How septic tanks work without pumping

In fact, this is not a completely true statement. In any septic tank, sooner or later, a layer of silt (heavy and non-recyclable particles) begins to settle, which must be removed. Septic tanks without pumping simply allow you to remove sludge as rarely as possible, quickly and efficiently, and most importantly - on your own, which is possible thanks to this principle of operation of the device:

- The system has 2 or 3 chambers, which are interconnected by a pipe and sealed side walls.

- Household effluents through the sewer pipe enter the chamber for primary treatment.

- Large particles in the waste settle to the bottom due to gravity, where they will decompose under the influence of anaerobic bacteria.

- Water with fats and small parts enters the second chamber through the pipe, where it is cleaned, as the debris is absorbed into the layer of sand, gravel or crushed stone.

- Purified water goes into the ground in the third chamber or overflows into the next chamber.

Advantages of septic tanks without pumping:

- cleaning the septic tank from sludge is necessary every couple of years;

- the system is simple and self-service is possible;

- if necessary (if the system is installed in a country house that you do not visit in winter, for example), the septic tank can be mothballed, and it will not stand idle in vain.

The following video shows a do-it-yourself septic tank with automatic pumping of water:

Ancient times.

We all know from history that the Greeks were one of the first engineers, and in the case of devices for processing human waste, they succeeded as early as 3700 BC. The first cesspools appeared in Greece, then India and, of course, the Romans made a step forward in this direction. There are documents dating back to 500 BC in which the Romans describe the laws governing the places of defecation, as well as setting the amount of a fine if someone accidentally steps on excrement. In the future, there were no big changes. The Middle Ages are generally famous for unsanitary conditions.

Victorian first septic tanks.

Then comes the time of Victorian septic systems and the 1848 AD law that prescribes sanitary requirements to every house, now every house must have a septic tank. In the 19th century, or to be more precise, around the 1860s, the first septic tank similar to the modern one was created by the inventor of the septic tank, John Mouras.

Registered with the septic tank patent office in 1881. Mouras started with a simple prototype, the main tank was made of concrete and the piping was made of clay. The pipeline carried wastewater from the house to the main tank where it settled, more or less clean water fell into the soil. The success of the inventor of the septic tank, John Mouras, swept across the world, the next country in which the first septic tanks spread was the United States in 1883. Since without due attention to the conditions and materials for the production of septic tanks, it can be dangerous both for humans and for the environment, the US authorities regulated production standards. With a Massachusetts State Council report on the relationship between disease and contaminated sewage, Massachusetts became the regulator of safety standards and septic tank manufacturing.

Modern septic.

During the post-war economic boom of the 1940s, septic tanks became much cheaper and fell in love with the people. In those years, septic tanks became truly folk wastewater treatment devices. In the 60s, outdated septic systems begin to fail, and the construction of sewage treatment plants cannot cope with the pace of urban growth. Further, in the 70s, there was a significant change in the standard of septic tanks, now the treatment plant must withstand a larger volume of wastewater.Then the Texas Environmental Quality Commission was created, and from 1993 to this day they govern the safety standards for septic tanks.

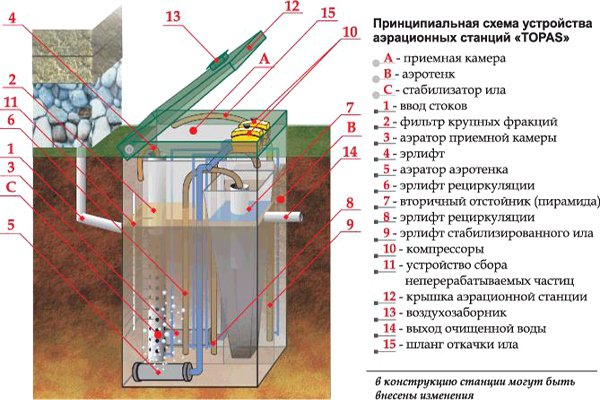

Let's talk about modern septic tanks, now plastic septic tanks continue to gain popularity instead of concrete ones. Modern plastic septic tanks with bacteria cleaning were invented in 1994 in the Czech Republic by Jan Paul and the first model was called Topas. In Russia, there is no consensus on which model of a plastic septic tank was the first imported, it is only known that the Topas model was imported in 1997. A few years later, Russian entrepreneurs realized that it was possible to make their own septic tanks even cheaper than imported ones. One of the first Russian models was the Tver treatment system. Its production of the Topas septic tank in Russia began after the end of the inventor's patent.

