Process and processing features

To apply liquid soundproofing indoors, you need

special technical equipment. Under pressure, the chemical composition is applied

on the surface, forming a polyurethane layer. Such insulation will protect the house from

noise, penetration of cold and various pests.

The work process is simple. If to work with

other materials need some preparation, then in the case of polyurethane foam,

all this is not needed. If there are large exfoliating

elements, then they can be dismantled, but otherwise nothing is needed.

Application technology

The technological process of applying sound insulation has

some resemblance to painting. Apply liquid soundproofing

evenly, like ordinary paint in several layers. Don't keep long

spray at one point to prevent large foaming. Thickness

layer should be three centimeters, this is quite enough for the material

provided the required level of protection.

Stage 1. Preparatory

As such a preparatory step in the processing of liquid

there is no sound insulation, but you can clean the surface of the wall from peeling

elements. It also does not hurt to cover the floor with plastic wrap.

or paper. Foam that gets on the floor will dry out and be difficult to clean.

If there are wires and sockets on the wall, then they

you should close it first so that in the end you don’t have to

completely change the wiring. For cables, use a special

corrugated casing. Upon completion of the preparatory work, equipment is brought in,

and you can start applying.

Stage 2. Primer

The surface of the wall should be treated with a primer. As for

any finish, the primer provides maximum adhesion to the coating. Apply

primer can be used as a hand tool: roller or brush, but also

spray gun. Liquid

wall impregnation is a prerequisite when working with surfaces.

@zhidkaya_shumoizolyatsia

@zhidkaya_shumoizolyatsia

Thanks to the primer on the surface of the wall under the sound insulation

fungus or mold does not form. The primer must be applied evenly throughout

surfaces. It is better to start the application from the top of the room, this will not

get leaks.

Stage 3. Applying soundproofing

Polyurethane foam must be applied in two stages. First

the layer is thin for the bond, and the second is denser. It is at the time of application

the second layer forms a reliable soundproof coating. Polymer

expands, and the resulting bubbles will be an excellent insulating layer. At

When working with a polymer, a special pressure tool is used.

When the insulation layer has reached three centimeters over the entire surface, you can

finish processing and stack inventory.

Stage 4. Drying

After completion of the application of the polymer material, it

must be allowed to dry. Depending on the manufacturer and composition of the foam, the time

drying may be different. When the insulation hardens, it forms a dense

porous structure. The outer surface of the coating is uneven, so for

to bring the wall to the ideal, it is necessary to use facing plates or

panels. Alternatively, decorative panels can be used, which,

despite the small thickness, they also have a certain level of sound insulation.

When all finishing and installation work is completed, you can hand over the object

owner.

To date, a variety of soundproof

materials is so large that you can pick up according to the requirements and

wishes. When it comes to a large apartment, then use

frame sound insulation will be beneficial for you, since its cost is cheaper,

rather than using liquid soundproofing. Liquid soundproofing of the floor in the apartment, as well as walls and

ceilings will make the room comfortable and convenient. The best option

processing is considered a small living space. Due to the small thickness

the soundproofing layer in the apartment will save those important centimeters.

As mentioned earlier, only an integrated approach to

noise isolation guarantees effective and reliable protection against various noise and

sounds. By installing external and internal sound insulation in the apartment, you can not

worry about your sleep and peace of mind.

On the features of liquid insulation.

Liquid car insulation is a great way to eliminate unwanted noise from the car, where its analogue is powerless. Due to the liquid structure, it is easy to isolate places in the car that are difficult to access. This type of insulation allows you to eliminate sounds coming from the bottom of the car or wheel arches. This means that if stones or other interference get into these places, there will be no extra noise in the cabin. The insulating compound is based on liquid rubber, which muffles the noise from the inside. In addition to the main role, sound insulation has a number of useful properties. It prevents moisture from entering the surface of the metal, reliably protecting the material from unwanted influences. Thus, the surface of the car retains its structure longer, extending the life of the car.

Usually, this tool covers the internal surfaces of the car. Unlike insulating material, liquid car soundproofing repels moisture, thereby prolonging the effect of insulation. Analog, quickly absorbs moisture and begins to conduct sound. This is one of the advantages of the new type of insulation.

Today, there are several types of liquid sound insulation. Depending on the type of application of the agent to the surface, two insulations can be distinguished.

In the first, an insulating agent is applied to the surface, together with the primer. This forms a more solid foundation for the insulation layer.

