Demand for the installation of plastic windows, which were recently at the peak of popularity, began to subside. Wooden structures became their competitors. However, both types of products have their strengths and weaknesses. We offer to conduct a detailed comparative analysis and find out which windows are better to install: plastic or wooden ones.

Ability to keep warm

The first thing we look at when choosing new windows is how well they are able to keep the temperature in the room.

The lower the thermal conductivity of a material, the less heat it gives off to the environment.

The thermal conductivity coefficient of polyvinyl chloride (PVC), which is used for the manufacture of plastic windows, ranges from 0.15–0.2 W / m K. The thermal conductivity of a wooden structure depends on the type of wood: for pine and oak it is 0.15 W / m K, for larch - 0.13 W / m K. Everyday practice has become the manufacture of frames of wooden eurowindows from glued beams, in which this coefficient is 0.1 W / m K.

Conclusion: wooden window structures retain heat in the room more efficiently than plastic ones.

Which windows breathe better

The gaps in previous generations of windows brought a lot of inconvenience, but there were no problems with the flow of fresh air. The tightness of modern structures with double-glazed windows seriously impedes air exchange, and, as a result, humidity increases in the premises, and the oxygen content decreases.

Where plastic windows are installed, regular ventilation is necessary, since PVC does not allow air to pass through. But it is not necessary to hope that the current wooden structures will save the situation. The amount of oxygen that overcomes the thickness of wood is negligible compared to human needs. In addition, the wooden frames of eurowindows are impregnated with a variety of protective compounds, varnished, which becomes another obstacle for the air.

Conclusion: in terms of air permeability, the properties of plastic and modern wooden euro-windows are the same, their use requires frequent ventilation.

Note: the output will be the installation of ventilation valves that provide fresh air with the doors closed. There are several options for such devices. The air valve can even be mounted in place of the window handle, where it will cope with both functions.

Environmental Safety

Polyvinyl chloride, which serves as a material for window profiles, under normal conditions is a chemically inert substance. What can not always be said about stabilizers, modifiers, pigments, and other additives in PVC profiles. But work in this direction is ongoing. For example, the lead salts previously used as a stabilizer have given way to harmless zinc and calcium compounds.

Speaking about the environmental friendliness of wooden windows, do not forget that the wood is treated with numerous impregnations: from insects and mold, unwanted exposure to moisture and ultraviolet rays. All such compounds are of chemical origin.

Conclusion: today, both types of windows, produced with strict adherence to technology, the content of harmful substances does not exceed the permissible limits.

Aesthetic requirements

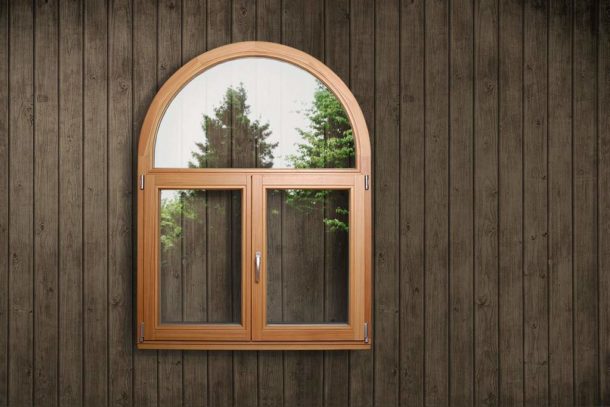

Windows should be attractive, harmoniously fit into the interior and facade of the building. Constructions of any configuration are made of PVC, including arched ones. The only limitation is the size: too small, as well as very large sashes are difficult to manufacture. Plastic is given any color, laminated to the selected texture, the desired type of wood. Of course, the imitation will be visible to the naked eye, so plastic is an unacceptable option for thin aesthetes.

There are no complaints about the appearance of wooden structures. Natural material looks good in any case: wooden windows are installed in country cottages, they are organic in the architecture of old city buildings, they have found a place in the interior of modern apartments.

