GOST R 51613-2000 - Pressure pipes made of unplasticized polyvinyl chloride. Specifications.

| Designation | GOST R 51613-2000 |

| Name | Pressure pipes made of unplasticized polyvinyl chloride. Specifications. |

| Title | Pressure pipes made of unplasticized polyvinylchloride. specifications. |

| Application | This standard applies to pressure pipes made of unplasticized polyvinyl chloride - PVC-U without a socket and with a socket, intended for pipelines transporting water, including for drinking water supply, at temperatures from 0 to 45 ºС, as well as other liquid and gaseous substances. The standard does not apply to pipes for electrical work and transportation of combustible gases intended as raw materials and fuels for industrial and domestic use. |

The text of the standard is given for informational purposes and does not replace the official publication.

Types and sizes

Pipes are made of the following types:

- without bell;

- with a socket for connection with an elastic sealing ring of a special section or other similar ones - Р;

- with a socket for adhesive connection - RK.

Pipe with socket for glue joint

Pipes are made in straight sections with a nominal length of 4 to 12 m with a multiplicity of 0.25 m. The maximum deviation of the length from the nominal is no more than 25 mm. Allowed in a batch of pipes in sections up to 5% of pipes of shorter length, but not less than 1 m.

It is allowed, in agreement with the consumer, to manufacture pipes of other lengths and other maximum deviations.

Symbol for pipes

The designation of pipes consists of the word "pipe", the abbreviated name of unplasticized polyvinyl chloride (UPVC 100, UPVC 125), socket type, standard size ratio (SDR), dash, nominal outer diameter, nominal pipe wall thickness, pipe purpose: household and drinking purposes denoted by the word "drinking", in other cases - "technical" and the designations of this standard.

Legend Examples

Pipe PVC-U 100 without socket, SDR 26, with a nominal outer diameter of 63 mm and a nominal wall thickness of 2.5 mm, for drinking water systems:

NPVC pipe 100 SDR 26-63x2.5 drinking GOST R 51613-2000

PVC-U 125 spigot with o-ring connection, SDR 17, nominal outer diameter 225 mm and nominal wall thickness 13.4 mm, for pipes not used for domestic and drinking applications:

NPVC pipe 125 R SDR 17-225x13.4 technical GOST R 51613-2000

PVC-U 100 pipe with solvent cement socket, SDR 33, nominal outer diameter 140 mm and nominal wall thickness 4.3 mm, for domestic and drinking applications:

Pipe NPVH 100 RK SDR 33-140x4.3 drinking GOST R 51613-2000

Technical requirements

Pipes are made from a composition based on suspension polyvinyl chloride with a K value of at least 67 (GOST 14040).

Pipes for domestic and drinking water supply are made from compositions approved for use by the health authorities of the Russian Federation.

By agreement with the consumer, it is allowed to manufacture pipes for technical purposes using secondary raw materials of the same composition, formed during the own production of pipes according to this standard.

Recommendations for the selection of pipes for the transportation of various media

The selection and calculation of the maximum working pressure of pipes for transporting various liquid and gaseous media, except for water, to which unplasticized polyvinyl chloride, sealing ring material and chemically resistant adhesive, are carried out on the basis of regulatory documents for the installation and operation of the relevant pipelines.

The coefficient of reduction of the maximum working pressure at a temperature of water transported through the pipeline up to 45 ° C for a service life of 50 years is given in the table.

|

Operating water temperature Tslave, °С |

Pressure reduction factor Ct |

|

up to 25 |

1,00 |

|

26-30 |

0,88 |

|

31-35 |

0,78 |

|

36-40 |

0,70 |

|

41-45 |

0,64 |

How to choose a pressure PVC UPVC pipe for water supply, what you should pay attention to.

UPVC - unplasticized polyvinyl chloride.For brevity, the "H" is often omitted from the abbreviation.

1) The pipe must be accompanied by permits confirming its compliance with the requirements of regulatory documents (DSTU, TU, technical certificate), as well as the corresponding permit from the MZU:

a) certificate of conformity and/or technical certificate;

b) the conclusion of the sanitary-epidemiological examination (for drinking water).

2) Visually, compliance with standards can be determined by the following features:

a) Pipe color - gray (different shades are allowed);

b) There is a factory-applied marking - clear and well distinguishable against the background of the pipe, resistant, not erasable;

c) The marking contains the data:

•Trademark and/or manufacturer's company name;

• name of material (PVC or PVC-U);

• serial number (S);

• nominal outer diameter;

•nominal pipe wall thickness;

•appointment of the pipe ("drinking" or "technical");

• nominal working pressure (PN) of water in the pipe at 20°C with the designation of the unit of measure (bar);

• designation of the normative document;

•batch number;

•Release date;

•additional information is allowed, such as manufacturer's contacts, production line number, etc.

