How to make a hole for a faucet in a stainless steel sink

From the author: I am glad to welcome you again, my dear readers! When we make repairs in the kitchen or in the bathroom, we will certainly encounter the installation of a sink.

For some people the hole underneath stainless steel sink faucet becomes a real mystery, which is quite difficult to solve.

I have repeatedly come across cases when a person decided on untested methods, thereby simply rendering an expensive product unusable.

One of my friends, who not only did not have special education and skills, but also did not even know how to hold a drill in his hands, decided to make such a hole with a hammer and chisel. Naturally, it turned out to be very crooked, and besides, more than it was necessary. When trying to correct his mistake, he deformed the shell so much that it could not be restored.

Be careful, now I will tell you two ways that will help you solve this problem.

Where to buy laboratory furniture at affordable prices

LLC "Innogen" is engaged in the sale and production of laboratory furniture. Today, the production of this company is in high demand in all CIS countries. The production facility is located on the territory of the Russian Federation, namely in the city of Pskov.

For the production of laboratory furniture, only high-quality and durable equipment for metal processing, as well as its painting, is used. It must be said that the laboratory furniture of the brand "Expert" received a quality mark, and is also fully certified according to all the requirements of GOST in Russia.

Over the past six months, I answered the question of how to make holes in stones, probably a dozen times. I decided to systematize it a bit and once again, in general terms, to tell - now without any individualism.

There is a very simple way - by ultrasound, but not everyone has the device, the ringing from it is worth, radiates, harmful and does not deliver pleasure - however, it works wonders quickly and in skillful hands. But we won’t even think about him, we are the old fashioned way

In relatively soft and not fragile stones - such as malachite, serpentine, lapis lazuli - you can make a hole just with a good metal drill - clamp the drill into a drill, put a pebble in water - fix it if possible - and go ahead. You can just keep a wet sponge next to the hole - the main thing is not to overheat.

If the hole is through, be sure to put it on another stone, it is even better to glue it with wax or paraffin, or at least with double-sided tape. Otherwise, there will be a chip at the exit.

With harder stones, the story is more complicated. Here you will already need a tubular, diamond-coated drill. They are also sold in special stores, such as "Sapphire" and in ordinary good household ones come across, and much cheaper. Their diameters are from 1-1.5 millimeters, up to 12-15, more is very rare and very specific. I have the most running 2-2.5 mm.

I immediately cut such drills - I cut off the shank a little - then the drill clamps deeper and does not hit, and this is very important

