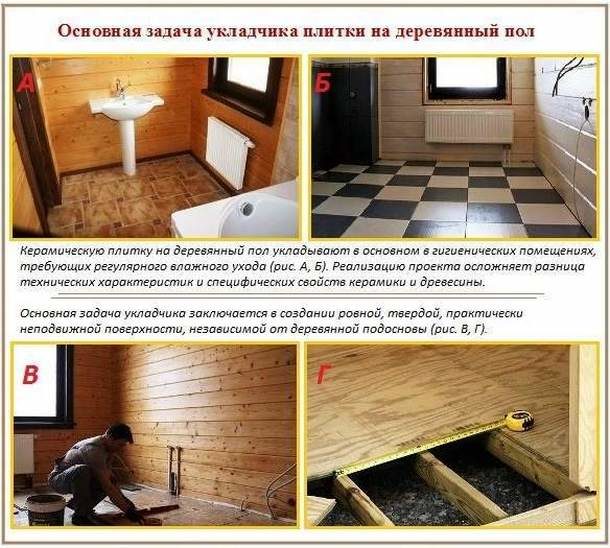

The base for tiles is most often a cement screed, but sometimes for various reasons it cannot be done. Is it possible in this case to lay tiles on a wooden base? And if so, how to do it, because wood and tiles are poorly compatible materials? The answer will be this: it is possible, but only if the surface is carefully prepared and a special technology is followed. Let's find out how to lay tiles in the bathroom on wooden floors with your own hands in accordance with all the rules.

The nuances of laying tiles on a wooden base

The tree is subject to deformation, it can dry out and swell, and these properties do not at all contribute to the creation of high-quality and durable tiled flooring. Due to the lack of static, the glue will crack, the tile will lag behind the surface. Therefore, it is necessary to create an insulating damping layer or to give the base greater rigidity.

When it comes to wooden floors in the bathroom, it is important to take care of protection from moisture, which leads to the formation of mold and fungus, rotting boards, and wood deformation. Ceramics is a reliable protection against moisture, if you properly prepare the base, and then process the seams with high quality.

After installing tiles on a wooden base, you need to be prepared for the following problems, which can only be eliminated before laying the finish coat:

- deflection of the surface with a step between the lags of more than 0.5 m or with a subfloor thickness of less than 20 mm;

- backlog of tiles from the base;

- a creak, from which a layer of ceramics will not relieve.

We will analyze the process of preparing the base and laying the tiles in stages.

Subfloor preparation for tiling

Before working with tiles, the condition of the surface is assessed.

- Remove decorative coatings in the form of linoleum, laminate, etc.

- The old waterproofing is replaced. The protective layer must be of high quality.

- Particular attention is paid to the inspection of the subfloor, which is made of cheap wood.

- Logs are made of high quality wood treated with antiseptic agents. You can not change them, but you need to check.

Tiles are not placed on a dilapidated floor, since the creak will not be eliminated, and the tiled floor will always be at risk.

The procedure for preparing a wooden base:

- A complete dismantling is carried out with the removal of coatings, finishing and subfloor. Disassembly is time consuming, but must be done for good results.

- The base is leveled.

- The dismantled floors are treated with a deep penetration antiseptic and flame retardant. Layers are applied several times with complete drying. If the ceiling is concrete, it is necessary to treat the surface with a primer and putty the cracks.

- The sheet piles are dismantled and replaced if wear is found.

The distance between the lags should not exceed 0.5 m. The tree may not withstand the load and the floor will sag. If this distance is greater, it is necessary to add logs, the optimal step is 0.4 m.

- In the presence of distortions, the structure is leveled with a screed or by using linings for logs.

Waterproofing should be laid under the logs: roofing material, polyethylene or special films that do not allow moisture to pass through and prevent the formation of condensate on the surface.

- The space between the base and the lags is filled with fine expanded clay. It serves as a heat and sound insulator, and also absorbs excess moisture. A gap of 5 cm is left on top for ventilation. It is necessary to ensure the release of air from the underground space.

- The basis for the tile is a board or thick waterproof plywood. Lacquer or paint is removed from old surfaces. A gap of 3-5 mm is left between the boards to compensate for deformations from moisture.The floor is leveled with a grinder, the cracks are puttied.

Creating an insulating layer

The rigidity of the screed or tile adhesive is much higher than that of wood used as a base. Therefore, between the tile and the floor there is a layer that compensates for the movement of wood, and also forms a waterproofing layer.