An example of correct marking:

TOV KaTZ NPVC S12.5-160 x 6.2 pitna 10.0 bar DSTU B V.2.7-141:2007 P.007 17.12.12 12:22 L No. 2 tel ... Explanation:

Explanation: Pipe manufactured by the Kalush Pipe Plant from PVC-U, serial number S12.5, nominal outer diameter 160 mm, nominal wall thickness 6.2 mm, intended for drinking water supply, nominal working water pressure not more than 10.0 bar, manufactured in accordance with DSTU B B.2.7-141:2007, batch: P.007, date and time: 12/17/12 12:22, line No. 2, contact phone.

d) The pipe must not have visible abrasions or deep scratches on the outer or inner surface;

e) The outer and inner surface of the pipe must be uniformly painted, without inclusions of a different color, stretch marks, traces of "bubbles", light spots, stripes, etc.

Pay attention to the color of the socket - here the color shade (compared to the color of the main part of the pipe) should also not change. If the shade of the bell is lighter, there is a high probability of a violation of the technology of its formation (bell).

3) Check by touch:

a) The outer and inner surface of the pipe must be smooth, without roughness and burrs;

b) The rubber sealing ring located in the socket of the pressure PVC pipe must sit very tightly in its seat. To manually remove the ring from the "correct" pipe, you need to make a lot of effort.

4) Conduct a strength experiment: pressure PVC pipe must be very rigid and durable. You can safely stand on it and even jump, no deformation is allowed.

5) Take an interest in the prices of PVC-U pipe raw materials - a high-quality pipe should cost more than raw materials for its weight.

6) Simplify your life - choose a reputable manufacturer and a reliable supplier you can trust.

Deciphering and using PVC

Abbreviation

PVC pipelines are used in the construction of a sewer network, due to the ease of installation work and low price. And also due to good technical characteristics, this type of pipe can be used in pressure systems. Its features include good dielectric ability, resistance to aggressive chemical environments.It is not subject to corrosive formations, is not afraid of moisture, ultraviolet radiation. Thanks to these qualities, PVC pipes are widely used both in industry and in everyday life.

Exploitation

PVC pipes are used in such areas as:

- construction of a swimming pool, fountain, water park;

- chemical production;

- food industry;

- Agriculture;

- in the construction of a sewer system.

- PVC pipelines are used for waste systems of these types:

internal networks; - outdoor;

external pressure systems; - with gravity drain.

They are practically eternal. Probably, for each product of plastic pipes, the manufacturer gives a guarantee of fifty years of service. Also, polyvinyl chloride is environmentally friendly and absolutely harmless. For the customer, this type of pipes is more interesting than any other plastic pipes, in terms of reliability and cost.

Currently, these materials are the most profitable option for waste systems, not taking into account the not very simple manufacturing process. For example, low-pressure polyethylene is simply poured into an extruder, raw materials for PVC pipes go through a complex multicomponent process and have a limited shelf life.

Now the use of PVC pipes made of plastic in the construction of a sewage system is widespread. They are gradually replacing the classic cast iron. Plastic has many good properties, and this is what distinguishes it from metal counterparts.

A range of PVC-U sewer pipes

First of all, PVC-U sewer pipes are distinguished by their scope. Exists:

- pipes for internal sewage PVC-U;

- PVC-U pipes for external sewerage, organized according to the principle of self-accuracy;

- pipes for external pressure sewerage.

Pipes for indoor and outdoor use differ in color. The first have a gray light, the second red or brownish red

It is important that the pipes used are suitable for the application. For example, PVC-U pipes for internal sewerage cannot be used outdoors, as they are simply not designed for high loads and atmospheric influences.

It is possible to use external sewer pipes for laying around the house, but it is irrational, since their prices are higher.

Dimensions

PVC pipe wall

The wall thickness of the pipes also varies depending on the purpose. The thickness of the material in PVC-U pipes for interior work is 3-3.5 mm. This thickness is due to insignificant physical loads on the pipeline, and the tensile strength achieved is sufficient. For the outer part of the sewer system, pipes with a wall thickness of up to 15 mm are used. Often, outer pipes have complex multilayer walls. Between the two layers of PVC is foam, aluminum or carbon fiber. This design is designed to improve thermal insulation performance, reduce the weight of pipes, and increase their strength.

