Properly selected and correctly applied foam for windows is an important component of their quality installation. It is difficult to imagine the installation of modern PVC window structures without this easy-to-use and reliable material. A novice master will have to understand the differences and features of the foam in order to choose a composition from a wide range offered by stores.

Properties and scope of the material

Polyurethane foam is a liquid polyurethane solution pumped into a cylinder under pressure. When exposed to air, it quickly hardens and at the same time significantly increases in volume.

There are 2 types of foam expansion:

- Primary (when the composition leaves the cylinder). Provides convenience of work: recesses of arbitrary shape are filled with a solution without effort.

- Secondary. Refers to the disadvantages: an increase in the volume of sealant during the final polymerization can deform the elements of the window. Therefore, it must be taken into account when carrying out work.

Completely hardened material acquires unique useful qualities:

- Low thermal conductivity is achieved due to air bubbles located in the thickness of the solidified material. If it were not for the price, the foam could well be considered as an alternative to the usual heaters.

- The presence of air voids increases the sound insulation of the entire window structure: vibrations transmitted to the window are damped with foam. Thus, it is an addition to the installed rubber seals, enhancing the soundproofing.

- Cured foam is electrically impervious, water-repellent, and will not rot or mold.

- High adhesion values allow the foam to be used as a fixing material: it securely fixes window or door frames, as well as other elements, in place.

- Depending on the brand, the composition does not support combustion or is completely immune to fire.

Due to its special properties, the foam is ideal for outdoor and indoor use. But, like any material, it has disadvantages:

- After solidification, the excess composition is cut off. And if the cut surface is not properly treated, then water will enter the open pores. Over time, this causes the destruction of the material.

- The cured composition does not withstand exposure to ultraviolet radiation, so it must be protected from direct sunlight.

- You have to follow the rules for storing cylinders: strictly in an upright position at a temperature range from +5 ˚С to +25 ˚С.

The high adhesion of the foam allows it to adhere reliably to surfaces made of different materials. Therefore, you should work with the composition very carefully: if it gets on your hands or other parts of the body, you can wipe it off only with the top layer of the skin, which will take at least a few days. Be sure to wear gloves when pouring. You should also securely cover all surfaces on which the solution can drip.

If the foam does get on the floor, furniture or other surfaces, it can be removed in several ways, which are written about. here.

Professional or household?

According to the design features of the cylinders and other indicators, household and professional foam are distinguished.

The compositions with which the masters work are used only with a special pistol. A special valve is provided for its fastening in the cylinder.

This design provides the following benefits:

- The ergonomics of the gun allows the master to fill the cracks with one hand. The second remains free, due to which it is possible to work alone at certain stages.

- The gun makes it possible to precisely dose the volume of the released solution. This reduces consumption by reducing unnecessary losses.

- A thin long nozzle will easily deliver the solution into hard-to-reach cracks and holes.

- The balloon can be used in any position.

- The reusable valve ensures the safety of the solution between repairs.

When choosing professional cylinders, you do not need to solve the frequently asked question: where to use the rest of the solution with benefit?

- Professional formulations have better performance characteristics than household ones. For example, they have a lower secondary expansion coefficient, which makes them more convenient to use.

Techniques for pouring foam using a professional gun are shown in the following video.

ibuilder.decorexpro.com/en/ strongly recommends: use only professional polyurethane foam for installing plastic windows. The secondary expansion will not create excessive load on the structure and will not displace the frame elements. The density of professional staff is maximum, and this will ensure the best quality of fastening, insulation and sealing of the seam.

Choose a pistol according to budget, ergonomics and service life. For a single procedure, the cheapest one with plastic parts is also suitable, and for professional use, give preference to collapsible high-quality models.

Household foam has less outstanding performance characteristics: worse adhesion, higher coefficient of secondary expansion, lower yield of material from the cylinder. It is sold in containers equipped with a plastic tube for supplying the solution. It is screwed onto the valve before blowing. It is recommended to use the entire bottle at once.

Working with household foam is less convenient: both hands are used, and the can must be placed upside down. This will ensure a more complete release of the solution. Use it with the utmost care, in the least important places. Fill the joint no more than 50% of the depth!

Soundproof foam

If the windows themselves do not transmit noise, then the mounting foam on which they are mounted is an excellent conductor of noise, as it is light, solid, and has a closed cell structure, which contributes to the unhindered passage of the sound wave.

Therefore, when installing windows or doors, it is necessary to use a special soundproofing foam, which, unlike conventional mounting foam, has properties that are important for soundproofing:

- high density, to reflect the sound wave;

- elasticity, to reduce vibration transmission;

- high-quality filling of cavities and cracks in order to prevent sound from “leaking” into the room.

These characteristics are MAXFORTE SoundFLEX foam.

Compared to conventional construction foams, the use of MAXFORTE SoundFLEX foam adds more than 10 dB to sound insulation, which is equivalent to a 2-3 times reduction in noise.

The difference between ordinary mounting foam and soundproofing can be seen in the video:

If a piece of mounting foam is squeezed in your hand, then it will simply collapse, unlike specialized soundproof foam. She will take back her shape like a sponge. It does not harden, and thus does not become a sound bridge.

Winter or summer?

Foam is divided according to the seasonality of its use. She happens:

- Summer, suitable for operation at temperatures above +5 ˚С.