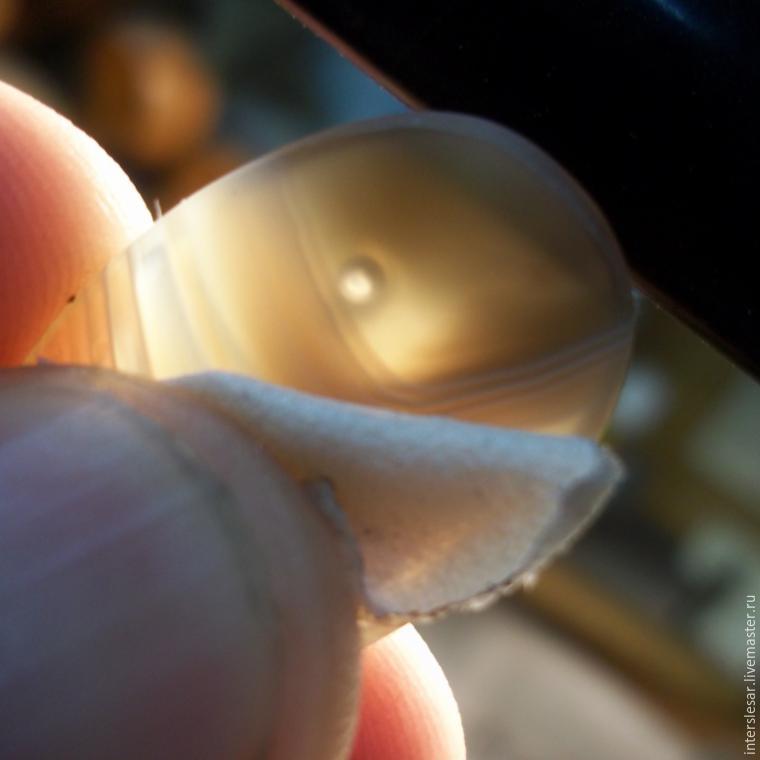

We take a stone, think of why we need it, choose a place, put a mark, seal the bottom with a band-aid and lower it into a bowl of water. Water is enough for two or three millimeters above the stone. The plaster will help the stone not to slip in the bowl and at least a little save it from chipping at the exit of the drill.

And we start at low speeds, slowly but surely, press down the drill in the right place

It is very important not to distort it. Every 15-20 seconds, the drill should be lifted - sludge is removed from the hole

After a few minutes, a groove is formed - and the drill is already receiving direction.

The drill blunts quite quickly, and does not even blunt - it “salts”, but this is very easy to solve - just put a piece of ordinary emery next to the stone and touch it from time to time with a drill.

When the drill deepens a few millimeters into the stone, it is desirable to break the core column that has formed with a pin, scriber, piece of iron and shake it out - then knocking it out of the drill is a little more difficult, although not a problem either.

When the hole tends to exit, you can start drilling from the other side, but this is only when increased requirements are placed on the quality of the hole.

A little more and the drill will go easily - it turned out, therefore, to the surface, which is what we need.

That, by and large, is all.

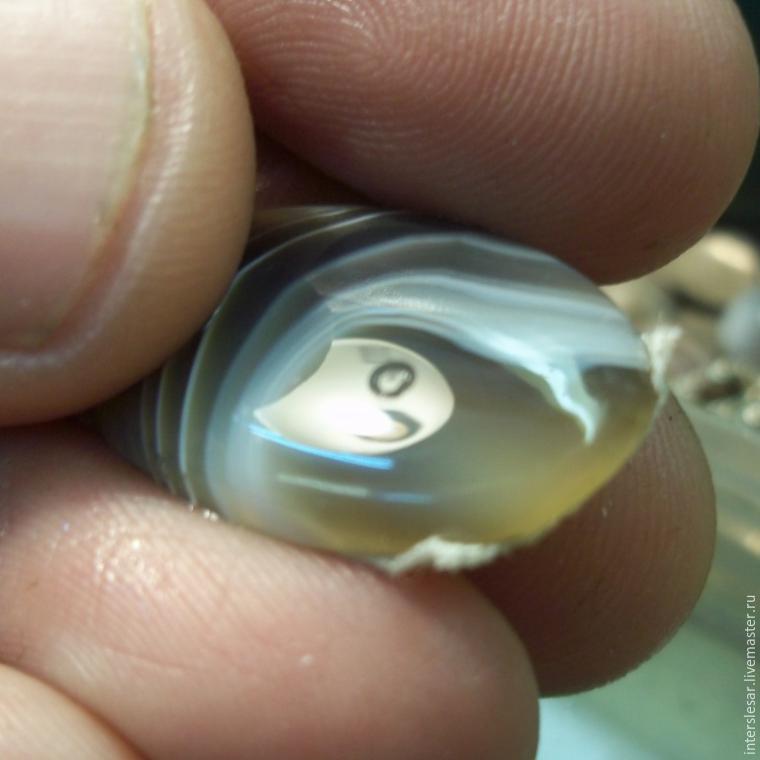

In this case, a 4 mm cabochon was drilled in about a quarter of an hour, but this drill has already made dozens of holes in agates and flints, the new one works faster.

Here on paper (on the screen) everything is quick and easy, in reality it is a little more complicated, and not even more difficult - you need to be prepared for the fact that it will start to work out normally somewhere in the fifth, sixth.

