Peculiarities

Sound insulation of the room with polyurethane foam is carried out by jet spraying the composition of some reagents, namely:

- polyester in interaction with polyisocyanate, forming foam with high expansion;

- flame retardants that prevent smoldering and corrosive smoke in case of fire.

After combining the components in the sprayer and applying them to the plane of the walls or other surface, instant polymerization and hardening of polyurethane foam occurs.

Residents who simply need soundproofing of their living quarters can resort to the help of companies offering a full range of services. Many of them have materials that meet safety standards, the latest technology and reasonable prices.

Cellulose based materials

Spray coatings are used to reduce boom times and noise levels in public and entertainment environments. The main component of insulation is cellulose fibers. They are not dangerous for the respiratory tract, they do not cause allergies, which characterizes the coating as an environmentally friendly substance.

The manufacture of this coating is carried out by spraying cellulose flakes impregnated with an adhesive composition onto a specific surface. Application is carried out using a specially equipped installation. The flakes of the material are supplied by an air stream from the equipment tank to the spray gun, where they are mixed with the adhesive composition and sprayed onto the surface that needs to be treated (partitions, floors, ceilings).

This technology makes it possible to form an acoustic coating without seams on a plane of various shapes, as well as to perform detailed processing of certain areas. Unlike slabs that absorb sound, the method allows you to find extraordinary design solutions, carefully fitting acoustic insulation into the finished interior.

The high adhesion of the adhesive to dissimilar materials makes it possible to produce strong coatings up to 70 mm thick.

If the spraying thickness is two centimeters, then the additional weight is evenly distributed over the ceiling covering and is about two kilograms per square meter. An even plane and the desired thickness of the finished insulation are achieved by spraying in the required number of layers. The optimal thickness of one pass is about 5 mm.

Increased work efficiency is another distinguishing feature of the coating. It makes it possible to install coatings in an extremely short time, without making significant changes to the established schedule for other finishing works. The appearance of finished coatings resembles splashes of plaster. There are two main types, which differ in the size of the flakes that make them up.

One type of coating consists of smaller flakes of cellulose, about 5 mm. It has a more uniform surface relief. The second type, respectively, with larger particles of cellulose and less even relief.

If necessary, the coating can be cleaned with a vacuum cleaner, for large surfaces cleaning with compressed air using a compressor is desirable. Ceiling coatings need to be cleaned less than once every two years due to the action of the antistatic additives used in the cellulose composition.

The coatings are technologically simple, economical, and are an excellent solution for imparting an acoustic effect in buildings with large volumes of premises, such as: entertainment centers, cinemas, gyms, restaurants, shopping malls, and the like.

You can see how to properly apply polyurethane foam for soundproofing in the video below.

If you need to protect yourself from noise

The soundproofing or sound-absorbing mixture of a modern look has mostly only positive reviews. All homeowners who are intrigued by the properties of the polyurethane foam spraying technique can contact trading companies whose professional employees can help make the home isolated from extraneous noise in houses built from any building material. The calculation of the final cost of the work will be made based on the results of measurements, calculation of the total processing area and the required thickness of polyurethane foam spraying, which depends on the thickness of the ceiling between floors or pouring concrete mortar and walls between apartments in the building.

If the priority preferences are in the environmental friendliness of the composition, certain deadlines for the work and a rational calculation of price and quality, then you can search for a suitable company on the Internet. Call the phone number or leave a request on the site, and the specialist will find the right comparable solution to a problem of any complexity.

Properties

In fact, noise is a collection of sound waves of frequency distribution. Waves are absorbed or displayed from them. A flat wall surface in a room reflects a sound wave that begins to maneuver among obstacles. This is how the echo is achieved.

