Basic cleansing techniques

Technological processes for the purification of domestic sewage are very effective. Clarified water after undergoing VOC treatment can be reused for garden irrigation or technical needs.

Technological processes for the purification of domestic sewage are very effective. Clarified water after undergoing VOC treatment can be reused for garden irrigation or technical needs.

The most commonly used methods for cleaning drain liquids are:

- biological;

- mechanical;

- physical and chemical.

For clarification of household and domestic effluents, due to simplicity and efficiency, the first two cleaning methods are usually used.

Mechanical Methods

During the application of any methods of clarification of contaminated liquids, at the initial stage, methods of a mechanical type are usually used, aimed at separating coarse impurities. The technology of mechanical purification is the simplest and most affordable. For its implementation, the contaminated liquid:

During the application of any methods of clarification of contaminated liquids, at the initial stage, methods of a mechanical type are usually used, aimed at separating coarse impurities. The technology of mechanical purification is the simplest and most affordable. For its implementation, the contaminated liquid:

- uphold;

- filter;

- filter.

The process occurs through the use of coarse filters or in settling facilities by settling heavy components under the influence of gravitational forces. Mechanical cleaning removes approximately 60-70 percent of contaminants from domestic wastewater.

During settling, it is possible to eliminate most of the oil-containing impurities that come through with industrial effluents. Mechanical cleaning is used by owners of car washes and oil refineries.

Clean mechanically and storm drains. For this, sand traps are attached to the highways. The composition of precipitation that is collected from the surface of the earth contains:

- soil impurities;

- branches;

- foliage;

- pebble inclusions.

Sand traps trap large debris, preventing it from clogging storm drains.

Biotreatment methods

The scheme of operation of a septic tank with aeration

The scheme of operation of a septic tank with aeration

The technological process consists in the use of aerobic and anaerobic microorganisms capable of processing complex organic components in sewage. In this case, they are decomposed into gas and water.

Aerobic microorganisms need oxygen to live. To increase the efficiency of purification, you will need to create suitable conditions by installing an aeration system.

Anaerobic bacteria do not require oxygen, so they are able to live in airtight containers. Their by-product is methane. Installations in which purification is carried out with the help of such microorganisms are equipped with a ventilation system.

2 Measures for the sanitary protection of water bodies

1. Legislative

2.

Organization of sanitary protection zones

3.

The device of treatment facilities for

processing of household wastewater.

Industrial waste is usually

cleaned at the factory.

Substances

wastewater are in different

physical state (solid, dispersed,

colloidal, liquid phase) and this allows

break down the entire cleaning process into

several stages:

a)

mechanical cleaning - isolation

suspended solids;

b)

biological treatment - mineralization

organic substances found in

colloidal and dissolved state;

v)

disinfection;

G)

biological ponds.

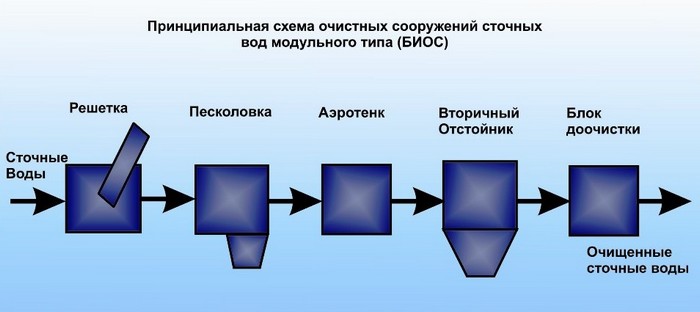

Types and principle of operation of VOC

Local treatment facilities for household wastewater contribute to the processing of waste into a relatively safe liquid substance that can be used for technical needs or drained into the soil.

Local treatment facilities for household wastewater contribute to the processing of waste into a relatively safe liquid substance that can be used for technical needs or drained into the soil.

VOCs that are used for bioremediation:

- Septic tanks are sealed chambers into which sewage is discharged. Anaerobic microorganisms live there, processing sediment and contributing to water purification. Liquid after a septic tank requires additional purification, for example, in a filtration well, before it is discharged into a reservoir or soil.

- Septic devices with biological filters. The principle of operation of the biofilter is to seep water through the thickness of coarse-grained material (crushed stone or sand), which is covered with a film of special bacteria. According to this scheme, filtration fields and well installations work. When effluents pass through a biological filter, due to microorganisms, the processes of oxidation and decomposition of organic components are activated.

- Bioponds are artificial water bodies with a depth not exceeding a meter. In them, the contaminated liquid after mechanical cleaning is processed due to the action of bacteria. To accelerate the activity of microorganisms, it is necessary to warm the reservoirs with sunlight: in the Central Russian winter, these ponds have low productivity and are almost never used. Strengthening the activity of aerobic bacteria is also carried out through forced aeration.

- Aerotanks are hermetically sealed installations in which forced aeration is used. In order to process the liquid faster and more efficiently, activated sludge is used, which contains the necessary microorganisms in its composition.

- Deep cleaning stations. The facilities are used for complex clarification of wastewater with maximum effect. After passing through them, the liquid becomes purified up to 98%. Water is driven through several different filters and treatment devices.

