Signs of a malfunctioning motor pump

A motor pump, or water pump, solves the problem of pumping water from open reservoirs. In this article, we will analyze in which cases you can fix the malfunction of the motor pump with your own hands, and when you should contact the repair shop.

The main symptoms of a pump failure include:

- black engine exhaust;

- unstable operation of the engine at high speeds;

- oil consumption in the motor pump engine is higher than usual;

- there is a leak in the pumping unit;

- reduced pump performance.

Motor pumps and pumps, like any equipment, can break down or work intermittently. They can be disassembled for minor repairs or maintenance.

If the cause of the malfunction of the motor pump is an engine breakdown, it is better to entrust the repair to professionals. If there is a warranty period for the equipment, you must contact the service center.

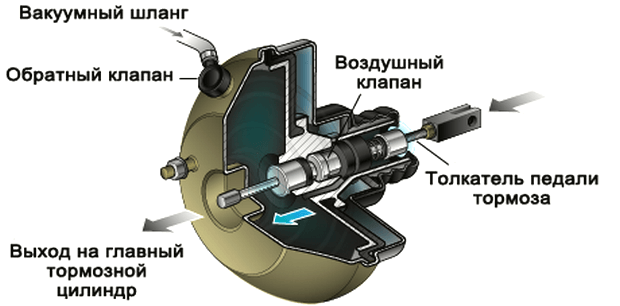

Symptoms of a malfunctioning vacuum brake booster

Due to the prolonged operation of the vacuum brake booster without replacement, defects may appear in it. Most often, the problem manifests itself in mechanical damage to the hose connection connecting the amplifier and the engine intake manifold. Mechanical damage or the formation of cracks in the rubber will lead to the fact that a vacuum will not be created in the working chamber of the mechanism, and this is necessary for its proper operation.

Internal parts can also fail in the vacuum brake booster, for example, the valve will lose elasticity or the working surface of the diaphragm will be damaged.

You can determine the malfunction of the vacuum brake booster by the following signs:

- The car began to slow down worse with the same pedal pressure;

- While pressing the brake pedal, hissing sounds are heard, at this moment the engine speed may increase;

- The car starts to "troit";

- Fuel consumption increases when the machine is running in the same mode.

In some situations, there may be other problems in the operation of the car due to problems with the vacuum brake booster. For example, spark plugs may stop working.

The pump is out of order

The biggest trouble that can happen with an electric pump is the burnout of the winding, while the device usually cannot be repaired (rewinding the winding with your own hands is difficult, and in a workshop, the cost of work and materials will not be comparable to the price of an electric pump).

With this malfunction, the electric pump will hum, but it will not be able to pump water.

Sometimes the impeller of borehole and well pumps may break, the check valve system (they will not let water through) and the piston ring of vibration models may fail.

Violation of the rules for the operation of submersible pumps, errors in the installation of the plumbing system, a sharp increase in water intake and a decrease in the flow rate of a well or well can lead to a hum of a working electric pump, in which water will not flow to the consumer. In most cases, you can repair electric pumps with your own hands, if you remove the device to the surface to accurately determine the problem area.

The pump for bottled water does not pump, there is a video.

There are a lot of types of water pumps: they can be both manual and electric, for 5 liter bottles and 19. In the event of a breakdown, it will not be difficult to repair a water pump if you know the principle of its operation.

A manual water pump (Pump) is tightly put on the neck of the bottle, when the button is pressed with a plastic corrugation, it pumps air into the container, increasing the air pressure in the bottle and thereby causing the liquid to rise up the tubes.

- What to do if the pump stops pumping water?

Where to look for damage and how.

The first thing to do is to disassemble the pump, the disassembled pump is shown in the picture above.

Inspect the parts for damage, special attention should be paid to the plastic corrugation, as it is usually made from the most common polyethylene.

Check whether the valve petals are in place; with their help, air remains in the bottle when the corrugation is unclenched after pressing the button.

If the valve is torn out, it must be put in place, the valves pop out due to a sharp effort when the water supply button is pressed.

4. If this did not help, check how the pump sits on the neck of the bottle, and whether the sealing ring is in its place. There should be no air leakage where the pump is put on the bottle. Sometimes, when removing the pump from the bottle, they do not loosen the clamp (holder) that holds the pump on the neck, and this leads to the rubber seal coming off

Such damage is hard to see with the naked eye. You can pull the edge of the seal, if it comes out freely, it must be put in place and, depending on the model, fixed. To do this, you need to disassemble the holder and put the seal where it is attached.

