Do-it-yourself production of a squeegee

If necessary, you can make a squeegee of the desired size yourself. To complete the work you will need:

- metal steel pipe - a pipe cut of the appropriate length;

- carpentry vise to facilitate work;

- equipment for threading: a die with a die holder for external threads or a tap for applying internal threads;

- file (intended for chamfering);

- grinder (hacksaw) for cutting, if you need to cut off part of the pipe for harvesting the drive;

- lubricant.

The work is done in the following order:

- with the help of a grinder or a hacksaw, a workpiece is cut off for a drive of the appropriate length;

Cutting a pipe with a grinder for making a squeegee

In accordance with the recommendations of experts, the length of the run should be 3-5 mm longer than the pipe break.

- chamfer is removed from the ends of the prepared cut;

- edges are treated with grease to facilitate threading;

- the drive is clamped in a vice;

- the selected equipment is threaded. The short part of the thread must be at least 5 threads, and the long part must be 20 threads. If necessary, the long part can be increased to 30 threads.

Thread cutting

When making the squeegee on your own, you should not forget about the personal protective equipment of the master. It is recommended to use gloves and a protective mask when cutting pipes.

purpose

The method of connecting the elements of the pipeline depends on several factors, for example, the material of the pipes, the type of transported substance, as well as the conditions of the working environment. The main purpose of the pipe fittings is to connect them to plumbing or gas appliances. Welding is not suitable here, because the connection must be detachable: if necessary, some element may have to be dismantled. For example, it is advised to use the squeegee in heating networks after the valve on the riser.

In the event of a breakdown, the presence of a drive will make it easy to get an element of valves in order to repair or replace it. Squeegees are also useful for cast-iron old radiators, their presence will help to clean the pipeline. This element is used to connect various heating equipment: tanks and gas boilers, as well as mixers. In the kitchen, the squeegee will come in handy when connecting the stove. Finally, it can be used to create an additional branch pipeline.

How to choose a sgon

When choosing a drive, you need to consider:

- type of connecting fitting;

- fitting material;

- technical specifications.

Varieties of sgons

It is possible to classify sgons according to the following criteria:

- depending on the design, there are:

- direct drive, designed for installation on a flat section of the highway (figure above);

- corner run, designed for areas with the need to change the direction of the pipeline system;

Fitting for changing the direction of the main

Straight and corner sgons differ only in appearance and purpose. All other parameters are completely identical.

- depending on the scope of application, there are:

- compensating slopes. In most cases, such devices are installed at the points of connection of plumbing or gas equipment, heating radiators, as they allow compensating for pipe deviation within 5 cm;

- short and long spurs used to connect other equipment of the pipeline system.

Varieties of squeezing for the pipeline

Many, especially novice plumbers, classify fittings such as barrels and threads as varieties of squeegee. However, this assertion is erroneous.

The barrel is a piece of pipe with threaded ends.In contrast to the squeegee, threads of the same length and size are applied to the pipe on both sides. Such a device is intended for connecting pipes without welding.

Fitting for connecting pipes to each other

A thread is a fitting made from a piece of pipe with a thread at one end. The device is used to connect other types of threaded fittings to a water, gas or heating system.

Device for mounting threaded fittings

Selection of manufacturing material

For the manufacture of sgons, materials such as:

- carbon steel. Steel fittings are characterized by low cost and a large margin of safety. However, due to the strong susceptibility to corrosion, their installation is carried out mainly on gas supply systems;

- galvanized steel. Such fittings are not subject to the formation of corrosive deposits, therefore they can be used in water supply systems, including drinking water supply and heating, as well as on other pipelines in places where precipitation is possible;

- stainless steel. Unlike galvanized fittings, stainless steel fittings are more expensive and are mainly intended for drinking water systems, as well as for connecting pipes in the ground;

- brass. Currently, due to the high cost, it is practically not used.

