Types of cork coating

Surfaces in the apartment can be isolated and protected from sound with different types of cork coatings, which are available in the following forms:

- Wallpaper.

- Panels or tiles.

- Rolls.

- liquid coating.

- Technical traffic jam.

They are based on paper, which makes the coating thin, no more than 1 mm thick, convenient to use, thanks to which it is not necessary to make substrates for cork wallpapers. Wallpaper is used to cover the walls. Glue them with ordinary glue. Cork wallpaper must be glued end-to-end, the duration of operation is about 10 years. Are issued in the form of a continuous cloth, rolls, self-adhesive material.

Panels or tiles

Their dimensions can be 600 by 600 or 300 by 300, with a thickness of 3 mm. Panels or tiles are made from granular cork under high pressure, pressure and temperature. The tile may contain various inclusions, be colored.

This type of cork coating is produced in the form of a solid two-millimeter layer, which has a width of 500 mm. The bottom of the rolls is made of granulated cork, which is processed under pressure, and the top is made of cork veneer. The cork rolls that cover the walls are waxed on top. Rolls are used as a substrate for laminate, wood, stone or ceramic surfaces.

In composition, it is a cork crumb, which is bound with an acrylic substance. Liquid cork coating should be applied to the walls with a spatula or with a special sprayer.

This type of coating is characterized by the following properties:

- Soundproof and insulate the room.

- Suitable for cladding facades, walls outside and inside, ceilings.

- Used to insulate attics and basements, create a waterproofing system on roofs and terraces.

- Suitable for creating underfloor heating.

Suitable for leveling the surface of walls, ceilings and floors. It has high properties of heat, noise and sound insulation. It is produced in sheets that look like chipboard, rolls, in the form of an acoustic bedding. Technical cork does not have a top layer of veneer, so the price of the material is lower than that of a liquid cork coating. There is also no wax and lacquer coating on the technical cork. It is used mainly to insulate walls, replace carpet, linoleum.

Wall soundproofing

Cork flooring works well for walls. Before applying it, all cracks in the walls should be repaired. The sound passes well through the holes for sockets and switches. In the presence of voids, they are laid with dense mineral wool, after which the hole is sealed with cement mortar or putty. After that, the socket is installed in place.

In panel houses, noise is transmitted at the junction of the plates. It can be significantly reduced by removing the plaster at the corners and filling the joints with mounting foam. In monolithic structures, this is not necessary.

Coating features

Before sticking the cork, the walls are primed to increase the strength of the connection. The optimal thickness of the panels is 3 cm. If it is less, the wall covering does not give the desired sound insulation effect, and it is unprofitable to make it thicker, since the plasterboard construction with mineral wool panels wins in terms of price / quality ratio. Here you can combine if you glue cork wallpaper on a soundproof plasterboard wall as a decorative finish.

The wallpaper is made on a paper base, on which varnish is first applied, and then agglomerated cork veneer 1 mm thick is glued.

A thin layer of cork reduces the level of noise from the outside, if the following rules are observed:

- Layering improves sound insulation.A thin protective coating is unlikely to help, but a wallpaper substrate made of technical cork will already be a little protection from sounds. The result is also obtained by a GKL construction with cork wallpaper pasted on it from the outside and a thermal insulation layer applied from the inside by spraying. Only you should not count on wallpaper, due to their small thickness. They will only slightly muffle the sounds inside the room.

- Additional lubrication of the joints of cork tiles allows you to get a solid coating.

- The joints of the upper layers should not coincide with the lower ones.

Is it possible to use such sound protection if it has a directional effect? Obviously yes, since there is no need to mute the sounds of the TV or audio equipment in the evenings, and children can play musical instruments in peace.

Cork tiles should be glued to the base in a checkerboard pattern. If they are thin, make a two-layer coating. In this case, it is better to make the outer layer with veneer, and for the inner one, a technical cork is quite suitable.

Choosing the type of cork cover

There is no particular variety in the form of products. They are available in rolls and sheets. The sheets are very diverse. Their thickness ranges from 2 mm to 50 mm. Panels without veneer come in black or white agglomerate. The first one is more used for the inner layers and the substrate, and the last one is better suited as a finishing material.

From above, the cork can be covered with other decorative material. The simplest is a layer of varnish. In rooms with high humidity, the walls are coated with sealant varnish. It is applied with a soft roller. After hardening, the wall is not afraid of wet cleaning. In case of violation of the protective layer, it can be restored by repeated application of varnish.

