Pool maintenance costs

As an example, consider a pool with a 3x7m mirror and the costs of its operation, depending on its type and source of heating, taking into account the current energy tariffs:

| pool type | Number of operating hours* | Heat loss, W*h / m2 | Pool surface area, m2 | Total heat loss, kW |

| Outdoor swimming pool without cover (water temperature +20℃) | 2880 | 450 | 21 | 27216 |

| Covered outdoor swimming pool (water temperature +20℃) | 3600 | 100 | 21 | 7560 |

| Indoor swimming pool (water temperature +20℃, room temperature +23℃) | 8760 | 90 | 21 | 16556 |

- * 120 days (summer 90 days, 15 days of spring, 15 days of autumn) x 24 = 2880 hours

- * 150 days (summer 90 days, 30 days of spring, 30 days of autumn) x 24 = 3600 hours

- *365 days x 24 = 8760 hours

Having the cost of 1 kW of thermal energy and the total heat loss, you can easily get the total cost of maintaining the pool in terms of heating (excluding other means and maintenance). Consider an indoor swimming pool (water temperature +20℃, room temperature +23℃) - 16556 kW of heat per year.

| Thermal energy source | energy carrier | The price of 1 kW of heat | Total heat loss, kW | Total costs for the maintenance of the pool, UAH |

| Heat pump (tariff "Electric heating") | air / electricity | 0.25 UAH/kW | 16556 | 4139 |

| Heat pump (tariff "Electric heating") | ground-water / electricity | 0.225 UAH/kW | 16556 | 3725 |

| Heat pump (standard rate) | air / electricity | 0.48 UAH/kW | 16556 | 7946 |

| Heat pump (standard rate) | ground-water / electricity | 0.42 UAH/kW | 16556 | 6953 |

| Gas boiler | natural gas | 1.02 UAH/kW | 16556 | 16887 |

| Solid fuel boiler |

oak firewood oak firewood |

0.59 UAH/kW | 16556 | 9768 |

wood pellets wood pellets

|

1.27 UAH/kW | 16556 | 21026 | |

coal coal

|

1.39 UAH/kW | 16556 | 23012 | |

| Electric boiler (tariff "Electric heating") | electricity | 0.90 UAH/kW | 16556 | 14900 |

| Electric boiler (standard rate) | electricity | 1.69 UAH/kW | 16556 | 27979 |

| Solar collectors | Sun | — | 16556 | only electricity is needed to operate the circulation pump |

As can be seen from the table, the sum of the content of the pool can vary significantly depending on the selected heating source. Therefore, the main advice is to carefully weigh everything and choose the golden mean. A more detailed calculation of the cost of 1 kW of thermal energy is here

Scheme of operation of a heat pump for heating a pool

The scheme of operation of a heat pump for heating a pool is quite simple and includes the following elements:

- Primary heat source - air, water, soil or process

- Heat pump

- heat exchanger

- Swimming pool water circuit

- Filtration system (not shown for simplicity)

As a rule, a shell-and-tube type heat exchanger is present in the circuit. Shell and tube heat exchanger - easy to maintain and durable. This type of heat exchanger is most often used for pool heating.

It is important to choose the right heat exchanger for a heat pump - Be sure to consult with specialists

Properly selected equipment and high-quality installation are the keys to success when implementing a pool heating system using a heat pump.

Calculation of heating a house with a heat pump

For the normal operation of the heat pumping installation, high-quality thermal insulation of the building is necessary. Therefore, before buying a heat pump, it is necessary to insulate walls, floors and ceilings, and then perform a heat loss calculation (Q).

A simplified formula for calculating the amount of heat (W) leaving the house through the building envelope (walls, windows, floor, ceiling) looks like this:

Q \u003d S x (difference in air temperatures indoors and outdoors) / Rt.

S is the area of the enclosing structure in m2;

Rt - thermal resistance of the material of the building envelope (taken from the tables of SNiP on building heat engineering).