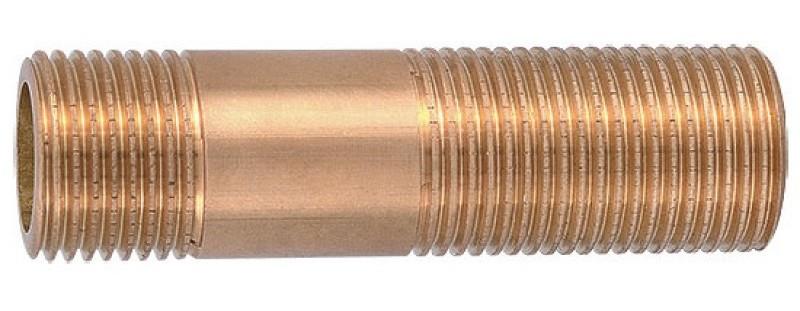

Brass pipe fitting

Definition of technical parameters

Metal slings are made in accordance with GOST 8969-2010. When choosing parameters, consider:

- thread type. Spurs can be left-handed or right-handed, internally or externally threaded. The selection of this parameter is carried out on the basis of the data of the equipment that needs to be connected using a fitting;

- conditional passage of the fitting in accordance with the diameter of the pipeline;

- the size of the thread applied to the fitting.

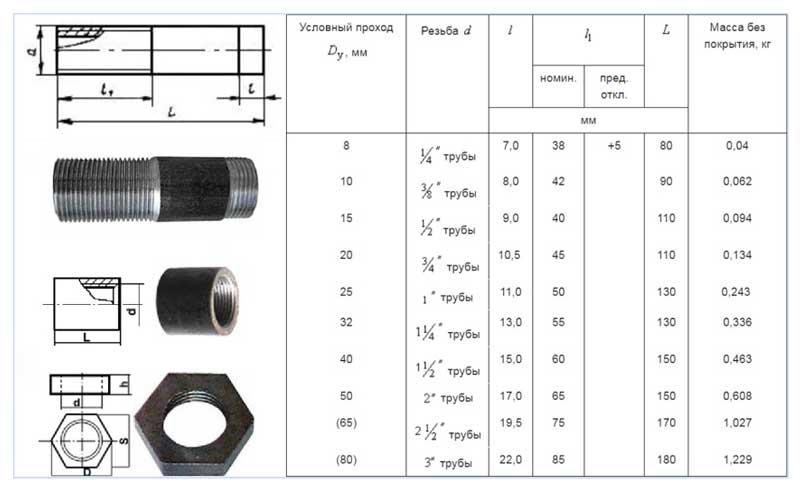

Standard sizes of metal spurs in accordance with GOST

All technical parameters are indicated in the fitting marking, which is applied in accordance with GOST 8969-75. For example, Sgon40-Ts GOST 8969-75 indicates that the fitting is made of galvanized steel (Ts) in accordance with the technical regulations and has a nominal bore of 40 mm.

Installation of spurs

The main advantages of installing sleds are:

- ease of installation. Connecting pipes with a drive does not require a welding machine and skills to work with it. The work can be done by a novice master;

- low cost;

- obtaining a detachable connection;

- the possibility of carrying out repairs without shutting down the entire pipeline.

Fitting Locations

Sgons are recommended to be installed:

- after taps and / or valves, which will allow you to turn off the subsequent section of the pipeline system for repair or maintenance work;

- on the central risers of any system;

- when connecting equipment (heating radiators, boilers, individual metering devices, and so on);

- on fixed liners.

