Water heater for electric heating

There are many ways to heat a house using non-traditional methods. However, not all of them are sufficiently effective, although there are those that have proven their efficiency in practice. One of the most effective and proven options in real life is the use of an electric water heater for heating.

The principle of operation of the water heater in heating

Non-standard at first glance, the design is characterized by relative accessibility in installation, as well as operational efficiency. Although this option is not without its drawbacks, it can be found in many domestic apartments.

- Main characteristics of the device

- What parameters are taken into account when choosing a storage device

- Indirect heating boiler

- Installation of the boiler in the system

Features and scheme for manufacturing an indirect heating boiler with your own hands

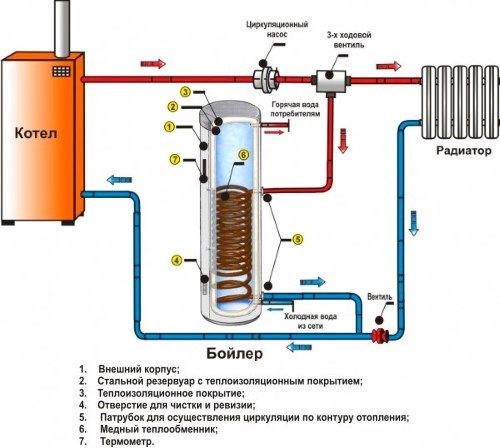

In appearance, an indirect heating boiler is a large storage capacity, independent of energy sources (gas, electricity, etc.). Inside the tank, made of corrosion-resistant material, a spiral tube is installed through which the coolant circulates. Cold water is supplied to the tank through an inlet pipe, usually located at the bottom. The heating of water in the boiler occurs evenly due to the moving coolant of the heating system. The outlet pipe for hot water is installed at the top. For ease of use, the pipes are equipped with ball valves. Outside, the tank is covered with a layer of thermal insulation.

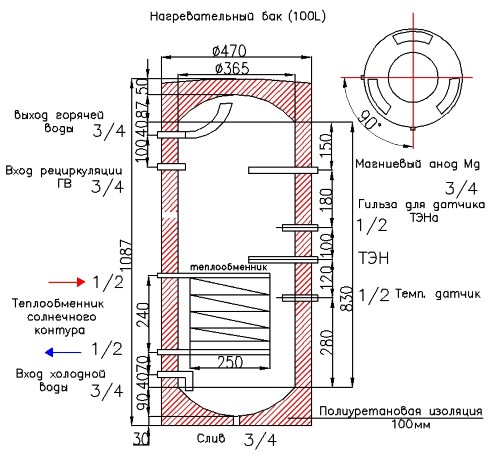

A drawing for the manufacture of an indirect heating boiler with a volume of 100 liters is shown below:

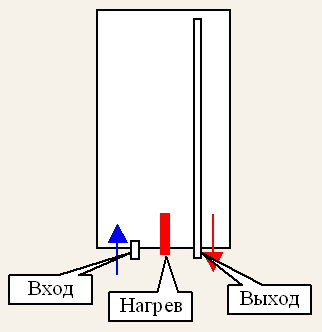

Schematic diagram of the boiler:

Heating water from the boiler enters the tank of the water heater, where, passing through a spiral tube, it is converted into cold water at the outlet. The return chilled water goes back to the boiler.

Which material is better

When constructing a heat exchanger, metal parts are used - galvanized sheets, gas cylinders, pipes of various diameters, cast iron blanks, etc. Cast iron is not recommended because, compared to steel, it is brittle and heavy, which makes it difficult to install on the chimney.

The best option is austenitic steel. Stainless steel easily tolerates thermal shocks, is resistant to mechanical damage, and can be independently processed and welded.

Galvanized steel is inferior to alloyed or austenitic steel, as it is not designed for heating. The high-temperature regime leads to the release of zinc oxides that are harmful to health, therefore, if it is planned to increase the temperature in the chimney to + 419.5 ºС, galvanizing should be abandoned. It is better to purchase expensive, but safe material.