Having alternately calculated the heat losses of walls, windows, floors and ceilings, they are summed up and the number of kilowatts lost by the house in 1 hour in the coldest period of the year is obtained. The power of the heat pump must not be less than the total heat loss. If, in addition to heating, the installation will heat water for domestic needs, then its capacity is increased by 20%.

When choosing an air-to-air or air-to-water heat pump, one should be guided by the thermal power that it develops in the low temperature region, since it is much lower than the power during operation in the warm season.

As an example, we present the parameters of the NIBE FIGHER F2300-14 air-to-water unit. Working in the temperature range from +7 to + 45C, it produces about 18 kW, and at an air temperature of -15C, only 10.7 kW.

Pool heat loss

To select the power of the heat source, it is necessary to calculate the heat loss of the pool. Of course, such a calculation should be carried out by a heating engineer, but, for a general concept of the order of numbers, we present an empirical table of pool heat losses. With its help, you can easily determine the required power of the heat source:

| pool type | Heat losses from 1m2 of the pool at different water temperatures, W*h/m2 | ||

| 20 °C | 24 °С | 28 °С | |

| Indoor swimming pool (room temperature 23 °C) | 90 | 165 | 265 |

| Indoor swimming pool (room temperature 25 °C) | 65 | 140 | 240 |

| Indoor swimming pool (room temperature 28 °C) | 50 | 100 | 195 |

| Covered outdoor pool | 100 | 150 | 200 |

| Uncovered outdoor pool (wind protected position) | 200 | 400 | 600 |

| Uncovered outdoor pool (unprotected from the wind) | 450 | 800 | 1000 |

It should be noted that the initial heating of the pool may take several days, so do not worry if the initial heating of the pool takes a long time.

Heat source options for pool heating

Consider the main sources of heat for heating the pool and compare their technical and economic indicators:

| Thermal energy source | energy carrier | pros | Minuses |

| Heat pump (tariff "Electric heating") | air / electricity |

|

|

| Heat pump (tariff "Electric heating") | ground-water / electricity |

|

|

| Heat pump (standard rate) | air / electricity |

|

|

| Heat pump (standard rate) | ground-water / electricity |

|

|

| Gas boiler | natural gas |

|

|

| Solid fuel boiler |

oak firewood oak firewood |

|

|

wood pellets wood pellets

|

|

||

coal coal

|

|

||

| Electric boiler (tariff "Electric heating") | electricity |

|

|

| Electric boiler (standard rate) | electricity |

|

|

| Solar collectors | Sun |

|

Solar collectors are beneficial for outdoor pools when the pool is operated in summer and off-season. In combination with a backup source of thermal energy, it is an excellent solution to ensure a comfortable water temperature in the pool.

Electric boiler - very high operating costs do not allow us to recommend this type of heating for the pool.

A gas boiler is a compromise solution, but the operating costs are still high, therefore, taking into account other disadvantages, it is not recommended for heating the pool.

Biomass boiler (wood, pellets) - this option is not as economical as it is more difficult to maintain, therefore, the person who equipped the pool is unlikely to want to spend his precious time on constant boiler maintenance. Based on the above - not recommended for pool heating.

A heat pump is an excellent solution for heating a pool.Autonomy - you can start the heat pump from your smartphone and the heat pump will raise the temperature in the pool to a more comfortable temperature on your arrival. There is no need to clean and check anything, everything works automatically, plus it is much cheaper than heating with gas, wood or electricity. Can be used to heat both indoor and outdoor pools. For outdoor pools, we recommend a combination of solar collectors and a heat pump, since during the main operating time - in summer, only solar collectors will work. Therefore, the maintenance of the pool will be practically free on sunny days, and when there is no sun, the heat pump will insure and you can always plunge into the warm water of your pool in the morning, afternoon and evening.