Places where installation of a drive is required

fitting installation

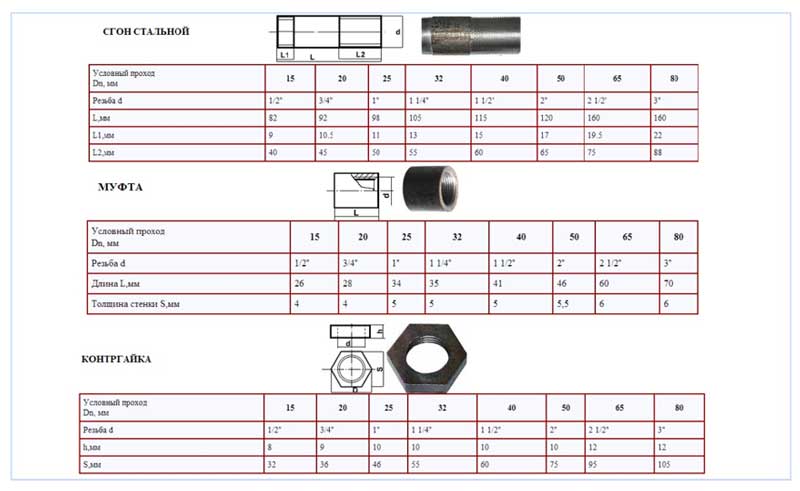

To install the pipeline, you will need to purchase a shackle with a coupling and a lock nut (a standard fitting kit).

Fitting set "Sgon"

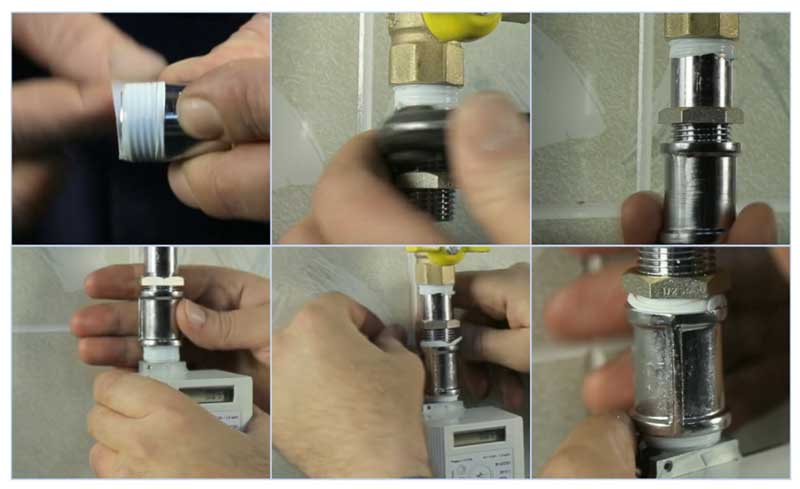

The connection of the sleeves with a coupling is carried out according to the following scheme:

- a lock nut is installed at the end of the long thread, and then the coupling is screwed on;

- sections of the pipeline system are connected;

- the coupling moves smoothly over a short section of the thread until it stops (“jamming”, as professional plumbers prepare);

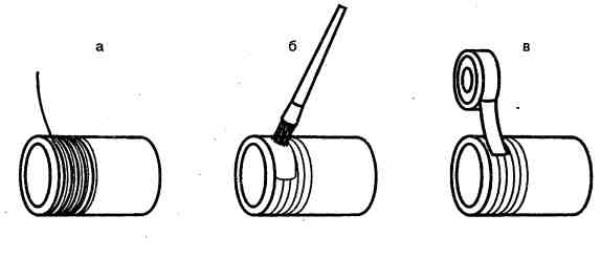

- a long section of the thread is sealed in any way: you can use an ordinary linen thread with additional fixation with paint or a special composition; you can use specialized tools, such as FUM tape, Tangit Unilok thread and so on;

Thread seal options

- the coupling is fixed with a locknut;

- all assembly elements of the connection are fixed with a gas key;

The sequence of assembly of the pipeline with the help of squeegees

- the tightness of the resulting connection is checked. If there is a leak through the fitting, it is recommended to increase the amount of sealing material and tighten the nut more tightly.

What is squeezing and how to install it, look at the video.

Standard shackles can be installed on piping systems subject to the following conditions:

- the maximum pressure inside the line does not exceed 16 atmospheres;

- the maximum temperature of the working environment is 175°С.

If it is necessary to install spurs on systems with other parameters, it is required to manufacture spurs according to individual parameters.

