Low batteries

Radiators with a small center distance have the following advantages:

- they can be placed under a low window sill;

- they have the maximum heat transfer per unit area.

Cast iron radiators .

The dimensions of the sections of heating radiators MS-140M-300-0.9 are:

- length 93 mm;

- depth - 140 millimeters;

- height - 388 millimeters.

Due to the smaller dimensions, the heat transfer of cast-iron heating radiators is reduced - it is equal to 106 watts from one section at an operating pressure of 9 kgf / cm². Among foreign analogues, there are cast-iron products with a center distance along the connections equal to 200 and 350 millimeters; the power of a section of a cast-iron radiator of this type is much higher.

Aluminum radiators. For low batteries made of aluminum, both domestic and imported, the spread in the value of the center distances is quite large. You can meet the sizes of radiators 150, 300 and even 450 millimeters. Since the possible length of the section starts from 40 millimeters, the device looks compact and unusual. Low aluminum heating radiators have height dimensions ranging from 200 millimeters. The depth of many models compensates for the lack of the other two parameters and is 180 millimeters.

As for the thermal power, it varies from a minimum of 50 watts per section to a maximum of 160 watts. The determining factor is the finning area of one section. At the same time, a change in dimensions does not significantly affect the working pressure - low aluminum devices are designed for 16 atmospheres, and when tested for 24 atmospheres. Bimetal radiators. All sizes of radiators that they have are also typical for aluminum heaters. Thermal power is within the same limits. On sale you can find aluminum low radiators, in which the heat transfer is 80 and 140 watts per section. Working pressure is 25-35 atmospheres.

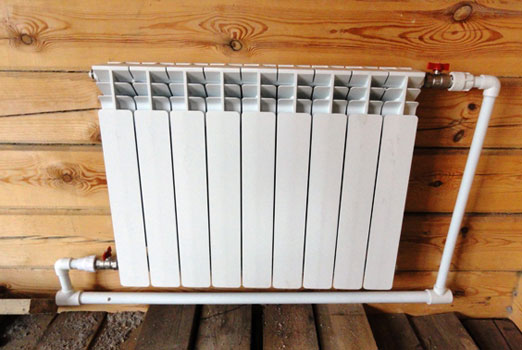

Bimetallic low radiators, such as in the photo, have two nuances:

- among heaters, there are batteries not with solid steel cores, but with steel tubes placed between aluminum collectors. Their operating pressure, specified by the manufacturers, is usually 12 or 16 atmospheres;

- they often do not have vertically arranged channels and, in the case of lateral connection, can be heated from collectors due to the thermal conductivity of aluminum. The circulation of the coolant is provided by the last section, since it is flowing.

What should be the dimensions

In order for the heating radiator to give off maximum heat (in this case, we are not talking about its thermal power, but about the efficiency of its work), the dimensions should be as follows:

- The length should be more than 70-75% of the width of the window opening.

- The height should be such that between the floor and the battery was 8-12 cm, and at the same time between the window sill and it was 6-12 cm.

If the recommendations are not followed, then the operation of the aluminum radiator will be accompanied by heat loss. Therefore, even if he can issue the necessary for a room with an area of 20 square meters. m 200 watts of heat, then due to incorrect dimensions in the room there will be insufficient heat. After all, part of it can be lost under the windowsill or go to floor heating.

When the length is less than 70% of the width of the window opening, the battery will not be able to create a thermal curtain that can block the movement of cold air entering through the window. The consequence of this situation will be the appearance of cold and warm zones in the room. Also, the windows will be constantly covered with steam.And even the power of the heating radiator, which is greater than the need, cannot become a lifesaver.

Therefore, if the window has a width of 2 m, then the length of the battery must be at least 1.4 m

Of course, in order to select a device with such a length, it will be necessary to take into account sections of different heights and their heat transfer. The calculation can take a long time, but it's worth it

Positive characteristics of cast iron radiators

Any coolant is suitable for them

While technical hot water gets from the boiler room to the battery, its quality does not get better. However, it was not ideal from the very beginning, and then, following the pipelines, it takes with it a fair amount of impurities. So, a certain liquid is already entering our apartments, which is quite chemically aggressive. This most aggressive water (more specifically, it has a lot of alkalis) also carries with it a bunch of small grains of sand that act like abrasives.

