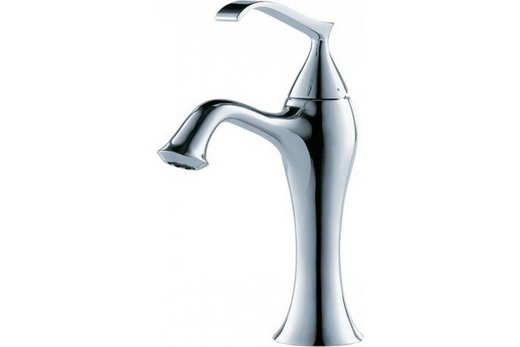

IDDIS Perfection CA56147C

- single lever mixer

- for kitchen (sink)

- brass body

- swivel spout

- nozzle-aerator

from 4000 rub. up to 6775 rubles.

stylish design

terribly splashes in all directions, although conceived for a flat jet

A comment

would gladly return.

after each turn on, you need to wipe everything around almost a meter from it from splashing (((I asked my friends, it turns out that all such taps splash.

Stylish design, original and very convenient opening handle

Noisy, splashes a lot

Interesting design.

Splashes horribly. Even with a little pressure, it splashes everything around the sink. After each use, you have to wipe everything around.

A comment

The perfect gift for an enemy.

High-quality, stylish, Russian plumbing.

Sprays water with a strong jet.

A comment

The mixer faithfully served for almost three years, is still alive. Quality and longevity are definitely the strengths of the Perfection. The design is pretty good. I also liked the handle for turning on the water, it is convenient to regulate the pressure. If in the process of washing dishes, hands in soap or something are busy, you can control the handle with your wrist, it is very convenient. With a strong jet, water begins to splash, this is a minus. You have to turn on the water carefully. You can get used to it, however, and in the end it does not greatly affect the convenience.

well built, reasonable price, design

sprinkles

A comment

I read the reviews before posting mine. As I see, the model has a common drawback, and at first I sinned that my individual copy was poured with water. Apparently the case when the functionality suffered due to the design. Now a few words about the good. The mixer is quite quiet in operation: plus I have a porcelain sink. If I wash the dishes in the kitchen, the child in the room will not wake up. For more than a year of use, it didn’t drip, didn’t break, there was no need to twist anything with a locksmith key or change consumables, which is good. The mixer is assembled with high quality, I am a techie by my first education. In general, if the manufacturer "finishes" the model, there will be a very decent mix. In the meantime, the existing minus makes us put a triple with a plus.

A comment

An interesting model and good quality, only splashes in all directions if you turn on the water strongly. There haven't been any problems so far.

A stone mixer is possible and such

Theoretically, Danila the master could carve a kitchen faucet out of malachite, but the price of such work would be like that of a cast-iron bridge from Moscow to St. Petersburg. Nevertheless, having a stone faucet in the kitchen or bathroom is a prestigious matter, and manufacturers meet the needs of buyers.

Mixer VGF4904 from Vigro

They go in a variety of ways. For example, the promoting website “Kitchen for Everyone” (http://kuhni-vsem.ru), recommending the products of the domestic company Vigro, reports that the faucets that make up the sinks made of artificial stone are painted with powder enamel, imitating the colors of certain types of stone.

Products of this type are relatively inexpensive. For example, the mixer VGF4904 goes for 3680 rubles, VGF41042 - 4550 rubles, VGF4070 - 6840 rubles. By properties, they do not differ from ordinary brass.

The manufacturer of the Edeny series faucets also, without any coquetry, informs that the brass body is coated with artificial marble. The same applies to Chinese faucets of the GranFest brand. Their price is low. For example, GranFest 3324 - 2500 rubles.

Faucet GranFest 0123 made in China

But other models of the same manufacturer are positioned as made of artificial stone. For example, GranFest 0123 for only 3050 rubles.

What is this artificial stone? How can such a sophisticated design as a ceramic mixer be made from it?

In a small investigation, materials on structural mixtures of the well-known German company Blanco will help. Their advertisement calls a certain Silgranit Puradur as a construction material. According to reference books, Silgranit is a mixture of 80% granite grains and 20% acrylic resin. Theoretically, such a compound has casting properties and simple parts can be cast from it.

Mixer Blanco Zenos S German production

What is happening: partly Blanco faucets are made of artificial stone, in the most critical parts - of brass with chrome plating. The price of such products: Blanco Zenos S - 26200 rubles, Blanco Yovis S - 32400 rubles.

Mixer Blanco Yovis S

It was not possible to find reviews specifically about faucets from Silgranit on the Web, but there are a lot of comments about Blanco sinks from this material. Consumers note the excellent appearance, but at the same time, they complain about chips, that stains from certain liquids (red wine, etc.) are poorly removed.

However, judging by the diversity of opinions, much depends on the accuracy of the users themselves.

To this we must add that Silgranit is the author's development of Blanco, protected by 7 patents. From what artificial stone the Chinese pour their ceramic mixers - it's hard to even guess.

