How to make a serpentine

The coil is an important part of the device. It can be based on a metal or metal-plastic pipe with a small diameter

As a rule, copper or brass are used, as they have a high level of heat transfer. The manufacturer can choose the diameter of the coil at his discretion. The main condition is that its contact with water should be maximum.

The serpentine tube is wound in a spiral onto a cylinder-shaped mandrel. For this purpose, a log or pipe with a large diameter is used. When winding the coil, it is necessary to monitor the turns. They must not touch each other.

Do not make the winding tight, as it will be very difficult to remove the coil from the mandrel.

The number of turns on the coil is directly dependent on the volume and height of the tank. As a rule, for every 10 liters, 1.5 kW of heat output of the coil is used.

What you need to know about security

Do not forget that we are dealing with a source of increased danger - an electric heater, so when assembling and using it, you must follow some rules:

Be sure to use a separate electrical line to connect the induction boiler, and also equip it with a safety group.

- If water circulates naturally in the boiler, then be sure to equip it with a temperature sensor so that the device turns off automatically when overheated.

- Do not plug a homemade water heater into a power outlet; it is better to run a separate line for this with an increased cable cross section.

- All exposed wires must be insulated to protect people from electric shock or burns.

- Never turn on the inductor if the pipe is not filled with water. Otherwise, the pipe will melt, and the device will close, or it may even catch fire.

- The device must be mounted at a height of 80 cm from the floor, but so that about 30 cm remains to the ceiling. Also, you should not install it in a residential area, since the electromagnetic field has a bad effect on people's health.

- Don't forget to ground the inductor.

- Be sure to connect the device through the machine so that in the event of an accident, the latter will turn off the power from the water heater.

- A safety valve must be installed in the pipeline system, which will automatically reduce the pressure in the system.

The law is that the drawbar, where they turn in and out

The design on YouTube is not illegal, but it is not very convenient. Even less likely to correctly configure it for use. Here are a couple of tips to help you do just that:

The radiator in the video resembles something from the hood of a car. There was no time to figure out what exactly it was, but the point is that you will need not just a coil, but just such a corrugated surface. This will significantly increase the efficiency of the device, which ultimately determines both the efficiency and the gas fee (if there is a meter).

This appliance is a flow type gas water heater, which should produce about 4 liters of warm water per minute. It is easy to calculate how much power it should have for this:

N \u003d A / t \u003d (4200 x 4 (45 - 8)) / 60 \u003d 10.36 kW, this is the power achievable for a factory gas water heater. Whether it will be possible to make an appropriate heat exchanger at home, you can find out only by trying.

The device itself is a coil, which is connected at one end to a cold riser, and at the other to a shower head or faucet. The flow is controlled by a valve. In this sense, you will have to use an old cast-iron valve at the inlet or a bronze one at the outlet of the coil.The radiator is placed on the grate of the hob and heated by one or two burners. It is clear that the hose must be heat-resistant, otherwise various unpleasant consequences are possible.

An adult must supervise the operation of the device and, in case of danger, turn off the blue fuel supply while someone is washing or doing the dishes. A gas water heater or an electric water heater is much safer from this point of view. I would also like to add that even purchased equipment needs to be configured, which means that the intervention of a qualified craftsman will be required. Sometimes a set of jets (nozzles) is subject to replacement, in other cases a gearbox is placed in the gas supply path. In the latter case, the system resembles a traditional propane-butane supply.

How to assemble an induction boiler yourself

The modern market for heating devices represents a large selection of different models of induction heaters for both domestic and industrial use. Despite the fact that today such equipment has not reached the level of widespread use in heating systems, its cost is high. The price for household boilers starts from 25,000 rubles, and for industrial ones - from 100,000 rubles.

In order to save money, you can make an induction heater with your own hands. Even a non-specialist can do such work.

Device with a welding inverter and plastic pipes

All materials and components that are used for assembly are available and are often at hand. What is needed for this:

- wire rod or stainless steel wire (diameter up to 0.7 cm);

- copper wire;

- metal grid;

- a fragment of a plastic pipe with thick walls for the heater body (inside diameter 5 cm);

- welding machine;

- adapters for mounting the boiler to the heating system;

- tools;

- pump to circulate water.