Septic Topas how it works

Topas series septic tanks are very popular systems, characterized by high efficiency and ease of operation. This is achieved through the following structure:

- 4 chambers, therefore 4 cleaning stages;

- several airlifts;

- special collection system for non-recyclable particles.

Important! The range of Topas septic tanks is very diverse - you can choose an option for a small family or a whole working pavilion up to 150 people. In the following video, you can clearly see the scheme and principle of operation of the Topas septic tank:

In the following video, you can clearly see the scheme and principle of operation of the Topas septic tank:

The size of these systems is small, installation is simple, and the septic tank does not make noise during operation. Uses very little electricity. It's also nice that a domestic-made unit will cost you cheap in terms of maintenance.

The advantage of this series of septic tanks is a very deep biological treatment (95-99%).

Probably the only problem that you may encounter when using it is power outages. The system is completely dependent on electricity, therefore, at the time of its shutdown, it is strictly forbidden to use a septic tank. This could cause serious damage or disable it.

General principle of operation of the treatment plant

The operation of autonomous sewerage is based on the rules of gravitational settling, supplemented by biological filtration (forced, natural). A complex system collects impurities, then microorganisms decompose the remains. Often use special bioenzymes and biofilters.

The sequence of processes is divided into 4 stages:

- Primary cleansing. Wastewater flows through pipes into the tank, where the mechanical collection of large elements takes place. Heavy particles remain at the bottom of the tank, while light particles pass into the next chamber.

- Decomposition. The descended insoluble substances are fermented for 72 hours, crushed into water, carbon dioxide and a thick sediment.

- Post-cleaning. In the second tank of bacteria, drugs start the processes of re-decomposition.

- Jet outlet. Depending on the quality of the treatment plant, a clean liquid is left for watering the garden or wastewater for ground filtration.

Simple septic tanks in the chambers free the drains from impurities, after which the residues go into the ground through the drainage layer. Deep cleaning designs are represented only by factory models. More expensive facilities reach the maximum degree of filtration (90-98%).

The principle of operation of the treatment plant.

Basic schemes of popular models

Manufacturers of autonomous sewer systems are improving technology, so the user is offered many convenient options. The more filtration cycles, the better the result.

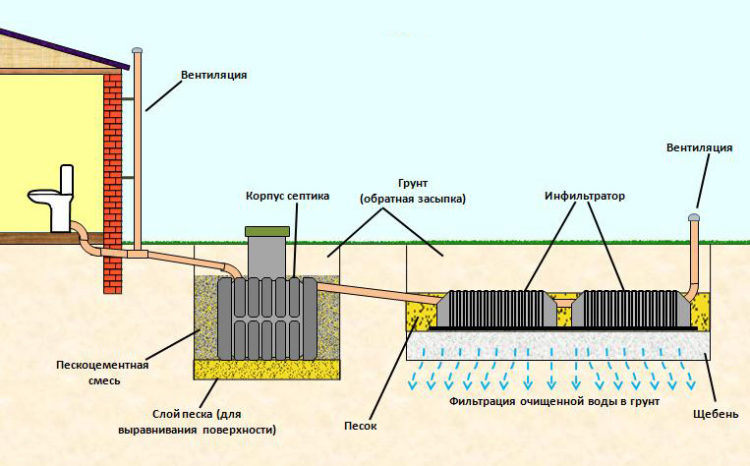

Tank - complex cleaning with an infiltrator

The scheme of the septic tank Tank - complex cleaning with an infiltrator.

A popular septic tank with a soil treatment design. A plastic tank with rigid ribs can be mounted in any soil.The system consists of removable units, so if necessary, you can add an additional module.