Characteristics of heat pumps

The main indicator by which the efficiency of a heat pump is evaluated is the heat conversion coefficient, abbreviated as KPT (in the English abbreviation COP). It has nothing to do with the usual efficiency for us - the efficiency factor. KPT (COP) shows how many kilowatts of energy the pump pumps per kilowatt of electricity it receives. Depending on the operating conditions, the CPT of a heat pump can be from 3 to 5, which, without further discussion, confirms the economic benefits of its use.

The most stable performance indicators are demonstrated by soil and water installations, since the temperature of water and soil does not fall below zero degrees. Units that collect heat from the air depend on its temperature. With minus thermometer marks, their performance decreases by an average of 40-50%.

The second operating parameter is power in kilowatts. It is selected based on the magnitude of the heat loss of the building.

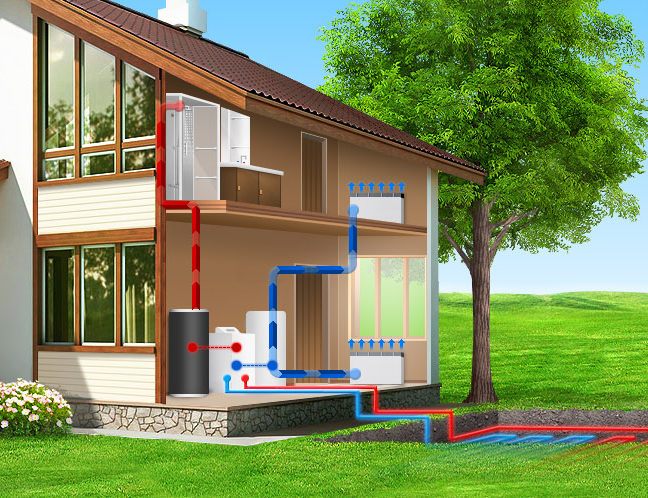

How to install a heat pump in a house

- It is possible to place modern heat pumps in the basements of residential buildings. This is especially true for geothermal equipment with the connection of an inclined bush circuit. In this case, the well for the collector can be located directly under the house, in the basement.

- Requirements for installing a heat pump in an apartment building. Be sure to install a backup heat source. In winter season, the defrost module will stop for 3-4 seconds. At this point, you will need to compensate for the lack of heat.

- The pump is installed in any room that is large enough to accommodate the storage tank and provide unhindered access to all components of the system for maintenance.

To start heating the house with a heat pump, you need to invest money. Subsequently, the costs will fully pay off. The time required to reach zero is 3-8 years.

Which heating is better for a home - gas or heat pump

Energy-saving technologies for the home are slowly but surely replacing traditional types of heating. The only thing holding back the widespread adoption of installations is the need for a significant initial investment of money.

Most manufacturers have been working on reducing the cost of technology for a long time, therefore, the prospects for using heat pumps in heating systems for private houses are quite optimistic. In the near future, we can expect an increase in the number of sales by 10-15%.

Heat pumps are not limited to domestic use only. It is possible to use heat pumps in heating multi-storey buildings, as well as industrial facilities. If we compare the effectiveness of the use of gas boilers and heat pumps, we can clearly see what prospects exist for each type of equipment.

Disadvantages of heat pumps

The main disadvantage, especially noticeable when operating in apartment buildings, is the dependence of heat pumps on temperature fluctuations.And if geothermal models are more or less resistant to changing weather conditions, then air stations sharply reduce productivity if the temperature drops to -15 ° C.

Installation of heat pumps with an earth circuit costs an additional 30-40% of the total cost. The work requires the involvement of specialized machinery and equipment. The price for modern models can reach 1200-1400 thousand rubles.

In comparison, the purchase and installation of a gas boiler will cost only 200 thousand rubles. The efficiency of gas equipment does not depend on external factors, and installation takes 1-2 days at the most.

Advantages of heat pumps

Economic efficiency is the main advantage of heat pumps. Financial costs during the heating season are less than natural gas, almost three times less. You don't need any permissions to connect. The exception is geothermal equipment, you will have to formalize the right to drill wells. The operation of heat pumps is absolutely safe and environmentally friendly.