And it begins to actively corrode steel batteries, for example. And grains of sand, like emery, rub their thin walls. And cast iron does not care about all this - after all, it is chemically passive, and the walls of radiators made of this metal are very thick. And in the summer, when water is drained from the system, the cast-iron battery will not rust from the inside.

Max working pressure

The working pressure of cast-iron radiators is from 9 atmospheres or more, depending on the manufacturer and model. They tolerate water hammer well and are therefore often used in central heating systems.

Durability

If you wash cast iron batteries from time to time, and also replace the intersection gaskets as necessary, they will respond to such care gratefully. They will be able to work for fifty years, regularly heating your rooms. By the way, retro-batteries made of cast iron are still alive in St. Petersburg, which were cast at the first factories. More than a hundred years have passed, after all.

low price

If we compare the price of cast iron batteries with the cost of bimetallic products that have become fashionable recently, then cast iron will be much more profitable for the budget. And if you have to buy radiators not for one room, but for several, then the savings will be very, very impressive.

Design features

Aluminum radiators

Aluminum radiators look stylish and neat. The sections included in the battery are interconnected by special nipples. Gaskets installed between the sections provide the necessary tightness. On the inside of the heater there is a system of aluminum fins, which allows to achieve a large heat transfer area.

Aluminum radiators can be made in two ways, one of which is extrusion. This method allows you to get light and very cheap heating devices, which, unfortunately, are not of high quality. Cast aluminum radiators. will cost a little more, while they are able to provide a longer service life, in comparison with their cheap extrusion counterparts.

Bimetal radiators

The name of these heaters indicates that bimetallic radiators are made using two different metals. The ribbed battery case is made of aluminum alloy, which can provide high heat dissipation. Inside the bimetallic battery there is a tubular core along which the coolant moves. The core tubes can be made of steel or copper. The inner diameter of the channels through which hot water flows for bimetallic heating devices is smaller than for aluminum radiators, so the likelihood of clogging of the channels is higher.

How to choose and install an aluminum radiator

- if you still decide to install an aluminum battery in a house with central heating, then it is better to stop at reinforced products designed for a pressure of at least 16 atmospheres;

- for private houses, radiators of a standard (European) type are quite suitable.

There are also a few other things to take into account:

What is the coolant temperature.

The method of connecting the pipeline, which can be one-sided or two-sided. In the first case, the number of battery sections should not exceed 8-10 pieces. Otherwise, the distant compartments simply will not warm up.

In order to achieve optimal operation of the heater, the minimum distances to obstacles must be observed: 3 cm from the wall, 10 cm from the floor and from the window sill.

At the point of entry and exit of the pipeline, it is worth installing shut-off valves, including thermostats

It is also important to install an air release valve.

Under no circumstances should copper piping be used. Regarding the boiler with a copper heat exchanger, there is an opinion that it is far from the battery, so it should not lead to corrosion.

In high pressure systems, it is recommended to use pipes made of metal, but aluminum cannot be in contact with cast iron and steel surfaces without treatment.

- pliers;

- screwdriver;

- drill with impact mechanism;

- hydraulic level.

After all the preparatory work, you can install the batteries in stages:

- assemble the sections into a single radiator;

- connect shut-off and control valves, as well as air valves to it;

- drain the coolant from the system;

- install brackets for the battery on the wall and fix the heater to them;

- connect the radiator with pipelines according to the selected heating scheme;

- check the heating system.

The video shows the process of assembling an aluminum radiator with your own hands:

If you have doubts about your abilities, it is better to entrust the installation to professionals. Only with proper installation will it be possible to fully appreciate all the positive qualities of aluminum radiators.

You should also refuse to purchase and install if you live in an apartment building and are not sure about indicators such as operating and pressure pressure in the heating system and the quality of the coolant.

Low aluminum radiators

Such devices for space heating have a height of 200 to 450-500 mm. The lowest representatives have a center distance of 150 mm. The smallest section width is 40 mm. As for the depth, this characteristic differs significantly from the options with medium and high height. Sometimes it can reach 0.18 cm. Of course, this is done to compensate for the lack of thermal power due to low altitude.