Heating tanks in the chimney

A tank for heating water on a tuba has been installed since ancient times, it is enough to recall the legendary Russian samovar, a kind of symbol of our people. This principle was first used in it, for this reason such systems are also called samovar.

Advantages of samovar structures

- When a stove is heated in a bathhouse, the pipe in it will heat up in any case, it is stupid not to use this energy and it can safely be considered completely free.

- Depending on the type of fuel, the temperature of this part of the structure varies between 300 - 700 ºС. Moreover, a significant advantage is that the pipe heats up evenly over the entire contact area.

- The volume of such a tank can be quite large, because the distance from the furnace to the ceiling will be at least one and a half meters, and such a heater can be equipped along the entire length of the pipe.

- Such a heater, in most cases, does not need an additional pump, heat exchanger or electric heater.

- A normal stove for a small steam room has an average pipe cross section of about 115 mm. Given the thickness of the container, the transverse dimensions of the entire structure will be within half a meter. That allows it to be placed in any, even a small steam room.

- Installation does not require fundamental knowledge of heat engineering or to be a super-fitter. Almost any owner will be able to install such a container on the pipe with his own hands.

- And finally, when compared with a boiler, the price of such a miracle will be quite affordable, and the investment will be one-time.

Disadvantages of this type of heaters

The most significant drawback is that the tank for heating water on a pipe can be installed exclusively on metal structures.

Ceramics or brick for pipes do not have such a level of heat transfer.

Designs in which water is poured through the top, directly into the steam room, will increase the level of humidity in the room.

Hot metal walls of the tank are a source of danger, careless touching can lead to injury.

Choosing the right capacity

container material

In the old days, cast iron was the most popular material. Of course, it will heat up a little longer, but the temperature will keep better. An important factor is the resistance of cast iron to corrosion and a long service life. But cast iron is a heavy material and such a container will need a powerful support.

Ferrous metal for these purposes is now practically not used due to the tendency to corrosion and the high probability of deformation during sudden temperature changes.

Stainless steel is deservedly considered a universal material. This metal is not afraid of corrosion and has a relatively low weight. In order to weld a large capacity tank, a sheet with a thickness of 1.5 - 2 mm is sufficient. During temperature changes, such containers are not deformed.

The video in this article shows the opinion of a specialist.

Conclusion

Our country is rich in craftsmen, but the bath is considered an object with a high degree of danger. Based on this, we do not recommend installing artisanal tanks. There are now enough certified products on the market, the price of which is quite affordable.

Connecting an instantaneous water heater

In a flow-type boiler, water passes through its shell, and the heating element turns on only when the water flow moves in the device case. Therefore, overheating in this system is practically impossible and a pressure relief valve is not placed in the heater.

A shut-off ball valve and necessarily coarse sand filters are placed in the cold water supply pipeline of the instantaneous water heater - the absence of filter elements is a gross violation of the operating rules and may cause the service organization to refuse to fulfill its warranty obligations.

Rice. 9 Installation examples of instantaneous water heaters

Do-it-yourself instrument manufacturing options

We offer several easy-to-do-it-yourself projects that, if desired, can be made from metal parts using welding and power tools.

Overview of the gas cylinder heat exchanger

If you install a home-made device on a potbelly stove, the heating efficiency in the room will increase by 30-40%. The smaller the area of the garage or workshop, the higher the productivity of the device.

We suggest considering an option that is ideal for small stoves of the "potbelly stove" type, which are actively used for heating garages.