The main heating of the house with the help of a heat pump has significant advantages over the operation of gas boilers, but due to the high cost of equipment using low-grade energy, they are inferior to them in popularity.

Calculation of power and temperature of a warm water floor

Well-Known Brands and Estimated Prices

The market for heat pump equipment in Russia has been formed. The leading positions here are occupied by foreign companies such as: Nibe (Sweden), Mitsubishi Electric (Japan), Danfoss (Denmark), Vaillant (Germany), Viessmann (Germany), Mammoth (USA) and others. Russian-made products (trademarks Henk and SunDue) are not inferior in terms of "price-quality" to eminent brands.

The estimated price (for 2016) of an imported ground-to-water heat pump with a capacity of 10 kW, designed to heat a house with an area of 100 m2 (without installation) is 500,000 rubles. For drilling wells, pipe installation and commissioning, you will have to pay an average of 80,000 rubles, not including additional materials.

Domestic equipment is cheaper. The price of a Russian heat pump similar in parameters is about 360,000 rubles. Its purchase with turnkey installation will cost about 430,000 rubles. Estimated price of 10 kilowatt air-to-water heat pump from 270,000 rubles. The average cost of this unit with a turnkey installation is 320,000 rubles.

Reviews of real owners of this type of equipment are overwhelmingly positive. They note the reliable operation of geothermal heat pumps and low operating costs (maintenance, electricity).

The fears of those who are still thinking about buying an air-to-water heat pump based on the practice of using this technique are not justified. These units consistently produce heat up to an outdoor temperature of -25C.

