1 Purpose, pros and cons

When the coolant heats up, the pressure in the heating system circuit and boilers increases due to an increase in the volume of liquid. Since it is an incompressible medium and the system itself is sealed, this can lead to breakage of pipes or boilers.

For this reason, it is recommended to install a membrane expansion tank for heating. It is a tank connected with a pipe to the system. Excessive pressure in it will be compensated by volume, which will ensure full operation of the circuit. The expander takes in a certain amount of liquid when the volume and pressure increase, and then, when these indicators decrease, it returns it back. Such devices differ from similar devices of another type in a number of advantages:

- they can be used in any water, even if it contains a lot of calcium;

- allowed to use for drinking water;

- have a large useful displaced volume (compared to tanks without a membrane);

- air pumping is required in a minimum amount;

- installation is fast and does not require large expenses;

- operating costs will be minimal.

But it has an expansion tank and cons. Sometimes you can run into problems when installing it, because it is quite large. Heat losses increase due to the fact that the coolant gives off heat to the expander.

What is a diaphragm expansion tank

An expansion tank is an important element in heating, because it prevents the coolant from boiling, which can lead to bad consequences.

Such tanks can be used in different systems:

- with heat pumps and solar collectors;

- with independent heat source;

- connected to the district heating network according to an independent scheme;

- with closed loops.

Expansion membrane tank can be with a fixed and replaceable baffle. The first, made with an internal cavity divided into two parts by a securely fixed membrane, which is located along the perimeter of the section.

Tanks with a replaceable baffle differ from fixed ones in that the coolant is in a membrane tank and does not come into contact with the steel surface. Mounting and dismantling of the membrane is quite simple, through the flange, which is bolted.

Advice. When installing a membrane tank, it is necessary to securely attach it, because during operation, the mass of the tank increases.

Purpose and features of membrane tanks for heating

Membrane tank design

First you need to know the functional qualities of this device. When water is heated in pipes, natural expansion and pressure increase occur. If the value exceeds the normalized value, a stabilization mechanism is needed. This is what membrane tanks for heating systems are designed for, which may differ in technical and design characteristics.

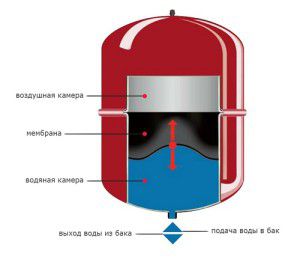

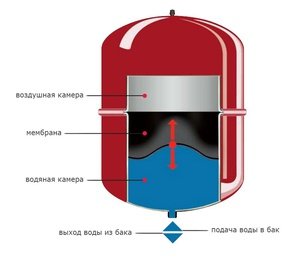

They are a sealed container, divided into 2 areas - water and air chambers. Between them is an elastic membrane. An appropriate branch pipe is provided for connecting the water supply, and a pressure injection system is located in the air chamber. The principle of operation of the expansion membrane tank for the heating system is to increase the usable volume as a result of the displacement of the elastic membrane towards the air chamber.To do this, it is necessary to connect the water pipe to the heating pipe, and create a pressure in the air chamber, the value of which should not exceed the nominal value for the heating system.

Installing a membrane tank in a heating system has the following advantages:

- Automatic stabilization of the critical expansion of the coolant;

- No water loss due to evaporation;

- Possibility of installation both for system with distilled water, and with antifreeze;

- Simple installation and replacement of the membrane when its service life is exceeded.

But how to choose the right membrane tank for heating, the principle of operation of which is so simple? To do this, you first need to familiarize yourself with its varieties.

The membrane tank for heating according to the principle of operation is similar to that for the water supply system. But the design of the latter is not designed for high temperatures. Manufacturers mark them in blue, and heating ones in red.

The design of the expansion membrane tank

One of the most important element of the membrane expansion tank is the membrane, which can be of two types:

Diaphragm valves are used in tanks with a small volume and cannot be replaced. Balloon tanks can be easily replaced if necessary, and this type of expansion tank is more reliable due to the fact that water is in the membrane and does not touch the tank body.

Advice

When choosing a membrane expansion tank, it is necessary to pay attention to the material from which the membrane is made.

Tank installation steps

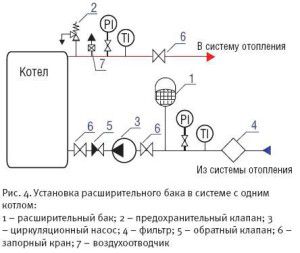

Membrane tank connection diagram

For a qualified installation of a membrane tank in a heating system, it is necessary that the room meets the operating conditions. The temperature in it should not fall below 0 degrees with a stable humidity indicator. It is necessary to determine the installation site, since the system is characterized by pressure drops during its start-up. Therefore, it is not recommended to install expansion membrane tanks for heating immediately after the boiler on the outlet pipe.

The next criterion is the absence of turbulence in the water flows, which can simulate overpressure. It is best to install membrane tanks for heating systems on the return pipe in front of the circulation pump. The installation technology consists of the following steps:

- Insertion into the pipeline. Typically, the diameter of the expansion tank pipe is 3/4. Therefore, an appropriate threaded channel must be installed in the return pipe;

- Installation should not be obstructed by objects or elements of the system. External mechanical load on the tank is excluded;

- It is best to use paronite models as gaskets, as they withstand pressure and high temperatures well;

- The membrane expansion tank for heating must be equipped with an air valve. It is necessary to stabilize and regulate the pressure in the air chamber.

Each time a closed heating system is started, an increased pressure indicator will act on the membrane. Therefore, it is recommended to check the condition at least once every 2 years and, if necessary, replace it.

This is a typical installation scheme that does not take into account the features of a particular heating system and its constituent elements. During installation, frequent mistakes should be avoided, which can lead to improper functioning of membrane tanks for heating systems.First of all, setting the maximum pressure value in the air chamber. It should be less than the calculated critical by 10-15%. Otherwise, the membrane will not expand towards the chamber, which will lead to rupture of pipes and failure of heating radiators. To avoid this, it is necessary to install a pressure gauge, which is recommended by Wester, whose membrane heating tanks are characterized by high reliability.

To install a membrane tank in the heating system, you must make sure that there is no such tank in the heating boiler. If its volume is not enough according to the calculations, you can mount an additional tank.