Construction using aerated concrete and gas silicate blocks has a lot of advantages. This is the speed of erecting walls, significant savings in money, excellent thermal insulation characteristics of the material, reducing the total weight of the structure being erected. At the same time, there are a number of features that must be taken into account when working with aerated concrete and gas silicate: requirements for a foundation or base, mandatory reinforcement of walls from gas silicate blocks, the subtleties of their masonry, and protection from environmental influences.

Advantages of aerated concrete

The use of cellular concrete, as this material is also called, gives a lot of advantages during construction:

- Since gas silicate blocks are quite light, the whole structure will weigh much less than when using brick or ordinary concrete. This allows you to get by with a more modest foundation when building a house, and if we are talking about partitions in an apartment, do not exceed the permissible load on the floor slabs.

- At a price, this material will be cheaper than brick or cinder block. Savings can reach up to 30%.

- After laying the walls, it is not necessary to plaster due to the smooth surface of the blocks. Evenness of the surface is also facilitated by thin seams compared to walls made of other materials. If you use an adhesive solution, then their thickness should not exceed 3 mm.

- Due to the high air content, aerated concrete has excellent thermal insulation characteristics. This allows you to save on wall insulation.

- In terms of environmental friendliness and vapor permeability, gas silicate blocks are similar to such a building material as wood. But they are fire resistant, unlike the latter, so their use in an apartment is safer.

- Aerated concrete and gas silicate walls provide good sound insulation.

- Blocks are easy to process, no specialized tool is required.

Disadvantages of cellular concrete

The characterization of the material will not be complete without taking into account its shortcomings. Like any other building material, cellular concrete has its weak points:

- The porosity of the material reduces its strength. Aerated concrete is not used in the construction of multi-storey buildings; a mandatory procedure is to strengthen the gas silicate masonry with metal reinforcement at the level of window and door openings, as well as in the upper row of blocks along the entire perimeter of the walls being built.

- Cellular concrete extremely poorly tolerates bending or torsion deformations. Therefore, for the construction of walls, a reliable strip foundation is required. When using a columnar base, there are high chances that such a wall will soon crack due to the slightest ground movements.

- Aerated concrete and gas silicate walls absorb moisture from the environment well. Therefore, external wall decoration is required. In its process, it is necessary to create a barrier that prevents the ingress of moisture. Gas silicate blocks are not recommended for use in rooms with high humidity, such as a bathroom.

- The process of laying on the adhesive mortar is quite specific and requires certain skills and special tools. For such work, it is better to hire a specialist, which, in turn, leads to an increase in the cost of construction. The use of cement mortar makes the process similar to building walls from brick or cinder block, but in this case, due to thicker seams, peculiar cold bridges appear, and the thermal insulation characteristics of the partition being erected are significantly reduced.

Types of aerated concrete blocks

The strength of blocks made of aerated concrete and gas silicate is inversely proportional to their thermal insulation characteristics.The greater the porosity of the material, the better it retains heat, but at the same time it is able to withstand a significantly lower load.

The strength of gas silicate blocks is indicated by the letter "D" in the marking and shows their density:

- Blocks marked D1000–D1200 are the most durable. They are used to build load-bearing walls.

- Average indicators for strength and thermal insulation have blocks marked D400–D900.

- Aerated concrete marked D300-D400 is suitable for the construction of interior partitions, as it has good thermal insulation characteristics with low strength.

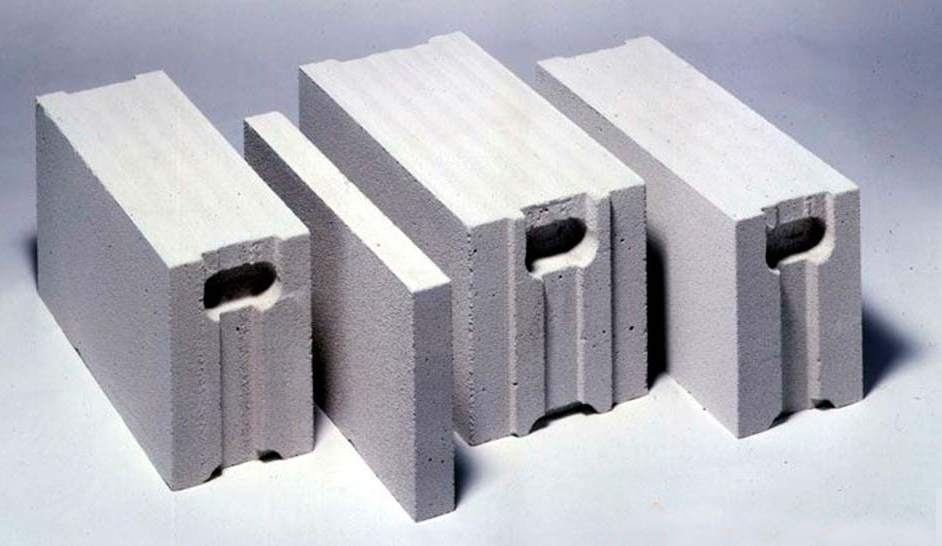

Blocks are divided into three main groups:

- Smooth.

- Narrower blocks for partitions.

- U-shaped. They are used when laying jumpers.

The height of all types of aerated concrete blocks is 200 mm, length - 600 mm. The exception is the U-shaped variety, which has a length of 500 mm. If necessary, an aerated concrete block can be easily sawn with an ordinary hacksaw, but there is also a special tool for processing this material.

