Soundproofing sockets

Sockets and electrical accessories are the most important component of any home. Not only ensuring the proper operation of power systems, household appliances and equipment, but also the safety of residents depends on their installation. In addition, socket boxes that are not properly installed in partitions can serve as a conductor of strong noise, which affects sound insulation and, as a result, comfort.

Sometimes the noise conducted through the sockets can cause discomfort to several people at once. As it was, for example, in the case of one of our clients. In one hotel, when dividing one large room into several smaller ones by partitions, soundproofing of sockets was not made. As a result, guests in neighboring rooms could hear each other well. The hotel representatives turned to us for help. Our company provided all the materials they needed to carry out the work. Everyone was satisfied with the result.

Experts in their practice quite often face the issue of high-quality soundproofing of sockets, because, as you know, it is through incorrectly mounted sockets that up to 25% of sounds can pass into the room. This is especially true for houses with through channels for sockets (for two apartments at once) and any type of partitions.

For example, if we consider the passage of sound with a power of 80 dB from a source located behind the wall, then about a quarter of all conducted sound will fall on the cavity in the wall.

Before proceeding to the description of soundproofing solutions for sockets, I would like to draw attention to the following. Let's explain why it is unsafe to use mounting foam: being a highly flammable material, it can flare up from a spark on the wiring

Let us explain why it is unsafe to use mounting foam: being a highly flammable material, it can flare up from a spark on the wiring.

There are four main options for solving the soundproofing of sockets:

- Overhead sockets.

- Specialized inserts in the frame / Soundproof box.

- Reinforced soundproof boxes.

- Sound insulation of socket boxes already mounted in partitions.

Overhead sockets were widely used in Soviet times. The advantages of this solution include a high degree of sound insulation, since the main reason for the passage of sound - a hole - is absent. Only the wire is removed from the soundproof structure, the output of which is sealed, and the socket box is screwed to the wall with self-tapping screws.

- High degree of sound insulation

- Low cost solution

Morally obsolete appearance

Frame inserts. A newly developed solution that provides excellent sound protection, but requires careful installation and is not cheap enough.

High degree of sound insulation

- Required to install a frame with a minimum thickness of 50 mm

- Requires care during installation

- High price

Reinforced soundproof boxes are various variations on the Legrand theme and other options available on the market. These specialized soundproof junction boxes are rare on the Russian market. Such solutions are very expensive, so we will not consider them in our article.

Sound insulation of socket boxes already mounted in partitions. In some cases, when the budget or other reasons do not allow soundproofing sockets, membrane-based materials can be used to reduce the noise level. The outer surface of the underlay is pasted over with a membrane and inserted into the partition.

Properly installed under the socket allows you to significantly reduce the penetration of sounds into the room and improve the sound insulation of the wall.In some cases, installing a socket box is practically the only reliable and soundproofing way to fix the socket. For example, when installing it in plasterboard structures.

Soundproof socket boxes

Often the reasons for the penetration of noise from neighbors are not thin walls, but cracks and holes in them. Including sound penetrates through through electrical outlets. If you put your ear to the outlet, it will immediately become clear whether it is necessary to soundproof the outlets in the apartment.

Developers at the design stage provide through holes for the installation of electrical fittings. Builders mount sockets in reinforced concrete wall slabs, which are adjacent to two apartments, directly. There remains a through channel through which noise can almost freely enter your apartment.

To get rid of such a problem, you can make soundproofing sockets in the apartment. To do this, you need to dismantle the socket and the mounting box, observing the rules of electrical safety. You can even see the bottom of the junction box of a neighbor's electrical outlet. A cut-out washer made of mineral wool or basalt cardboard is inserted into the hole and sealed with gypsum-based putty or cement. Next, install your electrical outlet

Please note that mounting foam cannot be used to seal the outlet hole, since it is highly flammable, which is dangerous in case of even a small short circuit, and is also not a soundproof material. Of course, you can do the soundproofing of sockets with your own hands, but for the efficiency and safety of you and the room, it is better to use the services of an electrician.

