For apartment buildings, one of the most pressing problems is good audibility between neighboring apartments. The peace of the residents is often disturbed by too noisy or active neighbors, and the owners of the apartment must always control their behavior in order to avoid scandals and complaints. Sound travels best through floors. Soundproofing the ceiling in an apartment under a stretch ceiling will help solve this problem.

The device itself of this finishing element provides for a certain level of noise cancellation. For example, the disadvantage of a suspended structure is that the sound is well conducted by the frame elements. The soft fabric of the stretch ceiling and the air gap between it and the floor slab can muffle the sound from the neighbors by about 5 dB. If you use a special perforated film, which appeared not so long ago in the arsenal of installers of such coatings, then the effect will be more noticeable. True, the price of finishing also increases significantly. You can save money if you additionally place available noise-absorbing elements under the film. Moreover, such a modernization of the ceiling in an apartment under a stretch ceiling with your own hands can be done without any problems.

Types of materials used for sound insulation

Soundproofing under a stretch ceiling can be made using various materials. Before stretching the stretch ceiling, you need to complete their installation. Two types of materials can be distinguished:

- They reflect a sound wave, as a rule, have a solid mass and a dense surface - soundproof materials.

- Slow down the speed of the sound wave and quench it due to the large number of pores - sound-absorbing materials. Here the rule applies: the thicker the coating layer, the better the sound-absorbing properties.

The best result is a combination of two types of materials. In this case, a kind of sandwich is obtained: a layer with sound-absorbing properties is covered on both sides with sound-reflecting elements.

Sound insulation of the ceiling under the stretch ceiling can be carried out using the following materials.

MaxForte EcoAcoustic

MaxForte EcoAcoustic - soft, fibrous soundproofing material, consisting of polyester fiber, its advantage is that this material is a 100% environmentally friendly product, moreover, it is hypoallergenic, due to which it is suitable for use in children's rooms, kindergartens, schools, etc. .

This material does not have a binder, it is made by Thermo-bonding. Therefore, it is 100% polyester fiber, without any additives.

Mounting method:

- Before starting work on soundproofing the ceiling, carefully inspect the ceiling for cracks. Cracks must be expanded and sealed with a cement-sand mortar (CPR). Look at the places where the floor slabs adjoin the walls. If gaps are found, they must also be eliminated.

- On the stove MaxForte-EcoAcoustic apply 3-4 strips of foam MaxForte-SoundFLEX and press it to the ceiling for a few minutes. Thus, the entire surface of the ceiling is covered.

- We install a fabric stretch ceiling.

The advantage of mounting on foam is not only simplicity, but also the absence of unnecessary holes in the ceiling, while there is no debris from drilling concrete. Fast, simple and efficient.

Also, this material is not afraid of moisture, and when neighbors are flooded from above, the material will not lose its properties and shapes.

In addition to protecting against airborne noise and reducing echo in the apartment, EcoAcoustic removes the drum effect from the stretch ceiling, which appears due to the fact that the stretched panel reflects sound waves coming from the floor slab and returns them back.

Maxforte SoundPRO

Maxforte SoundPRO is a composite sound insulation based on aluminosilicate fiber, with a minimum thickness of 12mm, the material provides maximum protection against airborne and impact noise and is indispensable in small apartments, where every centimeter counts.

The material is completely non-combustible, resistant to moisture and does not rot.

Refers to the sound absorption class "A", the maximum of five possible.

Mounting method:

- Carefully inspect the ceiling for cracks between the floor slabs. The cracks must be embroidered and sealed with gypsum plaster or cement-sand mortar (CPR). Look at the places where the floor slabs adjoin the walls. If gaps are found, they must also be eliminated.

- Fasten the MaxForte SoundPRO rolls to the ceiling over the entire area using dowel-mushrooms 70 mm long (2-3 mushrooms per m2). The rolls must be overlapped by 4-5 cm. The joints between the MaxForte SoundPRO rolls are sealed with reinforced mounting tape.

- We install a fabric stretch ceiling.

Efficiency is achieved due to increased sound absorption in the room: the noise passed from the neighbors decays faster, since the sound insulation layer on the ceiling prevents the sound wave from making multiple reflections (as a result of which it would be amplified), on the contrary, leading to a rapid attenuation of the latter.

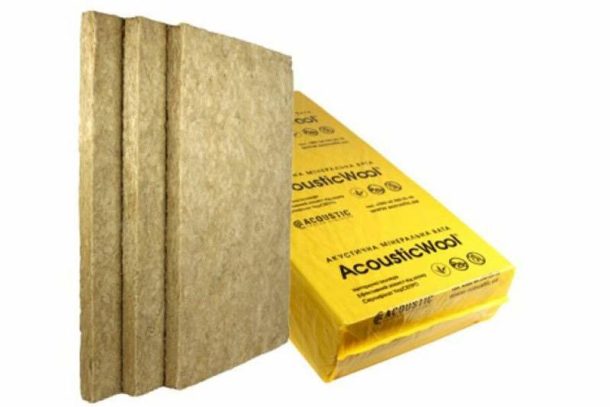

Mineral wool

One of the most popular content. In addition to good sound insulation, it allows you to solve the problem of warming the apartment. Can be glued to the ceiling, but it is better to use a frame structure. The size of its cells should be chosen so that the insulation boards are inserted with some effort.