Cork soundproofing walls what to expect

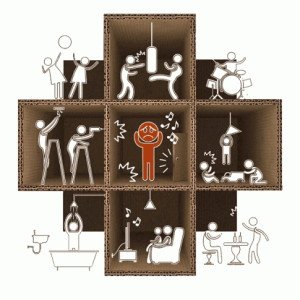

Soundproofing an apartment is not a big problem, except for residents of private houses, remote from noisy highways and the railway. For urban residents, even living in a separate house, noise is always a big hindrance. And there is nothing to say at all about the numerous residents of panel houses - for them this is not just a hindrance, but a real, big problem, no matter how quietly the neighbors behave.

The urgency of this problem is confirmed by the presence of a huge number of various technologies and soundproofing materials. It is impossible to single out a single, best solution - in each case, many factors should be taken into account: the area of \u200b\u200bthe room, the thickness of the ceilings and walls, budget possibilities, and even relations with neighbors.

For example, let's take an apartment in a new building, which is just beginning to be populated by permanent residents. In this case, the purchase of housing is traditionally followed by repairs. New settlers, as a rule, are quite accommodating people, and they can still find a common language with each other. With neighbors from above, you can agree on joint soundproofing of their floor. If this can be done, then in your apartment it is no longer necessary to do the same procedure with the ceiling.

There are walls, the sound insulation of which depends on their thickness, the area of \u200b\u200byour apartment and your budget. So, if the thickness of the walls is only some 15 cm (half a brick), then it will reflect noise up to 47 dB. In this case, a two-brick wall will reflect all 60 dB. From these examples it is also clear that you will not achieve a large acoustic effect by increasing the thickness of the walls.

Depending on the area of your apartment, you can give preference to either thin materials that “eat” only a few centimeters from all sides, or roll up a full-fledged sound insulation using multi-layer structures (vibration isolation, mineral wool, drywall). However, in the second case, you will have to give at least 10 cm of space on each side.

Soundproofing walls in an apartment with cork (cork panels, cork wallpaper, panels) refers to the first case - when you need to save space.And at the same time, its use will not bring much effect in combination with thin walls, since the sound insulation index of the material is 12-15 dB, and the absorption coefficient is about 0.3 on a scale from 0 to 1.

For example, thin walls will be able to reflect 47 dB. Plus, a few centimeters and a dozen decibels will be taken over by finishing materials - plaster, putty, wallpaper. That is, the volume of a normal conversation (45 dB) in this case, you will not hear from a neighboring apartment. Now let's add 15 dB of cork soundproofing index, we get a value of about 70 dB. And the crying of the child reaches all 80 dB - here are the first noises for you. And if the neighbors like to listen to loud music (85-90 dB), cork insulation will not help you at all. Given the high cost of the material, the cost of soundproofing with cork will be completely unjustified.

How can you isolate yourself from noise

Today, whatever materials are on the shelf, their essence boils down to one of the three whales on which, as it is known, the globe rests:

-

The first large group includes cotton wool of various origins. First of all, it is, of course, minerals and glass. The first attempts to invent something in this direction were made more than a century ago, but not for soundproofing. The ancient encyclopedia of English industry even contains instructions. The first experiments were based on observations of volcanic activity and were not entirely successful. It was noticed that fast air currents, sweeping over the crater of the volcano, pull out the thinnest flexible threads. In exactly the same way, attempts were made to make mineral wool on their own. From the bellows, air rushed at high speed over a bath of molten rock. As a result, not only was it possible to obtain soft mineral wool, but also the workers of the shops acquired lung diseases, in many cases with a fatal outcome. It got to the point that the people took to the demonstrations, refusing to produce what we are going to soundproof our apartments with today. A lot of time has passed, the technology has improved, and today you can see satisfied scientists in the pictures of the thirties of the last century, pressing a white fluffy lump to their cheek. You can never think that this is mineral wool.

-

The second large group includes structures based on a change in the density of the layers of the building sandwich. It can be different materials. We classify them as a separate group, because these are layered structures for sound insulation that have similar features. The composition may include, for example, the same mineral wool. The difference is that a relatively light insulator layer is complemented by a surface frame of a relatively dense material. In this case, not only good sound insulation is provided, but also surface mounting of drywall is simplified in many respects. At the same time, the process of installing sound insulation on the wall is accompanied by a number of features. In particular, a special soundproofing tape must be laid around the perimeter. But that's not all. Each docking unit is mounted to the load-bearing wall using special fasteners that come with the wall soundproofing material. At the same time, the strength of the structure remains in doubt, because mineral wool is not very rigid. If in the usual case, the crate is made by us according to our own requirements, then here we are forced to trust the manufacturer of sound insulation for walls. This is especially evident in such cases as, for example, the need to hang a plasma panel with a large diagonal on the wall. A TV can have a mass of about one hundred kilograms. It is clear that the wall in this case should not fail.