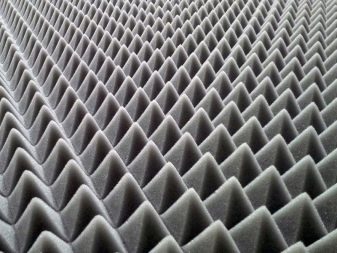

To smooth out the noise in the rooms, soundproof foam rubber was created. The design of the foam rubber is formed by a myriad of polyurethane cells. Inside them is air, which is revealed when examining foam rubber under a magnifying glass.

The formal name of foam rubber is elastic polyurethane foam. This is a material with an open cellular structure that makes it easy to absorb liquids and absorb air. When forming the average thickness of the material, the sound wave is repeatedly reflected from its micropores and loses its energy. The higher the density of foam rubber and the smaller the cell size, the higher its sound insulation properties.

The main rooms, the soundproofing of which has practically useful value, include:

- company/office;

- residential building/apartment;

- recording studio.

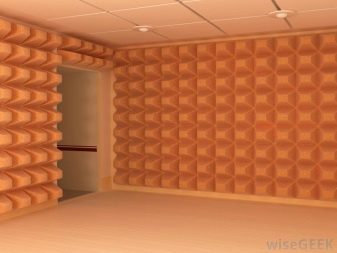

The office is a point of significant concentration of a huge number of employees who fulfill their obligations and form serious noise pollution. At the same time, an atmosphere is created in which the productivity of labor declines among employees, and inattention increases. Significant noise reduction can be achieved by spreading the panels.

Residential building, apartment - places for recreation, recuperation. But you will only have to dream of peace if the house is located on a festive street, and the neighbor started repairs. It is impossible to fully restore strength in such an environment.

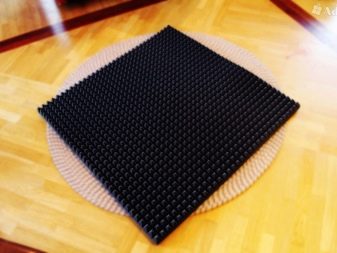

Soundproof foam rubber plates will help to eliminate the problem. They do a great job of keeping outside sounds out of the room. Sound isolation will be especially useful for those who have small children. It will help maintain an atmosphere of calm and comfort.

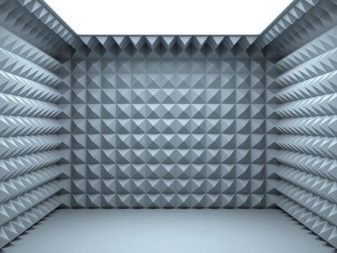

It is almost impossible to imagine recording studios without adequate noise isolation. The characteristics of the recorded sound are negatively affected by any third-party noises and sounds.

Varieties

When planning the acoustic subspace of a room, one should not forget about the rules. If they are followed, the maximum effect is achieved:

- sound mappings are eliminated;

- the necessary degree of sounding of acoustic systems is formed.

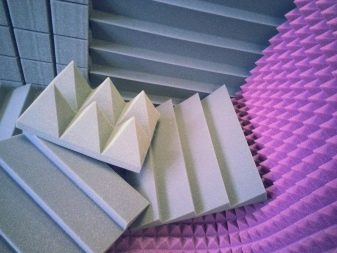

Soundproofing foam rubber panels are divided into two main categories:

- for absorption of low frequencies (LF);

- absorbing medium and high frequencies (C / HF).

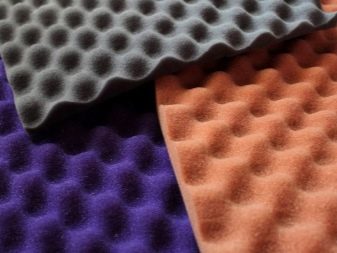

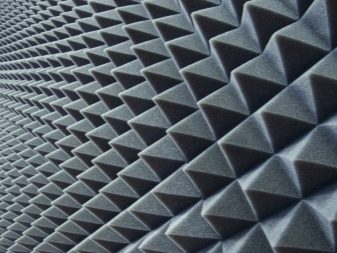

Panels of the first type affect the absorption of low frequencies. They are performed as bass traps and cubes. Neutralizers of average and high frequencies are presented by soundproof panels such as "Wave", "Pyramid", etc.

