Finding a reason

To troubleshoot a water pump, it is important to first find out the cause of the breakdown. But first of all, it is necessary to determine those conditions without which the normal operation of the device is impossible:

- The amount of water that the pump will lift up. Reducing its level can affect the pressure.

- The power supply parameters must comply with the technical characteristics of the pump. In other words, it is necessary to correctly select the power of the device in accordance with the depth of the well and the calculated water flow.

- Pump serviceability.

- Taps, filters, valves, pipes and other elements of the device must also be in good condition. Failure of at least one component of the system will lead to malfunctions.

Often, tap water in a private house is needed not only for domestic consumption, but also on the street (for watering the garden, washing the car). Therefore, the cause of the malfunction should be sought in three directions - in the hydraulic system, indoors and outdoors. How to determine the cause? Let's use the elimination method.

First, disconnect the supply hose located in the caisson. If at the same time water flowed, then the problem is either indoors or in the pipes on the street.

If there is no liquid, then the reason may be hiding in the well itself or in the details of the pump. Sometimes this situation also happens - the device is buzzing, but there is no water. Then the most likely reasons are:

- Incorrect installation or some parts of the pump that are not quite suitable.

- A decrease in water in the well, as well as surges in the electrical network, can also be the culprit in water supply problems.

- Phase failure during operation of the electric motor.

The pump is buzzing, the impeller is spinning, but water does not appear immediately.

- The non-return valve is clogged with fine sand. Inspect, clean, check performance.

- The mesh on the suction pipe is clogged with dirt.

- The pump is sucking air from somewhere. These may be leaks in the joints, less likely to drop to a critical level of the water mirror, provided that the automatic dry run does not work or is absent.

- The tightness of the membrane in the accumulator is broken.

If you, Lyudmila, are not very well versed in technology and cannot diagnose the equipment yourself, we recommend that you contact the specialists: the coordinates of the regional service center should be indicated in the warranty card for your waterworks.

In a private household, a drainage pump performs many useful functions, including pumping water from wells, pools, sewer sumps and flooded basements. Responsible owners try to adhere to the rules for operating the drainer in order to ensure its smooth operation and not be left at the most inopportune moment without a much-needed device. Nevertheless, even in this case, no one is immune from unforeseen problems. The situation when the drainage pump buzzes, but does not pump water, is one of the most common. At the same time, the complexity and speed of eliminating such a malfunction depends on its cause and knowledge of the device device.

How to ensure the stable operation of the water supply system

In order for the plumbing system to function successfully, it is necessary to provide a certain level of pressure and water pressure. When there is no access to centralized water supply, this problem is easily solved with the help of a pumping station. It usually consists of:

- pump;

- membrane storage tank;

- automatic control unit (pressure switch, pressure gauge, etc.).

The pump pumps water, which enters the tank. When the pressure in the tank reaches a certain maximum level, the pump is switched off.Gradually, the water from the tank is consumed for various needs and the pressure drops. At a minimum pressure level, the pump turns on again and water enters the tank. The process is controlled automatically.

With the help of such a unit, it is possible to provide water supply to a house, a bathhouse and other buildings located on the site. Having studied the principle of operation, you need to start studying possible breakdowns and ways to eliminate them.

Having studied the principle of operation and the device of the pumping station, you can do it yourself repair

What to do next

If cleaning the well did not help, then the following situations may be the causes of the malfunction:

- failure of mechanical parts of pumping equipment;

- breakdown in the power supply system;

- violation of the tightness and integrity of the main pipeline;

- malfunction of one or more pump control units.

But in order to understand exactly what the reason is, the submersible unit must be raised to the surface from the well. Then the pump is lowered into a container of sufficient size filled with water and started:

- If the engine starts to work when starting, then there is no breakdown in the electrical system. Otherwise, such malfunctions can be suspected. But the search and elimination of the causes of the breakdown of the electrical system should be carried out by an experienced specialist.

- It is worth watching a running motor. At the same time, try to visually assess the integrity of all pipelines and hoses. Sometimes the pump does not lift water well due to the fact that the tightness of the hoses is broken, and the pressure in the system has dropped.