The Tank cycle is a "classic" biological filtration. In the first tank there is a mechanical separation of sewage. In the second container, the anaerobes are broken down into simple compounds.

The two-chamber models are finished in the infiltrator, while the 3-piece models are subjected to additional bacterial treatment.

Topas - multi-stage biofiltration

The vertical septic tank is divided into 4 sectors, between which wastewater circulates. The components are interconnected by hoses. The pipe pump transfers the purified liquid, dirt, debris from one part to another. The device is powered by electricity.

In the first sector, aerobic microbes decompose effluents into light components. In the next compartment, water is removed from small particles. In the sump, sewage is converted into sludge. The last chamber accumulates pure liquid. If the tank is full, the equipment warns the owner with a signal.

Triton - non-volatile cleaning system

An inexpensive model without pumping out will not take up much space on the site. The unit carries out coarse and biological separation, additionally performs soil purification. The equipment consists of 2 containers, which are connected by nozzles. The liquid settles in the first tank, gradually flows into the second. Branded infiltrate treats water with bacteria.

Ecopan - six-stage wastewater filtration

Ecopan septic tank scheme - six-stage wastewater filtration.

The device consists of 6 parts, in each of which there are complex processes:

- separation;

- anaerobic treatment;

- aerobic digestion;

- cleaning with a dolomite bioreactor;

- removal of precipitation.

In the storage tank, liquid accumulates, which can be used for technical purposes. 3 settling tanks provide high-quality release from impurities.

Microbes need oxygen to live, so the model is connected to electricity.

Rodlex - storage type septic tank

The sewer tank works on the principle of a cesspool. The hollow tank with legs and screw neck is made of durable polymer material that will last at least 50 years. The seamless technology ensures the tightness of the case. The special shape of the tank allows it to withstand ground pressure.

The septic tank model is buried to a depth of 2.5 m, drain pipes are connected. To prevent sewage from spilling, it is necessary to install a rubber cuff lubricated with silicone sealant at the hose entry point. The capacity of the device is 4000 liters, so you need to periodically pump out the liquid.

Fast - aerobic recycling technology

Self-regulating vertical type apparatus quickly processes sewage. In the receiver, effluents are affected by aerobic bacteria. The fan supplies oxygen, increasing the rate of splitting into water and sediment. The airlift moves the liquid to the anaerobic segment, where clarification occurs and a clean residue exits.

The Fast septic tank adapts to drains with chemical additions and large parts. Under the influence of an aggressive environment, microorganisms die. The cellular structure of the module protects useful components from destruction, creates favorable conditions for development. Self-regulating system does not take up much space on the site.

A septic tank is a modern autonomous sewage system that will provide comfort in a country house. Models differ in principle of operation, complexity of installation and price, so you can choose the right option for your needs. Popular types are easy to use, will serve property owners for decades.

Components of a septic tank

All cleaning structures consist of:

- Tank for settling drains. Such containers are most often made of plastic, metal. If a septic tank is equipped with their own hands, then such a tank is built underground from concrete or brick.

- Pipeline: incoming and outgoing.Pipes for overflowing wastewater are installed at a slope so that the liquid flows smoothly between the tanks.

- Service elements: wells and manholes. There must be at least 1 well on the outer route of the sewerage pipeline. If the length of the structure exceeds 25 meters, there should be 2 wells.

- Ventilation system. It is necessary for air exchange, which ensures the maintenance of the desired temperature, the removal of methane and the normal vital activity of microorganisms. The simplest ventilation is constructed from 2 risers: 1 is installed at the beginning of the sewer system, 2 - at the extreme section of the septic tank.

Features of the work of different types of septic tank

In order not to make a mistake in choosing the type of autonomous sewage, it is necessary to correctly calculate the number of daily drains. The volume of tanks depends on the number of residents and the average daily water consumption. It is forbidden to install devices with a filtering bottom on clay and loamy soils, with a close location of groundwater.