PVC-U sewer pipes have an indicator of ring strength, which characterizes the ability of the pipe walls to withstand compressive loads. For each type of pipe, this indicator has its own designation. The "weakest" pipes for internal use are marked SN2. The ring strength of external sewer pipes is 2 and 4 times higher and is marked SN4 and SN8, respectively. SN8 PVC-U pipes are laid under busy highways and in areas with high soil mobility.

Performance characteristics

Secondly, PVC-U pipes are not subject to corrosion and the effects of most chemically active substances. Thirdly, their service life can be 50 years or more.

The disadvantages of PVC-U pipes include the vulnerability of most types of pipes to rodents, which can damage the pipeline in the house. A significant disadvantage of such pipes is their small operating temperature range from -5 to 60 ° C, so the outer sections of sewer systems have to be laid deep into the ground below the freezing level.

If we correlate all the pros and cons, then PVC-U sewer pipes can be concluded that this material is very practical and easy to use. And given all the technical limitations, the sewer systems installed using these pipes will do their job perfectly and last a very long time.

Pros and cons of unplasticized PVC casing

Casing pipes for wells, the material of which is PVC-U (unplasticized or unmodified polyvinyl chloride), have a number of advantages:

- meet all necessary sanitary and hygienic requirements;

- have high resistance to chemically aggressive environments;

- withstand long-term operation (PVC casing pipe can last more than half a century);

- have high strength with a relatively small specific weight;

- provide exceptional tightness, as, as a rule, threaded PVC casing pipes are produced;

- have high resistance to formation and development of corrosion;

- easy to install;

- transported without problems (as mentioned above, products made of PVC-U are lightweight);

- have the ability to successfully endure mechanical loads that can withstand casing products made of metal;

- do not emit harmful substances (PVC is a material inert to water);

- do not grow over time and practically do not wear out;

- have a relatively low cost when compared to PVC casing pipes with similar products made of metal.

The use of PVC-U pipes for outdoor sewerage

For sewer lines, PVC-U pipes are used both at the stage of reconstruction and for laying new highways.

It should be taken into account, the peculiarity of the operation of external sewer systems

It is extremely important that the material of tubular products is suitable for the conditions in which it functions. External lines must be resistant to ultraviolet radiation, temperature and pressure changes, not deformed from possible hydraulic shocks

In this sense, pipes made of unplasticized polyvinyl chloride fully comply with the requirements for an external sewer network:

High strength. Withstands external pressure up to 160 atmospheres (depending on wall thickness), internal - up to 25 bar, resistant to hydraulic shocks.

Light weight products

Despite this, the pipeline submerged in water does not float, which is important for terrestrial networks.

Low hydraulic resistance and, as a result, a decrease in the likelihood of blockages.

Simplicity and convenience of installation. Special equipment is not required.

Products are easy to cut.

Minimum labor costs for maintenance and repair of finished networks.

UV resistance

Suitable for open laying.

Long service life, 50 years or more.

Among the shortcomings, one can note a serious deterioration in strength characteristics at negative ambient temperatures, as well as the impossibility of using the material for transporting working media with temperatures above +40°C. When heated above 50 ° C, the pipe material begins to release chemical compounds hazardous to health.

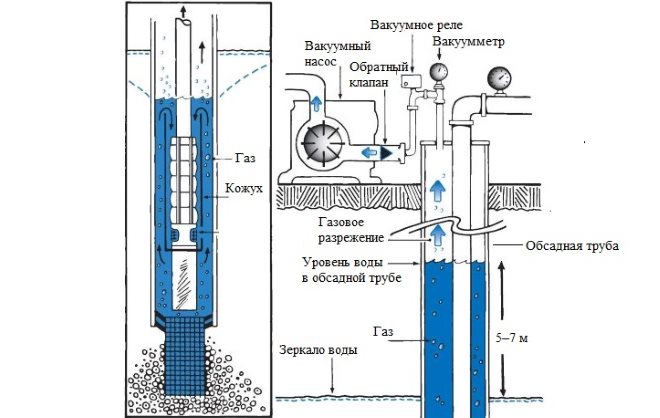

Varieties of pipes for arranging wells

Drilling a well is only part of the task that needs to be solved in order to provide your summer cottage or personal plot with water coming from underground sources. To raise water to the surface, a pump is needed, and first it is necessary to lower a casing pipe into a hole drilled in the ground.

Well device with casing pipe

As mentioned above, products made of metal, asbestos cement and PVC (PVC) can be used. For use as casing metal and asbestos-cement pipes, lifting equipment is necessary, since they are heavy. Metal pipe rolling, in addition, is quite expensive, so its use is associated with significant financial costs.