Stainless steel wire must be cut into pieces 0.5-0.7 cm long. Fill the plastic pipe tightly with them and close it on both sides. It should not have free space. A metal mesh is installed at the bottom of the tube, which allows you to keep the steel particles inside.

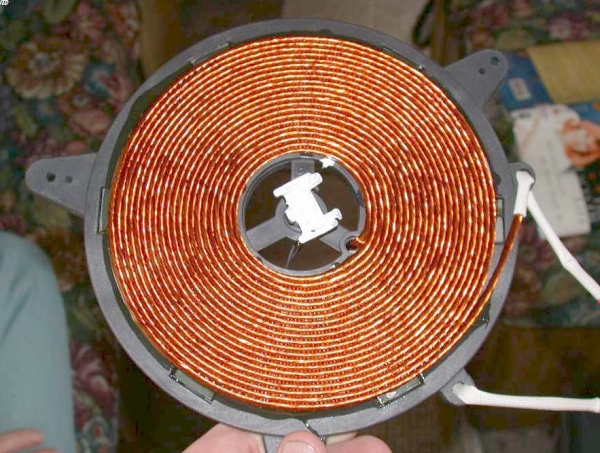

Next, you should make the main heating component - an induction coil. Copper wire is wound on a plastic pipe. It is necessary to make at least 100 neat turns at the same distance from each other. Then the induction coil is connected to the individual heating system. The boiler is installed in any part of the pipeline. To pump water, you need to build a pump.

A home-made device is connected with an external copper winding to the inverter. Be sure to carry out work on electrical insulation and thermal insulation of the boiler. All open areas are covered with special material. Basalt wool is used for insulation. This is necessary in order to heat the pipe without losing heat energy to the air.

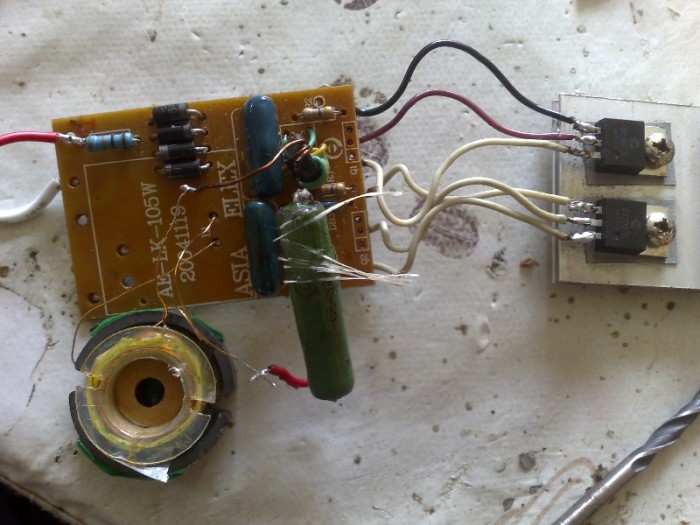

Device with transformer

This option is easier to assemble than the previous one. What you need to make your own hands:

- three-phase transformer with the possibility of mounting;

- welding machine;

- copper winding.

It is necessary to insert the pipes one into the other, weld. The sectional design should resemble the shape of a donut. It performs two tasks at the same time - a heating element and a conductor. Then the heater body is wrapped with copper wire and connected to the transformer. To prevent heat loss during operation, a protective casing can be built on the boiler.

Induction heating is a good alternative to standard heating systems. Its efficiency is about 97% efficiency. Such systems are economical, operate on any liquid, operate silently, do not emit harmful substances.

If the assembly rules are followed, the boilers are safe to operate. They are durable.But if any element becomes unusable, replacing it will not be difficult. All materials are easily replaceable and available.

Advantages of induction type units

The undoubted advantages of this type of home heating devices include the following characteristics:

- efficiency - the processing of electrical energy into heat occurs almost completely without significant losses;

- ease of use - constant maintenance of units of this type is not required;

- compact dimensions - induction water heaters are small in size, they can be installed in the heating system in almost any room;

- quietness in operation - this equipment operates quite quietly, no noise occurs during its operation;

- long service life - induction units are durable, can function uninterruptedly for 30 years or more;

- high environmental performance - no harmful emissions occur during the operation of the device, a chimney and a ventilation system are not required.