Accumulative waste system

An improved likeness of a cesspool consists of a sealed tank for sewage. The sewerage scheme is an external pipe system and a storage tank. For drains, a single-chamber tank is used, which, as it is filled, is cleaned with the help of a sewage service.

To prevent the movement of fluid in the opposite direction, it is necessary to additionally install a special valve. The meter with alarm will notify you when the tank is full.

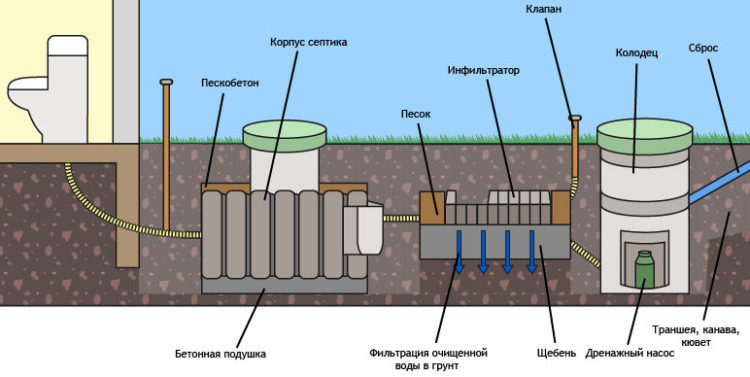

Settling tanks with soil treatment systems

An overflow device of 2 or 3 segments is used for thorough filtration of sewage. Dirty liquid enters the storage tank, inside which it breaks down into components under the influence of anaerobic microorganisms. Effluent passes through several stages of natural separation.

The filter well is used in sandstones. Assemble a structure of brick or reinforced concrete. The base of the structure is filled with drainage (crushed stone). More complex functions are performed by the underground treatment field. The complex of pipes with perforation is located on a special site covered with gravel. Impurities pass through a thick layer, gradually being cleansed.

For a thorough filtration of sewage, a sump is needed.

Septic tank with biological treatment

Microorganisms are the basis of deep filtration.

The liquid through the sewer enters the tank, where it undergoes multi-level cleaning:

- Sump. Anaerobic microbes mechanically separate heavy, light fractions.

- Decomposition. Aerobic bacteria break down waste. Continuous air supply required.

- Disinfection. Filtered water is treated with chemicals.

Bioseptic cleans up to 98% of wastewater. Microorganisms function with a regular supply of oxygen. To ensure the system is fully functional, the equipment must be connected to electricity. Current drops negatively affect the filtering properties of the structure.

Types of septic tanks and their device

There are several types of septic tanks, which differ in the principle of operation:

- Biological. The liquid is cleaned from various contaminants without harm to the environment using a filter with aerobic bacteria.

- Natural or sump without pumping.

- Mechanical. It is divided into several settling tanks with filters for various purposes through which water is pumped.

- Electric or compressor. Septic tank with forced cleaning. It is divided into several settling tanks, into which the liquid is pumped using a pump. This allows you to speed up the purification of water from solid fractions and sludge.

The main elements of a septic tank

A special treatment plant not only accumulates runoff water, but also gradually filters out impurities. An independent sewer is an improved version of an outdated cesspool.

The units consist of 4 main elements:

- Drives. Tanks are made of plastic, concrete, brick or metal alloys.Wear-resistant models made of polymers, fiberglass promise tightness for decades.

- Pipeline. The parts are mounted at an angle, ensuring free flow of liquid between the tanks.

- Wells, holes. Maintenance components make it easier to control the operation of the treatment system.

- Ventilation. For high-quality processing of wastewater, it is necessary to maintain the necessary microclimate for anaerobic or aerobic bacteria. Inside the structure, natural air exchange and temperature are created. A simple sewer-septic tank consists of 2 risers (at the beginning and at the end).

The efficiency of the design depends on the number of tanks. Single-chamber solutions are an improved cesspool that is suitable for summer cottages. In a private house with permanent residence, it is better to mount models with 2 or 3 tanks. The more containers, the better the performance of the device.

The principle of operation of septic tanks.

The sewage treatment plant is one of the key parts of the sewerage system.