Aerated concrete wall masonry

Aerated concrete walls can be built one or two blocks thick. When using the second option, you can lay the blocks on the cement mortar, since the cold bridges will be blocked by the second row.

Single-row masonry when erecting partitions is best done using a special adhesive solution prepared from a dry mix according to the manufacturer's recommendations. The lowest row is laid on a waterproofing gasket made of roofing material, bituminous mastic or glass isol. The seam between the foundation or floor slab and the first row must be at least 20 mm thick. The finished solution is applied using a tool such as a notched trowel. It is convenient to use special carriages whose dimensions match the thickness of the building material.

Blocks are placed on the adhesive solution from above, while horizontal movements should be avoided. This can lead to uneven joint thickness or incomplete filling of the joint with adhesive. The seam should be no more than 3 mm thick, otherwise the heat and sound insulation characteristics of the aerated concrete wall may deteriorate significantly.

Vertical seams can be omitted if they have profiles and are inserted into each other according to the "groove-protrusion" system. As a rule, well-known manufacturers use this principle, which entails an increase in the cost of work. When laying from cheaper material, vertical seams must be filled with glue. It may even be necessary to grind the surfaces of the blocks to obtain thin seams.

When laying, it is imperative to dress the rows, while the blocks must be displaced by at least 100 mm.

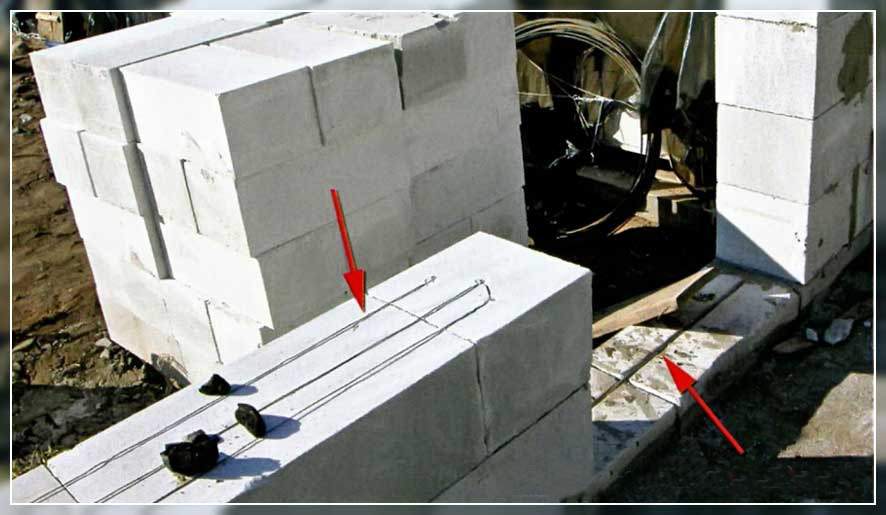

Reinforcement of gas silicate masonry

It is advisable to reinforce the wall with reinforcement every four rows of blocks. Be sure to reinforce the topmost row at the level of floors and rows under window openings. Reinforcement with a diameter of at least 8 mm, pre-treated with an anti-corrosion compound, is placed in specially cut grooves. In each block, two such grooves are made at the same distance from the edge. After laying the reinforcement, they are filled with mortar so that it does not protrude beyond the surface of the block.

To form door and window openings, U-shaped blocks are used, inside which support elements, for example, reinforced concrete beams, are laid. So the entire surface of the wall will look uniform.

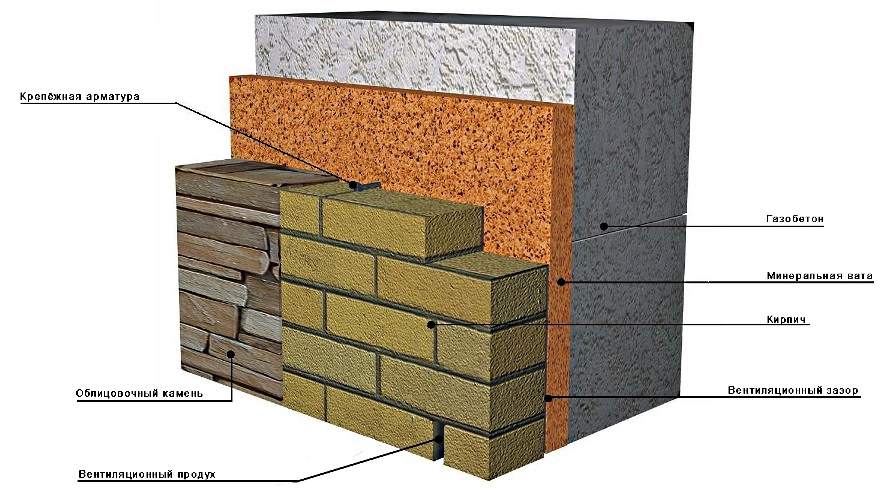

Interior and exterior wall decoration

In order for a wall of gas silicate blocks to retain its characteristics for a long time, it is necessary to protect it from the effects of the external environment, especially from moisture. Outside, aerated concrete walls are plastered, bricked or covered with siding.In harsh climates, an additional layer of insulation is placed between the finish and the aerated concrete wall. It is important to follow all manufacturer's recommendations.

From the inside, more often used for decoration drywall, or simply plaster for painting or wallpapering.