Due to its practicality, affordable price and ease of installation linoleum is one of the most popular materials used in floor renovation. It is not difficult to lay it, but a perfectly flat base surface is required, otherwise, even through a rather thick coating layer, all the defects of the old floors will appear: height differences and gaps between the floorboards. Laying plywood on a wooden floor under linoleum is the easiest, fastest and cheapest way to prepare the base for this material.

Why plywood?

Of course, there are other decent ways to get perfectly flat surface for linoleum instead of a cracked and uneven old wooden floor. But laying plywood under linoleum has a number of undeniable advantages:

- It is not required to dismantle the old coating, and this is a significant saving of both time and money.

- Sheets of plywood will help distribute the load more evenly throughout the floor. This will avoid deflection and creaking of the floorboards when walking, such a coating is able to withstand solid loads for a long time without deformation or other undesirable consequences.

- If the old floors are uneven, then plywood will allow them to be leveled without much effort and expense.

- There is no fear that after a certain period of time the floors will acquire relief, which will eventually appear on linoleum.

- In parallel with direct tasks, laying plywood will increase the heat and sound insulation of the floor.

- Plywood installation work is available to almost any layman, the most minimal building skills and watching a training video are enough. In addition, these works do not require the purchase of any special tool. The only exception is a floor grinder, but you can do without it if you can’t borrow it from friends or rent it.

- This is the most cost-effective way to lay linoleum on a wooden floor.

Some disadvantages of plywood sheets

Despite the impressive list of advantages, plywood is far from being an ideal material and has quite significant drawbacks that must be taken into account when using it:

- It is quite flammable. This drawback can be eliminated by impregnating the sheets with a flame retardant solution.

- Hygroscopic, meaning it is susceptible to moisture. Therefore, it is extremely undesirable to use plywood in rooms where the humidity exceeds 68% for a long time. If there is no other way out, then special moisture-resistant plywood should be used in the bathroom or kitchen. In this case, do-it-yourself impregnation of ordinary sheets with a special composition will help a little.

- Impregnation with an antiseptic is obligatory, since plywood is a favorable environment for the reproduction of various microorganisms and fungi.

- Due to changes in temperature and humidity, the material will experience certain deformations, therefore, technological gaps between the seams and around the entire perimeter of the coating are required.

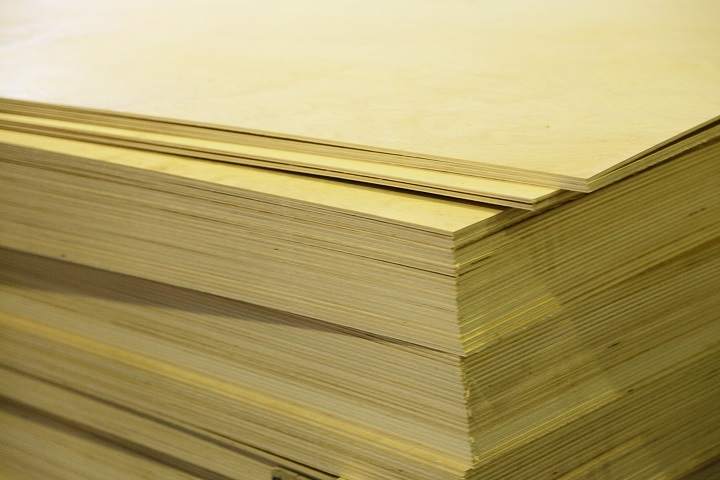

What kind of plywood to choose?

The right choice of material is the key to preparing a quality base for linoleum. What can be guided?

- For any premises, not only for the bathroom or kitchen, moisture-resistant plywood should be preferred. It is better to protect yourself from the possible penetration of liquid under the linoleum, and this can happen in any room: moisture can seep through inaccurate mopping, leakage from heating radiators is possible, or you can simply spill something. Having saved on the material, you can then spend a lot of money replacing the swollen floors. Moisture resistant plywood is marked "FC".