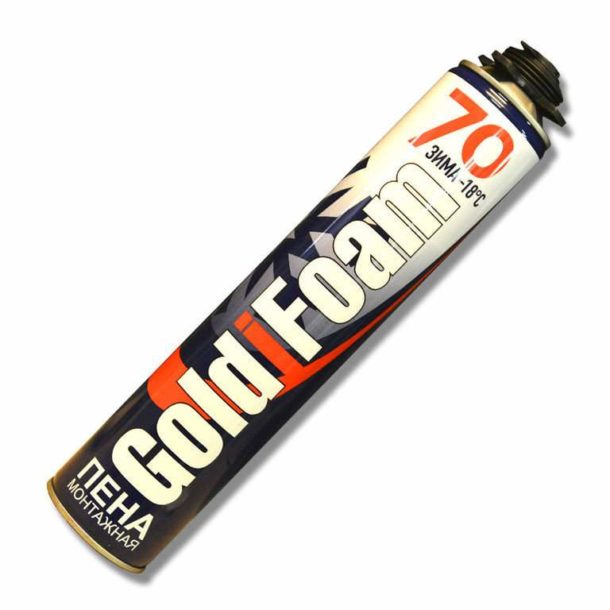

- Winter, allowing to seal gaps at temperatures down to -18˚ C.

- All season. Found and used less often. Professionals advise using it during transitional periods in autumn and winter, or getting by with the first two varieties.

Flammability of foam

Also, the compositions differ in flammability parameters:

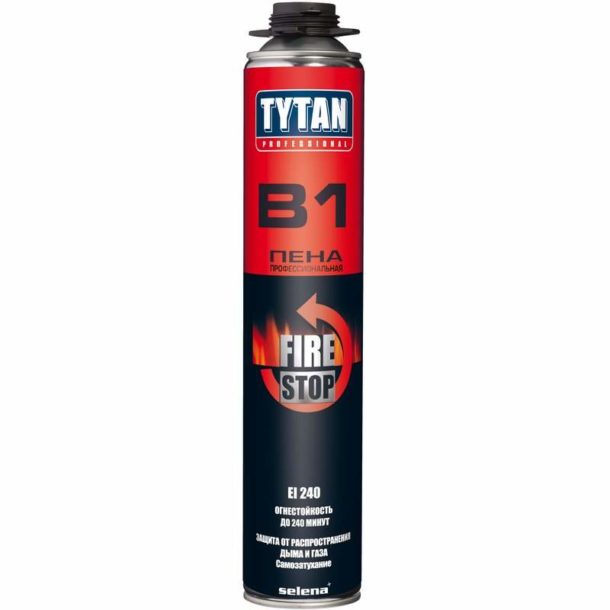

- B1 - the highest class of fire safety, does not ignite even when in contact with an open flame.

- B2 - does not burn on its own, without an additional source of heating. Such compositions are called self-extinguishing.

- B3 - the lowest flammability class. This material is not recommended for use, especially in residential areas.

Rules for choosing foam for mounting PVC windows

For quality window installation the composition that is most suitable for a particular case is selected. What to look for when choosing?

- The temperature at which the gaps will be sealed. According to it, winter, summer or all-weather foam is chosen.

- On the coefficient of secondary expansion. The lower the value, the better. It is recommended not to use compositions with an indicator of more than 15-20%. Professional foam easily fits into such a framework, but with a household one, the choice should be made carefully.

- For the expiration date. No one can predict how the behavior of the solution will change after the storage time has elapsed. It's better not to risk it.

- To the fullness of the balloon. Underfilling is a common occurrence. It is easy to check: for this, the can is weighed. A full container of 750 ml weighs about 900 gr.

Many problems are caused by the calculation of the required number of cylinders. It is believed that for one linear meter when installing windows in a high-rise panel, 300 ml of foam will be required, for brick the volume of material is 400-450 ml, for Stalin-built houses - 500 ml. But on the cylinder, the manufacturer indicates the yield of the sealant under ideal conditions; in reality, this cannot be achieved. Therefore, an extra tank in reserve will not hurt.

Rating of brands of polyurethane foam

Professionals prefer proven brands. The following assembly compositions have proven themselves on the Russian market:

- "Moment-Montazh" - foam from a domestic manufacturer. More often all-weather, presented in professional and household containers. Dense, homogeneous with good adhesion, it can be painted. The material is characterized by secondary expansion, so you need to work with it carefully, fixing the window elements with spacers.

- Soudal - compositions with a finely porous structure without an unpleasant odor. Three modifications - summer, winter, fire-resistant. Shrinkage and secondary swelling are minimal, the material is characterized by high adhesion, uniform hardening. For delicate installation work, SOUDAFOAM GUN LOW EXPANSION with minimal re-expansion is suitable.

- Makroflex is a sealant with good adhesion and uniform structure. With the primary expansion, it increases by 2 times, the secondary one is insignificant. It happens summer and earth. Cutting excess is allowed after 3-4 hours.

- Penosil is a non-shrinking compound with low secondary expansion and a dense structure, odorless. Gives a record high output.

- Titan. Does not emit toxic fumes during operation, has a slight non-caustic odor. The extension of the second type is practically absent. It is presented by household and professional, winter and fire-resistant options. Dries quickly, excess can be cut off after an hour.

Conclusion: which foam is better for plastic windows

We have sorted out all the properties and parameters of the choice of foam and now we will briefly and clearly answer the main question. So, for the installation of PVC windows, a professional composition of a proven brand with minimal secondary expansion, corresponding to the temperature regime, is best suited.