When using a special multifunctional film, the shock-absorbing layer should be placed with the hard side against the tiles, and the elastic side against the boards. For them to breathe, the material must allow steam and air to pass through, but block the penetration of moisture.

Waterproofing can be rolled or liquid.

- Hard material is rolled out on the floor and secured with tape.

- Drying oil or latex impregnation is applied to a wooden surface and a paint grid is immediately laid.

A damper against the movement of wood can be an elastic substrate made of glue, on which the tile is attached.

Intermediate layer between tiles and wood: options

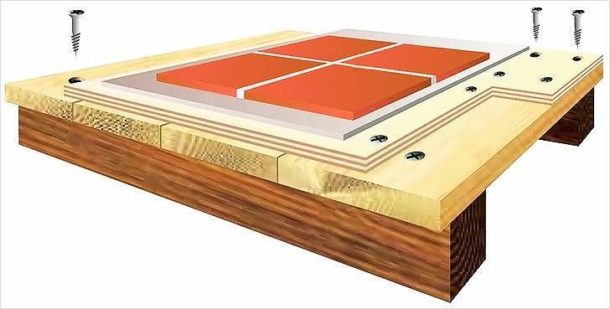

It is not recommended to lay tiles directly on a wooden floor. The floor covering may warp and crack. Under the ceramic tiles there must be a rigid base, which is used as one of the following materials:

- plywood, OSB;

- self-leveling compound;

- gypsum fiber.

Preparing plywood and edged boards

When laying tiles on wood without additional stabilization of the base, a special adhesive with elastic properties will act as a layer that will compensate for fluctuations in the parameters of wood, which remain after hardening. Compositions of Lacrysil, Liokol, Kreps, Ceresit are suitable. Before applying the adhesive, grinding and sealing the seams with putty will be required.

Laying plywood or OSB boards on boards will increase the reliability of the base, although it is recommended to use the same epoxy-polyurethane composition as glue.

self-leveling floor

For a tree, dry self-levelling mixtures compatible with it are selected. They do not contain casein, a substance that destroys the structure of the tree, and there are fibrous additives to improve adhesion.

- The perimeter is pre-pasted with a damper tape to the height of the fill and tiles.

- The prepared mixture is applied to the thoroughly cleaned floor. The layer thickness is 2.5–5 mm.

- While the composition is liquid, air bubbles are removed from it using spiked rollers.

Tiles on such a base are laid in the same way as on a regular screed.

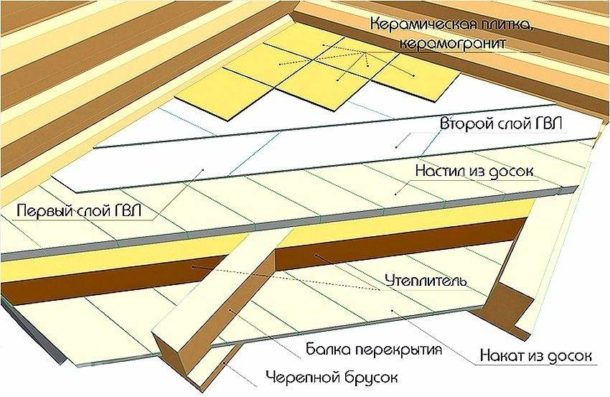

Dry screed (GVL)

First, gypsum fiber is laid on the boards, and tiles are mounted on it. There are no wet processes near the tree at all, which prevents it from getting wet. The ideal option is "Knauf-superpol" from GVL.

- GVL slabs are laid on a flat subfloor with offset adjacent strips in a checkerboard pattern.

- They are connected to each other using locks with glue or sealant applied to the protruding parts.

- After laying each block, gypsum fiber sheets are attached to the floor with self-tapping screws.

- Before fixing the tiles, a primer is applied to the GVL surface, which must be compatible with the composition of the adhesive.

The procedure for installing tiles on a wooden surface

The sequence of actions will be as follows:

- From the middle of the walls, perpendicular lines are drawn, and the center of the room is located.

- The floor is laid out with tiles using crosses and a building level. The evenness of each element is checked. Laying starts from the side opposite the door.

The direct layout scheme makes it possible to save on trimming, and the diagonal one - to correct the curvature of the floor from opposite walls diverging in a trapezoid.

- First of all, all solid tiles are laid out. After the glue has hardened, when it is already possible to walk on the floor, the tile is cut and mounted at the junction.

Conclusion

Floor tiles are the perfect solution for your bathroom. It can even be used on wooden floors if the substrate surface is properly prepared. Here it is important to make it durable, even and with reliable protection against moisture. All the details of the process are in the video below.