The second type, applying the product to the cleaned surface.

Professionals, I recommend combining the usual material for car insulation, together with a liquid insulator. Liquid agent, copes well with the elimination of noise in the bumps and cavities of the body. One of the positive properties of the liquid material is protection against impacts and scratches. Rubber coating, prevents the destruction of metal surfaces. Due to this property, the liquid is very relevant for insulating the bottom of the car.

If we emphasize the advantages of a modern analogue of car insulation, we can distinguish the following qualities:

- Simplicity and convenience in use.

- The ability to isolate hard-to-reach areas of the car.

- Useful properties (moisture repellency and impact protection).

- Good noise reduction during machine operation.

- Acoustic sound improvement.

- Prevention of car upholstery noise.

Soundproofing plaster

Soundproofing can be provided not only through the use of paints and varnishes, but also thanks to soundproofing plaster. The composition of the plaster includes special components, the presence of which is achieved isolation from sound effects. These are fillers in the form of small 5 mm granules. Expanded clay or pumice is most often used as a material for granules. At the same time, the granules are distinguished by their low weight, since they have a hollow structure.

Also, aluminum powder can be added to the soundproofing composition. When such a powder goes through the drying stage, gas is released from it, which ensures the porosity of the material. The loose structure makes it possible to delay the propagation of sound, since the waves are repelled by very small particles.

Note! There is a misconception about the inability of plaster to act as soundproofing. In fact, the plastered surface is able to dampen a significant part of the sound wave, but only if the composition was applied in compliance with the technology

It is not recommended to paint a plastered wall with dense paints and varnishes, such as enamel, since such actions lead to the loss of a significant part of the soundproofing properties. The fact is that thick compositions fill the small pores of the plaster, which negates all the advantages of a porous material. In addition, you should not cover the plaster with wallpaper, as the glue (viscous substance) also clogs the pores.

Plaster is an environmentally friendly material, so it can be used even in children's rooms. In addition, relief plastered walls look very decorative, which makes them pleasing to the eye and, in addition to their utilitarian function (noise protection), can play the role of interior decoration.

Applying plaster

Before applying acoustic plaster, it is necessary to carefully prepare the surface. To do this, the wall must be leveled, dirt and dust removed from it, and a primer must be applied.

Note! The primer will better grip the wall if you add ten percent lime paste to it. When the primed surface dries, you can apply the plaster composition

It is important that the surface after plastering remains flat, and the layer of material does not exceed 2-3 centimeters.

When the primed surface dries, you can apply the plaster composition

It is important that the surface after plastering remains flat, and the layer of material does not exceed 2-3 centimeters.

If it is likely that the working day will end faster than the entire surface is covered with acoustic plaster, it is recommended to make a layer 1/3 thinner than necessary. In this case, the work will continue by applying a new overlap layer. If you immediately make a uniform layer and do not complete the work, then ugly joints that are noticeable to the eye will remain in the future.

When the plaster is applied, it is not recommended to grout the layer. Instead, it is better to treat the surface with a trowel. If the plans include painting the wall, it is recommended to use only water-dispersion coatings: although the application of paint is undesirable at all, water-based paints harm the soundproofing qualities of the material to the least extent.

Noise-insulating coatings or plaster by themselves are not able to completely protect the premises from noise, since this business requires a set of measures where a number of materials are used. However, as an additional measure, the soundproofing composition will certainly improve the soundproofing performance.

What is the essence of liquid sound insulation

Liquid noise insulation is a material that is applied to

wall, floor or ceiling surface to provide ingress protection

various noises and sounds. As is known today, noises are divided into two

main types:

- Air;

- Vibrating.

Airborne noise refers to sounds that are transmitted over

air. Air sounds include: a loudly working TV,

conversation heard from neighbors or sounds coming from the street. For absorption

airborne noise requires a soft and porous surface of the soundproofing

material, which, due to its structure, absorbs part of the waves and makes it

quite acceptable.

Vibration sounds are mainly heard as a result of work

electrical tool or household appliances. This noise can be transmitted

hard surfaces, and to protect against it, you need special

vibration pads and other elements.

It should be noted that among all insulating materials

there is practically no such product that could simultaneously and with the same

indicators to keep both types of noise.Some materials are porous and soft, others

on the contrary, they are downed and elastic. The only insulation option that combines

two types of insulation are considered liquid Shumka.

Despite the fact that this material has only recently begun

appear on the market, has already been able to attract the attention of many buyers.