Replacement and repair of defective parts

Now that you know how the hydraulic machine is disassembled, you can try to repair the submersible pump with your own hands.

Basically, the blocking of the impellers occurs due to filling them with sand

or due to the formation of dirt deposits on them. In addition, the impellers can solder together when a high temperature occurs in the block when the pump is idling (dry running). To repair this section of the unit, it is necessary to remove the impeller(s) and remove the accumulated dirt. If the impellers are damaged, they will need to be replaced with new ones.

Engine

Self-repair of the pump motor is not recommended, since the diagnosis of this unit and subsequent repair require special knowledge and the necessary equipment.

In some models of pumps, in order to remove the motor, it will be necessary to press it out using special equipment. Oil seal and bearing replacement

also carried out in the service center.

If engine hums and won't start

then check the capacitor. It is located in the pump block in which the motor is installed.

Advice! Before disassembling the engine block, try to rotate its shaft with the pump block disconnected. If the shaft rotates, then the reason may lie in the jamming of the impellers.

But when the impeller shaft rotates without problems, then in order to remove the hum in the water pump, you should disconnect the capacitor and change it to a new one. Of course it's better check this part with a multimeter

, since similar symptoms can be caused by a short circuit in the motor windings.

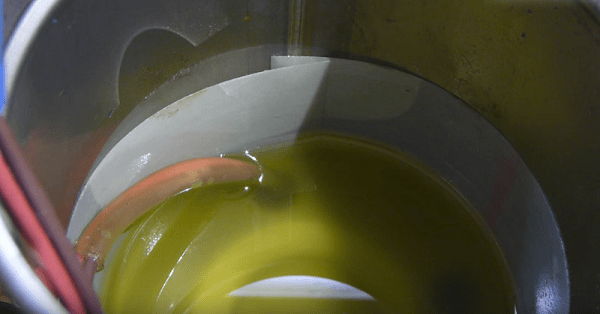

The water pump engine is located in a special glass filled with oil, and by its condition it is possible to determine some breakdowns in the electric motor unit.

-

The oil has a characteristic, unpleasant odor

. This means that the engine is still in working condition, but it worked with large overloads. -

cloudy oil

- water has entered the motor housing due to a crack in the housing or failure of the stuffing box (cuff). -

Black oil with an unpleasant odor

. In this case, we can say with great certainty that the varnish on the engine coils burned.

If, when opening the engine, the above changes in oil quality were noticed, then you first need to repair this unit, and only after that fill in new grease.

What is the phenomenon of cavitation

Everyone knows what is dissolved in water some gases

. When a liquid moves at a certain speed, rarefaction zones sometimes form in it.In these zones of low pressure, gas bubbles begin to emerge from the water. After the bubbles enter the high pressure zone, they collapse. This process occurs with the release of a large amount of energy, from which the impellers and the pump snail are destroyed. The following photo shows the impeller of the unit, destroyed by cavitation.

The energy of collapsing bubbles can create shock waves

causing vibration. It spreads throughout the unit and affects not only the impeller, but also the bearings, shaft and seals, from which these parts quickly become unusable.

The cavitation effect can most often be observed in pumping stations that operate on suction

. In such systems, the impeller creates a vacuum, due to which water rises through the hose from the well. But if there is a lack of liquid at the inlet to the pump, then an excessive vacuum occurs in the impeller zone, provoking the occurrence of cavitation.

To prevent cavitation in the pumps, the rule should be followed: there should be more water at the inlet than at the outlet. This can be achieved in several ways:

- move the device a little closer to the source;

- you can increase the diameter of the suction pipe (hose);

- to reduce the resistance in the suction section, the suction pipe can be replaced with a pipe made of a smoother material;

- if there are many turns on the suction pipe, then, if possible, their number should be reduced;

- it is desirable that all bends have large turning radii.

Advice! Do not lower the suction hose of the station into the well to a depth of more than 8 meters. Typically, the maximum immersion depth of the hose (pipe) is indicated in the equipment manual.

Any malfunction of the water supply system at home is the result of an error of the organization or individual involved in its implementation. In this case, the homeowner has a good chance to learn from his mistakes by repairing the electric pump with his own hands and, under a “successful” set of circumstances, improve his health by transferring water manually from the nearest water source for some time.