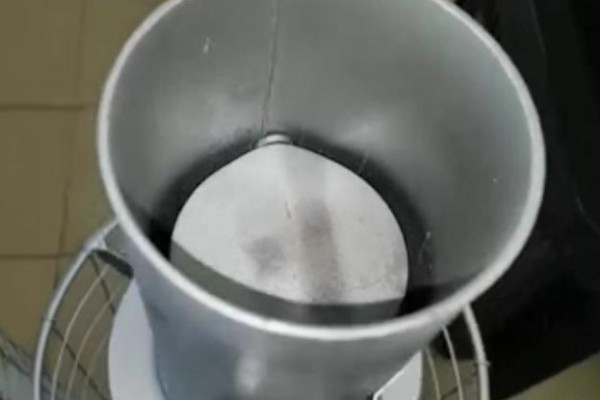

In general, a rather neat and productive heat exchanger for a stove that heats a small room is obtained from a gas cylinder. To further increase the heating efficiency without a fundamental change in the design, fans can be installed on the pipes, and the number of pipes can be increased to 4-5.

Photo review of the Feringer economizer

Factory models of popular manufacturers can serve as a sample for manufacturing. For example, the Feringer company, known for the production of furnaces, offers ready-made chimneys, which are essentially heat exchangers.

Consider models of a simple design. All the details of which they consist can be done independently.

The main idea that can be taken from the advanced Feringer models is the use of four pipes instead of one. If the stove is already installed in the garage or utility room, we remove part of the chimney, install a four-pipe economizer instead - and the temperature in the room immediately rises by several degrees.

Homemade air convector

The proposed model is completely made of steel parts. This is a heat exchanger, which in size is about 1.5 times the volume of the chimney.

It is a drum with tubes located perpendicular to the chimney. Stainless steel was not chosen in vain - it easily tolerates high temperatures, cleans well and does not burn through.

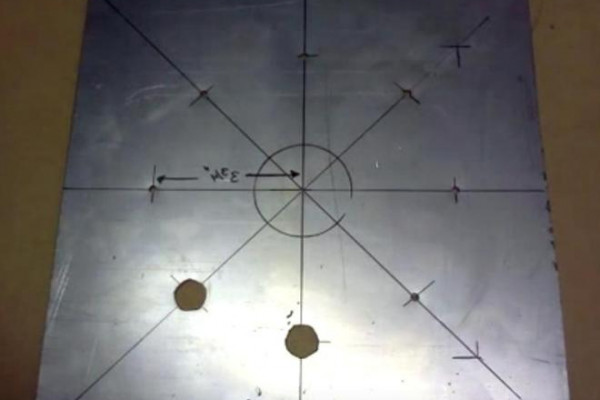

For work you will need:

- steel pipe with a diameter of 30 mm (for the manufacture of 8 identical segments);

- pipe fragment 50 mm (for the central channel);

- metal sheet 2 mm thick (for the manufacture of 2 round plates and a casing);

- a 20 l paint can (for a chimney adapter).

It is also necessary to prepare a tool for cutting and welding metal.

This is one of the best options for an air heat exchanger for a chimney stove for a garage or utility room. The design can be simplified by welding metal partitions instead of tubes, but the principle of operation will remain the same: heated air from the chimney will be an additional source of heat for the room.

The article recommended by us is devoted to the manufacturing process of the chimney for the stove-stove. It is better to equip the chimney immediately during manufacture with a heat exchanger.

Heating the house with a boiler

Good heating is one of the most important factors that distinguishes a comfortable home from a home in which a person cannot feel comfortable. Today, there are many traditional heating systems with which you can heat a country house of any size. One of the most popular systems is gas heating. Natural gas is considered one of the cheapest heat carriers in our country. But, unfortunately, gas pipelines are not extended everywhere. Therefore, heating systems that use a different coolant, such as hot water, are very popular. And the basis of such a system can be an ordinary boiler.

Installation and operation of a heating boiler

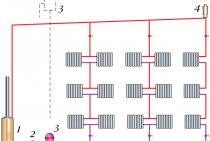

Boiler in the heating system

After performing all the necessary calculations of the boiler power and its volume, you can proceed to integrate the device into the heating system

An important task is to determine the installation site. Having decided on the purpose of the boiler in the heating system, you need to read the instructions for its installation

The best option would be to install in the immediate vicinity of the boiler. In this case, the transfer of thermal energy from the coolant to water is the most efficient.