- But a leak may not be noticed right away, especially if the damage is very small. To make such places more noticeable, the outlet on the hose must be closed by hand. Then the pressure in the pipeline will increase, and jets of spurting water will appear in places of depressurization.

Is it possible to fix the problem with the pump yourself

The desire of any owner to solve the problem of pumping water without the involvement of specialists is quite natural. However, this is not always possible, especially when it comes to serious malfunctions with the mechanical or electrical part of the device.

If the drainage pump is buzzing, but does not pump water at a low liquid level, this situation is spelled out in almost any instruction manual for this equipment. If possible, the pump part must be lowered deeper or the remaining water must be taken manually.

With a wedge of the shaft, disassembling the device is indispensable. Here you will need a special tool and certain skills in repairing such devices. A mechanical problem is often solved by replacing the impeller or bearings. With the electrical part, everything is much more complicated, since a burned-out engine needs to be rewound, which can only be done in the factory.

The performance of the drainage pump largely depends on its proper placement and the compliance of the quality of the pumped water with the capabilities of the device.

Before disassembling the device, you should really evaluate your knowledge and skills. Unprofessional repair often leads to the impossibility of restoring the functionality of the equipment. Therefore, if the drainage pump is buzzing, but does not rotate, it is better to involve specialists and save yourself from having to buy a new device.

Further action plan

Why does the pump not pump water from the well even after cleaning? The following problems may be the cause:

- Malfunctions in the electrical system.

- Damage to the mechanical parts of the pump.

- Violation of the tightness of the pipeline. There may also be holes and cracks in the pipes.

- Malfunctions in the operation of the pump control units.

To figure out exactly what exactly broke down, we take the pump out of the well and immerse it in a container filled with water. It can be a large basin or a barrel. If the motor is running, then there is no breakdown in the electrical system. If the engine does not start, you need to call a specialist.

While the engine is running, visually check for holes or cracks in the pipes and hoses. Remember that even a slight deformation will result in a pressure drop. For a more accurate result, close the outlet hole with your hands. Then the pressure inside the pump will increase and even small places where there is a leak can be seen.

If any hose is damaged, do not seal it. It's better to buy a new one. The fact is that even after a quality repair, the hose will not last long due to its operation under water pressure - the adhesive tape will constantly break off, and the glue will be washed off.

Drainage pump does not pump water main reasons

There may be several reasons why the drainage pump is buzzing, but does not work, that is, it does not pump out water.

Insufficient water level

Since drains are submersible pumping equipment, they must be located in the aquatic environment. To prevent the pump from running dry, a special protection is installed on this device - a float switch that turns off the device in case of insufficient water level in the source.

There are situations when the engine is running, but the liquid is not pumped out. As a rule, this is due to the cavitation mode - as a result of too much power of the device, water simply does not have time to penetrate between the impeller blades. In this case, the pump must be immersed deeper.

Mechanical failure

If the drain pump hums but does not spin, then the problem is most likely caused by a mechanical problem. If the impeller blades are damaged, a broken part can lead to a wedge in the shaft. Another reason for shaft jamming is the loss of bearing system performance.

Checking this is easy enough. It is necessary to get the device out of the water, having previously disconnected it from the power supply, and try to turn the impeller by hand. In case of difficult rotation, additional disassembly of the device will be required.

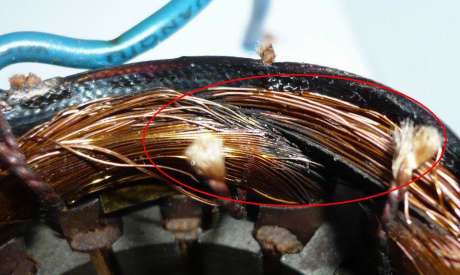

Interturn short circuit of the electric motor

The lack of rotation of the engine, in addition to a mechanical failure, can be caused by an electrical problem. If the drain pump hums strongly when turned on, while the power cable starts to overheat, then the most likely cause is an interturn short circuit of the motor winding.