- The third group includes various polymeric materials. Noise insulation for walls can be supplied in the form of slabs. For flooring, the polymer is shipped in granular form.In this case, it is something resembling fish caviar with large grains. A layer of sound insulation of a certain thickness is spread on the floor, which polymerizes within a few hours. A screed is applied on top. In this case, it is recommended to use a floating floor construction together with sound insulation. We tend to distrust any polymers in the design of our premises. Everyone who wants to soundproof walls with foam plastic should know that after a number of years, artificial materials undergo a decay process. All this looks beautiful on the screen, in practice it requires replacement after a fairly short period of time.

You probably noticed that we didn't say anything about the cork tree. Why? We tend to attribute this noise insulator to the second group. That is, the quality of the coating is achieved due to the different density of the layers. Be that as it may, the cork tree can really be considered as separate options for soundproofing. Therefore, it will not be a mistake to single out this class in an independent group. What would we say about the cork tree, would it be an acceptable option in this case?

Cork flooring on the ceiling

High-quality insulation of an apartment can be done by applying a cork coating to the ceiling surface. To install tiles, rolls or panels, you need a square with a ruler, a rubber roller, a notched trowel, a chisel cord, glue, a sponge or rags.

The process of attaching cork material to the ceiling is carried out in stages:

- Check surface.

- Remove varnish or wallpaper.

- Plaster with sandpaper.

- Align the ceiling with putty or plaster.

- Dry the surface.

- Inspect the plug for possible defects.

- Mark the ceiling using a cord, a square and a pencil, which will help to properly glue the cork panels.

- For large slabs and panels, it is recommended to carry out the gluing work from the center of the ceiling surface.

- The panels are attached to a waterproof adhesive, which is applied to the material with a spatula or roller.

- The panel is pressed against the ceiling, and then rolled over it with a roller along its entire length. Residues of glue must be removed with a rag.

During operation, the ceiling covering must be observed carefully. During the heating season, the gaps between panels or wallpaper may increase or decrease. This is not a defect, but the properties of the cork coating. To maintain a stable temperature in the room, you can use different climate equipment and equipment.

Once a month, the coating must be cleaned of dust and dirt using a damp cloth or vacuum cleaner. To remove stains that cannot be wiped off with a rag, you need to take fine-grained sandpaper and clean it off. Then wipe the place with a damp cloth, and when it dries, cover with wax or varnish.

Cork floors

The floor surface in houses or surfaces where cork is used for insulation is of two types:

The first type of cork flooring is available in the form of tiles, the thickness of which varies from 2 to 6 mm. One of the sides has an adhesive base, which allows them to be easily attached to the floor. It is necessary to choose adhesive cork floors if you plan to use such material for the floor for a long time. Within 10 years, the adhesive cork coating will serve perfectly. Then you need to clean it, dry it and apply a layer of varnish on top.

Floating cork floors are in the form of panels, 9 to 12 mm thick. Between themselves, the panels are fastened according to the tenon-groove system. Sometimes floating panels include a vinyl backing. One of the advantages of such a coating is easy assembly and dismantling, if it is necessary to replace the floor covering. There are other options for soundproof substrates for wallpaper.

Benefits of cork flooring

- Original appearance.

- Environmentally friendly material that does not rot. It also does not absorb bad odors.

- High sound insulation. The sound absorption coefficient at a frequency of 2.1 kHz is 0.85. For common similar materials, it is about 0.7. Low frequency noise and vibration are reduced to a lesser extent.

- Low thermal conductivity. The material is widely used for thermal insulation of premises. Compared to other materials, a 3 cm thick cork cover provides the same thermal protection as 10 cm of pine or 20 cm of cellular concrete.

- The material is not electrified and does not attract dust.

- High strength, wear resistance and elasticity. The cork is able to restore its shape after the action of loads due to high elasticity. However, traces of furniture and sharp objects remain on the coating, which indicates the need for careful handling.

- Cork material treated with special substances does not burn, it is classified as a non-combustible substance.

- Cork noise insulation does not require special care, and wet cleaning is possible if the coating is protected by a layer of varnish.

Cork wall covering

Before you start working with the material, you need to let it acclimatize inside the apartment. After purchase, cork should be left in the package for 2-3 days, and only then you can start working with tiles or rolls.

The gluing process takes place in several stages:

- The surface of the wall is checked, if it is covered with drywall, then the surface should be treated with a primer. This is necessary so that the drywall does not get wet from the glue. Old wallpaper, glue, paint are removed from the wall, and only then the surface is primed to make it even.