The principle of operation of septic tanks

Processing is carried out through physical and biological processes. In the first case, this is filtration and settling, and in the second, the process of vital activity of microorganisms. Different types of septic tanks can process wastewater in one or more of the ways listed above. Also, the final degree of purity of the discharged liquid will depend on the number of purification steps. And depending on this, it will be discharged directly into the ground, into post-treatment systems, or into special storage tanks for further use for technical purposes (for example: watering plants or washing a car).

The inner part of the septic tank body can consist of one or more departments, in each of which wastewater is processed. The material used in the manufacture of the case is waterproof and has increased strength. In each of the products there is a receiving department (or similar to it), which initially receives effluents from the sewer pipe. Here, most often, liquid settling occurs, in which the solid fractions settle to the bottom, and the lighter ones rise to the surface in the form of a fatty film. A semi-clarified liquid remains in the middle. The biological part of the processing consists in aerobic or anaerobic colonies of bacteria that decompose organic compounds into water, sediment (silt) and a mixture of various gases.

Ultimately, the sediment (sludge) is pumped out by sewers, and the clarified liquid is discharged by gravity or forcibly under the action of the pump from the septic tank.

As a result, water enters the post-treatment and disposal systems:

- filtration fields look like a network of perforated drainage pipes. The entire system is laid in trenches and covered with a mixture of sand and gravel.

- filtration wells look like ordinary wells (only without a bottom), in the lower part of which there is a filter (sand and gravel pad more than 1 m thick).

- factory-made products (infiltrators) have the appearance of an inverted semi-container. They are also installed on a sand and gravel cushion.

- for the removal and accumulation of liquid, having a degree of purification of 95-98%, ordinary sewage reservoirs and ditches are used.

The post-treatment device is selected based on the parameters of the outgoing liquid (the degree of its purification).

The principle of operation of septic tanks

Also, post-treatment facilities can only be installed in areas dominated by sandy, gravel, crushed stone or pebble soils. In places with predominantly clay soil, it is necessary or connect to the central sewer (if any), or use local treatment plants (VOCs) that process wastewater up to 95% or more purity.

The influence of the material on the properties of the septic tank

A great influence on the functioning of a septic tank for a country house is exerted by the material from which the frame of the sewer system is made.

Among consumers, models made from modern raw materials in the form of plastic and fiberglass have become very popular.

Such samples of treatment systems have a number of undeniable advantages:

- Plastic septic tanks are completely sealed, which absolutely eliminates the penetration of an unpleasant odor to the surface and the ingress of sewage into the ground.

- The weight of these structures is very small, due to which their installation does not require the use of special equipment and may well be done by hand. However, this property of the septic tank can also partly act as a disadvantage, since, due to the excessive lightness of the structure, it can be easily damaged inside the soil in the event of movement of its layers or due to changes in the groundwater level.

- Plastic and fiberglass structures are resistant to corrosion deposits, which is especially important during precipitation.

In order for the septic tank not to deform, its walls must be of sufficient thickness, and the entire structure must be further strengthened by mounting special ribs on it, which give the system rigidity. Thanks to the equipment of such a system, you can forget about the need to concret the walls of the hole for the septic tank.

Some owners choose brick as a material for a septic tank. The laying of such a system does not differ in any complexity, however, such structures have a significant drawback - these are their poor tightness indicators.

Therefore, in the case of arranging a brick septic tank, it is extremely important to lay a waterproofing layer outside and inside its walls, having previously treated them with a cement-based solution. Another material used today for the equipment of autonomous sewer systems is reinforced concrete.

The designs of septic tanks mounted with its help are of two types:

- systems on a monolithic basis (construction begins with digging a pit and arranging formwork);

- prefabricated type septic tanks, which are assembled much easier - by using ready-made rings.

Thus, it can be noted that the arrangement of a septic tank for a country house is an extremely necessary process, therefore, such work must be approached as responsibly as possible. To do this, you can study various photo and video materials that are always available from qualified specialists, so that the treatment system is able to serve efficiently and reliably for decades.