But at the same time, you may encounter the following difficulties in organizing heating using a boiler:

- Supply of the DHW system. In a heating system with a solid fuel boiler, it is most convenient to place the boiler directly in the boiler room. But then, to supply heated water to the premises, you need a separate pump and control devices for it;

- Large capacity. if heating is planned through a boiler for large residential areas. There is a problem with the placement of the heating element;

- Power supply to ensure the operation of the heating element. For the normal functioning of the boiler for heating a private house, it is also recommended to install an autonomous source of electricity.

Having solved these questions, you can proceed directly to the installation.

Control of water temperature in heating through the boiler is carried out using the installed thermometer. It is not included in the standard package and therefore it is necessary to purchase this device separately.

Installation of a storage heating tank

To install the heat accumulator, it is necessary to prepare a flat area in advance. Its large weight should be taken into account - if necessary, a separate foundation is made or the floors are reinforced.

The optimal mounting option is on a separate platform. In this way, contact of the body with the concrete surface can be avoided, which will reduce heat losses in the electric boiler for heating. Almost all manufacturers make containers on special legs. In their absence, it is recommended to install a heater on the floor.

The procedure for connecting the boiler to the heating system is to perform the following actions:

After installing the container, you need to check its position relative to the horizon. Deviations are not allowed.

Connect to the heating

It is important that the diameter of the pipes is equal. Otherwise, after connecting the boiler to the heating system, excess hydraulic resistance will appear.

If the installation is carried out in an unheated room, the boiler body is insulated.

A connection is made to hot water supply so that the boiler works not only for heating, but also for hot water.

Upon completion of this work, you need to check the tightness of all connections and start the heating system. Within 2-3 weeks, it is recommended to measure the temperature of the water in the tank and the coolant in the pipes after the boiler is turned off. So you can determine the actual time to maintain the desired level of heating in the heating circuit from the boiler.

In order to make full-fledged heating from a boiler, it is not recommended to use antifreeze. It is characterized by a relatively low heat capacity, which will affect the transfer of heat to water and back to the coolant.

Conditions for proper operation of the boiler

Scale on the heating element of the boiler

Maintaining a storage tank is practically no different from carrying out the necessary procedures to maintain the performance of any electric boiler with heating elements. And in this case, in order for the boiler to work normally in the heating system of a private house, it is required to follow the manufacturer's recommendations.

This can be ensured even before the heat supply from the boiler is done. It is best to purchase models with the so-called "dry heating element". On it, the formation of scale occurs much more slowly. You should also pre-filter the water before entering the storage tank.

In addition to these procedures, you must do the following:

- Once a month, check the integrity of the thermal insulation of the structure;

- Control the duration of maintaining the temperature of the heat carrier during the mode of operation of heat supply through the boiler. The difference between calculated and actual indicators should not exceed 15%;

- Connection tightness control. It is recommended to replace gaskets before each heating season. So you can achieve more reliable heating of a private house with the help of a boiler.

The control unit of some models is sensitive to voltage drops. To avoid damage to this expensive device, you should connect a stabilizer for the boiler in the heating system.

To clean the heating element from scale, it is necessary to dismantle it. But before that, you need to ask the seller whether the factory warranty is preserved.

Types of devices for the chimney

Among air varieties, a tubular heat exchanger is considered a traditional model for self-production, although there are many other options.

Consider the main types that are relevant for installation on the chimney of long-burning stoves, small-sized stoves, and mining stoves.The heat that they convert from the energy of combustion products is called dry.

If we represent schematically the internal part of the devices, then it can have the following variations.

Horizontally or vertically arranged pipes welded to the furnace body. The vertical arrangement is more efficient, as the air passes through the channels better. Production material - steel.

A pipe wrapped around the firebox. For good heat transfer, 2-3 turns are enough, which are better to slightly move apart to increase the heating area.

Partitions inside the body. A kind of labyrinth is made up of metal plates installed vertically. The optimal thickness of the parts is from 6 mm to 8 mm.