I’ll also pay attention to the following points - the drill is quite soft, its walls are thin, it must be extremely gently clamped into the cartridge. When you put aside the tip with the drill clamped so that it doesn’t cling to anything, it bends instantly and practically does not straighten to normal

After work, be sure to immediately clean it from the inside, otherwise the sludge will dry out and there will be problems in the future. It is also better to drill soft stones with such drills - carefully and with dignity. You can also drill with a conventional drill - it is better to put it on its side, and constantly dipping a pebble under the drill. And remember the rules for working with electrical appliances!

It seems to be possible on this and complete about the holes

And about this agate one of these days I will try to continue.

How to Drill a Hole in a Sink or Sink

When buying a new sink, the question often arises - how to drill a hole. The answers to this and related questions can be found in this article.

How to drill a hole in a ceramic sink

When does the question arise? Sinks without a hole were installed in Soviet bathrooms where there was one faucet per sink and bathtub. Recently, this option has been used less and less, but sometimes, with budget repairs, apartment owners want to save money on buying a new sink.

Sink without tap hole.

And so, you have a sink that does not have a hole. Working with ceramic sinks can seem like a daunting task, but you'll be fine if you follow the tips below. It's simple.

What are the basic rules for furniture in the laboratory

The most basic rule for laboratory furniture is that it should be ergonomic and practical. Conducting experiments and research of a different nature should be carried out in a convenient and well-planned environment. Different decor in such rooms is categorically unacceptable.

The second rule says that a table or any cabinet, whether it is retractable or not, should be simple and multifunctional. For any business, there must be certain furniture that will be responsible for a particular task. For example, a drying cabinet must be used only for drying.

The third rule is: laboratory furniture in Moscow

must be very strong, as it will have to withstand not simple loads. The strength of such furniture should be at the highest level, as a rule, laboratory furniture should be resistant to cracking. Often such furniture is made of durable material, such as plastic, metal or glass.

Best Answers

Nadezhda Golysheva:

the Swedish Mora fittings have a diameter of 32-36 mm.

Vladimir Petrov:

And you first buy a crane and then see what diameter to cut the hole so that with a margin

Santa Claus:

35mm

Oleg Zlanepomniyashchiy:

In any self-respecting firm of plumbing manufacturers, there is an instruction that is attached to the corresponding product.

Oleg Losev:

a 35mm drill usually comes with a sink ...

Sergei Anisimov:

In sinks a la stone with a wing, which can be placed with the trough located on the left or right, the set comes with a cutter for self-drilling a hole for the mixer on one side or the other, and so this cutter has a diameter of 35 mm.

Where to cut a hole

Another significant question that will arise no matter what materials the sink was purchased from is to cut a hole in it from the front side after the installation has taken place? Or do it before installation and from the back side?

Each method has a number of advantages and disadvantages.

In the first version, the edges on the front side will be much smoother, but there is a chance to spoil the front side of the sink with a drill, and if it has a narrow rim, then split the edge.

In another option, the risk of spoiling the bowl is much less, but there is a chance of getting a sloppy edge of the hole on the front side. In many cases, this is not a problem, since the edges of the hole are closed with a tap. When turning over, there is an option to casually make a hole on the wrong side, thanks to this it is best to highlight the side on which you want to install the faucet.

In any of the ways, it is best to place the hole further from the edge of the product, but at the same time, without hitting the bowl. To do this, at the beginning of work, you need to attach the lower nut of the water tap to the sink and highlight its center.

Differences of stone algomerate shells

If, for example, you purchased a sink made of stone agglomerate, it will be a little easier to work with it.

Artificial stone sink from agglomerate Well-known manufacturers in most cases attach a cutter or core, which knocks out a piece of stone that has already been drilled, but not completely. If they are not present, then a great option is to use a diamond-coated cutter or crown and proceed as you would when working with porcelain stoneware.

A fostner cutter will also handle a hole in a stone agglomerate product. But get ready for the fact that then it will need to be sharpened, or even completely thrown away.