It is worth saying that few manufacturers produce radiators with a center distance of 150-250 mm. The main ones are Sira, Global, Rifara. The smallest products of the first have a height of 245 mm. The inter-pin distance is 200 mm. Depth varies by model. So, Alux has a depth of 8 cm, and Rovall - 10 cm. The smallest radiators of the other two manufacturers have almost the same dimensions.

If we consider heating radiators with a center distance of 300 mm or more, then almost all companies produce them.

Advantages and disadvantages of an aluminum heater

Aluminum products have a number of positive qualities that are the reason for the popularity of this product.

- Aluminum radiators weigh relatively little, which makes them easy to transport and allows you to do your own installation.

- Such batteries look attractive and can not only heat, but even decorate various rooms.

- Features of the material and well-thought-out design of the batteries cause high heat transfer. Aluminum batteries can significantly save heating costs by reducing the volume of coolant in each section.

- Such batteries quickly respond to a change in the coolant supply: they cool down and cool down almost instantly. This allows you to warm up the premises in a short time and increases the efficiency of thermostats, which is also the reason for reducing heating costs.

- The powder coating simplifies the maintenance of the batteries, eliminating the need for periodic painting.

- There are models that can withstand high pressure.

- All this is combined with a relatively low price.

But such products also have several disadvantages that you need to know about before buying:

- In prefabricated devices, rubber sealing elements are used, which makes it impossible to use antifreeze as a coolant.

- Low protection against corrosive processes. To extend the operating period, it is necessary that the water has a neutral acidity and does not contain abrasive particles that can damage the protective film.

- Inside the heater, air may accumulate, to bleed which it is necessary to equip the battery with an air vent.

- The weak point of such a battery is the threaded connections.

Nevertheless, for the most part, the properties and features of aluminum heaters make them ideal for heating systems.

How to calculate the number of sections

But you can do this calculation yourself according to a simplified scheme. This method is suitable for rooms with a standard ceiling height of about 2.5 m, you only need to know the area of \u200b\u200bthe room.

In most areas of Russia, climatic conditions require that the heating power of each square meter be 100 watts. Therefore, you need to multiply the area of \u200b\u200bthe room by 100. And divide the result by the thermal power of 1 section of the battery model you have chosen.

For example, there is a room of 20 m2. To heat it, 2000 W of thermal energy is needed. We divide this value by the heat transfer rate of one section of the selected radiator, for example, by 180 watts. If rounded up, you get 12 sections.

For corner rooms with a balcony, you need to increase the resulting value by 1/5, this also applies to the situation when they plan to hide the battery behind the screen. Also, heat transfer losses can be 20% for one-pipe systems, about 12% for a two-pipe bottom connection, 2% for a cross connection.

There are a few more nuances that you need to know when buying and installing radiators.

Other Options

Aluminum radiator in the interior of the room

Weight matters when choosing fixtures for a heater.

The passport indicates the mass of one section. To determine the total weight of an unfilled radiator, this parameter must be multiplied by the number of sections. Depending on the dimensions, the weight of one section can be from 1 to 1.47 kg.

The volume of water in the radiator is also calculated from the parameters of one section, which must be multiplied by the number of sections.

The capacity (internal volume) of a section depends not only on its dimensions, but also on the thickness of the shell. The average capacity of one aluminum section is in the range of 250 - 460 ml. The internal volume of the radiator is taken into account when calculating heating systems and has the most direct impact on the volume of coolant required to fill them.

The maximum allowable coolant temperature for aluminum radiators is standard and is 110 degrees.

A large selection of design solutions for vertical heating radiators allows them to be installed even in rooms without windows. Photos of interesting models.

Which radiators are more suitable for which systems

one.Now, having considered and compared the main characteristics of radiators, we can draw conclusions. First, let's find out which heating radiators are better - aluminum or bimetallic - for an apartment in a multi-storey building. It uses central heating.

- The pressure in the system can change dramatically, reaching exorbitant values. Water hammer is possible.

- The temperature will also not be stable, sometimes changing greatly during the heating season and even during the day.

- The composition of the coolant is not clean. It contains chemical impurities, as well as abrasive particles. It is hardly possible to speak of a pH not exceeding 8 units.

Based on all this, you can forget about aluminum batteries. Because the central heating system will destroy them. If electrochemical corrosion does not eat, then the pressure will be finished with temperature. And the water hammer will make the last, “control shot”. Therefore, choosing from two types of radiators (aluminum or bimetal), stop only at the latter.