Rice. 1 Downhole pump assembled

This sequence of actions applies to all types of pumping equipment, regardless of the place and method of installation. It should be noted that the pump power supply system, in addition to wires switched by switches, does not have complex circuits, therefore, if the water submersible pump does not pump water, but starts and buzzes, problems with the supply of the necessary supply voltage can be eliminated in the vast majority of cases.

First of all, the repair of electric pumps should be started by turning off the supply voltage, removing it from the water intake source and disconnecting the outlet hose.

When reconnecting, the reasons why the pump does not work can be divided into several sections according to the place of manifestation - we will consider them below.

If the unit works, but does not pump water

Let's say that there are no problems with the electrical system and the integrity of the hoses, but the water pump still does not pump fluid from the well. To look for the answer to the question why the device does not pump water remains only in the pumping equipment itself. To do this, you can do the following:

- First you need to check the filter device and check valve. They may be clogged, so they will need to be cleaned. In some cases, it may be necessary to replace these products or one of them with a new element due to the complete wear of the old part.

- The second node to be checked in the BC (household centrifugal) pump is protection against "dry running". The sensor could simply burn out, so the unit began to work in the well without water. This quickly leads to overheating of the motor and failure.It is better not to repair such equipment, but to replace it with a new product. So it will be more reliable and safer to operate the unit in the future.

The nuances of breakdowns depending on the brand of the pump

When operating pumps from different manufacturers, it was noticed that some brands of devices are often subject to the same breakdowns. From this it follows that these models of units have their own distinctive features in terms of the occurrence of malfunctions.

Aquarius

Aquarius pumps have prone to overheating

, especially if they work in wells of small depth. If a cheap model breaks down, its repair costs about 50% of the cost of a new device. If the device is out of order, then it is easier to throw it away than to repair it.

Grundfos

Most models of this manufacturer have valve system

. Also around the engine there is a special thermal insulation. Sometimes pump failures occur due to the failure of the listed parts. Because the thermal pad is around the motor, it will need to be removed from the housing for repair.

Baby

Apparatuses "Baby" are products of domestic manufacturers. The cost of repairing units of this brand is not high, and most of the breakdowns are repaired by the owners of the devices themselves. The main failure often encountered in this pump is loud noise

during operation of the hydraulic machine without pumping out the liquid. This behavior of the device means that there was a rupture of the central axis holding the anchor and the membrane.

Gilex

The engine in the vortex and rotary pumps "Dzhileks" is oil-filled. Therefore, a frequent breakdown of these units is oil leakage from the engine

. It can only be topped up at a service center.

Brook

There is an opinion that the operation of the drainage pumps "Brook" can continue without interruption for 7 hours or more. This is explained by the peculiarity of their design, which meets all European standards. Despite this, the device overheated

as well as pumps from other manufacturers. Therefore, it is recommended that after every 2-3 hours of operation of the device, give it time to “rest”.

Marquis (Marcus)

The owners of the Marcus well pump sometimes notice that the device turns on only after a slight blow either on the pipe leading to it, or after hitting the hydraulic machine itself. This error is explained by “souring” of the impeller

, which will have to be cleaned by disassembling the unit.

Common motor pump problems and their elimination

Pump motor does not start

Reasons why the motor pump engine does not start:

- there is not enough gasoline in the pump tank;

- you need to add oil;

- incorrect connection - the motor pump starts only in a horizontal position;

- the fuel cock is closed;

- the carburetor damper is open;

- the carburetor is very dirty;

- oil enters the combustion chamber of the motor pump;

- the air filter is dirty;

- the spark plug is covered with soot.

As you can see, if the motor pump engine does not start, this problem can in most cases be fixed independently.

The motor pump is unstable

The cause of the unstable operation of the motor pump may be a dirty air filter. You can clean or replace the filter yourself.

Malfunction of the pump part of the motor pump - no suction

Reasons for the lack of suction in the motor pump:

- damage to the intake hose;

- wear of the pump seal;

- insufficient water level in the pump section.

The motor pump began to pump water weakly

Reasons for the low performance of the motor pump:

- the intake filter is clogged;

- incorrect connection with the intake sleeve or mismatch in diameter;

- there is a lot of water in the outlet sleeve.