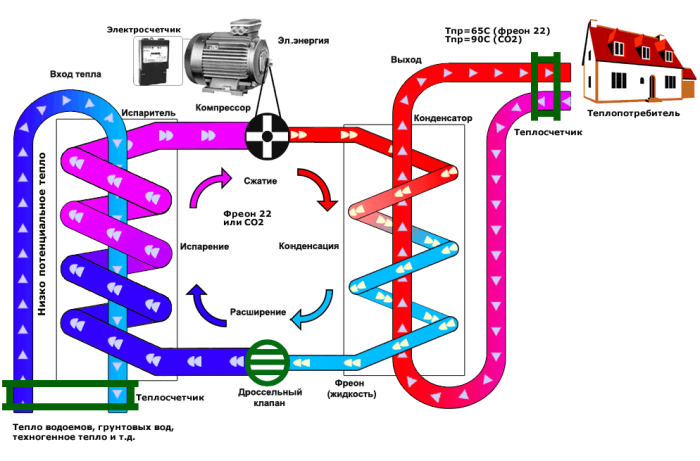

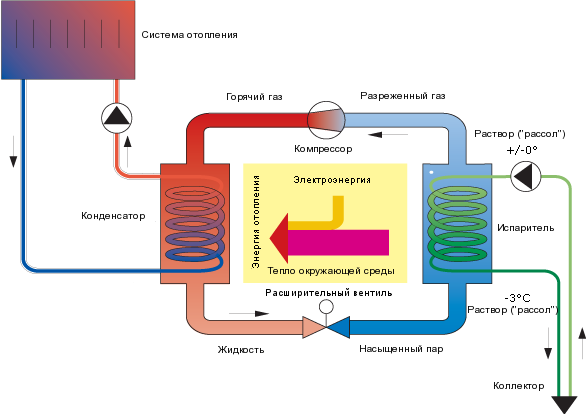

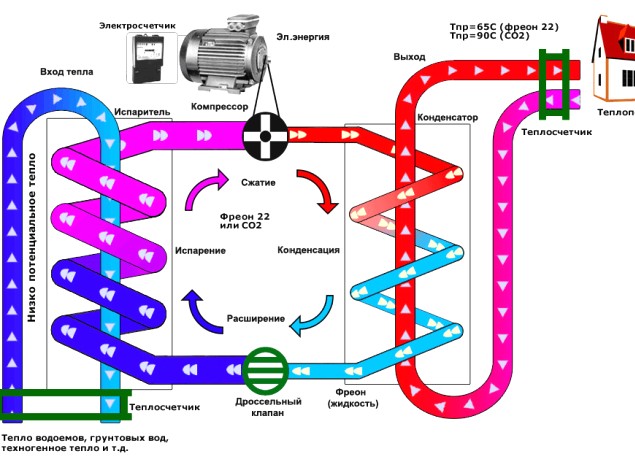

Principle of operation

All the space around us is energy - you just need to know how to use it. For a heat pump, the ambient temperature must be greater than 1C°. Here it should be said that even the earth in winter under snow or at some depth retains heat. The work of a geothermal or any other heat pump is based on the transportation of heat from its source using a heat carrier to the heating circuit of the house.

Scheme of operation of the device by points:

- the heat carrier (water, soil, air) fills the pipeline under the soil and heats it;

- then the coolant is transported to the heat exchanger (evaporator) with subsequent heat transfer to the internal circuit;

- the external circuit contains the refrigerant, a liquid with a low boiling point under low pressure. For example, freon, water with alcohol, glycol mixture. Inside the evaporator, this substance is heated and becomes a gas;

- the gaseous refrigerant is sent to the compressor, compressed under high pressure and heated;

- hot gas enters the condenser and there its thermal energy passes to the heat carrier of the house heating system;

- the cycle ends with the conversion of the refrigerant into a liquid, and it, due to heat loss, returns back to the system.

The same principle is used for refrigerators, so home heat pumps can be used as air conditioners to cool a room. Simply put, a heat pump is a kind of refrigerator with the opposite effect: instead of cold, heat is generated.

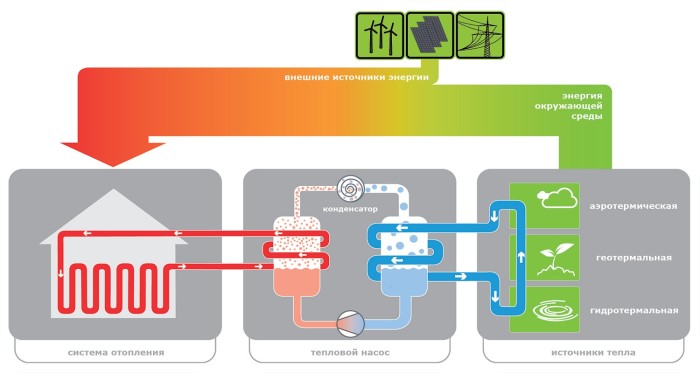

Do-it-yourself heat pumps can be designed based on three principles - according to the energy source, the coolant, and their combination. The source of energy can be water (reservoir, river), soil, air. All types of pumps are based on the same operating principle.

Classification

There are three groups of devices:

- water-water;

- groundwater (geothermal heat pumps);

- use water and air.