2. Now consider the heating system installed in a private house. A well-functioning boiler produces a constant low pressure, not exceeding 1.4 - 10 atmospheres, depending on the boiler and system. Pressure surges, and even more water hammer, are not observed. The temperature of the water is also stable, and its purity is beyond doubt. It will not contain any chemical impurities, and the pH value can always be measured.

Therefore, aluminum batteries can also be installed in such an autonomous heating system - these devices will work perfectly. They are inexpensive, have excellent heat dissipation, and their design is attractive. In stores you can pick up batteries made in Europe. It is preferable to choose models made by casting. Bimetallic batteries are also suitable for those who live in their own house. If you have the desire and enough funds, you can put them.

Just remember that there are many fakes on the market.

And if a model (whether aluminum or bimetallic) has a suspiciously low price, then you can already be wary. In order not to get into a mess, check that each section and the packaging (high-quality and full-color) have the manufacturer's marking

Specifications of Conner Cast Iron Batteries

The main technical characteristics of Conner cast iron radiators are given below:

- power - 120-180 W;

- the maximum temperature of the heat carrier is +110 degrees;

- battery operating pressure - 12 atmospheres. But the device can cope with a pressure of 20 atmospheres. Water hammers are not terrible for Conner units;

- radiators have wide channels. Therefore, they do not create much local resistance.

The dimensions, weight and volume of the section of this model are slightly reduced. On Conner cast-iron heating radiators, the reviews of the owners can be reduced to the following: they warm up the room efficiently and quickly, are durable, and have an excellent design.

The choice of cast-iron heating radiators today is quite large.

The choice of type, model, size, power and other characteristics of a cast iron battery depends on the area and features of the room, the number of windows and external walls, and the conditions for using the heater. Any cast-iron heating battery whose characteristics correspond to the heated room will work efficiently, create warmth and comfort in the apartment.

You can install a cast iron battery by calling a plumber or carry out this procedure yourself.

If you decide to install a cast iron radiator on your own, it is very important to connect it correctly.

You also need to make sure that the device is in good condition. Especially when the manufacturer's battery life is coming to an end. A cast iron radiator can last much longer than the specified period if the appliance is of high quality, installed correctly and maintained in good working order.

- How to pour water into an open and closed heating system?

- Popular Russian-made outdoor gas boiler

- How to correctly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes in case of malfunction

Recommended reading

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement entails legal liability. Contacts

Main dimensions

Dimension means:

The center distance (it is also called inter-nipple or center-to-center) should not be confused with the height of the radiator. The first indicator indicates how many centimeters are between the upper and lower collectors (holes). The height is the distance between the lowest and highest point of the section.

Aluminum heating radiators have the following dimensions:

- The center distance ranges from 150 to 2,000 mm. Very tall radiators are rare. The most popular are radiators with an inter-nipple distance of 500 mm. This is because the existing heating network pipe system was created for cast-iron batteries, which have the same center-to-center distance. Since many owners did not have and do not have the desire to digest pipes, they simply selected / selected a suitable radiator and, thereby, raised the popularity of a battery with a center distance of 0.5 cm. This indicator is very important, and therefore manufacturers indicate it in the name of the battery (RAP-500, Rococo 790, Magica 400, etc.).

- The height is in the range of 245-2000 mm. According to this criterion, batteries can be divided into low, medium and high. Features of each type will be discussed below.

- The depth of the section is from 52 to 180 mm. Some models may have greater depth, however, this is rare.

- The width of the section is 40-80 mm.

Water hammer resistance

Aluminum heaters are able to withstand an increase in pressure in the system up to 16 atmospheres. for some models, this figure is 20. Not much. As a result, pressure surges can result in cracks and battery failure. In the event of a water hammer, aluminum

Due to the presence of a durable steel or copper core inside the bimetallic heaters, these batteries are not afraid of increasing the pressure in the system up to 40 atmospheres. Even a powerful water hammer will not disable the bimetallic battery.

