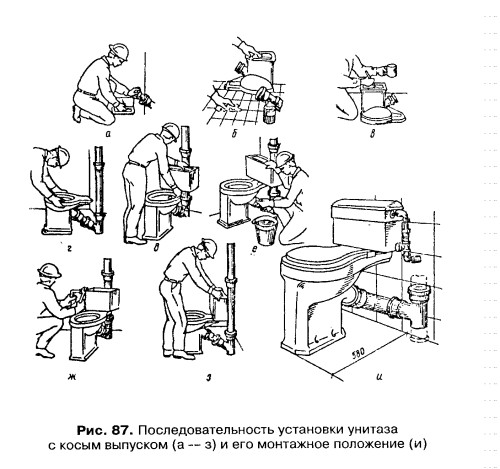

Installation of a new toilet

The toilet must be installed on a special gasket, for this a thin sheet of rubber or a piece of old linoleum is suitable. The toilet bowl is placed on the found material, and the place where it stands is outlined with a marker, places for fasteners are allocated. Then, with a sharp knife or scissors, all this is cut out. The gasket is placed on the floor, applying a thin layer of silicone sealant under it for structural reliability. The sealant fills in irregularities and provides good tightness, which will prevent moisture and dust from collecting. After completing this operation, you can start drilling. Drilling can be carried out along the gasket, or before it is installed. With a glued gasket, installation is easier, as it is a kind of guide. First you need to position the toilet so that it is easy to connect to the pipelines, then circle the place on the floor and glue the gasket there. This will be the guideline.

Sometimes you need to lift the toilet a little. For example, if there are two toilets in the system - one in the toilet and the other in the bathroom. So that the water does not stagnate at the lowest point, one of the toilets must be raised by 3-4 cm. A two-inch board is taken for the stand, which is cut to size, a rubber gasket is placed on top of it. All this is held together with silicone sealant.

in two ways: with long metal dowels or large plastic bolts. Dowels are considered the easiest and most convenient way, they are easier to buy than specialized sanitary fasteners. The sanitary set consists of 2 long screws, 2 plastic dowels, 2 washers, 2 silicone washers and 2 decorative plastic caps to be put on the screw heads. First, holes are drilled, and then dowels are hammered into them. Next, the toilet is installed and screwed to the base. The first stage is completed, the connection of pipelines remains.

Fittings for the drain tank are easy to install, you just need to fasten the necessary nuts. Installing the corrugation is more difficult. The corrugation is a special polymeric accordion pipe designed to connect the outlet of the toilet bowl and the entrance to the sewer. Previously, there was no such accordion pipe, and builders had to adjust the toilet to the sewer inlet so that the pipelines connected exactly. The junction was wrapped with a kind of fur coat, for which rags, plaster and paint were used. Corrugation simplified the sealing process.

It is very important to lubricate all joints well with sealant. Novice craftsmen often lubricate only the lower part of the connections with the corrugation, coupling and sewer

Over time, the sewer can become clogged, all drains can go through the top edge, which was not lubricated with sealant. With proper installation, it is necessary to apply a thick layer of silicone sealant on both sides of the corrugation with a strip about 2-3 cm wide. The corrugation connects the outlet and the neck of the sewer, while the joints must be pressed down well. After installing the toilet, do not use it for 4 hours, so that the sealant takes a good fit. The toilet must be installed securely and firmly.

Removing an old toilet

Before installing a new toilet, you need to dismantle the old one, you can handle this yourself. There is an option to use the old toilet bowl again, for example, in the country. But in terms of economy - this is not the best option. All plumbing fixtures are designed for a certain service life, so they can quickly fail if you do not change parts. Replacing parts with new ones can cost as much as buying a new economy class toilet. Therefore, if the toilet has served most of its life, it is better not to reuse it.

Before dismantling, it is necessary to clean the pipelines.The easiest way is to pour hot water with some kind of detergent into the sewer pipes. If you simply drain the water from the tank, this will not help much, since the old plumbing is being dismantled, and therefore there are deposits inside that will prevent dismantling. To flush the pipes, you need to take 2-3 buckets of hot water and dilute one bottle of whiteness or domestos in them, then pour it all into the toilet. Now you can start dismantling.

Toilet installation diagram.

The tank is most easily dismantled, difficulties may arise with the lower fasteners. In Soviet times, it was not common to bolt the toilet bowl to the floor, most often the toilet bowls were installed on the mortar. Since the same plumbing fixtures were installed throughout the country on concrete floors with nondescript tiles, the described method was widespread. You can break such a base only with a puncher and a hammer. Don't forget your goggles, as shards of faience can get into your eyes. If the toilet was installed relatively recently, then to dismantle it, you need to unscrew the screws with which it is bolted to the floor.

When you can pour out a little water, so you need to prepare rags and buckets in advance. Next, you need to seal the sewer pipe using a piece of polyethylene and tape. Polyethylene should simply be wound around the hole and secured with tape. This procedure is necessary in order to prevent overflow if too much waste flows from above. The intake opening must be cleaned before sealing. If the sewer is cast iron, then you can use a hammer and a spatula. If the pipes are plastic, then they can be cleaned with a sharp knife.

After dismantling the old toilet bowl, it is necessary to clear the place where the new device will be installed. If the floor surface was damaged during dismantling, the imperfections can be filled with a repair mortar. It is not necessary to wait for the solution to dry completely, since the defects are usually small, and there are support points for the base of the toilet bowl. It takes a month to completely dry the cement mixture, after which the surface under the toilet will be a monolith.