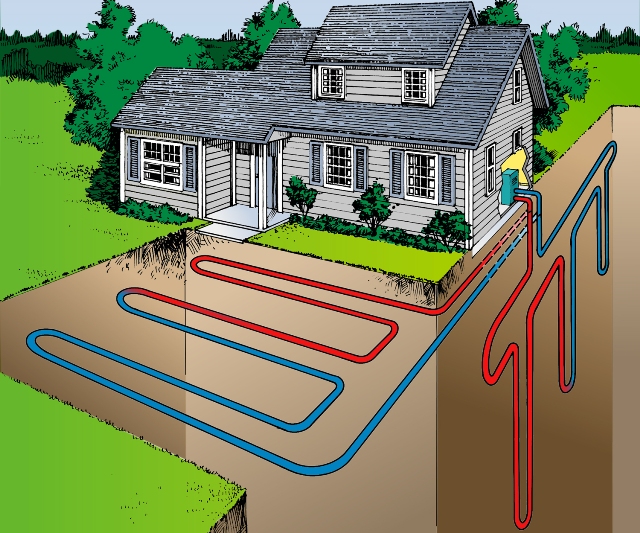

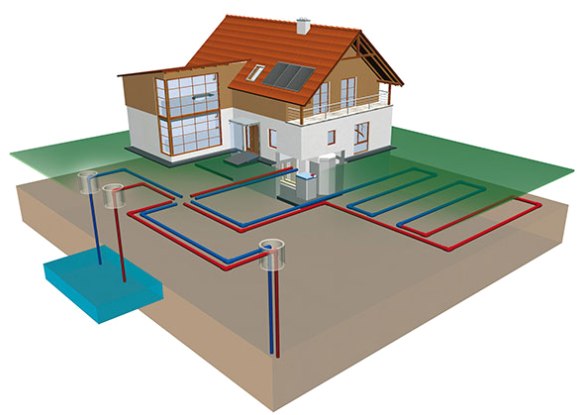

Thermal collector "ground-water"

A do-it-yourself heat pump is the most common and efficient way to generate energy. At a depth of several meters, the soil has one constant temperature and is little affected by weather conditions. On the external contour of such a geothermal pump, a special environmentally friendly liquid is used, popularly called "brine".

The outer contour of the geothermal pump is made of plastic pipes. They are dug into the ground vertically or horizontally. In the first case, one kilowatt may require a fairly large area of work - 25–50 m2. The area cannot be used for planting - only planting annual flowering plants is allowed here.

A vertical energy collector requires several wells of 50–150 m. Such a device is more efficient, heat is transferred by special deep probes.

"Water-water"

At great depths, the water temperature is constant and stable. The source of low-potential energy can be an open reservoir, groundwater (well, borehole), wastewater. There are no fundamental differences in the design for heating of this type with different heat carriers.

The “water-water” device is the least labor-intensive: it is enough to equip pipes with a heat carrier with a load and place them in water if it is a reservoir. For ground water, a more complex design will be required and it may be necessary to build a well for the discharge of water passing through the heat exchanger.

"Air-water"

Such a pump is slightly inferior to the first two and in cold weather its power decreases. But it is more versatile: it does not need to dig the ground, create wells. It is only necessary to install the necessary equipment, for example, on the roof of the house. This does not require complex installation work.

The main advantage is the ability to reuse the heat leaving the room. In winter, it is recommended to have another source of heat, since the power of such a heater can be significantly reduced.

Specifications

Most zealous owners want to save on heating and water supply of a private house. For such purposes, a heat pump is suitable.

It is quite possible to build it with your own hands, saving money at the same time - a factory device is very expensive.

Properties and device

The device has an external and internal circuit along which the coolant moves. The components of a standard appliance are a heat pump, an intake device and a heat distribution device. The internal circuit consists of mains powered compressor, evaporator, throttle valve, condenser. Fans, a pipe system, and geothermal probes are also used in the device.

- does not emit any harmful substances, absolutely environmentally friendly;

- there are no costs for the purchase and delivery of fuel (electricity is spent only on moving freon);

- no need for additional communications;

- absolutely fire - and explosion-proof;

- full heating in winter and air conditioning in summer;

- a self-built heat pump is an autonomous design that requires a minimum of control effort.

How a heat pump works

The simplest example that clearly explains the principle of operation of heat pumps is a household refrigerator. We all know that in his freezer, food is cooled due to the circulation of the refrigerant. Taking away the internal heat, the refrigerator throws it out. Therefore, the freezer compartment is cold, and the rear grill of the device is always hot.

The principle of operation of a heat pump is the opposite. Taking heat from the environment, it transfers it to the house. Figuratively speaking, the “freezer” of this device is located on the street, and the hot grill is in the house.

Depending on the type of external heat source and the environment that collects energy, heat pumps are divided into four types:

Installations of the first type extract heat from the ground using tubular collectors or probes. In the external circuit of such a pump, a non-freezing liquid circulates, transferring heat to the evaporation tank. Here, thermal energy is transferred to freon, which moves in a closed circuit between the compressor and the throttle valve. The heated refrigerant enters the condenser tank, where it gives off the heat it receives to the water sent to the heating system. The heat exchange cycle is repeated as long as the unit is connected to the mains.