Many people think that induction boilers are much more profitable than other home heating options. And compared to equipment equipped with heating elements, the heating time of these units is almost twice as fast. Due to the constant circulation and vibration of the liquid, scale does not form in the pipes and inside the device, which greatly facilitates the maintenance and care of the heating system.

But this type of device also has some disadvantages. And the main disadvantage is that induction equipment is quite expensive in terms of cost. But you can try to make such a heater for heating the house yourself.

Pros and cons of induction devices for heating water

The device has a fairly simple design and does not require special documents allowing the use and installation. The induction water heater has a high degree of efficiency and optimum reliability for the user. When using it as a boiler for heating, you don’t even need to install a pump, since water flows through the pipes due to convection (when heated, the liquid practically turns into steam).

Also, the device has a number of advantages, which distinguishes it from other types of water heaters. So, induction heater:

- much cheaper than their counterparts, such a device can be easily assembled independently;

- completely silent (although the coil vibrates during operation, this vibration is not noticeable to a person);

- vibrates during operation, due to which dirt and scale do not stick to its walls, and therefore does not need to be cleaned;

- has a heat generator that can be easily sealed due to the principle of operation: the coolant is inside the heating element and the energy is transferred to the heater through an electromagnetic field, no contacts are needed; therefore, sealing gum, seals and other elements that can quickly deteriorate or leak will not be needed;

- there is simply nothing to break in the heat generator, since the water is heated by an ordinary pipe, which is unable to deteriorate or burn out, unlike a heating element;

Despite the huge number of advantages, the induction water heater has a number of disadvantages:

- the first and most painful for the owners is the electricity bill; the device cannot be called economical, so you have to pay a decent amount of time for its use;

- secondly, the device gets very hot and heats up not only itself, but also the surrounding space, so it is better not to touch the body of the heat generator during its operation;

- thirdly, the device has an extremely high efficiency and heat dissipation, therefore, when using it, be sure to install a temperature sensor, otherwise the system may explode.

Other ways to make a water heater

You can build a water heater that operates from the sun. This is a fairly common design, which is distinguished by efficiency. The device is often found in country houses. Making the device is not particularly difficult, so many can build it with their own hands.

- large capacity tank (100 l or more);

- PVC pipes for filling the tank and supplying water to it;

- 20 mm steel corners or 50 mm square wooden bars for a frame for a container.

As a container, it is more expedient to use polyethylene barrels. They are distinguished by strength. They should stand in a sunny place where there is no wind. As a rule, the summer shower roof is chosen for installation.

In order for the barrel to heat up better, it must be painted black. Screens are mounted on the leeward side for protection. They are constructed from boards covered with reflective material like foil. In this case, the sun's rays are directed to the tank and increase the temperature of the water. In hot weather, in a container of 200 liters, you can get water, the temperature of which will be 45 ºС.

Homemade induction boilers

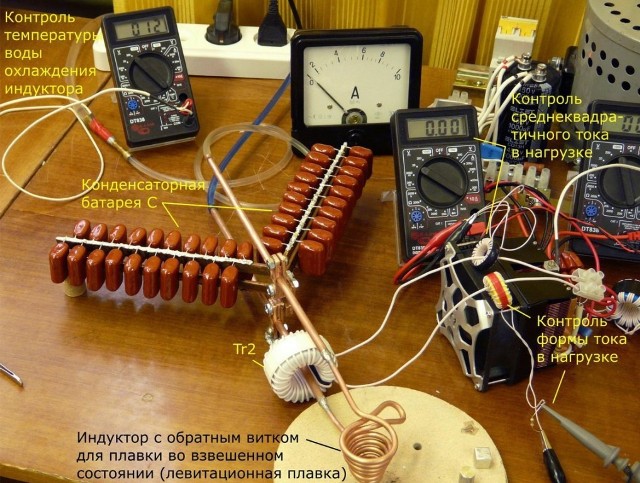

The simplest scheme of the device, which is assembled, consists of a piece of plastic pipe, into the cavity of which various metal elements are laid in order to create a core. It can be a thin stainless wire rolled into balls, chopped into small pieces of wire - wire rod with a diameter of 6-8 mm, or even a drill with a diameter corresponding to the internal size of the pipe. Outside, fiberglass sticks are glued to it, and a wire 1.5–1.7 mm thick is wound on them in glass insulation. The length of the wire is about 11 m. The manufacturing technology can be studied by watching the video:

Then a home-made induction heater was tested by filling it with water and connecting it to a factory-made ORION induction hob with a power of 2 kW instead of a standard inductor. The test results are shown in the following video:

Other masters recommend taking a low-power welding inverter as a source by connecting the terminals of the secondary winding to the coil terminals. If you carefully study the work done by the author, then the following conclusions arise:

- The author did a good job and his product, of course, works.