It should be noted that due to the soft structure, after drying, the composition hardens,

forms a so-called vibration barrier that prevents noise and

sounds. The composition is sold in liquid form, and applied to the surface

three centimeters thick

A small layer of material is guaranteed to provide

effective protection against sound waves. After drying, the sound insulation of the walls in the apartment has

bumpy surface, so use it as a finish

impossible, it is necessary to sew up with plasterboard or chipboard

The composition is sold in liquid form, and applied to the surface

three centimeters thick. A small layer of material is guaranteed to provide

effective protection against sound waves. After drying, the sound insulation of the walls in the apartment has

bumpy surface, so use it as a finish

impossible, it is necessary to sew up with plasterboard or chipboard.

Features of thin sound insulation

Recently, thin soundproofing materials have become quite common, which provide protection without losing living space.

They are called soundproof membranes. They can be mounted not only on walls, but also on ceilings, partitions or floors.

Thin soundproofing of walls has a number of significant advantages:

- The thickness of the product is only 3.7 mm. The material is able to provide maximum sound insulation with minimal loss of space.

- There are practically no other protection options with the same efficiency.

- The product is made from environmentally friendly components. The composition does not contain bitumen and rubber. The material itself is quite durable and has an increased service life. It is these characteristics that ensured such popularity of membranes.

- Installation of products is quite simple, even a person who does not have construction skills can handle it. A structure is created, the thickness of which does not exceed the mark of 5 cm. In this case, the noise level will be reduced by about 70%.

To mount the membranes, you will need to build a metal frame, its fastening will be carried out using a direct suspension.

This is what will save most of the space. The procedure for this is as follows:

- a frame is being built;

- slabs based on mineral wool are laid in it;

- the membrane is stretched;

- the structure is covered with a sheet of drywall. For more information about modern soundproofing materials, see this video:

The length of 1 roll of the membrane is 5 m, and the width is 1.25 m. The weight of 1 m² of material is approximately 8 kg.

Liquid soundproofing for interior processing

Bituminous mastic is not suitable for internal use,

but there are materials that will protect the house from noise much more effectively and save

heat. Polyurethane foam coating is the best option

soundproofing for a small apartment. It should be noted that with a thickness

only three centimeters, the layer effectively retains both air and

vibration noises.

For processing the surface of a wall or ceiling, it is not necessary

special preparation, it is enough to clean the treated area from

peelable elements and you can get to work. In time, such processing

will take about three hours, provided that a highly qualified

specialist.Polyurethane foam is applied using special equipment,

therefore, without the involvement of specialists can not do. Not everyone has a liquid insulation gun

at home, so you should contact the masters.

After the soundproofing is applied, it needs

dry. After final drying, the surface is sewn up with sheets

drywall or other decorative elements.

Helpful Tips

These tips should be taken into account at the stage of preparation, during direct application, as well as after treating the car with liquid soundproofing materials. There is nothing complicated in them, but this way you will know for sure that you are doing everything right.

- Always shake cans and mix liquid formulations prior to application. Liquid rubber is a multi-component product, some of the additives in which can gradually settle to the bottom. As a result, the insulator turns out to be broken into layers, during the application of which not all properties can be obtained, or the effectiveness of metal protection can be reduced;

- Use of sprayers. If the soundproofing is presented in the form of a spray can, such a product should be applied evenly and smoothly. Do not rush anywhere, otherwise you risk only ruining everything. Never hold the balloon in front of one point for a long time, but also do not skip areas of metal surfaces. Too thin a layer will not cope with the loads, and an excessively thick one will dry for a long time;

- Protection of car elements. Since liquid rubber is not applied to all surfaces, they must be protected from the product. Use duct tape or wide tape. After completing the work, carefully remove them;

- Read the instructions. The advice is banal, but for some reason it is he who is most often ignored by motorists. No one argues that many drivers have previously had to work with liquid soundproofing materials. But each manufacturer has its own characteristics, characteristics and properties, uses different additives, which is why there are no universal instructions for use. It is necessary to carefully read the manual for a particular liquid insulator in order to avoid mistakes, and to make the most of the material's capabilities;

- Combination of traditional and liquid insulators. In fact, this is the best decision that you can make if you want to create the highest quality sound insulation;