Asbestos-cement products are more affordable, but they are inconvenient to install and very susceptible to mechanical stress. When using asbestos-cement pipes as casing, situations often arise when they burst due to external loads, which leads to well erosion and subsequent clogging. Restoring it in this case is almost impossible, so the way out is new drilling. This, of course, leads to additional financial costs.

Socket connection of PVC-U pipes

How to calculate casing diameter size

Before purchasing materials and arranging a water-lifting well, its dimension should be determined. Manufacturers offer a wide range of casing materials for wells.

The minimum diameter of products is 90 mm, the maximum diameter is 225 mm. The wall thickness varies from 7 to 20 mm. For domestic wells, casing pipes 125 mm in diameter are common sizes. Thick-walled products are used for the installation of deep artesian wells.

The choice of well size should be guided by considerations of practical expediency. The dependence here is this - the more water is required daily, the more power the pump will use. When calculating the diameter of a well, the depth of its drilling is also important, the larger it is, the more powerful the pump will be required to raise it to the surface.

The more powerful the pump for pumping water, the larger its dimensions and the wider the well will be required to submerge it. Pumps with flow rates up to 8 mm have a body diameter up to 122 mm, which does not require a pipe larger than 125 mm.

PVC pipes or cast iron pipes - which are better for sewerage

Looking ahead, we note that PVC-U pipes are completely out of competition with their counterparts. Why this is true will become clear from a comparison of the following:

- 1.Unlike cast iron piping, UPVC sewer systems will not rust or collapse. First of all, this is due to the production technology. So, if in the first case metal was used for production, then plastic is used for PVC-U, which is not afraid of corrosion, direct interaction with water. Along with this, polymer pipes are not afraid of chemical activity, which can be caused by the acid base of food products, as well as chemicals for washing tiles and dishes. This implies a big plus of polymer pipes - the service life is 60 years, which is 3 times higher than that of cast-iron counterparts.

- 2. PVC-U has a light, one might say airy structure, which allows a small number of craftsmen to work with these pipes.Along with a low specific gravity, it is worth noting the simplicity of the design. In turn, the simplicity of the design allows you not to use a special tool for installation, which means that it does not require certain skills. For example, in order to lay a sewer from cast-iron pipes, you need to have a welding machine, get a work permit, and notify neighbors about the work being done. At the same time, it is not a fact that you will surely weld cast iron, because microscopic holes may remain through which an unpleasant odor will pass. In the case of UPVC, everything is much simpler. It is enough just to combine two pairs of pipes, sawing off the desired length if necessary. At the same time, the sealing ring that is available simply will not allow you to make the joint incorrectly.

- 3.Low cost uPVC. Just imagine, plastic and metal. Of course, the metal will cost many times more, despite the fact that its performance is much worse.

- 4. High coefficient of resistance to high temperatures. This means that the polymer sewer system will never burst or leak, which will allow you to avoid unplanned repairs. In the case of cast iron, sooner or later, the thermal expansion of the metal will lead to a violation of the strength at the welding site of two sewer sections. In this regard, it will leak and timely repairs will be required.

- 5.High coefficient of frost resistance. If you use cast iron on the street, then it will have to be buried one and a half meters or more. In the case of using PVC-U, you can drip a 50 cm sewer pipe.

Summing up this article, we note that not all the positive qualities of PVC-U pipes are listed here. But this is quite enough to draw conclusions in favor of polymer sewage.

What do the symbols in the label mean?

To navigate when choosing a PVC-U product, you should pay attention to the marking. If PVC-U 110 pipe is required, the diameter and other specifications are abbreviated on the outer surface of the product

The maximum marking interval is one meter.

For marking, methods are used that do not affect the performance of the walls. In particular, a heated metal tool is used.

The following indicators can be found in the marking:

- material used in the manufacture; type of pipe, diameter, wall thickness; technical conditions; date of production.

The abbreviation NPVC is used for the Russian-language designation of the material. The international equivalent is PVC-U. Further, the marking indicates the presence of a bell.

The following numbers convey information about the outer diameter of the product. If it is a PVC-U 160 pipe, the number 160 should be in the marking. If necessary, the manufacturer includes additional information in this list.

UPVC pipes make up a significant proportion of water pipes used in modern construction.

They are known for their reliability and availability in the market. The marking applied on each pipe will allow you to navigate the characteristics of the product and choose the right one for installation at the facility. UPVC pipes are quite successfully used in space heating.

Pipes made of polyvinyl chloride (PVC) are famous for their high resistance to chemically active substances, as well as durability, which makes them indispensable in the construction and repair of external sewer systems.

The low price, low weight and ease of assembly of structures made of PVC products ensured the immense popularity of this material.