- Take measurements of the wall in width to correctly mark the location of the first panel or tile.

- The vertical is outlined with a plumb line, which must be placed on the edge of the first tile, panel or wallpaper strip.

- The cork backing in rolls must be taken out and put under the load for a day, which will facilitate the gluing process. If it is necessary to make markings, then it is recommended to use the outside. Cork in tiles or panels does not need to be leveled, but such material should be checked for uniformity.

- The glue is applied with a roller on the surface of the substrate and on the wall, after which it is necessary to wait a few minutes for it to be absorbed. Then you can glue the material on the wall, walk on the substrate with a roller, knock with a hammer - wooden or rubber.

- The gluing process starts from the center of the wall, having previously marked out to the sides, down and up. In the indicated directions it is necessary to glue the substrate. The tile should hold tightly, so after applying to the wall, it is tapped with a hammer and pressed with a roller.

- Excess parts of the cork are cut off with a knife.

A cork backing in the form of slabs or a panel perfectly replaces the wallpaper, giving the room warmth and comfort. To improve durability in operation, it is recommended to treat the material after gluing with varnish in two layers.

For gluing the material, it is worth using such types of glue as:

To apply it to the cork, it is worth using a notched trowel, which will allow you to evenly distribute the glue on the surface of the material.

How to get rid of impact noise

Here you need to approach the problem from the other side, the task is not to absorb the wave of sound that interferes with you, but to repel it. Building materials that differ in porosity will help well: polyethylene foam, cork substrate or extruded polystyrene foam.

The difficulty lies in the fact that such insulation should be laid on the floor of the apartment located above you, and this is possible only in the case of good relations with neighbors. Such soundproofing of the ceiling will be the most effective, a multi-layer floating floor will be created, which is easy to lay with your own hands.

Soundproofing the ceiling

soundproofing layer on the ceiling serves to get rid of the tramp of the neighbors living above.

A common way is to create a false ceiling, for which you will have to sacrifice the volume of the room. A thin cork coating will not create sound insulation, it is advisable to use it together with other materials. When using a multi-layer structure of different density, the effect of sound protection increases. If only cork plates are used, their thickness must be at least 3 cm.

The order of installation of the coating:

- The ceiling is leveled. In this case, it is not recommended to use gypsum putties.

- The surface is degreased and a primer is applied, which can be an aqueous solution of glue or a special cement-based primer.

- The surface of the ceiling is divided into 4 identical sections, its center is located.

- The central tile is applied and outlined. Then places are marked for the rest.

- An adhesive is evenly applied to both surfaces, after which the tile is attached to the ceiling. After finishing work, you should walk on the plates with a roller, thus ensuring a secure fit.

Soundproofing cork walls in the apartment how it is done

Cork soundproofing of the ceiling is possible using both technical and decorative panels. In the first case, the sheets are attached with the first layer directly to the floor. Use glue - it will save a lot of time and effort. For fastening, a good acrylic adhesive is suitable, which is applied to both surfaces. Soundproofing the ceiling with a technical cork in combination with suspended structures will give a very good result! If you use decorative panels, then they are already glued to the surface of the plasterboard structure, inside which other insulating materials are hidden.

Decorative cork with the same glue can decorate the walls. In the living room or hallway, they can be left without additional coatings, but in the kitchen, in the bathroom or toilet, it is better to protect the surface from moisture with the help of special cork lacquers. The usual varnish, which is suitable for any wood, creates a membrane that is too strong and brittle, which is supported from the inside by strong wood, but the cork wood is resilient and elastic, it easily compresses and returns to its original position.

Therefore, the varnish must also be elastic enough not to crack at the first press. As a rule, such compositions have a very unpleasant odor, so when you varnish the panels, try to take your family to the country or to relatives for a few days. Complete polymerization of the film occurs after a week or even longer, depending on the temperature and humidity of the room.

Due to its elasticity, the cork substrate will relieve the load from the locks of the laminate or parquet board, but in order for the sound insulation to be effective, the technical cork must be laid at least in two, and preferably in three layers. Cork flooring together with the underlayment will complete what has been started - not a sound will penetrate into the room from the neighbors from below. By the way, this is a very pleasant flooring - in addition to the unusual texture and color, due to the elasticity of the material it is very easy to walk on it, less effort is spent, and the load on the spine feels completely different.

Cork oak bark is not widely used. In the manufacture of products, up to 60% of waste is generated. Now they all go to the manufacture of technical cork, from which floor, wall or ceiling coverings are made.

cork wall