Finally, a few words about DeStone products. DeStone faucets are a hollow column (cylindrical or in the form of a tetrahedral obelisk) made of natural marble with a spout and a control lever made of chrome-plated brass. It is not difficult to hide ordinary ceramic cartridges for mixing water in such a column. You only need machine equipment for turning marble.

The difference between bronze and brass

Bronze, like brass, is based on a copper component. Some grades of these alloys have a similar color parameter, but completely different properties. The bronze item has a structure of a coarse-grained type with a dark brown or reddish tint, in contrast to yellowish brass with a fine-grained form.

It should be noted that the presence of tin in a bronze alloy in large quantities gives it an almost white color. Modern compositions contain an alloying tin component or any other (beryllium, lead, aluminum, silicon with zinc). Numerous things made of brass and bronze have differences, which can be determined by knowing their technical parameters.

Metal objects made of brass and bronze are distinguished by weight. A bronze thing is heavier than a brass one, however, before determining the alloy, it is necessary to take products of the approximate same size for comparison. To determine what material a thing is made of, you must try to bend it. A brass object can succumb slightly, and bronze can break. You can try to make a small saw with a hacksaw, in which the bronze part will produce small chips. It will not change its characteristics when heated.

To understand how to distinguish brass from bronze, you can apply the chemical method. A small number of chips of both alloys are placed in different glass containers with dilute type nitric acid (parts 1 to 1). It is necessary to wait some time so that the bulk of the metal has time to dissolve in the chemical composition. The liquid that does not reach a boil is kept on low heat for half an hour. In the composition with bronze shavings, a whitish tin precipitate is formed.

Bronze is used for the manufacture of large items, as it is more resistant to abrasion. In addition, a variety of marine accessories are also made from this alloy, which is not afraid of exposure to salt water, is not subject to oxides and does not rust.

Summary of the article.

When buying a mixer, pay attention to the following parameters:

- Faucet Weight – The faucet should be heavy.

- Material - the mixer must be made of brass. DO NOT BUY SILUMIN MIXERS.

- The coating on the faucet should be even, shiny and free from stains.

- Ceramic cartridge and ceramic faucet boxes - these elements will ensure a long service life of the mixer.

On store shelves, products from silumin are increasingly coming across. It can be pans, pots, faucets and other items. This material is obtained artificially, the answer to the question is more detailed:

silumin - what is it

you will find in the article below.

Alloy groups

Silumin alloys

are divided into several groups. Such a distinction is made according to the purpose of the materials:

- AK 12 is a eutectic silumin, it contains silicon in the amount of 12%. During heat treatment, the casting does not harden and does not become hard during shrinkage. Parts made of this material are structurally designed for hermetically sealed low-load devices.

- Highly alloyed hypereutectic silumin is marked, for example, AK4M5. It belongs to the piston group, it is used when performing work with high-temperature conditions. It has high resistance to high temperatures and wear resistance. The use of this alloy for critical products operating under high loads. These are large and critical parts.

Steel mixers the main thing is that the stainless steel is stainless

Have you ever wondered why stainless steel faucets are so rare? The material is excellent in every way!

Schein stainless steel faucet

Firstly, the mixer is a rather complicated part in terms of configuration, and stainless steel is difficult to process. That is, high-quality steel mixers can be produced only by enterprises of high technological culture. And there are few of them.

Secondly, the “stainless tap” is sensitive to water quality. A filter should be installed in front of it.

Omoikiri Takamatsu stainless steel faucet

Faucets made of materials such as bronze, copper, etc., or finished in these materials, are often marketed as antiques. Read more about such gadgets in the article on our website "Retro Mixer"

The traditional supplier of faucets finished in bronze is East Asia. Read about Chinese mixers here: http://remontspravka.com/china-mixers/

German products in the Russian Federation have always had the features of elitism. Faucets made in Germany are covered in a separate review on our website

But if you are lucky and you are not too lazy to apply filters, then stainless steel faucets are beyond praise.

Mixer made of steel-stainless steel Zorg

Another iron alloy - cast iron - was once one of the main materials for plumbing, but is now out of use. It is impossible to meet a “cast iron faucet” at home, in the kitchen or in the bathroom in our time. For domestic needs, this material is too fragile; casting and machining it are expensive.

How to repair silumin products

How to glue silumin

? To restore the appearance, you can apply epoxy glue. But at the same time, it should be borne in mind that under increased loads this product will not work.

Operation technology:

- Degrease the places for gluing and dry a little.

- Dilute the adhesive in the appropriate consistency and apply to the surface intended for gluing.

- Connect the parts of the product and make efforts, then leave for a day at rest.

Silumin repair by welding

It is wrong to think that

silumin welding

is an easy process that anyone can do.

When welding products, many questions can arise. The material heats up quickly, as a result of which an oxide film begins to appear. This phenomenon will not allow the parts of the product to connect. Therefore, the choice was made in favor of welding with argon, since it is this gas that provides protection from external negative factors during operations. The alloy will better restore and strengthen the structure.

