

Small air bubbles that have not yet formed a plug, but are already actively released from the coolant, turn it into a water-air mixture. It is dangerous for a circulation pump that is not adapted to pump gas. Plain bearings are installed on the shaft of the pump unit, which must be located in a liquid medium. The high air content in the coolant leads to premature wear of the elements due to the effect of dry friction.

If you do not bleed air from the heating system, its excess in the coolant can lead to a stop or breakdown of the circulation pump. This is dangerous for solid fuel boilers that are not equipped with automation: when the circulation stops, the cooled coolant will no longer flow into the boiler's water jacket. Overheating and boiling of liquid in a confined space threatens to explode if the safety group does not work.

Knowing how to bleed air from a heating system can deal with air lenses in radiators made from materials that are prone to corrosion and overgrowth. The air contains carbon dioxide and oxygen, and they contribute to the process of decomposition of calcium and magnesium salts, which are dissolved in water. The reaction proceeds with the release of carbon dioxide. Under the influence of high temperatures, hydrocarbon compounds form a layer of limescale, and carbon dioxide contributes to the corrosion of metal surfaces. As a result, the battery wears out faster.

To avoid unpleasant consequences, by starting the heating system at home after the summer break, you should check it for air jams. If it is airborne, promptly take measures to eliminate the problem.

Methods for eliminating air congestion

Removing plugs with the installed air vent

Before you remove the airlock in the heating, you need to find out its properties. Chief among them is the density, which will always be lower than that of water. Accordingly, the liquid will displace air up and in the direction of circulation.

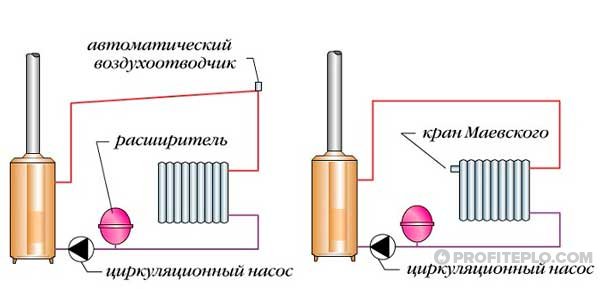

Therefore, to remove airiness, it is necessary to ensure the release of steam. To do this, you should install special devices - air vents and Mayevsky taps. They work on the principle of a check valve. When a certain pressure is exceeded, steam acts on the valve seat. The rod moves, releasing air from the radiator or pipe. After the normalization of pressure under the action of the spring, the rod takes the old position.

An air lock in a cast iron or aluminum radiator can damage the housing. Therefore, when such a situation arises, it is necessary to immediately solve the problem.

We determine the cause

Video: The second car with a problem: the stove does not heat up - there is air in the system!

The main indicator of the appearance of an air lock is that the stove does not work, or the stove does not work well. But this can also happen due to the fault of the same thermostat. If it jams in the open position (the antifreeze moves in a large circle all the time), then the engine simply will not reach operating temperature and the stove will not heat up.

Therefore, if you decide to fix problems in the operation of the cooling system, first check the operation of the thermostat. To do this is simple, consider the actions using the VAZ-2109 as an example.

Start the test with a cold engine. We start the engine, open the hood, find the upper large pipe going to the radiator - it is supplying and comes from the thermostat, we try its temperature by hand. If the thermostat is working properly, then the pipe remains cold until the engine warms up to operating temperature.As the motor picks up temperature and the thermostat opens, the pipe will begin to heat up.

If the thermostat is functioning normally, but the heating system is not working, there is likely an air lock in the system that needs to be expelled. But before that, eliminate the cause of its appearance. To do this, we carefully inspect the connections of the pipelines of the system, if there are any smudges.

Inspect the water pump and motor at the junction of the cylinder block with the head. Traces of antifreeze leaking indicate gasket damage. Eliminate the cause of the formation of an air lock, and only then solve the issue of airing.

A common cause of a plug is a violation of the technology for replacing and adding antifreeze, a problem with a non-heating stove is associated with it.

Heating system without air pockets

So that in an individual heating system the air does not accumulate in problem areas, but goes outside, it is necessary:

- correctly design and install the pipeline, correctly install radiators;

- use automatic and manual air vents.

Consider how to expel air from a heating system with natural circulation and top wiring

When arranging the pipeline, it is important to observe such an angle of inclination at which air bubbles move freely upwards, to the highest point of the contour, without accumulating on turns and gentle sections. At the highest point of such a system, an open-type expansion tank must be installed through which air bubbles enter the atmosphere

To bleed air from a system with a forced movement of a coolant or a gravity system with a bottom wiring, a different principle is used.. Return pipelines are mounted under a slope (this makes it easier to drain the liquid from the system), and automatic valves are installed at the top of all individual circuits, through which air is discharged as it accumulates.

In addition to automatic air vents, Mayevsky manual taps are also used in the system. These air vents are installed for heating radiators upper branch pipe on the opposite side of the pipe supplying the heated coolant. To ensure that air enters the valve and does not accumulate in the upper radiator manifold, it is recommended to install the heating device at a slight angle. Bleeding is done manually as needed.

How to find an airlock?

Ideally, the system handles airing on its own thanks to automatic valves through which air is bled. Having found that a separate heating device or part of the circuit does not work properly, it is necessary to find the place where the air has accumulated.

Touch the radiator - if its upper part is colder than the lower, then the coolant does not enter there. To release the air, open the Mayevsky faucet mounted on a steel, aluminum or bimetallic radiator, or a valve valve that is mounted on cast iron batteries.

You can also determine the place of airing by sound - under normal conditions, the coolant moves almost silently, extraneous gurgling and sounds of overflow occur due to an obstacle in the flow .

Metal pipes and heating appliances rattle with light blows - in places where air accumulates, the sound is noticeably louder.

Getting rid of the airlock

If there are manual air vents on the radiators, there are no problems with how to remove air from the batteries. With the help of a screwdriver or a standard key, the Mayevsky tap stem is slightly unscrewed, while a suitable container is placed under the drain hole (a half-liter glass jar is enough).The release of air from the heating system using a manual air vent is accompanied by hissing and whistling, then splashes appear, after which the coolant begins to flow in a thin stream. At this stage, the Mayevsky tap should be closed.

Note! If the battery continues to heat poorly after de-airing, the problem may lie in the blockage. In this case, the heating device is dismantled and washed

After reinstalling the radiator, check the system for air pockets.

To remove an airlock from the heating system, if it has accumulated away from the air vent (manual or automatic), proceed as follows :

- Open the air cock or valve closest to the air bubble.

- They begin to gradually feed the system with a coolant so that the liquid, due to an increase in volume, displaces the air bubble towards the open air vent.

What to do in difficult cases when the cork is not removed by adding the volume of coolant? In such a situation, in addition to increasing the amount of coolant, it is required to add pressure, heating the liquid to critical temperatures. Care must be taken to avoid scalding yourself with the splashes that accompany the release of air through the automatic valve.

Important! If a plug is systematically formed in the same section of the pipeline, cut a tee in this place and install an automatic valve