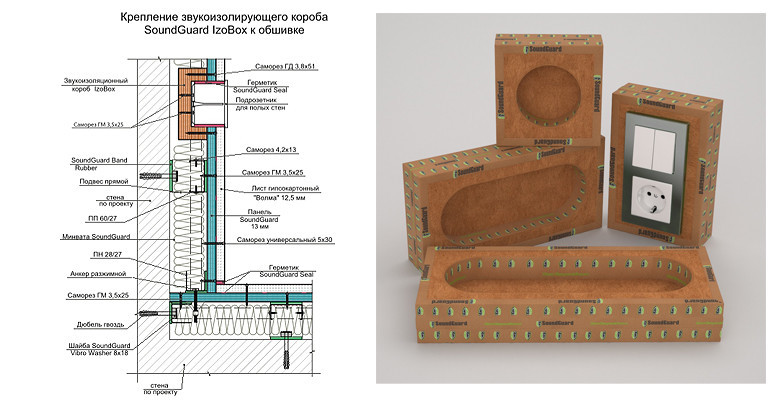

For complex soundproofing of sockets and mounting boxes, SoundGuard has developed special soundproofing IsoBox socket boxes. There are 4 variants of boxes for a different number of electrical sockets to choose from. IsoBox sockets will save you from the penetration of noise through sockets and switches. This does not require additional materials, the box is designed so that the installation of one of it is enough to achieve the result. You can find soundproof socket boxes on the site in the "Additional materials" section.

Starting the installation of soundproof socket boxes, first a thickening is made of 2 layers of GVL, glued with sealant and fastened with self-tapping screws. Then a hole is drilled in the center for the wires in the box and filled with sealant. Next, you can mount the soundproof structure, while you need to bring the wire to the right place. In the soundproofing structure, a place is cut out for a soundproof socket box, which is glued with a sealant. After that, the system is ready for further processing. Making soundproofing of sockets in a panel house or any other will not be a problem if you use modern materials and soundproofing technologies.

Dismantling the built-in socket

First you need to remove the socket. For this you need:

Coordinate your actions with your neighbors, because you can inadvertently knock over their outlet, causing a short circuit.

Turn off the power supply to the apartment.

Check the mains voltage with a multimeter - there is no guarantee that the repairmen correctly connected the power cable to the apartment.

- Remove trim panel.

- Amortize the two screws clamping the adjustable legs.

- Remove the electrical outlet structure. Here you can see several wires with ends wrapped in terminals. The power cable traditionally protrudes from the top of the wall surface.

- Loosen the screws on the terminals and remove the socket block. The ends should be wrapped with electrical tape.

- Here you can find an electrical (installation) box in a glass-shaped configuration, which you need to get.The current boxes are made of plastic, the old designs are made of metal.

- By pointing a flashlight, you can see the neighbors' socket box. Upon detection of influxes of building mortar, it is necessary to clean them, eliminating dust and pollution.

Soundproofing materials

The owners of an apartment with a poor level of sound insulation are most often forced to solve the problem on their own. To begin with, you will have to deal with the sources of extraneous sounds, and then proceed to the purchase of soundproofing materials.

Modern building materials make it possible to achieve high-quality sound insulation both in a new building and in a long-standing building.

soft insulation

Soft roll materials have good sound-absorbing characteristics and are small in thickness. They do not hide space and can be used even in small apartments. Soft insulation is able not only to absorb third-party noise, but also to repel them from its surface, and thanks to the porous and elastic structure, sound vibrations are distributed evenly throughout the entire thickness of the building material.

Basalt (mineral) wool

Mineral wool is made on the basis of gabbro-basalt rocks with the addition of binding materials. Carbamide resins, bentonite clays, phenolic alcohols, bituminous and composite compositions can be used as a binder.

The material is produced in the form of rolls or plates, used for finishing walls, ceilings and decorative partitions.

Cork

Roll material with a natural composition and a polyurethane binder. The structure of the material resembles many frozen bubbles that retain heat inside and do not allow noise to penetrate inside.