Pipeline Assembly Technology

To assemble the pipeline, you must perform the following sequence of actions:

- First, the sleeve must be screwed onto the pipe.

- Then the side with a short thread is screwed into the coupling (sometimes it is connected directly). Details should be tightened until it stops, then the connection will turn out to be reliable.

- A lock nut is screwed onto the long side of the drive.

- It is followed by a connecting fitting.

- Then the end of the drive is applied to the pipe and the coupling is screwed so that it passes to the pipe. The connection will be easier to perform in the case of maximum coincidence of the axes of the parts.

- The fitting must then be secured with a locknut. To do this, it should be twisted to the sleeve so that there is a distance of 2-3 cm between the parts. This space must be filled with flax strands. They should be wound in the direction of rotation of the nut. Then the locknut should be tightened until it stops. This must be done to seal the connection and prevent water from leaking through it. A wrench should be used to tighten the lock nut, as its edges are narrow.

Spurs for pipes dimensions according to GOST

The drive is a piece of pipe with double-sided threads of different lengths, its average size on the short side is 5 threads, the long one has a length of at least 20 turns. Metal or galvanized drives with a short threaded end are connected to the equipment (gas stoves, heating radiators, boilers), and a coupling of the appropriate length and a lock nut move along the long thread. When docking, a long sleeve with a sealing seal (linen tow, plumbing thread, FUM tape) is screwed onto another pipe, on the other side of the sleeve, the wound seal is pressed with a lock nut.

The parameters of the spurs are regulated by GOST 8969-75, where their size, the length of the threaded sections, and the thread diameter in inches are indicated.

Rice. 2 Sgon - appearance and materials of manufacture

How is the installation of the drive into the system

Steel connecting couplings for installation and plumbing devices installed after the valves are mounted in compliance with the following rules:

- Fittings must have a gap length between pipes of no more than 5 mm. taking into account the deepening of the side with a short thread in the connected equipment or fittings.

- On the threaded side with a length of at least 20 threads, a steel lock nut and a coupling are successively screwed on.

- Linen fiber or thread is wound along the thread

- During installation, flax fiber is wound on the short side, lubricated with a special paste and the pipe is screwed into the outlet pipe of the valve by hand, and then pressed with a gas wrench. For convenience, a second key is used, holding the valve body with it to prevent turning on the pipeline.

Rice. 5 Connecting steel parts according to GOST 8965-75

- The connecting parts are screwed onto the long side: a lock nut until it stops and a coupling, flax is wound onto the connected pipe along the thread.

- They drive the long coupling down and screw it onto the pipe, pressing it with a gas wrench.

- Flax fiber is wound from the other end of the coupling, coated with paste and tightened with a lock nut.

Dismantling recommendations

To prevent the appearance of rust on gas and water pipes, they must be painted. The service life of the pipeline after painting will increase, however, after that, the dismantling of threaded connections becomes quite difficult. For this reason, it is not necessary to paint a place with a thread several times, one layer is enough. To facilitate parsing, these areas should be smeared with grease.

If the joints on the disassembled section of the pipeline were painted several times, then it is necessary to first remove the paint layer. To do this, you can use a blowtorch or a knife.

The material from which the fitting is made affects the complexity of dismantling. For example, ductile iron parts screwed onto steel pipes will not be difficult to unscrew with a wrench. Such details practically "do not grow together" with pipes. But the clutch made of steel cannot be untwisted with a key.

You should not reinforce the key with a lever, otherwise it will be damaged, and the part will remain unscrewed.

Conclusion

So, we found out that this is a pipe clamp and a coupling. Using these parts, a collapsible pipeline connection is created. The use of a surge provides the possibility of dismantling a certain section of the system without the need to disassemble the entire pipeline in case of repair work.

In this article, I want to introduce the reader to one of the simplest fittings for installing steel water pipes - a drive. We will find out what it is and find out how and where the drive is mounted. In addition, we have to get acquainted with the typical problems of connections with spurs and how to eliminate them.