It is recommended to paste over the structural elements of the frame in the place from the contact with the ceiling with a special damper tape. It will not allow sound to propagate through the profiles or bars of the crate.

Mineral wool loses its properties when moisture enters, so it is necessary to ensure good waterproofing of the ceiling from above, and a vapor barrier membrane must be present at the bottom. A solid ceiling layer of mineral wool will force you to reduce the height of the room by at least 10 cm.

If in the first place the task is to provide sound insulation, and not insulation, then you should choose mineral wool with the appropriate properties. You can focus on the name: "Shumanet", "Shumostop".

Cork, wood panels

acoustic panels and cork slabs are an environmentally friendly and safe material. But it hardly makes sense to use them in combination with a stretch ceiling: the beautiful appearance of the products will be hidden by the canvas. In this case, they are unlikely to justify their considerable cost.

Acoustic membranes

The most modern type of materials. Favorably distinguished by excellent soundproofing properties, small thickness, environmental friendliness and fire resistance.

There are only two negative points: these materials have a solid weight, so it is preferable to mount them on a rigid frame, and a rather high cost.

Acoustic membranes can be mounted on the ceiling with a special adhesive, there are also self-adhesive varieties of this coating. They can be used both in combination with other materials, and as the only way to protect against noise. It all depends on the characteristics of the room and the tasks to be solved.

Preparatory work

The quality and durability of the soundproofing of the ceiling under the stretch fabric will directly depend on the preliminary preparation of the base surface.

- The old coating should be removed from the ceiling.

- Thoroughly seal all cracks and cracks special sealants.

- Be sure to apply a primer with antiseptic properties: after installing the stretch ceiling, it will be problematic to detect and remove mold or fungus that has appeared in time. The primer will also improve adhesion when bonding soundproofing materials.

Subtleties of sound insulation under a stretch ceiling

The variety of soundproofing materials gives rise to many combinations and designs of the soundproofing layer. Each design has its own fastening algorithm. But for all, the following general points can be distinguished:

- Soundproofing must be securely fastened to avoid any of its elements falling onto the stretch ceiling.

- Before installation, the materials must be allowed to mature for at least a day in the room where they will be used.

- The noise-absorbing coating should form a single plane that does not protrude beyond the tension level of the canvas.

- All joints between elements must be carefully sealed. When laying in two layers, they must be shifted relative to each other so that the joints do not coincide.

When installing acoustic membranes, such as, for example, "Texound", adjacent layers are superimposed on each other. Then they are carefully cut with a knife, and the resulting even joint is sealed with a burner or a building hair dryer.

- Hygroscopic materials, such as mineral wool, must be reliably protected both from moisture ingress from the outside and from water vapor from inside the room. Therefore, it is necessary to have a waterproofing on the ceiling and a vapor barrier membrane between the material and the stretched canvas.

- When installing a frame structure, it is necessary to paste over its elements with a self-adhesive sound-absorbing tape.

- Before installing soundproofing, it is necessary to carry out all communications, remove the fastening elements of lighting fixtures. It is better to remove the wires in special corrugations.

It should be noted that luminaires built into the ceiling do not combine well with mineral wool insulators. There is a high probability that they will overheat and often fail.

Mounting methods

Sound insulation can be attached in three main ways:

- fit into the cells of the frame;

- stick to the surface of the ceiling;

- attached to special dowels in the form of fungi.

For reliability, it is recommended to combine these methods. So, if you glue slabs of material to the ceiling, then it would be useful to additionally fix them with fungi. Five pieces are enough: 4 are attached at the corners, and one in the middle of the plate.

When choosing an adhesive, it is imperative to take into account the recommendations of the material manufacturer: the wrong choice of adhesive composition can lead to the destruction of sound insulation.

The choice of soundproofing scheme and materials is best made, focusing on the reviews of acquaintances and friends. It is better to buy soundproofing from a trusted manufacturer, so as not to waste money and time in vain.

Cost of work

Soundproofing the ceiling under a stretch ceiling in Moscow and St. Petersburg will cost from 700 rubles. up to 3,000 rubles for 1 sq. m. The price depends on the materials used and the number of layers. For the minimum amount you will receive a single-layer soundproofing coating, for the maximum - a three-layer, most often including special acoustic mineral wool, closed-cell polypropylene and drywall.