The degree of resistance of the battery to water hammer should be paid attention to by the owners of apartments in houses with central heating, where the likelihood of overpressure is quite high. In the heating pipes of a private house, due to the autonomy of the system, water hammer cannot occur, so the use of aluminum radiators is permissible

Some myths and recommendations for choosing

Currently, on the network forums dedicated to the subject of heating apartments and private houses, disputes “bimetal or aluminum” do not subside. Numerous opinions are so contradictory that the average homeowner or tenant is unlikely to be able to make the right decision. Moreover, on the pages of thematic forums there are a number of myths that put a person who is not a specialist in this field into a dead end. Here are some of the main myths:

- aluminum radiators are not able to withstand high network pressure;

- silumin, which is part of aluminum radiators, is subject to rapid corrosion, which will soon make the entire battery unsuitable for further operation, and, therefore, preference should be given to bimetallic heating devices;

- aluminum, which is part of the radiators, together with another metal that is in contact with the coolant, creates a galvanic couple and, as a result, is very quickly destroyed under the influence of electrochemical corrosion;

- in contact with dirty coolant water, aluminum releases a significant amount of oxygen into the system;

- steel parts of bimetallic batteries rust very quickly, rot, after which the battery becomes unsuitable for further use;

- as well as many other fantastic statements.

Some of the processes described in these myths actually take place. However, the degree of their influence is so negligible that the battery can serve faithfully for more than a dozen years. Thus, if you bought not a cheap fake, but a high-quality product, performed the installation correctly, you should not worry about the manifestation of the factors described above.

A few tips to help you make the right choice of heating radiators:

- For autonomous heating systems of private houses, it is better to choose aluminum radiators.

- Aluminum-based radiators can be used in the heating systems of apartment buildings. To do this, you need to take into account the magnitude of the working pressure and use products only from well-known world manufacturers.

- In multi-storey buildings (16 or more floors), bimetallic batteries should be chosen for heating systems.

- If the heating system of a multi-storey building includes not only risers, but also horizontal branches, aluminum radiators can be used.

- If there are doubts about the reliability of aluminum batteries, you need to buy and install bimetallic heaters. This will ensure reliable operation.

Aluminum or bimetallic heating radiators connected to the central heating system will provide a comfortable temperature in the home and have a long service life only if they are periodically flushed. The ideal flushing frequency is once a year. If this is not possible, flushing must be performed at least once every 3 years.

Characteristics of cast iron radiators of various manufacturers and models

In Soviet times, there were countless factories for the production of cast-iron radiators - after all, there was no alternative. Here, for example, are just a few of their types: NM-140, NM-150, Minsk-110, R-90, RKSH. Almost all of them are no longer produced. Long lives, perhaps, only one tested model - MS-140, classic and solid.

The new models look prettier, for example, the MS-110 of the Santehlit plant has a shallow depth (only 11 centimeters) and fits well under narrow plastic window sills.

In Cheboksary they make FM radiators with one, two and three channels. Their outer side is flat, which looks quite aesthetically pleasing, and it is easier to wipe the dust.

Beautiful two-channel radiators are produced in Minsk, about 10 models in total.

Sectional batteries made of cast iron are also brought to us from abroad. Foreign products are smoother both outside and inside, so their heat transfer is higher. Let's note the Chinese company Konner (the models "Hit", "Modern" and "Fort" are especially good).

The Czech plant Viadrus, the Turkish company DemirDöküm and the Spanish concern Roca also make good radiators. European manufacturers make very elegant batteries with cast iron patterns. True, such radiators are much more expensive than domestic ones.

Technical characteristics of cast iron radiators ms 140

These devices are manufactured in accordance with GOST 8690–94.

Previously, all standard sizes were used quite widely, and they could be seen not only in residential apartments, but also in administrative and industrial buildings. At the moment, cast-iron radiators ms 140 500 and 300 are most often used. Other modifications are extremely rare and, as a rule, they are made to order.

The main characteristics of heating radiators ms 140 500 are as follows:

- pressure. Working pressure is up to 9 atmospheres, and pressure testing - up to 15 atmospheres;

- heat transfer is low and equals 175 W;

- each section has two channels;

- section dimensions: height - 50 cm. width - 9.8 cm;

- the capacity of one section is 1.35 liters of water;

- the radiator is able to withstand coolant temperatures up to +130 degrees.

It is worth considering the device of a cast-iron heating battery model ms 140 500. Gray cast iron is used for production. The nipples are made from ductile iron. Gaskets are installed between sections. For the production of gaskets, heat-resistant rubber is used.