Cork is an excellent solution for new buildings, where the use of special compounds for soundproofing is not provided. The cork surface is well kept on the floors with the help of an adhesive composition.

Penolon

The material is made from polymers that are foamed using a certain technology and saturated with hydrocarbons. The result is a three-dimensional product with a cellular structure and excellent soundproofing characteristics. The material holds heat well, repels moisture and absorbs noise.

Penolon is used to insulate all parts of the building - when laying the foundation, arranging the roof, for insulating door and window structures, as a substrate for laminate.

Cork-rubber backing

Composite material, which is a mixture of granular cork and synthetic rubber. It is used as a layer under floor coverings, ceramic tiles, natural stone slabs, etc.

solid insulation

Solid materials have improved soundproofing characteristics. But due to the large thickness of the insulating layer, they can reduce the physical volume of space, which makes them unsuitable for arranging small apartments.

Styrofoam

Foamed plastic gas-filled mass of white color is one of the most popular materials for insulation and soundproofing walls and ceilings. Styrofoam plates are safe for human health, have a long service life, are not amenable to combustion and decay. Styrofoam is easily glued to other materials, easily cut with a knife or a hand saw, fastened with special glue or dowels with wide caps.

Styrofoam

It is made by adding gas to the polymer mass of polystyrene. In terms of performance, it exceeds foam plastic - it is stronger and better protects against noise.

Multilayer panel

The design consists of sandwich panels and finishing facing sheets of drywall, 12.5 mm thick. The material does not require a metal frame - fastening to the wall is carried out using special units provided for by the design of the product.

Soundproofing is also achieved through the use of such materials:

- basalt fiber slabs;

- glass wool;

- plates made of polyester fibers;

- fiberglass boards;

- drywall;

- mineral membranes based on aragonite;

- bitumen-cork substrate;

- fiberglass;

- vibroacoustic sealant;

- silica fiber;

- soundproof wallpaper.

Handy soundproofing

The easiest way to achieve noise reduction in a room is to use interior items:

- thick curtains on the windows;

- carpets on the walls;

- carpeting on the floor;

- furniture walls and slides;

- soft headboards on the walls.

Soundproofing the walls in the apartment

Work on soundproofing walls begins with the identification of cracks and holes. All defects found must be covered with putty, and large holes must be plastered.

The best way to soundproof walls is to install a plasterboard structure, inside which one of the types of rolled or rigid insulating materials is placed.

- Make marks on the surface of the floor and ceiling, connect them with construction cord.

- Fix the guide profile to the floor, ceiling and wall using a perforator and dowels.

- Paste the profile with soundproof tape along the bottom.

- Install the corners of the rack profile into the guide profile and fix the products with screws.

- Place the sheets of the selected sound insulator into the resulting frame.

- Attach drywall on top with self-tapping screws.

- Stick reinforcing tape on the joints between drywall sheets, and additionally putty the holes on top.

Peculiarities

The manufacture of reinforced concrete slabs involves the formation of loose slots to simplify the work of electrical installation masters. Repairmen carry out the supply of several power cables to them. They connect a couple of flush-mounted sockets in neighboring apartments. Sometimes they do not bother with an elementary gasket with a soundproof result.

Tenants need to eliminate this imperfection of a standard building on their own, otherwise their comfort will steadily deteriorate and not always only with a hum from their neighbors. Through the air duct, bad odors, allergens, tobacco smoke, microbes are constantly drawn into the apartment. Soundproofing sockets can be done on your own or use the services of specialists.

Upon closer examination, it turns out that the problem is solved in one of the following ways:

- moving the built-in electrical outlet to a more suitable place;

- changing the built-in socket to a consignment note;

- laying a soundproof base under the outlet.

Hidden, internal or built-in is called a socket built into the wall. Outside, there is only an overhead decorative and protective console. Built-in sockets are used when dismantling hidden wiring. Gating them is a laborious undertaking, although they look neater. You can move a hidden outlet by drilling another hole next to the old one and making a groove for the wire.