- No calculations were made for the thickness of the wire, the number and diameter of the turns of the coil. The winding parameters were taken by analogy with the hob, respectively, the induction water heater will turn out with a power of not more than 2 kW.

- In the best case, a home-made unit will be able to heat water for two heating radiators of 1 kW each, this is enough to heat one room. In the worst case, the heating will be weak or disappear altogether, because the tests were carried out without a coolant flow.

It is difficult to draw more precise conclusions due to the lack of information about further tests of the device. Another way to independently organize induction water heating for heating is shown in the following video:

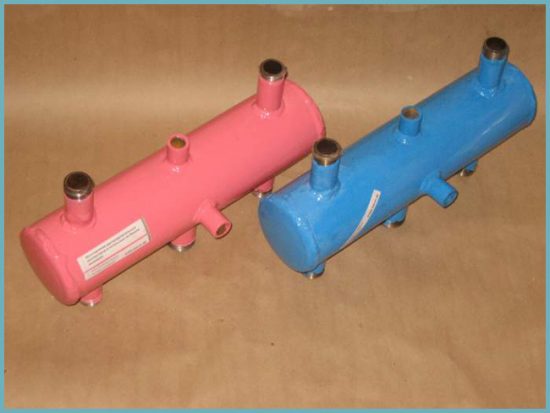

A radiator welded from several metal pipes acts as an external core for eddy currents created by the coil of the same induction hob. The conclusions are as follows:

- The thermal power of the resulting heater does not exceed the electrical power of the panel.

- The number and size of the tubes were chosen at random, but provided sufficient surface for the transfer of heat generated from the eddy currents.

- This scheme of the induction heater proved to be successful for the specific case when the apartment is surrounded by the premises of other heated apartments. In addition, the author did not show the operation of the installation in the cold season with fixing the air temperature in the rooms.

To confirm the conclusions made, it is proposed to watch a video where the author tried to use a similar heater in a separate insulated building:

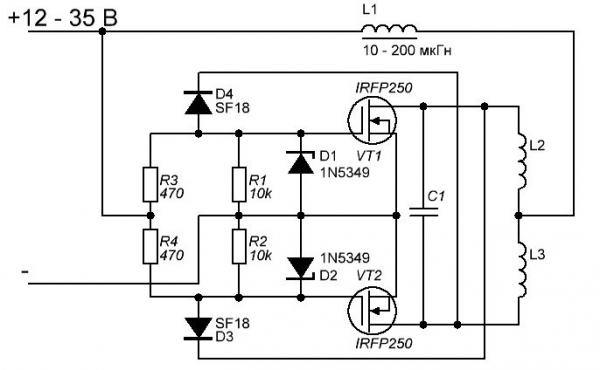

Do-it-yourself induction water heater diagram

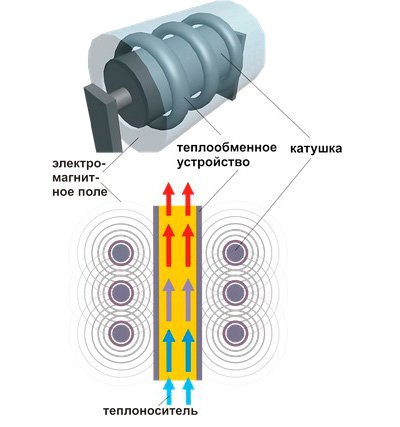

The device is a transformer having two windings: primary and secondary. The first circuit converts electrical energy into eddy currents, thereby creating a directional induction field, which provides induction heating. On the secondary circuit, the converted energy is transferred to the coolant (in our case, it is water).

In addition to the transformer, the device has a generator and a pump (optional).