On a note. The color is usually determined by the type of wood. But in some cases, a special primer is used to create the desired shade. With its help, an inexpensive pine product is visually transformed into oak, ash and even rosewood. Another option is to cover the frame with decorative fine wood veneer.

Wooden windows are also given the shape of an arch, but here the variety is limited by the value of the bending radius.

Conclusion: in terms of aesthetics, plastic window structures do not compete with wooden ones, although they provide designers with an endless field for creativity. But in any performance, they cannot achieve the natural sophistication of a natural material.

Reliability

The PVC frame expands even slightly under the influence of elevated temperature. As a result, a poorly reinforced window profile can be deformed. It is highly likely that a frame made from low-grade raw materials will turn yellow over time.

Today's wooden windows, unlike previous generations, do not stick out, do not dry out, but they are not without flaws either. For example, frames made of light wood under the influence of ultraviolet light gradually darken. Rain, hail, sun, frost eventually leave ruthless marks on them. Even with all kinds of impregnations, they cannot withstand fire.

On a note: window structures made of wood and aluminum have shown themselves well, while simultaneously possessing the advantages of wood and the ability of metal to resist the adverse effects of the environment.

Conclusion: in terms of strength and wear resistance, wooden frames are somewhat inferior to plastic ones. PVC windows are impact resistant, do not need to be painted or varnished, and are resistant to moisture. But all this applies to profiles from high-quality raw materials, manufactured in compliance with the technologies.

Features of care

Today's wooden windows don't require as much maintenance as they used to, but from time to time the frame coating needs to be updated. With plastic, things are simpler: it does not require special procedures, everything is limited to removing dust with a damp cloth.

Conclusion: plastic windows are easier to care for and maintain than wooden ones.

Service life

According to various reviews, the time of use of plastic windows ranges from 20–30 to 45–50 years and depends on the properties of the thermoplastic polymer (compound) used in the production of profiles and operating conditions. Some German companies have specially developed technologies for the manufacture of PVC profiles in relation to the Russian climate, which is characterized by frequent and extreme temperature changes.

The lifespan of wooden windows exceeds the life of plastic ones. But this is possible only in the case of high-quality performance, with special compounds that enhance resistance to external influences. Durability also depends on the type of wood. Larch frames will last 50, pine - 55-60, oak - at least 90 years.

Conclusion: wooden windows are more durable than plastic ones, while the service life of both types of structures is calculated in decades.

Issue price

The money for installing new windows will have to be spent tangible. Savings on the quality of fittings, the thickness of the double-glazed window or profile eventually it will turn into cold in the apartment, icing or condensation on the windows. But you can save on the frame material: plastic windows are cheaper than wooden ones.

Conclusion: in the long term, due to the longer service life of wooden structures, the price partially pays off, but the cost of their use is still 30% higher.

Which windows are better, PVC or wooden: final comparison

Each type of window has its strengths.

PVC windows:

- have an affordable price;

- practical;

- organically fit into modern styles of interior design;

- not afraid of moisture;

- unpretentious in care;

- quickly produced.

For plastic profiles, unlike wood, certification is required, which gives a guarantee of quality.

Wooden windows:

- retain heat better;

- serve longer;

- beautiful, which makes them a desirable component in the design of the most sophisticated interiors.

In addition to advantages, both types have disadvantages.

Cons of plastic windows:

- Polyvinyl chloride, when heated, even by the sun, emits harmful substances, although in minimal quantities.

- Deformations, chips of plastic cannot be repaired.

Cons of wooden window structures:

- No matter how technologically advanced the protective coating is, at least once every 5 years even modern Euro-windows will have to be re-coated with yacht varnish.

- High combustibility of wood.

- Long production time.

- Great cost.

When the decisive factor is the price, it remains to choose plastic windows. How to do it right is written here. If cost is of secondary importance, then, as they say, there is freedom of choice: one can proceed from personal ideas about beauty and comfort. But you need to keep in mind that there are much more positive reviews about wooden windows.