By opening the valves and releasing fluid from the hose, you can increase the performance of the motor pump.

Motor pump is overheating

The ambient temperature for efficient operation of the motor pump without interruption should not exceed 40°C.

Summing up, we can say that the motor pump is quite easy to use. Often, malfunctions of the motor pump can be eliminated independently. If a serious problem arises, then there are always specialists who will come to the rescue to solve it. Our workshop for the repair of construction, garden, pumping equipment will quickly diagnose the malfunction and perform high-quality repairs of motor pumps and gasoline pumps.

| address in Rostov-on-Don | telephone | working mode |

| st. Dovatora, 215 | +7 (863) 294-68-92 | 9:00-18:00 without a break, |

Saturday and Sunday - days off

If the motor pump engine does not start, the motor pump is unstable, there is no water suction, the motor pump pumps water weakly, overheats, there is a leak or black exhaust gases - contact the Alfa-Rost repair service center in Rostov-on-Don.

A motor pump is a surface pumping device that is widely used in various sectors of human life and activity. On the shelves of modern specialized stores, you can see a large number of these devices, which differ not only in price and country of manufacture, but also in purpose. Buying a motor pump is an expensive financial investment. Before going to the store, it is necessary to consult with experts and study the advantages and disadvantages of each model so that the purchased product does not disappoint with poor quality and does not turn out to be useless. The service life of a motor pump is affected not only by the model and build quality, but also by proper operation and competent care.

Common cause

If your pumping equipment is buzzing, as during operation, but does not pump water from the well, then the reasons may be related to mechanical damage or clogging of the hydraulic structure. To begin with, try to remember what water came out of the tap on the eve of the breakdown.

If a turbid liquid flowed from the tap or the pressure suddenly began to decrease under the standard operating mode of the pumping equipment, then the trouble most likely lies in the well itself. This happens if the hydraulic structure is silted up or clogged. This phenomenon is commonly referred to as well sanding. And it can be called:

- small algae that live in water;

- solid impurities brought by the current;

- shedding of rock from the walls of the tunneling;

- sand lifted from the bottom of the well by pumping equipment.

All these components can clog the clearance of a hydraulic structure. As a result, first muddy water with sand will come out of the tap, then with air, and then the flow will stop altogether. In this case, the protection against dry running in your pumping equipment may not work.

To fix the problem, you need:

- Pull the submersible pump out of the well.

- All water from the hydraulic structure is pumped out.

- Disinfection of the interior space.

- Re-pump out the water. The time for re-pumping depends on the disinfectant used.

After cleaning the well, the pump should start working. But even if this did not happen, you should not hang your nose, because cleaning the hydraulic structure will benefit the quality of the water and the durability of the source.

Malfunctions of protective systems of pumps

Usually, a properly assembled water supply system and quality pumps have devices that prevent them from idling.

In the event of a malfunction of such protective devices: a dry-running relay for a well and float switches for drainage, a well or fecal pump, the devices can work in the absence of water.

Sometimes the float switch of well or drainage pumps, due to improper installation, does not lower along with a drop in the water level (it falls on a hillock or clings to a protruding object) - this leads to the operation of the electric pump in idling mode and its further failure.

Vibrating pumps, which usually do not have external protective devices connected in the system, working for a long time without water after a drop in its level, can fail if there is no built-in thermal protection.

What to do next

If cleaning the well did not help, then the following situations may be the causes of the malfunction:

- failure of mechanical parts of pumping equipment;

- breakdown in the power supply system;

- violation of the tightness and integrity of the main pipeline;

- malfunction of one or more pump control units.

But in order to understand exactly what the reason is, the submersible unit must be raised to the surface from the well. Then the pump is lowered into a container of sufficient size filled with water and started:

- If the engine starts to work when starting, then there is no breakdown in the electrical system. Otherwise, such malfunctions can be suspected. But the search and elimination of the causes of the breakdown of the electrical system should be carried out by an experienced specialist.

- It is worth watching a running motor. At the same time, try to visually assess the integrity of all pipelines and hoses. Sometimes the pump does not lift water well due to the fact that the tightness of the hoses is broken, and the pressure in the system has dropped.

- But a leak may not be noticed right away, especially if the damage is very small. To make such places more noticeable, the outlet on the hose must be closed by hand. Then the pressure in the pipeline will increase, and jets of spurting water will appear in places of depressurization.