Units and parts of the heat generator

The device includes:

- an alternator that increases the frequency of the current;

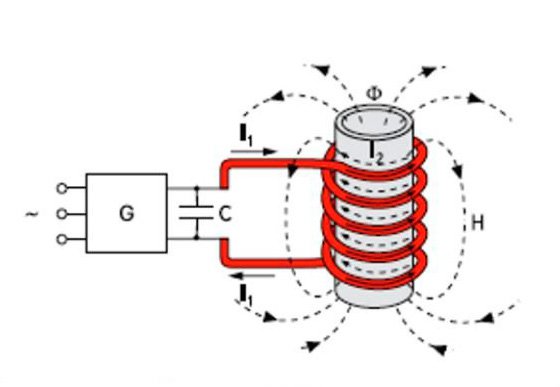

- an inductor that transforms electricity into magnetic energy is a coil of copper wire;

- heating element, most often its role is played by a metal pipe.

Principle of operation

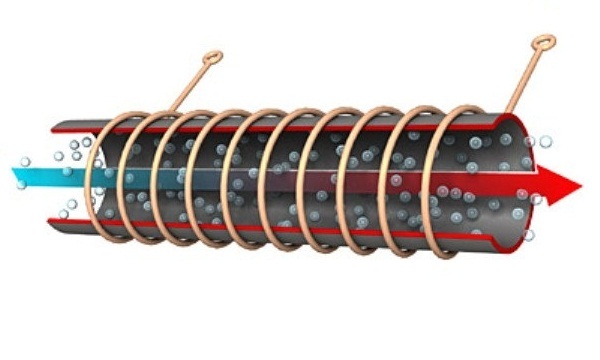

The induction water heater consists of a generator, a coil and a core, the latter is heated by electromagnetic energy.

The device converts electrical energy into electromagnetic energy. The latter, in turn, acts on the core (pipe), which heats up and transfers thermal energy to the water. All these energies are converted by an inductor consisting of a coil and a core. The generator is used to increase the frequency of the current, since it is difficult to achieve high heating with a standard frequency of 50 Hz.

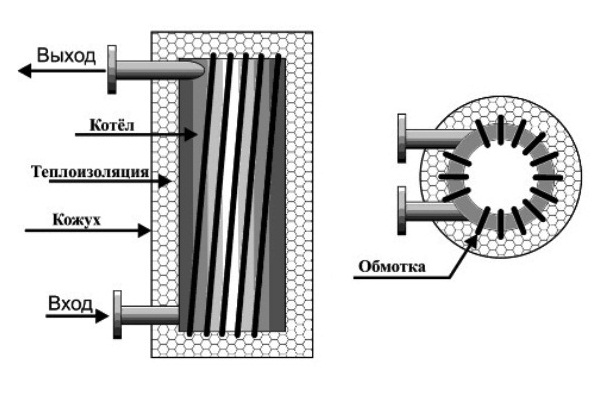

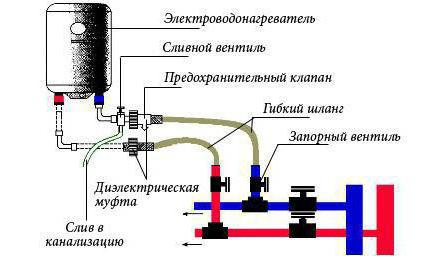

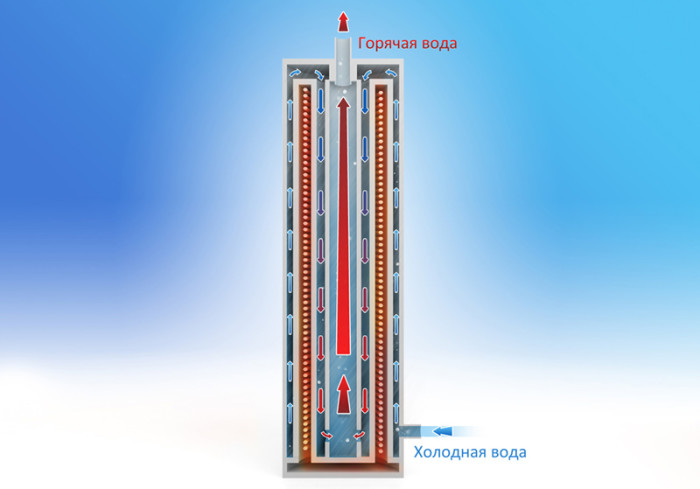

Design of an indirect heating boiler

An indirect heating boiler is a storage tank that is not dependent on energy resources (gas, electricity, etc.). Inside the tank, made of stainless steel, there is a heating element in the form of a spiral.