- Degreasing. This is the moment when not all manufacturers can be trusted. Some of them write on the packaging with their liquid rubber that it is not necessary to pre-degrease the surfaces, since their composition will do just fine without this preliminary preparation step. It is possible that this is the case. But it is better to play it safe by using degreasers. If the rubber does not adhere tightly to the metal surface, the layer may swell, exfoliate, which will eventually provoke the formation of corrosion. Plus, the quality of the sound insulator itself will decrease;

- Do not break the drying regime. Often, drivers see that the insulator has dried up already on the second day, so they are in a hurry to get behind the wheel as soon as possible and check the operation of the liquid sound insulation in action. A very common and serious mistake, which is not recommended. Even if it feels like the rubber is completely dry, when you have to wait 4 days, wait the full 4 days. And only then you can drive the car out of the garage.

Each car owner decides for himself whether to soundproof him with liquid means on his own or seek help from car repair shops. The main thing here is not to save on high-quality materials, and also to follow all the rules for preparing a car for applying liquid sound insulation. Then the time and financial costs will be able to fully justify themselves.

Varieties of liquid soundproofing materials

To date, manufacturers of liquid sound insulation

offer customers various types of material that can be selected according to

manufacturer, characteristics and cost. Polyurethane foam materials

are produced in different countries, which is related to their variety, effectiveness and

price. Among the most common are the following:

- Polyurethane Foam Synthesia this material

produced in Spain. The main advantage of sound insulation is its acceptable

cost in relation to quality. The material is made from environmentally friendly

pure components, so it can be used for processing in residential areas.

Also, the positive qualities of the foam include the fact that it can be

use at different temperatures. - Polyurethane foam soundproofing Ecotermix,

is a product of joint production of Russia and China. material can

used in various rooms and has a high level of fire resistance.

Also, this soundproofing protects the wall surfaces from biological formations.

fungus and mold. Speaking of foam cost, it can compete with

products from other manufacturers. - Demilec polyurethane foam material is produced

in USA. This product can be classified as a high-end product, which

testifies to high quality, reliability and cost. Efficiency

soundproofing is quite good, but not everyone can afford it. - Bayer polyurethane foam is produced in Germany and already

well-known brand all over the world. As always the same German

quality and relatively low cost of the material makes it popular

among buyers. If you need to perform high-quality sound insulation according to

relatively low cost, the Bayer brand provides its

product.

Depending on your budget, you can choose

the most suitable soundproofing option that will help protect the apartment from

noise and save money.

Liquid soundproofing

Liquid soundproofing of the walls is carried out by spraying polyurethane foam. This material has good soundproofing properties. Liquid wall mix fills almost any hole, while creating a layer of monolith that prevents the penetration of unwanted sounds. After hardening, the foam does not have a lot of weight, so there will be no extra load on the coatings.

Liquid soundproofing of the walls in the apartment will also protect against rodents and many insects. The polymer can be applied without prior preparation, the construction of the frame is also not required. During operation, a minimum amount of pollution is formed. The service life of the foam is extremely high, the coating can last up to 50 years. For more information about wall decoration with polyurethane foam, see this video:

The only drawback of this method is the need to use a professional tool. It does not make much sense to acquire it, the best option is to call a specialist. The cost of such processing is approximately 1500-2000 rubles for 1 m².

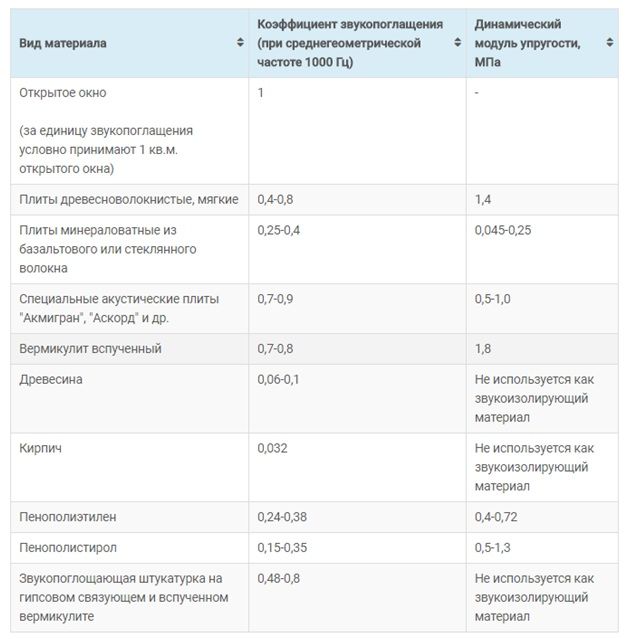

In the following table, you can see the sound absorption values of different materials.