Types and causes of malfunctions

A motor pump is a simple device that consists of two parts:

- internal combustion engine;

- pump part.

Experts identify several types of breakdowns of gasoline, electric and gas appliances and the causes of their occurrence.

- Inability to start the engine (for example, 2SD-M1). Possible reasons: lack of fuel in the tank, low oil level in the engine, incorrect position of the device, presence of oil in the combustion chamber after improper transportation, opening of the carburetor damper of a cold engine, no spark between the electrodes during rotation of the engine shaft, clogging of the filter device, closed supply valve fuel.

- Interruptions during work. Causes: dirty air filter, breakage of the rotor speed regulator, deformation of the valve seat, use of poor quality fuel, worn gasket, deformation of the exhaust valve parts.

- Engine overheating. Causes: incorrectly set engine parameters, use of inappropriate fuel, work at an altitude of more than 2000 m, operation in unsuitable climatic conditions.

- No water entering the pump. Causes: lack of filled water in the pump, air entering the intake hose, loose fixation of the filler plug, air passing under the sealing gland.

- Low volume of pumped water. Causes: intake of air at the inlet, contamination of the intake filter, discrepancy between the diameter and length of the hose, overlapping or clogging of the intake taps, finding the water mirror at the maximum height level.

- Failure of the time relay and protection system. Causes: contamination of the internal system of the pumping device, operation without oil supply.

- Extraneous noise. The reason is the deformation of internal parts.

- Automatic shutdown of the device. Causes: occurrence of overload in the system, violation of the integrity of the engine, soil ingress.

- Breakage of the magnet in the vibrating device.

- Breakdown of starting condensate.

- Heating of the working fluid.

How to disassemble the unit to diagnose a breakdown

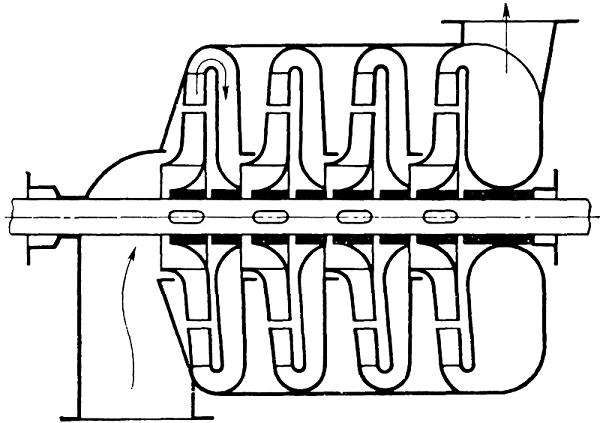

In case of pump breakdowns requiring replacement of parts located inside its housing, disassembly of the unit will be required. A submersible pump consists of a motor compartment and a compartment with one or more impellers, the purpose of which is to capture water.

. Below is a diagram of the device of that part of the centrifugal pump where the impellers are installed.

As can be seen from the figure, the impellers are mounted on the shaft of the unit. The more of them, the higher the pressure created by the pump.In the second compartment of the hydraulic machine is located rotary engine.

It is in a sealed case, and to open it, you need to know some of the nuances.

So, in order to move from theory to practice and disassemble the pump, follow these steps (depending on the manufacturer, the design of the unit may differ).

- Unscrew the 2 screws holding the mesh of the device.

- Remove the mesh and turn the motor shaft by hand. If it does not spin, then the problem may be either in the engine compartment or in the pumping part of the apparatus.

- First you need to disassemble the pumping part of the device. Unscrew the 4 screws holding the power cable channel and disconnect it from the machine body.

- Next, unscrew the 4 nuts holding the pump flange.

- After unscrewing the fasteners, separate the pumping part of the apparatus from the engine. At this stage, it is possible to determine in which section the jamming occurred. If the shaft of the pump compartment does not rotate, then this assembly must be disassembled.

- Unscrew all fasteners holding the lower flange of the pump part of the unit.

- An adapter must be screwed into the fitting located at the top of the block, which will help keep the threads from damage.

- Secure the pump in a vise.

- Having picked up a suitable tool, unscrew the bottom flange.

- The impeller assembly can now be pulled out and inspected for faults.

- Next, you should check the support shaft for wear or play.

- To replace (if necessary) the impellers, it is necessary to fix the shaft in a vice and unscrew the top nut.