Cold water enters the tank through the inlet pipe located at the bottom of the device. Heating of water in the unit is carried out by means of the moving heat carrier of system of heating. The outlet pipe for hot water is located at the top. To make the use of the tank convenient, it is equipped with ball valves. The outer part of the device is covered with heat-insulating material.

The diagram of the water heater is shown below.

The advantages of the unit include:

- possibility of connection to the central heating system;

- installation near the heating boiler;

- small cash costs when installing the circuit;

- economical use of energy resources;

- water supply with a constant temperature indicator.

Do-it-yourself flowing induction water heater

Before proceeding with the installation, you need to stock up on the necessary parts. So, the best option would be a welding high-frequency inverter, smoothly changing the current range. Such a device will cost the least. A more expensive option would be a three-phase transformer, which is the AC power source for the water heater inductor. In this case, it is worth using a coil of 50-90 turns, and as a material, take copper wire with a diameter of 3 or more millimeters.

As a core, you can use both a metal and a polymer pipe along with a wire (it is used as a heating element). In the latter case, the thickness of the walls should not be less than 3 mm in order to calmly withstand high temperatures.

To assemble the water heater, you will need: wire cutters, screwdrivers, a soldering iron and a welding machine if a metal pipe is used.

Installation of an induction water heater

Wrap the pipe with copper wire, making about 90 turns.

There are many options for assembling the device. We suggest trying to assemble the device according to the following scheme:

- Prepare the workplace, materials and tools.

- Fix a small piece of polymer pipe (remember that the minimum wall thickness should be 3 mm).

- Trim the ends of the core to leave 10 cm of spare wire for the taps.

- Mount a corner on the lower outlet.In the future, the return from the heating should be connected here (if the heater is used as a boiler).

- Lay the chopped wire tightly around the pipe. It is necessary to make at least 90 turns.

- Install a tee on the top pipe through which hot water will exit.

- Mount the protective circuit of the device. It can be made from both polymer and metal.

- Connect copper wire to the water heater terminals, then fill the core with water.

- Check the functionality of the inductor.

The main types of breakdowns

Modern manufacturers have learned to create excellent luxury water heating equipment. For efficient operation, it uses gas, rarely fails. However, even the best gas heaters cannot avoid breakdowns. The list of unavoidable faults includes:

- water leaks;

- poor heating of the liquid;

- discharging power elements;

- weak water pressure;

- no gas.

Owners of gas boilers can repair some malfunctions on their own. Any person can change the batteries in the power device. It is also easy to eliminate the weak water pressure - perhaps just excessive scale has formed in the heat exchanger. To remove it, remove the heat exchanger and rinse thoroughly. You can also use special descaling fluids for this purpose.

It is not difficult to solve the problem of poor water heating on your own. The main cause of such a malfunction is often soot contamination of the heat exchanger. The elimination of this problem lies in the removal of the mentioned element and the removal of plaque. In case of more significant malfunctions, you should contact professionals.

The main types of breakdowns

Modern manufacturers have learned how to create excellent luxury water heating equipment. For efficient operation, it uses gas, rarely fails. However, even the best gas heaters cannot avoid breakdowns. The list of unavoidable faults includes:

- water leaks;

- poor heating of the liquid;

- discharging power elements;

- weak water pressure;

- no gas.

Owners of gas boilers can repair some malfunctions on their own. Any person can change the batteries in the power device. It is also easy to eliminate the weak water pressure - perhaps just excessive scale has formed in the heat exchanger. To remove it, remove the heat exchanger and rinse thoroughly. You can also use special descaling fluids for this purpose.

It is not difficult to solve the problem of poor water heating on your own. The main cause of such a malfunction is often soot contamination of the heat exchanger. The elimination of this problem lies in the removal of the mentioned element and the removal of plaque. In case of more significant malfunctions, you should contact professionals.

Those who have seen enough of the video on YouTube about a homemade gas water heater, which consisted of a coil placed directly on the hob in the kitchen, have probably already been dreaming about how you can get a lot of boiling water cheaply. In fact this is not true. Today we will talk about why you should not do a gas water heater with your own hands.