Pipes passing through the furnace.

With vertically arranged channels, the air movement is more intense, therefore, the performance of the device is increased. But in some cases, devices with horizontal pipes or with partitions are appropriate. Each of these models is suitable for self-production, if you have welding skills.

Traditional heating systems

In search of a universal solution, craftsmen have tried many options and each of them is good in its own way.

It cannot be clearly said that there is a universal option, so you should choose depending on the conditions that exist at a particular facility.

- In the process of building a bath, many modern owners prefer to go the easiest way and purchase an electric boiler. The option is undeniably worthy, but it requires a constant supply of water, plus for a large capacity, electricity costs will be sensitive.

- A classic is the water-heating tank built into the oven. Such containers heat up quickly, the installation instructions for such heaters are the simplest, in the most accessible version, it is enough to put the tank on the stove. But it will be located low and, being in the steam room, will become a source of wet steam, which is not always good.

- Remote tanks have proven themselves well, when the main tank is mounted at a comfortable height in a dressing room or shower room, and heating is carried out through a heat exchanger installed in the furnace. They work thanks to the elementary laws of physics, cold water enters the heat exchanger through the lower pipe and, heating up, returns back through the upper conduit.

- But the most profitable and convenient to use are containers mounted directly on the chimney, and we will talk about them further.

Do-it-yourself boiler for heating

It should be noted that the cost of factory models of a boiler for heat supply to a summer residence is quite high - from 7,000 rubles. and more. An alternative option is to make the structure on your own.

You can use any steel container for this.

It is important that its volume corresponds to the calculated one. To organize heat supply schemes from a home-made boiler, you will need the following components:

- Tank. It is best to order a stainless steel structure or make it yourself. The body must have holes for soldering the inlet and outlet pipes;

- Coil. The best option is to install a copper structure. This material has optimal parameters for the transfer of thermal energy;

- Fastening of branch pipes for connection to heating and GVS.

To ensure thermal insulation, it is recommended to make a double casing. Glass wool or basalt insulation is installed between the walls. The recommended layer thickness is 5 cm. The procedure for installation and commissioning is no different from factory models.

How effective is the use of a boiler in heating a house? It all depends on the correctness of the calculations of the parameters of the entire system. Only after calculating the optimal characteristics and testing them in practice can we talk about the true efficiency of the boiler installation.

The video shows an example of using a boiler in a heating system.

How to make an electric water heater with your own hands

But a more optimal way is to make an electric water heater with your own hands. A homemade water heater will cost much less, and it will take very little effort to make it. How to make a water heater with your own hands is described below.

This do-it-yourself device allows you to save money and eliminates the worry of how to provide a private house or cottage with cheap hot water, especially in winter.

On sale there is a washstand with a built-in heating element and a plastic tank of 10 liters at a very “democratic” price, only water must be poured into it through the lid. And this means that again you will have to use various ladles and jars, but this is not very convenient.

At present, it is not difficult to install a 120-liter tank and a pump in the kitchen (with autonomous water supply, all these designs are always available).

The pump allows you to fill a tank of this volume in 10 minutes without any hassle. This amount of water can be enough for a family of 4-5 people for 2 days without observing the austerity regime. In this case, the water from the tank should be supplied to the sink by gravity, i.e., the tank can be installed in a room adjacent to the kitchen on a high rack. For "gravity" such pressure should be enough.

DIY homemade electric water heater

For a water heater with your own hands, you need to complete the system for automatically filling the tank. For these purposes, it is necessary to cut the corresponding hole - a toilet valve with a float and slightly alter the design. Inside the tank there are stiffening ribs for which the float will touch, so you need to shorten the rod on which it rests, slightly bending it “in place” in order for the system to work.

Before you make a water heater yourself, consider where the tank will be installed. In order not to clutter up the kitchen, place it in a utility room that communicates with it, where the storage tank is located, connecting it to the sink mixer using a hose from the washing machine.