How to weld silumin?

Process description:

- Prepare electrodes for welding, tungsten non-consumable ones are suitable for these purposes. For welding products, it is recommended to use solders: HTS-2000, Harris-52 or ER 4043, designed for welding aluminum structures.

- Degrease the edges to be welded.

- To ensure reliable weldability, the part must be fixed in a rigid fixture.

-

Before carrying out welding work, the surface should be heated up to 220

0

C. Steel spacers should be used to dissipate heat. - Carrying out welding work. Alternating current is used for surface welding. The work is done manually.

After work, the products can be operated at reduced loads.

Before the actual

silumin welding at home

It is recommended to practice on samples.

Materials from which mixers are made.

Modern mixers are made mainly of two materials:

- Silumin is an alloy of aluminum and silicon. It is made from Chinese low-quality faucets. The main disadvantage of this material is its fragility (it can literally be broken with bare hands). The silumin mixer is easily recognizable by its light weight and low price. In appearance, it will be nondescript - with poor, cheap coverage and backlash

- Brass is an alloy of copper and zinc. Strong and expensive material. Faucets made from it are more expensive, but they can last five or more years without the need for repair. A brass faucet can also be identified by weight, but only in its case this weight will be impressive. There is a large selection of European and Chinese brass faucets on the market.

For those who doubt, I post a video from HansGrohe, which shows the process of making a real brass mixer. This is how plumbing is done in Europe. High-quality materials and expensive, skilled labor are used here.

European or Chinese faucet

From my sales experience, I can say that European manufacturers are superior in quality to Chinese ones, but among the latter, you can also pick up worthy specimens. The trouble is that our importers prefer to buy low-quality goods from China at low prices and get more profit from it. At the same time, the Chinese product has a negative image, although, in fact, there are worthy specimens that are not inferior to well-known European brands. I can also tell you a secret - some European manufacturers have long moved production to China. Thus, they achieved cost reduction without loss of product quality.

To distinguish brass from silumin, you need

It is important to pay attention to the material from which the mixer is made. All experts unequivocally advise choosing faucets made of brass (a multicomponent copper-based alloy), but at the same time they warn: 90% of plumbing products in this category are fakes made of silumin (aluminum alloy with flint)

In appearance, it is difficult for a simple buyer to distinguish a brass mixer from a cheap counterpart from silumin, since the mixers are covered with chrome on top. Externally, the products are actually the same, so be guided by the following criteria:

- First, ask the salesperson to show you some brass faucets. Take them in hand. If the mixer is made of high-quality metal, it is heavy and weighty - about 3 kg, if made of silumin - light.

- Secondly, look into the inside of the mixer - for a brass product, it should be yellow and smooth.

By the way, the Chinese craftsmen have learned to make silumin mixers very similar to their brass counterparts. Therefore, there is another criterion that will help determine the mixer material:

- All brass products are made by casting, only after that they are machined. Therefore, there is not a single joint inside the brass mixer, the surface is smooth, there are no roughnesses. Silumin faucets cannot be made by casting. This alloy is very brittle, all joints and roughness will be visible on it. Carefully inspect the mixer.We noticed joints, roughness, indentations - this is not brass in front of you.

- There is another clue - labeling. Brass is marked with the letter "L", silumin - "AL". This information can be found in the technical data, where the material of the product is indicated.

- Brass faucets are made without any frills, frills and "flowers". The manufacturing technology does not allow to "bend" the copper alloy, like powder silumin.

Thus, in order to distinguish brass from silumin, you need to carefully consider and “feel” the product, familiarize yourself with the documents for the mixer.

Kitchen faucet device

A mixer is a plumbing device designed to mix flows coming through pipes of cold and hot water supply and, as a result, obtain a jet of water of the required temperature. To implement this task, the following types of control mechanisms are used:

- valve. The classic solution, the regulation of water flows in which is carried out by turning two crane boxes (valves). This is at the same time the most common and most unreliable option - the service life of the sealing elements (gaskets) does not exceed 6 months, after which the taps begin to leak. The main feature of the faucet mixer for kitchen is the gasket material: rubber or ceramic.

- Lever. Adjusting the pressure and temperature of the water at the outlet of the mixer is carried out by turning a special lever, inside of which there is a cartridge mechanism. It is much more convenient to use a lever mixer than a valve one: you can adjust the pressure and temperature with one hand.

- Sensory. This mixer has no external adjustment elements (lever or valve) - the desired parameters are set once during installation using a special screw. There is a sensor element on the spout that reacts to the approach of hands and turns on the water. More advanced models are able to change the pressure of water and its temperature depending on the distance to the hands.

Regardless of the type of control mechanism, the design of the kitchen faucet includes a spout (also called a gander), flexible connections for connecting to water pipes and an aerator (divider) - a mesh put on the spout that breaks the jet. In addition, faucets can be equipped with dispensers for liquid soap and detergent, a flexible hose, a spout for filtered water and other “bells and whistles”.