Work principles

To assemble an induction boiler with your own hands, you need to study what it consists of and understand the principles of its operation.

The device heats up due to the energy of the electromagnetic field. The coolant takes it on itself and converts it into heat.

The magnetic field is created in the inductor (this is a cylindrical coil with a large number of turns). Passing through it, electricity creates a voltage around itself. The magnetic flux moves in a vicious circle perpendicular to the electric field. Alternating current creates eddy currents and generates energy into heat.Electricity is transferred to the heater without direct contact.

Induction heat is used efficiently and economically, so water with this method of heating reaches high temperatures in a short period of time. The coolant receives about 97% of the energy.

Components of an induction water heater

The organization of the heating system in your own house with the help of an induction boiler will not require its major redevelopment. The basis uses a transformer consisting of primary and secondary windings.

Vortex flows are formed in the primary winding from electrical energy and create an electromagnetic field. It falls on the secondary, which has the function of a heater.

The secondary winding is the boiler body. It includes elements such as:

- external winding;

- core;

- electrical insulation;

- thermal insulation.

To supply cold water to the device and remove warm water to the heating system, two pipes are installed to the water heater. The lower one is mounted on the inlet section, and the upper one on the hot water outlet part.

The heat generated by the boiler is transferred to the coolant. Most often, water acts as its quality, as it is able to quickly take away heat. Due to the built-in pump, hot water enters the heating system through the pipe. The liquid constantly circulates, so overheating of the equipment is not possible. Cooled water is supplied, and hot water is discharged.

During circulation, the heating fluid vibrates, which prevents scale deposits inside the pipes. You can install an induction water heater in any room, since no noise is created during operation.

Conclusion

The rapid rise in the cost of energy resources is forcing many to create cheap alternative devices. Many build a water heater with their own hands and create comfort at minimal cost.

A water heater is a device designed to transform various kinds of energy into heat, which is then transferred to a coolant, which is water. The industry offers various options for such devices. The heat source in them can be electricity, gas, solid or diesel fuel. Along with this, alternative energy sources are becoming popular - the sun, wind.

All heating systems on the market are divided into two types:

The design of the first involves the use of a tank in which a certain temperature is maintained. When the tap is opened, cold water enters the sealed container, and hot water is squeezed out into the pipeline. Thus, in the middle of the tank there is always a certain amount of heated coolant. Storage units differ in their size and long-term heating of water. Their use is justified in systems with a large number of water intake points. Devices are produced with a tank volume from 10 to 200 liters.

Flow devices have a completely different principle of operation. In them, the water is heated only in the case of its circulation, that is, when the tap is opened. Their advantage is in small dimensions and easy installation. Of the significant drawbacks, there is a large power required for the rapid heating of water.

At the same time, if several water intake points are used at the same time, the tank will not be able to provide uniform heating and the temperature of the coolant will begin to change abruptly. In practice, it will take from 30 seconds to 2 minutes for water to flow from the tap at a normal temperature.

The heat carrier is heated using a gas burner located at the bottom of the tank, or an electric heating element (TEH). But there are also products that use a water or steam exchanger to maintain the temperature of the coolant.

In addition to the tank and heat source, the design of the storage device includes:

- 1. Temperature control device. This is a set of devices designed to maintain the set heating value. The most commonly used temperature sensors are connected to the electronics unit, which controls the on and off of the heating system.

- 2. Protection. To avoid the increase in pressure inside the tank, which occurs due to the expansion of heated water, various devices are used. It can be either an additional expansion tank or a safety valve. In addition, depending on the source of heating, a complex of protective devices is used to prevent gas leakage and current breakdown to the case.

- 3. Trumpet. Two pipes are used in water heaters: one serves to supply a cold carrier, and the second to issue a hot one.

- 4. Check valve. This small device allows you to keep water in the tank, even if it is absent in the supply system. It allows the medium to flow in one direction and does not allow it to flow in the opposite direction.

Boilers can be closed and open type. The former are used in conjunction with a centralized water supply system, and the latter are designed to serve one water intake point by shutting off pipeline water not at the outlet, but at the inlet to the boiler. It is this water heater that is easiest to make with your own hands.