Recommended for the heating element system - "Ariston" for 1.2 kW with a built-in thermostat. Under it, you should make a fitting hole in the tank and cut out the gaskets from the rubber. The recommended electrical circuit involves the installation of a circuit breaker in the kitchen and two indicators placed in a neat box.

One indicator should show that the homemade electric water heater is on, and the second should light up (only when the thermostat will turn on the heating). On the body of the heating element is the corresponding connector. At night, you can turn off the toggle switch of the circuit breaker, thereby turning off the entire system.

It is recommended to wrap the water tank with insulation, and make a plywood box on top. Then the design will keep warm and look more neat, and the top of the box, in addition, can be used as another shelf in this case.

The insulation of the tank will keep the water warm until the morning, so in the morning the heating element can be turned on for a short time.

You can also use a plastic tank, but it is unreliable. It is better to use a stainless steel tank as a tank, for example from an old washing machine. This container is quite suitable and durable.

Such a system usually works for quite a long time. The problem can occur in winter due to freezing of water in the system. Therefore, water for the winter period must be drained if you do not plan to use it regularly.

The principle of operation of the air heat exchanger

The main purpose of the heat exchanger is to transfer energy from the combustion products in the chimney to the coolant, which is water or air. Heat exchangers installed in chimneys (this applies to water modifications) are often called economizers.

These devices collect and transfer heat into the room, which simply escapes into the atmosphere, so that the thermal energy generated by the furnace is used to the maximum. In addition to ordinary tap water, other liquids are sometimes used - oil or anti-freeze.

In this regard, all devices are divided into two large categories:

The choice of one type or another depends on several factors. The most important of them are the configuration and material of the chimney, as well as the characteristics of the device itself.

Let's see how the air model works. The design of the device is simple: a rugged case with partitioned off internal space. The role of partitions is played by plates or tubes, the main function of which is to slow down the movement of heated gases and direct heat in the right direction.

Some partitions (flaps) are not soldered, but made movable. By pushing in / pulling out the metal plates, you can adjust the traction force, thereby reducing or increasing the performance of the heater.

Air heat exchangers are called convectors, because their operation is based on the principle of convection. Cold air from the room enters the device, where its temperature rises due to exposure to hot flue gases. In a heated state, it moves further through another hole - back into the room or into the heating system.

Advantages and disadvantages of an indirect heating boiler

Pros of using a DIY boiler:

- connection to the central heating system;

- installation near a heating boiler;

- low costs for installation of the circuit;

- significant reduction in energy consumption;

- providing water at a constant temperature.

The disadvantages include the following:

- boiler installation requires a large area or a separate room;

- it takes a long time to heat a large volume of water, while heating the premises will be carried out with less intensity;

- rapid deposit formation on the serpentine tube requiring chemical or mechanical cleaning twice a year.

Then the heating of water will be carried out using electricity. In this case, you can turn on the boiler at night, when night, low tariffs are in effect, or as needed.

Making a boiler with your own hands

Due to the rather simple principle of operation, such a device can be made independently. Now let's look at how to make an indirect heating boiler with your own hands.

All work on the manufacture of a water heater consists of assembling the components of the structure:

Tank

A tank is used as the capacity of the boiler. Its volume depends on the needs of the owners of the house in hot water and is calculated from the amount of 50-70 liters per person daily. Approximately for a family of 4, a 200-liter boiler is suitable.

For the heating device, the tank must be made of stainless steel, aluminum alloys or other material resistant to corrosion. As an alternative - a gas cylinder, but its walls must first be cleaned and primed. Without this action, hot water will smell like gas.

5 holes are made in the tank: 2 on the side for mounting the coil, one at the bottom for the inlet pipe, one at the top for water extraction and one at the bottom for the drain tap. To use the boiler outside the heating season, it is necessary to provide for the installation of a heating element. A bottom hole is also drilled for it. Locking elements or ball valves are attached to the holes made.