The overhead socket is fixed over the wall surface under the external wiring. Its mini body rises by 5 cm, but this is not always necessary in new buildings. When repairs are not expected, it is more profitable and cheaper to soundproof an existing hidden electrical outlet. This is not as hard to do as it seems: the socket and box are removed from the socket hole, a soundproof base is placed in the slot, and the structure is installed in place.

Soundproofing standards in panel houses

In Russia, noise insulation standards are strictly regulated and enshrined in the set of rules for noise protection SP 51.13330.2011. The regulations apply to airborne and impact sound levels:

- airborne noise (voices, music, etc.) - sound insulation at the level of 50 dB;

- impact noise (repair work, movement of furniture) - the permissible sound pressure level is 60 dB.

According to building codes, the optimal thickness of reinforced concrete floors is 160 mm. For inter-apartment partitions, 100-150 mm is enough. But practice shows that a comfortable stay in the apartment in terms of noise level will be possible with a partition thickness of more than 200 mm.

Soundproofing of central heating risers

Central heating pipes passing through floor slabs must be installed in special sleeves according to the regulations. These are large diameter pipes that perform the function of sound insulation. If the norms have not been met and the sleeve is missing, the owners will have to isolate the risers themselves.

- Remove grout around the pipe.

- Wrap the freed pipe with mineral wool or glass wool.

- Cement the space between the pipe, floors and insulation.

- Cut off the rest of the soundproofing material.

- Carefully putty the surface and smooth out the bumps.

Soundproofing the ceiling in the apartment

For the ceiling, it is better to choose lightweight materials that will not peel off from the surface under the weight of their own weight. With the function of protecting the ceiling, special membrane products, sound-absorbing plates, ZIPS panels will do well.

The soundproofing of the ceiling can be carried out according to the same method as the soundproofing of the walls. Drywall and a layer of insulating material will do an excellent job of protecting against extraneous noise and cold. However, this technology is more suitable at the stage of rough or overhaul, when it is possible to carry out large-scale finishing work.

If the need for soundproofing arose later, it is better to abandon the construction of the frame in favor of soundproofing panels.

- Preliminary preparation of the ceiling - remove the old decorative coating, cover up the cracks.

- Glue insulating strips around the perimeter of the ceiling.

- Starting from the corner of the room, mark the ceiling - outline the contours of the plates and places for fastening the screws.

- Attach the panel according to the markup and drill holes for the screws.

- Attach the slab to the ceiling with the vibration isolation mounts that come with it.

- Complete the sheathing of the entire ceiling, carefully fitting the panels to each other.

Sound insulation of joints, windows and doors

Sound insulation of the joints between the plates is carried out with conventional putty mixtures. All detected gaps and defects must first be expanded using a screwdriver or chisel. Then the cracks are cleaned of dust and sand, primed and covered with putty. When the putty mixture dries, the joint surface is covered with acrylic sealant.

Modern double-glazed windows with triple glazing technology are well protected from street noise. All gaps between the wall and the double-glazed window must be carefully insulated with mounting foam. If the window has lost its tightness, it should be re-foamed and a sealant applied. If necessary, install platbands and flashings made of PVC.

The doorway is isolated around the entire perimeter with special rubber gaskets. The space between the opening and the door frame must be sealed with a cement-based mortar.

Causes of poor sound insulation of panel houses

There are several reasons why panel houses cannot boast good insulation from airborne and impact noise:

- low quality of construction and repair work, the presence of unsealed seams and gaps between the plates;

- illiterate housing design, which leads to poor docking of panels, cracks and distortions;

- non-compliance with the technology of installation of inter-apartment and inter-room partitions;

- the use of cheap and low-quality soundproof materials;

- non-compliance with standards for the thickness of floors and partitions;

- illegal redevelopment of the apartment by neighbors with violations of building codes;

- violations during the installation of window frames and doorways, as a result of which their tightness is reduced.

The main reason for poor sound insulation is the desire of developers to save on the construction of a building, primarily on sound insulation. It is impossible to assess its quality without special equipment and the involvement of specialists, and the developer's savings on soundproof materials will be up to 40%.