Allow me to introduce the hero of this article.

Self-manufacturing

Typically, sleds are made of steel, mostly galvanized. If the element is installed on an individual water supply system, from which water suitable for drinking comes, then preference is given to brass and stainless steel. Experts note the longest period of use for a stainless steel drive. They assure that this material will last four times longer than carbon steel and twice as long as galvanized steel.

Also, the drive can be made from a bronze, copper and cast iron tube. Depending on the material chosen, the possible operating conditions, the service life, and the cost of the product will be determined. For example, a copper drive will not be subjected to temperature fluctuations and ultraviolet radiation. As for the price, one of the cheapest options is an aluminum element. You will have to pay twice as much for a zinc part, three times as much for a stainless steel fitting.

It is quite possible to make a squeegee with your own hands. Sometimes this is done to save time and money, and sometimes to compensate for the lack of a part of the right length in the store. Usually only the tube is made independently, and the coupling with the lock nut is taken from another set. When choosing a suitable material, it should be remembered that the pipe must have walls of considerable thickness.

Consider the algorithm for making a drive at home.

First of all, a blank of the required length is cut from the gas pipe of the required size. Clamping the part in a vise, both ends of the pipe are processed with a grinder, sandpaper or a hacksaw. It is recommended to pre-lubricate the surface with oil, its use will greatly simplify the process.

Next, threads are to be cut on both sides: 20 on one side and 5-6 on the other. This is done by screwing the plate with the guide frame into the pipe, and initially you will have to apply maximum effort, and then everything will go by itself. You can stop pressing the die after the first two turns

Cutting is done both in the forward and in the opposite direction.

It is important not to forget to periodically remove the tool and clean both it and the pipe from chips.After the initial cutting, it will be necessary to carry out another, finishing one.

See the video below for information on how to install a squeegee on pipes.

Is it possible to make a squeegee on your own and how to do it

When arranging a pipeline with your own hands, sometimes a situation arises when a selection of the required length of spurs is required - according to standards, factory products cover only a narrow range of sizes and diameters. In this case, a self-made pipe is used, and the clamping locknut and coupling of the required diameter are taken from another workpiece. For manufacturing, you need to use a section of a gas pipe that is suitable in length, for work you will need a die with a holder or a screw clamp, oil, a vise for clamping the workpiece, a hacksaw or a grinder for cutting the pipe.

Rice. 7 An example of mounting a drive on an FUM tape for installing a gas meter

Work is carried out in the following sequence:

- A workpiece of the required length is cut off from the pipe, the part is clamped in a vise, the outer ends on both sides are protected with sandpaper, a grinder or a file.

- Lubricate the pipe surface from the side of the short thread, insert a die into the holder or die and press it tightly against the end, trying to maintain a strictly perpendicular position relative to the axis of the workpiece.

- They begin to screw the die into the pipe, while applying maximum force, after several turns and grasping the teeth of the die by the thread, clamping force is not required.

- Cutting is carried out in the forward and reverse direction, periodically removing the tool and cleaning it from chips with a clean rag along with the pipe surface.

- After passing 5 - 6 turns on the short side, the part is turned over and they start cutting a long thread of 20 turns at the other end.

Rice. 8 How to make a do-it-yourself drive

Sgon is one of the common options for connecting steel pipelines to plumbing and gas fittings and equipment. When properly installed, the coupling provides a reliable, durable and tight connection; if necessary, a fitting of a suitable length is easy to do with your own hands.

Conclusion

We will consider our acquaintance with one of the oldest fittings for steel pipes to have taken place. As always, you can learn more by watching the video in this article. I look forward to your additions and comments. Good luck, comrades!

Pipe shackles are a connecting fitting made in the form of a pipe cut with threaded ends. For ease of installation, the thread on the spur varies in length and size. Surges can be used in the construction of water pipelines, gas pipelines, heating and sewer systems. How to independently choose the most optimal device for a particular situation and install it, read on.

Connection fitting for pipeline