The most important task of soundproofing material is the elimination of sound signal reflections and the compression of its “loops”. Foam rubber will not help if you need to completely eliminate the found sound frequency: its task is to eliminate the results of problematic frequencies in the lumen.

In the corners of the room, low frequencies accumulate, heading towards the listener with a conditioned delay. Therefore, the main purpose of bass traps is to eliminate the accumulation of low energy.

In this case, the relief of the panel does not matter. The size of this type of soundproofing panel depends on the size of the room and the intended outcome.

From the weight and shape of the panel, when choosing, its properties will directly depend. So, the “Wave” relief brings a velvety sound-absorbing effect. Such panels can completely fill the room.

And the Pyramid panels bring the best result with a small number and are located in the established areas of the room. Foam rubber is widely used in acoustic devices as a replacement for conventional synthetic winterizer. They fill the distance inside the speakers and subwoofers. It gives improved sound waves of medium and high frequency range.

Other soundproof panels differ mainly in configuration and certain degrees of efficiency.

Polyurethane foam spraying method

Sound insulation of the ceiling in multi-storey buildings is applied by continuous spraying of the composition of interacting reagents on the base surface in several approaches, the number of which is determined by the thickness of the ceiling from the top floor and, depending on the financial feasibility, for installation work. If suspended plasterboard ceilings are provided, then before starting to spray the insulation, it is necessary to install the ceiling frame structure, and when equipping the ceiling with tension material, there is no need for these actions, since the main parts are mounted on the walls.

Noise isolation on the floor is carried out in two ways:

- between the lag, on which the floorboard is laid;

- on the ceiling from the lower floor, which forces the polyurethane foam to be poured with a concrete solution of fifty millimeters thick.

Before applying polyurethane foam to partitions between rooms and external walls, it is necessary to install the crate using bars of wood or metal profiles, which make it possible to attach a mesh for plastering or sheathing with sheet building materials.

Specifications

When working with soundproof foam rubber, there is no need for special skills or abilities. It is easy to cut, and due to its barely perceptible weight, it can be mounted on double-sided tape.

Some factors of propagation and absorption of sound waves are taken into account.

- Distance. The energy of sound waves scattered over a distance is weakened if soundproofing material is used.

- Damping. Soundproofing material is effective in reducing the response vibration in the room, absorption, diffusion or reproduction. The absorption of sound by the foam panels helps to reduce the sound level. Diffusion or reproduction coherently transforms undesirable sounds into usefulness.

Foam rubber absorbers with open pores act on the principle of noise absorption in the material structure. They effectively absorb noise in the microwave. The absorbance of the foam panels is staggering even at low frequencies.

Installation subtleties

External noise exposure can be easily reduced or eliminated under normal conditions. The main interest in sound insulation in modern homes are windows.

To reduce the sound, you can use honeycomb air chambers or foam rubber. Honeycomb structures (from 1 to 3 cells) make it possible to achieve a high degree of sound attenuation.

Panels of soundproofing material can become a ceiling or wall part - to reduce the sound level from neighbors.

In addition, the installation of soundproofing material achieves the effect of reducing noise in rooms with a large number of employees and office equipment. Noise reduction helps to increase the working capacity and productivity of employees. In production halls, soundproofing material gives a tangible reduction in overall volume and sound reflections from operating equipment.

The thickness of such panels can be from 5 to 100 mm. When choosing a thickness, you should choose panels according to the following principle: the higher the noise level, the thicker the sound insulation layer. For housing, apartments or representative offices, panels with a thickness of 50-70 mm are suitable.

Typical panels have a grayish or brownish tint, however, if necessary, panels of the desired shades can be ordered.