Benefits of liquid soundproofing

Liquid soundproofing mortar has the following advantages:

- After processing, the wall acquires excellent heat and sound insulation properties. This will not only get rid of extraneous noise, but also save on heating.

- The polymer is able to penetrate into the smallest cracks, which will allow you to process openings in doors and windows. This procedure, in addition to soundproofing, will help to forget about drafts.

- High adhesion to the surface. It is not necessary to install the crate, the polymer can also be applied to the ceiling without prior preparation.After work, a minimum amount of pollution is formed.

- The ability to carry out a complete sealing of the room. After processing, a monolithic layer is created that will fill all the holes between the structures.

- The lightness of the material. The frozen foam has a minimum weight, so there will be no load on the load-bearing elements of the dwelling.

- Thanks to the structure consisting of small cells, sound insulation allows you to suppress sound waves in a wide range.

Types of polyurethane foam for liquid sound insulation

There are a fairly large number of varieties of polyurethane foam.

Such material is manufactured in different countries, the types differ in their effectiveness and, of course, cost.

The most common are the following options:

- Synthesia polyurethane foam. Produced in Spain. The main advantages include reasonable cost, environmental friendliness and the ability to use at any time of the year at any temperature.

- ecotermix. Produced by China together with Russia. The material has a high level of fire resistance and is able to provide protection against the formation of mold, fungus and other bacteria. The cost of such products compares favorably with the main competitors.

- Demilec polyurethane foam. Produced in the USA and belongs to the premium soundproofing materials. It is the highest quality and most reliable solution for protection against extraneous noise. The only drawback can be considered a high cost, but you have to overpay for the quality.

- Polyurethane foam Bayer. It is a reliable solution from a German brand. The product quality is at an acceptable level, spraying is carried out using a special device. For more information about the components for the production of polyurethane foam, see this video:

As can be seen from the article, liquid soundproofing is the best solution for protecting against extraneous noise. This processing option allows you to achieve maximum protection efficiency, while the product life is at an extremely high level.

The most obvious purpose of paint or plaster when applied to the walls of a house is to give the surface a more attractive, updated look. However, this is not the only task of the finishing material.

It is equally important to protect the base material and occupants from adverse environmental influences. For example, you can protect yourself from noise with the help of soundproofing paint and plaster.

Other types of insulating materials protect against moisture and electric current. This article will discuss the types and features of the use of insulating materials.

Applications

Insulating materials can be used to protect buildings of various types - not only residential, but also for technical purposes. Insulation is able to protect the room from excessive moisture, electric current and noise exposure.

Moisture protection

The issue of waterproofing is one of those problems that can be solved with the help of a paintwork material. It should be noted that most of the paints, one way or another, have waterproofing properties. However, if you need really serious protection, you can not do without a special LMB. After coating with such a composition, the surface will withstand even direct exposure to water for a long time.

Waterproofing coatings must be distinguished by certain qualities:

- The paint should be intended for both interior work and facade decoration, since double-sided painting provides more reliable protection.

- It is desirable that, in addition to moisture resistance, paintwork materials are resistant to ultraviolet rays and temperature extremes.

- The composition should include anti-salt additives and antifungal drugs.Antiseptic qualities are very important for good waterproofing, because moist material is an ideal place for mold and mildew to develop.

Note! The quality of the paintwork material is affected not only by the expiration date, but also by the storage conditions. The paint should not be in too cold rooms (at sub-zero temperatures) or too hot

Information on the terms and conditions of storage can be found on the product packaging.

Noise isolation

An increased level of sound insulation can be achieved by painting the surface with a special paint. Noise-insulating coatings have a number of characteristic features:

The basis of this type of paint is bitumen or an acrylic composite element. Both substances have a number of features: acrylic is better suited for indoor use, since it is practically odorless (water-based), and bitumen is much more effective outdoors, but not suitable for indoor use, as it smells unpleasant

At the same time, bituminous coatings are much cheaper than acrylic ones, which is important when painting large areas.

The maximum level of sound insulation can be obtained by applying the composition in a thick layer. As a working tool, it is recommended to use a brush or roller

The paint dissolves in the synthetic composition.

For isolating moving elements (for example, parts of a machine or a car), bitumen-based coatings are best suited. This group of colors is able to absorb not only sounds, but also vibrations.