This is one of the most common problems with drains without dry-running protection. During operation of the submersible pump, heat is removed from the electric motor with the help of water, while during idling the motor overheats, which causes a violation of the insulation of its windings and loss of functionality.

Sometimes a burnt motor winding is visible to the naked eye.

Air valve problems

Some models of drain pumps are equipped with a special air bleed valve. Due to operation in a difficult environment, water with various impurities enters the device, which eventually causes the ball located in the valve hole to stick. In the absence of a constant air outlet, the pump stops pumping water and runs in idle mode.

2 Repair of drainage pumps

The malfunctions listed above for the drain pump cannot always be fixed on their own. You can independently fix a weakened shock absorber, release or replace the float, eliminate mechanical damage that caused the impeller to jam, and replace the supply cable.

The simplest of all this will be fixing the shock absorber. To do this, you will need to disassemble the body of the device and tighten the loose nuts on the mounting bolts. Be sure to lock the top nut so that there is no further loosening. It will take some time to replace the power cable. Replacement of the condenser is possible in some models of drains.

The rest of the malfunctions are almost impossible to eliminate without the involvement of service workshops. For example, with a broken stem, it is easier and sometimes cheaper to purchase new equipment than to disassemble and try to repair. Valve replacement is a complicated and unprofitable undertaking to solve the problem on your own. The replacement of a burnt winding must be carried out in specialized workshops.

2.1

The most common causes of breakdowns

If it becomes necessary to repair pumping equipment, it is necessary to find out the probable cause of its breakdown, which are often:

- Failure to comply with the terms of periodic inspection and repair of equipment.

- The equipment has been operated incorrectly. During operation of the device, its operating parameters were exceeded.

- The pumped liquid contains solid impurities larger than required.

- Prolonged use of the pump in dry mode.

- Installation of equipment was performed incorrectly or poorly.

- The hydraulic accumulator, the relay are out of order, there is no filter.

When the first hints of a breakdown appear, the following components of the device should be immediately checked:

The ideal distance between the electromagnetic coils and the piston must be set from 0.4 to 0.5 cm. If these distances are not observed, the coils will beat if the gap is too large and the motor will overheat if it is small.

The piston must not have mechanical damage and defects, its condition must be elastic. The valve closing the inlets must have a clearance between the body of 0.7 to 0.8 mm. Air should flow freely when blown in at the intake side. It often happens that poor performance of the pump is not related to its failure.

There may be power fluctuations in the network.

Therefore, before disassembling the device, make sure that the mains voltage matches, which should be 220-240 V. It should be noted that for long-term and reliable operation of pumping equipment, it is necessary to carry out technical inspection and maintenance of the device in a timely manner and follow the rules of technical operation.

A number of other reasons

There are several more reasons why the pump stops pumping water from the well:

A significant decrease in the water level in the well. The main reason for this phenomenon is improper drilling. Often the water level drops in the summer, during dry periods. To prevent such situations, it is necessary to contact only proven well drilling companies, as well as use the dry running protection system. It will not be superfluous to clean the well with the help of special tools.

A centrifugal pump can pump out water faster than the well can refill. It is necessary to choose the right pump based on your personal needs. At the same time, it is better to buy a device with a power slightly higher than necessary, because guests may arrive, or you will need to water the garden with plenty of water. Do not forget to save it as reasonable as possible - do not open all the taps in the house at once and do not pour water in vain.

Weak pressure. Another problem that arises if you choose the wrong pump. For example, the depth of the well is about 50 meters. And the device is designed for a shaft length of about 30 meters. Of course, he will not be able to raise water to the surface with the necessary pressure.

Power outages can adversely affect the operation of all appliances, including the water pump. In this case, it is recommended to buy a voltage stabilizer, or connect the pump to the generator.

Disconnection of the pipeline. With this option, you can hear the "gurgling" of water. You need to check the water supply system and fix the problem.

Clogged pipes or system filters. Often occurs during the first, trial run of the pump and water well. At this time, sand or clay particles may enter the hoses or pipes.The main reason is incorrect or insufficiently high-quality assembly of the system

It is important to observe accuracy and accuracy during installation. To eliminate this problem, the pump can be washed in a container of water, after disconnecting the pipeline and check valve.