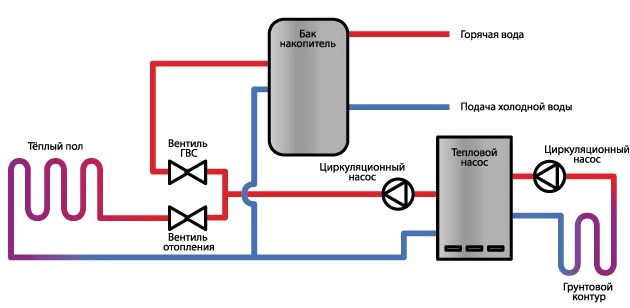

Heat pump operation diagram

The principle of operation of a water heat pump is no different from a ground heat pump. The only difference is that it is powered by water, not soil.

An air source heat pump does not need a large external collector to collect heat. It simply pumps street air through itself, extracting precious calories from it. Secondary heat exchange in this case occurs through water (warm floors) or through air (air heating system).

Assessing the economic side of the issue, it should be noted that the "soil-water" installation requires the largest financial investments. To install its heat-receiving probes, it is necessary to drill deep wells or remove soil over a large area for laying the collector.

The ground source heat pump cannot operate without an external piping system or deep wells with heat sensing probes

In second place is the water heat pump, delivered to the customer on a turnkey basis. For its operation, digging of the earth and drilling of wells is not required. It is enough to immerse a sufficient number of flexible pipes in the reservoir, through which the coolant will circulate.

Air-to-air and air-to-water units are the cheapest, since they do not need to install external heat receivers.

A feature of the installation of most heat pump systems is their connection not to heating radiators, but to a warm floor. This is due to the fact that the maximum water heating is carried out to a temperature of + 45 ° C, which is optimal for a warm floor, but insufficient for the normal operation of the radiator.

An advantageous feature for the owner of the operation of this unit is the possibility of a reverse mode - transfer during the hot period of the year to cooling the premises. In this case, excess heat is absorbed by the underfloor heating pipeline and removed by the pump to the ground, water or air.

A simplified structural diagram of a ground heat pump installation looks like this:

In addition to the heat pump, ground circuit and underfloor heating, we see here two circulation pumps, shut-off valves for hot water and heating, as well as a tank that accumulates hot water for domestic use.

Self-manufacturing of a heat pump

Given the rather high cost of this equipment, many do-it-yourselfers are tempted to assemble it with their own hands, using improvised units and components. What should be said about this?

This work includes two main stages: preparation of the external circuit and assembly of the heat pump unit itself. On your own, you can dig trenches for laying pipes. It is unrealistic to make a 50-meter well for mounting the probe without special equipment. Surface laying of the collector, according to experts, is disadvantageous, since it does not provide enough heat for stable operation of the installation.

Now let's see if it is possible to assemble a heat pump with your own hands. This requires the practical experience of a refrigeration master, since a beginner cannot fill the system with freon and pressurize it.

The manufacture of an installation based on units from an old refrigerator or air conditioner can only be considered as a demonstration option that has no practical value due to low efficiency.

A manual for assembling a heat pump based on an air conditioner compressor, a stainless steel tank (condenser) and a plastic barrel (evaporator) is replicated on the Internet. Having told how to wind copper tubes onto a cylinder and fix the compressor on the wall, the author ends his story with advice, after completing the assembly, contact the master, who will agree to perform commissioning and correct all the “jambs” made by the do-it-yourselfer. It is impossible to call this instruction a serious help for independent work.

We recommend reading:

- Which gas boiler is better to choose: types, characteristics, firms

- Fireplace stoves for summer cottages - varieties, how to choose your option?

- Heating mats for underfloor heating: installation under tiles and connection

- Boiler room in a private house: basic requirements and arrangement