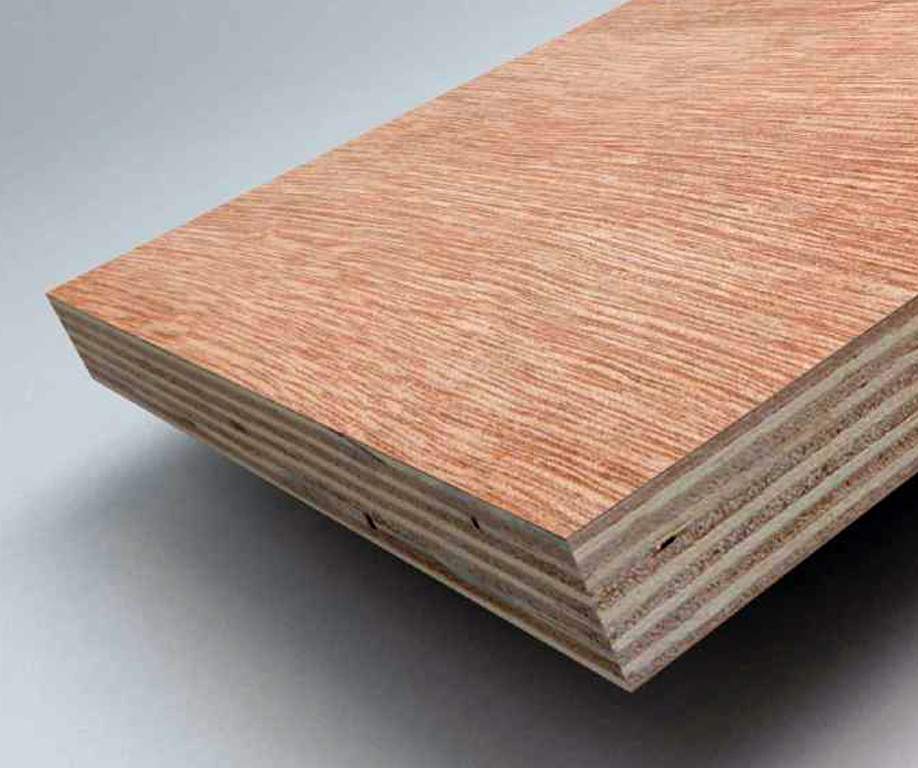

- The thickness of plywood sheets should not be less than 12 mm if the rough coating is laid in one layer. The greater the expected load on the floors, the thicker the plywood sheet should be taken. But it should be borne in mind that this layer, albeit slightly, will reduce the dimensions of the room.

- Hardwood veneer in the composition of plywood sheets allows the latter to carry higher loads compared to material made from softwood.

- Material sanded on both sides should be preferred. You can also use unsanded plywood marked "NSh", but it will have to be processed with sanding paper.

Materials such as MDF or OSB are significantly superior to ordinary plywood in terms of their qualities, but they are also much more expensive. With a sufficient budget, it is recommended to use them, the financial costs in the future will be more than offset by the strength and durability of the coating.

- If you doubt that you will be able to independently impregnate the sheets with the desired composition, then it is better not to risk it and buy pre-impregnated plywood, even if it costs a little more.

Surface inspection and preparation

Any surface requires preparation before reconstruction, and wooden floors are no exception:

- Skirting boards are removed if they are present on old floors.

- Checking waterproofing and the presence of sources of moisture. Without the elimination of the latter, it is pointless to lay plywood, they will fail in a fairly short period of time.

- Replace rotten or rotten elements.

- In old floors, gaps up to 5 cm in size are permissible. If the gaps between the boards are larger, then they must be eliminated.

- With significant differences in height between the floorboards, grinding will have to be performed, otherwise such relief will subsequently appear on the surface of the linoleum. To do this, you need to rent a grinder.

Before grinding, all metal elements are removed or recessed so as not to damage the abrasive. Loose floorboards are fixed with wedges, nails or self-tapping screws. Grind the floors diagonally, overlapping the strips and not holding the machine in one place.

In addition to the base, it is also necessary to prepare the plywood sheets themselves. First of all, you need to let them mature indoors for at least three days. If it is planned to impregnate plywood, then it is necessary to provide time for its drying.

Impregnation of plywood with polyvinyl acetate putty has become widespread as a relatively cheap but reliable way to protect plywood sheets. Also, do not forget to treat the material with an antiseptic.

Cutting sheets of plywood

On many construction forums, you can find recommendations for laying plywood, after cutting the sheets into identical square elements. This is not at all necessary, it is possible to carry out installation of entire sheets, if the dimensions of the room allow. It is important to observe the following rules:

- The borders of joining plywood sheets should not coincide with the cracks in the old coating.

- Elements should be stacked in a checkerboard pattern so that the seams between sheets of adjacent rows move at least 20–30 cm.

- It is also necessary to leave a compensating gap of 2-3 mm between the sheets, and about 10 mm between the plywood and the wall. This is necessary so that the coating does not swell due to thermal expansion of the material. Subsequently, the joints between the sheets are sealed with a special wood putty, and the gap around the perimeter of the room will be closed with a plinth.

It is most convenient to cut sheets with an electric jigsaw. The resulting scuffs on plywood are removed with fine sandpaper.

Sheet stacking

Cut sheets are laid out on the floor for fitting. It is better to number them and draw up the simplest diagram of their location, so as not to suffer later, choosing the desired element.

- Before applying the adhesive, the surface is cleaned of dust and degreased with white spirit. A layer of glue no more than 2–3 cm thick is evenly applied to the floor surface.

You can use special wood glue or self-made mastic: PVA is mixed with gypsum to the consistency of thick sour cream. An adhesive solution should try to smooth out the bumps and fill in the cracks.

- Plywood sheets are glued according to the laying scheme, their level is controlled, after which it is necessary to allow the adhesive solution to set. This will take 1-2 days.

- After the glue dries, additional fixation is carried out with self-tapping screws. They should be placed no closer than 20 cm from the edge of the sheet in increments of 15–25 cm. So that the self-tapping screws do not show through after laying the linoleum, they should be drowned, for which it is better to first countersink the holes.

- At the final stage, all joints are ground and leveled with putty on wood. You can use PVA glue mixed with gypsum or small wood shavings. And also putty holes in the sheets where the heads of the self-tapping screws are located.

In more detail and clearly the process of laying plywood sheets is shown in the video.

After the putty dries, the surface is cleaned of the resulting debris and linoleum is laid on it.