If the sound of a running engine is clearly audible and all possible causes of problems have been checked, but there is still no water in the house, we recommend that you pull out the pump and take it to a repair center.

Any malfunction of the water supply system at home is the result of an error of the organization or individual involved in its implementation. In this case, the homeowner has a good chance to learn from his mistakes by repairing the electric pump with his own hands and, under a “successful” set of circumstances, improve his health by transferring water manually from the nearest water source for some time.

Rice. 1 Downhole pump assembled

This sequence of actions applies to all types of pumping equipment, regardless of the place and method of installation. It should be noted that the pump power supply system, in addition to wires switched by switches, does not have complex circuits, therefore, if the water submersible pump does not pump water, but starts and buzzes, problems with the supply of the necessary supply voltage can be eliminated in the vast majority of cases.

First of all, the repair of electric pumps should be started by turning off the supply voltage, removing it from the water intake source and disconnecting the outlet hose.

When reconnecting, the reasons why the pump does not work can be divided into several sections according to the place of manifestation - we will consider them below.

Video repair when the pressure switch does not work

- De-energize the pumping station. Disconnect the wires by unscrewing the pressure switch. You can unscrew the cover on the engine and remove the wires, and then remove the relay itself;

- Clean the freed hole, as well as a similar hole in the cover;

- Assemble the relay. All previously washed parts must be installed in the same form as they were before disassembly. In this case, it is necessary to tighten the bolts diagonally to avoid distortion;

- Connect the station to the network and check the correctness of the repair. You can learn about connection rules.

If the pumping station is completely out of order and cannot be repaired, you should buy a new one. But then follow our advice that we shared

.

A pumping station is an excellent solution for organizing water supply in a private household. An unexpected breakdown of this complex of devices can cause a lot of trouble for the owners. Fortunately, most breakdowns are typical, they can be fixed at home. You should know in advance how to repair equipment with your own hands. This is what we will talk about now - stay with us and you will learn a lot of new things!

Malfunctions of protective systems of pumps

Usually, a properly assembled water supply system and quality pumps have devices that prevent them from idling.

In the event of a malfunction of such protective devices: a dry-running relay for a well and float switches for drainage, a well or fecal pump, the devices can work in the absence of water.

Sometimes the float switch of well or drainage pumps, due to improper installation, does not lower along with a drop in the water level (it falls on a hillock or clings to a protruding object) - this leads to the operation of the electric pump in idling mode and its further failure.

Vibrating pumps, which usually do not have external protective devices connected in the system, working for a long time without water after a drop in its level, can fail if there is no built-in thermal protection.

1 Principle of operation and causes of malfunctions

Drainage pumps are divided into two types:

- Deep.Such devices operate when immersed in the pumped liquid. A sleeve is attached to it, along which movement and ejection are carried out;

- Surface pump. There are two hoses coming out of it. One of them stretches to the tank, which is to be drained, and the second to the place of release.

Possible breakdowns are related to working conditions. The danger lies in the fact that solid particles can cause mechanical damage to the working units. In addition, drainage pumps have to work in conditions of high humidity. This threatens to cause a malfunction in the electrical part.

Too contaminated substance can also be the reason that the capacity of the operated pumping equipment becomes insufficient. In this case, the device cannot withstand the load and fails.

But, most often, the cause of the breakdown is hidden in violations of the rules for operating the unit. For instance:

- the suction hole of the surface pump is not covered with water (the sleeve is not recessed);

- the deep pump is partially submerged or not submerged at all (to insufficient depth);

- other reasons for air ingress (idle start, transfer without shutting down, and so on).

The list of symptoms that indicate that a drain pump repair is required is as follows:

- does not turn on when powered from the mains;

- turns on, but does not pump;

- gets very hot during operation;

- began to buzz not as usual;

- works, shakes, but at the same time it buzzes a lot;

- other side effects.

In most cases, you can solve the problem yourself. The main thing that you do not do is disconnect the drainage pump from the electrical network.