Technical characteristics of aluminum heating radiators, which must be considered when choosing a radiator

The technical characteristics of aluminum heating radiators make it possible to evaluate their effectiveness and choose the model that is most suitable for certain working conditions.

Consider what characteristics you need to pay attention to when buying, and also compare the main parameters of products from different manufacturers

The main technical characteristics of models of aluminum heating radiators are information that it is desirable to know before choosing and buying them. Along with the appearance (design) of the heater and its cost, the technical data allow you to compare different models with each other and choose the option that is optimal in terms of the main parameters.

There are quantitative and qualitative characteristics of aluminum radiators. Quantitative ones make it possible to compare heating devices in terms of their weight and size parameters and heat flow power. In turn, the quality characteristics take into account the design features and manufacturing technology.

Technical characteristics of aluminum heating radiators

Before buying an aluminum battery, you need to know the set of parameters that characterize it.

- The pressure that an aluminum device can withstand in operating mode can be from 6 to 20 atmospheres. It all depends on the manufacturer. Crimping (limiting) pressure for these products is about 25 atmospheres. For this reason, aluminum radiators do not always take root in houses with central heating, as there are surges of up to 30 atmospheres in the network.

- The distance between the axes is one of the main dimensions of the batteries, which is the distance between the inlet and outlet pipes. For aluminum radiators, this parameter can range from 20 to 80 cm, but more often there are instances with a distance between the axes of 35 or 50 mm, the height of the battery itself is 10 cm more. Before buying, it is necessary to measure the space under the window sill, the radiator should not stand upright, otherwise circulation will be difficult.

- The depth of the battery is 8-11 cm.

- The maximum coolant temperature that aluminum heaters can withstand can be 110 ° C.

- One of the most beneficial characteristics of aluminum heaters is the ability to give off heat - the heat transfer coefficient, measured in watts. This thermal parameter is indicated by the manufacturer for one section and can be equal to 80-210 W. Due to the special design and low inertia, heat transfer from aluminum radiators is quite high, which allows you to reduce heating costs by reducing the temperature of the coolant.

- The volume of coolant that fits in one section for batteries made of this metal is on average 0.5 liters.

This is how the main technical parameters of the battery look like.

It is also important for the consumer to know how long the radiator will last, how reliable it is.

Operational period

With regard to susceptibility to corrosion, this was discussed above. To extend the service life of the device, it is necessary to carefully select the coolant, which cannot be done in conditions of centralized heating. A private heating system allows you to do this.

Another factor that can negatively affect the durability is the ability of aluminum to easily crumple upon impact.

Manufacturers set the service life for their products - 5-15 years.

This parameter depends on the production method and assembly methods of the battery.

Production methods and assembly features

These heaters are mainly produced in two ways:

- with the injection method, the radiator is cast as a single piece;

- sections are obtained by extrusion, which are connected to the injection-molded top and bottom of the manifold, and all parts are then fastened together with an adhesive composition.

It is believed that batteries made from virgin raw materials are more durable.

The resistance of aluminum products to corrosion is increased by anodizing.

The subtleties of production that affect the quality of the product: cooling rate, crystallization process, pouring, etc. – may differ from manufacturer to manufacturer.

How to assemble a radiator

Aluminum heating radiators are assembled according to the following algorithm:

- put the battery on a flat surface;

- inspect each threaded connection for chips, cracks and carefully clean with sandpaper. Degrease the ends using gasoline. Gaskets can be washed in soapy water;

- connect sections. To do this, put the seals on the nipple-nut and attach it to both sides of the device section. Make a couple of turns with a wrench in the upper and lower holes. When the key stops turning, you can reach it using the lever;

- plug an unused hole. And on the other hand, attach a Mayevsky crane to remove excess air from the system. Now the radiator can be connected to the system according to the selected scheme.

Coolant for cast iron radiators

One of the significant advantages of cast iron models is insensitivity to various coolants. There is no need to monitor the acidity of the circulating fluid. The width of the channel makes it possible to freely pass and not allow impurities to accumulate inside, which are in abundance in central heating systems.

Cast iron radiators do not enter into chemical reactions with antifreeze, water or other liquids containing antifreeze additives. However, this does not mean that water treatment can be forgotten. Indeed, in addition to batteries, the coolant flows through pipe lines, inside the boiler and other installed equipment.