Coil

A copper or brass tube is suitable for this element, the diameter and length of which depend on the volume of the tank. On average, for every 10 liters, 1.5 kW of heat output of the serpentine tube is calculated. You can use a tube made of metal-plastic or other metal with good heat dissipation.

The tube is wound in a spiral onto a cylindrical mandrel. To do this, you can take a log or a pipe of large diameter.

When winding the coil, it is important to monitor the turns:

- for the best contact of the heating surface of the tube with heated water, the coils should not touch each other;

- do not coil with excessive force, then it will not be easy to remove the coil from the mandrel.

- The number of turns on the coil is calculated from the volume and height of the tank.

thermal insulation

Outside, the tank must be covered with a layer of insulation. It is necessary to increase efficiency and reduce heat loss. To insulate the container, mounting foam, mineral wool or any other heat-insulating material that is attached to the base with wire, glue or strip ties is suitable. For a neat appearance, it is better to cover the tank body with thin sheet metal or foil insulation.

You can also insulate the tank with another container of a larger diameter. To do this, a do-it-yourself boiler is inserted into a large tank, and the wall, according to the principle of a thermos, is filled with insulating material or foam.

Installation

- the coil in the center or along the walls is mounted inside the tank, pipes are soldered to its inlet and outlet pipes;

- for a vertically standing boiler, supports are welded to the bottom, for a hinged device - “ears” loops;

- heating element is installed;

- the boiler is tightly closed with a lid;

- connecting the coil according to the scheme for manufacturing an indirect heating boiler with your own hands to the circuit of the heating system;

- connection of the inlet / outlet pipe for water;

- piping to the kitchen or bathroom at the draw-off point.

Using a boiler for a water supply system for heating a house

One of the frequently asked questions regarding the use of a boiler in a heating system is the following: is it possible to use a boiler that is designed to simply heat domestic water in a heating system. There is no single answer to this question - it all depends on how branched the heating system itself is and what additional equipment is used.

The water supply boiler is characterized in that both holes (both the cold water inlet and the hot water outlet) are located at the bottom, and both of these holes have a small diameter (most often it is 0.5 inches or about 1.2 cm ).

Such an arrangement of holes excludes the possibility of water moving through the heating system on its own, since here cold water will not constantly “drive out” hot water from the tank and force it to move through the pipes. But, in general, such a boiler can also be used in a heating system if it is supplemented with a circulation pump, which will be “responsible” for the movement of water through the heating system. The effectiveness of such a system depends on several factors:

- on how powerful the boiler itself is. Suitable power is usually determined at the rate of 1 kW per 10 square meters of heated area.

- on how much power the circulation pump has

- on how extensive the heating system of the house is. It is best if it does not have many branches.

As for the type of boiler, here you can use both instantaneous and storage water heaters.

So, heating a house with a boiler is not a fantasy at all, but a completely viable version of a heating system.The main thing when creating such a system is to accurately calculate the required boiler power, based on the size of the house. In some cases (for example, if the area of \u200b\u200bthe house is large enough), the efficiency of the system can be increased by expanding the inlet and outlet for water, as well as by upgrading the boiler itself to increase its capacity.

07/07/2013 at 20:07

Conclusions and useful video on the topic

A few video recommendations will help you better understand the device and the principle of operation of a homemade heat exchanger.

Video #1 Tips for making a model from pipes:

Video #2 Aluminum decking model:

Video #3 A simple option from improvised materials:

As you can see, to increase the efficiency of the stove in the garage, utility room or bath, you can not spend money on expensive appliances, but make an effective device with your own hands. To work, you will need skills in working with metal and an approximate assembly scheme.

Do you know how to make an original version of a heat exchanger for installation on a chimney with your own hands? Have questions while reading the information provided or have useful information for site visitors and us? Please write your comments in the box below.

The bath is part of the culture of our people, and every good owner thinks about the issue of providing hot water during construction. Of course, there are modern heating systems and automatic hot water supply, but they are expensive and sometimes such time-tested options as a tank on a pipe for a bath turn out to be more affordable and most importantly economical.