Be sure to read the instructions and operating rules before taking any action so as not to inadvertently lose the product warranty.

Fake diamond

If the sink is implemented as a single piece with the countertop and the same color as it, then this is an acrylic decorative stone. Of the materials listed above, this one has the lowest density, which makes it the easiest to work with. If the purchased sink is actually made of artificial stone, then the answer to the question of how to drill a sink from acrylic stone is very simple - with traditional drills for working on metal or wood.

The hole for a typical faucet, in many cases, has a diameter of 35 mm. In a product made of artificial stone, it is easily drilled with a blade drill for woodworking or a forstner cutter of a similar diameter. You need to work at low or average speeds. When drilling into this material, the vast majority of chips will appear, and the plastic that is part of the artificial stone emits a bad smell, somewhat reminiscent of epoxy-based glue.

Acrylic stone sinkAcrylic stone is the softest of all acrylic stone options, due to which a significant part of the countertops is made from it. If there is a need to make a hole in it for a sink or hob, it is better to practice in advance in the middle of the cut-out part so as not to harm the entire countertop. Ignoring the fact that artificial stone is sawn with a jigsaw without big problems, it is undesirable to cut it with it.While working with a jigsaw, in other words, stress concentrators (sharp transitions, sharp corners, small cracks) often appear, which affect the life of the product.

If you are thinking about how to drill an acrylic stone countertop, then a milling cutter would be a great option, but it is not always available.

In this embodiment, it is allowed to cut a hole 5 mm smaller than necessary with a jigsaw. Once the work with the jigsaw is completed, bring it to a clean size with a milling cutter. Along the edges, it is imperative to make a chamfer R3, it will also reduce stress and increase the life of the countertop.

Additional information in this video.

Expert answers

Bulbosaurus:

Manufacturers of sinks made of artificial stone are a little cunning, declaring that such material corresponds to natural stone in terms of properties. In terms of properties, it may come close, but by no means in terms of strength. A sink made of artificial stone is essentially plastic, more precisely, a polymer mass mixed with stone chips. The proportions vary from 20 percent crumbs and 80 percent resin to 80 percent crumbs and 20 percent resin. In any case, drilling such material is much easier than natural stone. \

See here: How to drill a tap hole in an easylife.16mb m artificial stone sink/drill-stone-sink/

Valery.:

It is necessary to mark the circle of the hole of the required size with a marker and drill it with a drill along the marker with a dm 5mm drill,

daria kalashnikova:

drilled

NOT YET OLD:

Do not spoil the beauty, mount a wall-mounted faucet. Drill and you will have trouble - a place of constant leakage.

Andrey Kozmin:

stainless steel is easy to drill. there are special stepped drills, you can simply drill out according to the marking - then, anyway, the overlay closes. the main thing is what would happen according to the mixer.

yuri!!!:

I don’t know the thickness of the metal, but the principle is such a small drill in a circle, then a needle file, etc. if the metal is thin, then drill into the center and increase the metal with scissors.

Rogue of the Seas:

mark the circle under the mixer with a marker, carefully drill with a thin drill (3-4mm) along the inside of the marker, pick out with a stalemate

And I'm Fsia Taka Mysterious:

Cutter 32 mm for metal, it is placed in a drill! Pin a point with a dowel or nail in the place where the hole will be (there will be a crane). To do this, remove the sink. It is possible to embed the faucet directly into the countertop, the hole in the countertop should be treated with silicone.

Winds:

and these sinks are not provided for the hole)))

cons of stainless steel with holes - they bend and after a short time the fixing nut under the sink loosens and the mixer loosens - accordingly, there may be problems with rapid wear of the ge. gaskets and leaks..

a hole is drilled in the countertop, a cut is treated with silicone, a metal washer must be placed (glued) under the nut - the mixer will remain motionless - acc. more durable.