- At the next stage, the blocks are removed, washed and, if necessary, replaced with new ones.

- The assembly of the pumping part of the apparatus is carried out in the reverse order.

- To disassemble the electric motor, it must also be fixed in a vise.

- Next, remove the plastic flange protection by unscrewing the fasteners.

- Remove the retaining ring holding the cover with a pair of pliers.

- Remove the cover using a slotted screwdriver.

- Remove the rubber membrane from the housing.

- Remove the capacitor.

- At this stage, you can check the oil level, its quality, identify the cause of jamming, etc. The engine block is assembled in the reverse order.

Troubleshooting

If the motor pump does not start, stalls under load, does not pump or pump water, does not start, you must carefully remove the impeller, disassemble and adjust it. For each type of breakdown there is an individual solution to the problem.

If it is impossible to start the motor pump, the following measures must be taken:

- fill fuel in strict accordance with the manufacturer's instructions;

- checking the filling level with a dipstick and, if necessary, carrying out an additional filling of fuel;

- horizontal placement of the device;

- checking the operation of the motor shaft using a starter cord;

- cleaning the float chamber of the carburetor;

- removal of contaminants in the fuel supply filter;

- complete closing of the carburetor damper;

- removal of carbon deposits from the spark plug;

- installation of a new candle;

- opening the fuel supply valve;

- cleaning the filtering devices by unscrewing the bottom plug on the float chamber.

If there are interruptions in the operation of the device, the following manipulations must be carried out:

- cleaning the filter and all approaches to it;

- installation of new filter parts and snails;

- determination of the nominal value of the frequency of the rotor;

- pressure increase in the compressor.

In case of severe overheating of the engine, it is imperative to perform several actions:

- engine adjustment;

- compliance with the temperature regime of the environment during operation of the device.

Often, when performing work, the motor pump stops sucking up liquid and pumping water. In the event of this problem, there is an established algorithm of actions:

- adding water to the pumping part;

- tight closure of the filler plug;

- replacement of seals and stuffing box;

- replacement of the suction hose;

- sealing of places of penetration of air streams.

Many owners of motor pumps over time notice a decrease in the volume of pumped liquid and a sharp drop in device performance. The elimination of this breakdown consists of several manipulations:

- checking the connection of the intake hose to the pumping equipment;

- fixing the fastening clamps on the branch pipe;

- washing of filter parts;

- connecting a hose of the appropriate diameter and length;

- moving the installation to the water mirror.

To eliminate the breakdown of the time relay, it is enough to clean the internal equipment of contaminants, add the missing amount of oil and check the integrity of all parts. To resume the silent operation of the motor pump, it is necessary to check the absence of mechanical damage and various defects in the components. Only electricians of the service center can eliminate the breakdown associated with the disconnection of the device. Before calling a specialist, you can only check the junction box for the possibility of a voltage drop and remove visible soil particles inside the device.

Congratulations, you have become the owner of a motorized water pump!

And so, you assembled this unit, filled in the oil, what kind of gasoline to fill in the motor pump, you ask? 92 is the simplest without additives. In the 95th, the degree of combustion is higher, therefore, engine wear will be higher, and additives on the carburetor have a bad effect in this technique.

Then we connected all the hoses, poured water into the pumping unit. You didn't forget to do this, did you? Otherwise, the motor pump does not pump water, there is no pressure created by the impeller, in addition, you will have to take care of replacing the motor pump oil seal, and it is ceramic and more friction is created for dry, it may crack. We start, fine, the pump starts up, but there is no result. You add speed, the water poured out, but somehow badly, we turn off. And so, if you have done all the above manipulations, but nothing works, the pump sucks poorly, then at some stage there is air leakage, what should I do? We disconnect the hoses and start the pump with the pumping unit filled with water, after which we put our palm to the inlet, closing it, if there is a draft, then everything is fine. We wrap all the threaded connections with your hoses with a fum tape, maybe you didn’t do this, after which we rejoice at the quality of the work done.

If the motor pump does not suck in water, the reasons are not clear, we are taking it to the supplier, perhaps just a defective stuffing box, or the absence of an o-ring at the junction of the bell of the pumping unit, this is definitely not your fault, all costs are borne by the seller. In addition, do not forget that the time of continuous operation of the motor pump should not exceed 6 hours, overheating is possible.