When installing soundproof foam rubber, the following rules must be strictly observed:

- the panel cannot be crushed or deformed due to a noticeable decrease in its useful qualities;

- fasten the foam rubber to the base with glue or double-sided tape;

- foam panels are installed only for fixing indoors;

- the panels are located under the flooring, inside the walls or in the false ceiling structure.

The material is not whimsical to the rules of use and is an almost eternal material.

Thus, it remains to add that the panels of soundproof foam rubber do not need any maintenance and repair, the period of their use is not limited.

The soundproof panel is cleaned with a vacuum cleaner. The frequency of cleaning depends on the purpose of the room.

The impeccability of sound and the absence of noise pollution depend not only on decent and expensive equipment, but also on the appropriate decoration of the room where the soundproof foam rubber is fixed.

You will learn more about soundproof foam rubber from the following video.

Types of noise

There are many different noises, here are some of them:

Airborne noise. This noise is especially annoying, it causes an uncomfortable state. Airborne noise is reproduced when driving vehicles and due to the work of equipment outside the window. Loud neighbors or passers-by, sounds made by animals (dogs, cats and others) - all this includes airborne noise.

- Impact noise. This type of noise appears due to any knock. The irritating sound of the percussive variety produces a disturbance in the air, and knocks can be heard over long distances.

- structural noise. Occurs in the ventilation ducts, from improper operation of the water supply. Unpleasant sounds of a structural type can be heard through various devices in the room. These are various communications for heating, plumbing and ventilation.

Advantages of the method

When performing soundproofing of housing walls with PPU by spraying the composition onto the base, an additional number of problems are simultaneously solved:

- Production of thermal insulation of a room without seams with a service life of up to thirty years.

- Performing waterproofing of walls in rooms with high humidity, for example, in a bathroom or kitchen.

- The soundproofing of the floor covering, in addition to repaying extraneous noise, will create a layer on top of the screed that absorbs moisture in the amount of two percent. Whereas expanded polystyrene absorbs up to ten percent of moisture.

- Rooms with a corner location in a panel building will have thermal insulation and protection against fungi and mold, due to a decrease in the vapor permeability of the walls from the street.

- Noise insulation of the ceiling surface in the room will not need auxiliary suspension devices and difficult repairs, it is perfectly hidden under stretch ceilings.

- Polyurethane foam interacts remarkably with any surfaces, which makes it possible to spray over any base, including surfaces made of concrete, wood and gypsum fiber.At the same time, it fills all the seams and flaws in the flatness of the plane.

- The use of polyurethane foam in a wooden house makes it possible to exclude the installation of layers in the ventilation system and waterproofing, making it possible to spray from the inside onto the plane of the roofing material.

Where is used

Foam rubber is needed in many industries.

- Transport. Almost everywhere in the transport sector (cars, trains, planes, ships, etc.) there are component components based on foam rubber.

- Building. Currently, there is a huge variety of mounting polyurethane foams, without which no construction site can do today.

- Furniture manufacturing. A common property of foam rubber is the ability to absorb sounds. It is thanks to this feature of foam rubber that it is possible to create a room with acoustic purity and sound insulation.

Application area

The materials used for the manufacture of foam from polymers have a high expansion ratio, the volume of the composition expands up to twenty times, which justifies the limitations in use:

- the temperature of the sprayed surface should not exceed 100 degrees;

- should not be exposed to direct sunlight or other ultraviolet exposure.

This can happen when:

- insulation of the outer parts of the building or structural parts devoid of finishing material;

- thermal insulation of pipes designed to pass liquids at high temperatures.

The method of applying polyurethane foam by spraying is used in the following areas:

- soundproofing floors in housing and walls in houses built of panels, wood or bricks;

- thermal insulation of not very heated pipelines laid above the ground or buried to a shallow depth from ground level;

- thermal insulation of refrigerating chambers, refrigerators of various modifications and purposes.