Sergey Romanov:

there are crowns for metal, we have a price for them in the range of 1500-1800, the hole turns out to be neat, but do not forget to pour plenty of water, otherwise the edge of the saw will darken, good advice was given to drill with a small drill, but not 5mm, take it thinner (it is cheaper than crowns)

REM2009:

Drill in the center 6mm and then with such a drill to the desired size. (slang for "carrot") This drill in thin sheet metal allows you to get round, even holes, drilling in other ways is laborious and requires additional effort to obtain a quality hole. (often used in car service)

the best of the best:

in the market where sinks are sold, there is a special device, such as a clamp. Immediately squeeze out a pretty hole for the mixer. The fact that the metal is thin, yes. It is better to put a mixer with two valves on such a sink, and if it is “one-handed”, then it is completely easy to move. Fastening is thin, the crane bends.

mikhalych:

and it’s not fate to put it on the countertop? there are no problems at all with drilling and installation .... at what from any party it is possible to establish.

Expert answers

psychologist:

crown of the appropriate size.

SNV:

draw a circle under the mixer. We drill with a small drill in a circle.

Vladislav:

The cutter is special, the cost is about 180 rubles, first with a drill, then with a cutter inserted into the drill we expand it to the required diameter, be careful, it cuts metal very quickly, so do not get carried away.

Yegorych:

Previously, holes were made in a circle by increasing the diameter of the drill and then with a file. Now there are many ways: 1. There are special drills in the form of a crown, for centering the drill in the middle, they are made of a special alloy. The base is common, the crowns vary depending on the diameter. Ask at the store where they sell the instrument. 2. There is a special press consisting of two halves, one with sharp uneven teeth and enters the second with a bolt. We drill a 10mm hole, insert the bolt and tighten the two halves with a key. It turns out a smooth, precise hole. Such pieces are included in the IKEA kitchen furniture set. My daughter gave me and I only work for her.

Andryha:

With a narrow chisel (I make 10-12 from a drill) just put a piece of wood under the bottom, for example. Breaks through easily.

Alexander Adamov:

I did this with a sharp drill bit. An ordinary drill for metal does not take a stainless steel.

Cornelius Schnapps:

Usually such holes are made right at the point of sale with a special press, but in practice it was necessary to cut a hole with a knife, such as a shoe from Rapid.

Vadim Mortin:

Drills are sold specifically for drilling stainless steel (by the way, there are also cutting wheels specially for stainless steel), Draw a circle on the sink with a felt-tip pen, drill holes along the line (putting a board under the bottom), then cut it out with a narrow chisel along the drilled holes and finally clean it with sandpaper wound on a round stick (a piece of a mop handle).

User deleted:

you can just go to the market where they sell them and punch a dark from the seller (it costs from 200 to 300 rubles) or buy a 35 fostner drill and drill carefully with a drill

ZZ:

drill and drill!

alexey:

There are special nozzles for drills of different diameters - ask at the store where drills are sold

John G:

special “notches” are sold on the construction markets; they are a stamp tightened with a threaded screed ...

STRELKA:

This device is called a bimetal crown, put it on a drill and drill at low speeds. The price of this crown is around 170-180r. And the metal will be washed through with a notch and the mixer will not stand up clearly.

Linda Bender:

a mojka iz kakogo materiala?esli granitovaja, to niche sverlit ne nado, nado prosto v nuzhnom meste udarit molotochkom.

aNAchoret:

If the sink is metal, go to the market or to the store and ask to squeeze a hole where you need it. Issue price -200 rubles. Or buy a hole punch from them. Issue price - 700-2500 rubles. If the sink is fragranite, take a drill with a diameter of 4-5 mm and first drill many holes in circles from the bottom of the sink. There is a milled ring with a diameter of 35 mm, and then carefully from the front! ! beat with a hammer and grind with a grinder. Or go to the market again and they will do it for you. You can also buy a 35 mm Fosner drill and make it. Issue price from 700 rubles.

Farhad Rzayev:

there is such a cool cone drill, as it was invented just for almost such purposes. for example, this is a direct attribute of car audio studios