Membrane bioreactors are increasingly being used to clarify wastewater in enterprises and residential complexes. It combines biological treatment with activated sludge and mechanical membrane filtration. The membrane module is used to separate the sludge mass and is an alternative to the sedimentation of this substance in classical biological treatment plants.

Advantages of bioreactors:

- compact dimensions with high productivity;

- use of old cleaning complexes when upgrading equipment;

- the ability to work with a significant accumulation of activated sludge.

There are two types of biological reactors: with internal and external membrane placement. In the second option, the filter is isolated from the process chambers, and it is necessary to install intermediate pumping equipment.

mechanical cleaning

Mechanical

cleaning takes place on a series of sequentially

located structures, construction

who are destined for detention

different fractions of suspensions.

1.

Lattice

serves to trap large debris

- rags, paper, cotton. She represents

a series of parallel metal

rods fastened together and placed

vertically in the supply manifold

water to sewage treatment plants. gaps

between the bars are 16-70 mm. Removal

waste at large facilities

mechanical rakes. Further dregs

fed into the crusher and then into

digesters or processing is carried out

method adopted for neutralization

solid waste (composting,

plowing, biothermal chambers).

At small stations, they are harvested by hand

rake. Waste contains a lot of organic

substances that easily rot, they

not epidemically safe

and are in need of decontamination. Meaning

grids: frees sediment, falling out

in sedimentation tanks, from coarse impurities,

makes it more uniform

and facilitates its disposal,

prevents clogging of pumps and

sewage pipes

and sediment.

2.

sand traps

designed to hold heavy

mineral suspension (sand) before entering

waste water into a sump. Principle of operation:

the flow of waste water is given a speed

15-70 cm / s is enough to

light organic suspensions did not settle

and yet too small to

prevent heavy sand from settling.

Passing temperature not less than 70C.

Sand traps are settling tanks.

Types of sand traps: 1) vertical - with

circular motion of water 2) horizontal

— with rectilinear water movement 3)

aerated - pass through the bottom

compressed air for cleaning

sand from flakes of organic suspension.

Horizontal sand traps are different

simplicity of the device and high

efficiency. They have 2-3 sections,

each of which can work

on one's own. This allows you to turn off

1-2 sections for low water flow, e.g.

at night. Vertical sand traps more

compact and efficient. Flaw -

construction volume is less than

horizontal, fine sand

don't linger

3.

Settling tanks

—

with sludge treatment

—

without sludge treatment

Settling tanks

with sludge treatment

Are characterized

a large volume of the silt part for

long stay of sediment up to

the end of the fermentation process,

seals of detained suspended

substances (septic tank, two-tier sump,

clarifier-decomposer).

Settling tanks

without sludge treatment

a)

vertical sump - cylinder with

cone-shaped bottom, water enters

through the central pipe and then moves

by the cesspool.

b)

horizontal sump - attached

slope opposite to the flow of the liquid, so that

the sediment slipped or moved with a scraper,

and then accumulated in the silt space.

Depth 1.5-2 m, speed - 7 mm / s.

v)

radial settler - round shape

with a uniform slope of the bottom towards the center,

diameter from 16 to 40 m depth of water layer –

2-2.5 m. Water moves at a decreasing speed

from the center, where it flows from below to

periphery, where it overflows through

holes in the board in the outer circular

gutter. The sediment is removed with scrapers,

attached to a slowly rotating

form. Stay temperature 1.5 hours,

movement speed 7 mm/s. Efficiency

is 60%. The precipitate is converted to

digester where it is fermented.

Methane tanks

- closed tanks that have

at the top of the cap for collecting gas

(70% methane and 30% carbon monoxide), which

used as fuel in

boiler room of treatment facilities. Removal

digested and fresh sludge supply

produced by special pipes.

Sludge is heated hot

steam (100-112C).

There are 2 types of fermentation in digesters:

mesophilic (t-33C)

and thermophilic (t-53C).

Duration of fermentation is 10-20 days. At

thermophilic fermentation lose

viability of helminth eggs and

pathogenic microorganisms of the intestinal

groups. Drying of digested sludge

carried out on sludge sites.

Sites are divided into depth maps

0.7-1m, have a waterproof base

and drainage system for water supply. If

danger of groundwater pollution

ruled out, then the bottom can be natural

priming. The silt is distributed in a layer of 20-70 cm, it

dries up, the water is sent to the biological

cleaning from fresh sludge, or chlorination.

The sludge is used as fertilizer or

sent for biothermal treatment

(composting).

Cleaning rates

Effluent treatment facilities must provide the required degree of purification. The strictest standards exist only for wastewater generated from industrial enterprises. At the same time, the norms stipulate the permissible concentration in purified water of each specific substance.

For domestic sewage, such strict requirements are not imposed. However, the rules still prohibit dumping households. drains without treatment into open water bodies or soil. For this, homeowners can be held accountable.

For sewage of household origin, the concentration of certain substances is regulated by law only if they are discharged into a reservoir.The same applies to wastewater discharged after treatment to the relief, because in this case, sooner or later they will still fall into the reservoir.

There are no such strict requirements for effluents discharged into the ground after the treatment plant, since in this case the owner of the house himself is interested in thoroughly cleaning the liquid. Otherwise, he risks worsening the condition of his site to such an extent that it becomes impossible to live in the house.