Why is the headline important?

A city dweller is often unable to understand how important it is to keep the water source clean. We are used to the fact that clean water appears with the turn of a faucet in the kitchen or in the bathroom.

And if there is no water, this is a cause for indignation. In the case of arranging your own water supply, you will not have to be indignant at clogging the well and reducing the debit, that is, the amount of water available for pumping out.

What accidental pollution can threaten a private water intake?

The diameter of the well is only 11-18 cm. It would seem that what can get into such a small hole? Unfortunately, a lot. And the small diameter plays rather a negative role. For clogging, small items are enough. Birds, small animals, sponges, tools, lumps of dirt, all these items can completely block access to water and it is quite difficult to remove them.

In practice, I have come across cases when the cause of clogging was simply a large stone that somehow fell into the casing well. The cost of extracting the stone cost the owner of the well tens of thousands of rubles. The cost of the cover can be from 500 rubles for self-production, up to one and a half - two thousand when purchased in a specialized store.

Cleaning up the well is very laborious and takes a lot of time or costs a lot of money. Therefore, it is better not to skimp on the device or the purchase of the correct closing cover.

The device and the order of installation of the structure

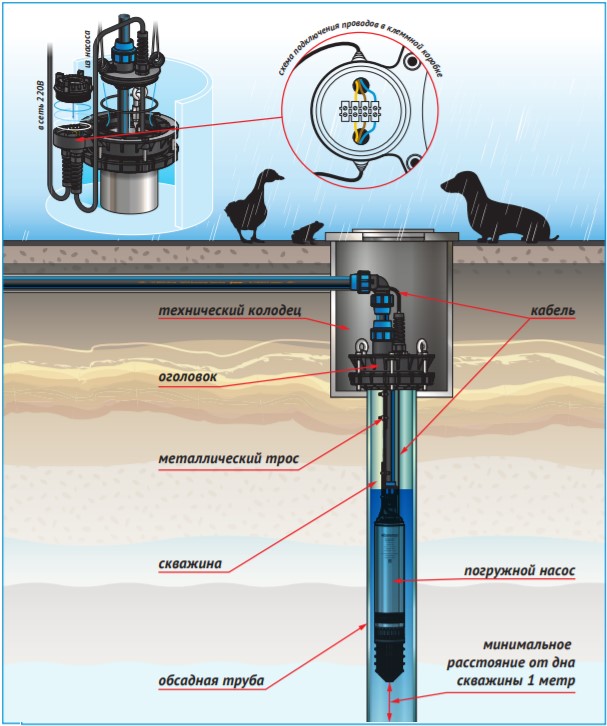

The head of the well is used to protect the reservoir from sewage, insects and debris.

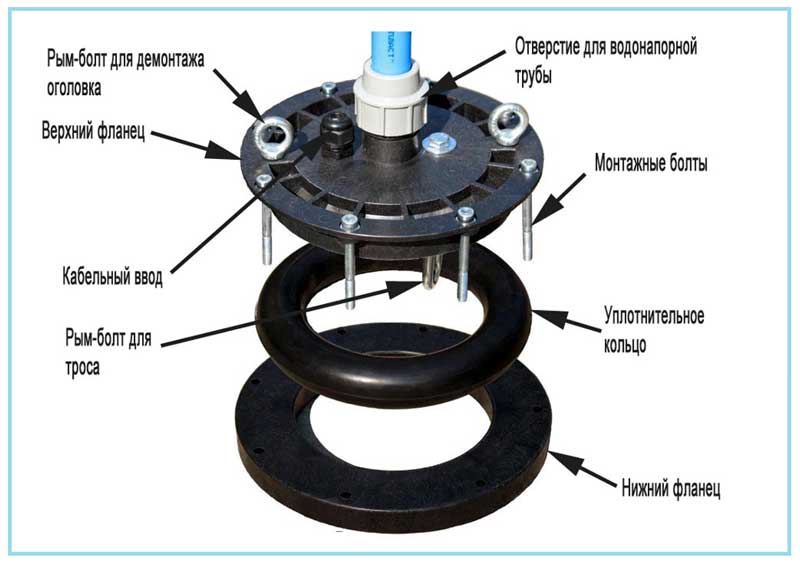

Before using this product, you should familiarize yourself with its structure. The headpiece includes a cover, a carabiner, fasteners, a flange design and a sealing ring. The cover is equipped with special bolts.

Installation is made without welding works. The structure is mounted using bolts. When they are tightened, all elements are compressed: flange, ring and cover. This ensures tightness.

The headpiece is designed to solve many problems:

- The well is equipped with a protection system and tightness.

- The debit of the well is increasing.

- The occurrence of ice and freezing during the cold period is reduced.

- Wires and a pump are easily attached to this device.

- Used to protect against damage or theft.

- Helps to switch to a smaller pipe diameter.

- Helps to increase the productivity of small wells.

- Prevents contamination of the source.

- Performs a decorative function.

Heads are made of plastic or plastic. Equipment that weighs no more than 200 kg is suspended from plastic products. Devices made of steel can withstand weight up to 500 kg.

Scheme of the design of a typical head

For installation, materials and special tools are purchased:

- cap;

- construction grinder;

- paints with anti-corrosion effect;

- keys;

- solidol.

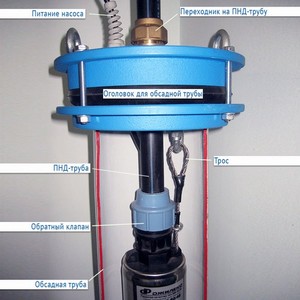

Installation consists in correctly clamping the sealing element between the flange part and the cover. Fasteners are tightly tightened. Before work, the casing pipe is cut. Then its edges are cleaned.

How to choose the right head for a well

To make the right choice, you need to know what the digital and letter markings on the products for sale mean, their decoding in order looks like this:

- OS - alphabetic characters designate a borehole head;

- A - anti-vandal design;

- P - made of plastic, if the symbol is absent, metal execution is implied;

- B - a symbol in the marking for Gilex composite heads, in which the central part with fixed pumping equipment (electric cable, cable and hose) can be freely removed and installed back into the well without removing the head from the casing pipe;

- 90-110 - numbers indicating what range of external dimensions of casing pipes the head assembly is designed for;

- 25,32,40 - these symbols follow the slash, they mean the outer diameter of the HDPE pipe for which the central collet is designed.

It should be noted that not all manufacturers support this marking and its sequence, there are AOC, OGS, OD designations that do not play a special role in determining the purpose of the goods.

Rice. 7 Scheme of installation of the Gileks OSPB head in the well

When choosing a cap, you should take into account some recommendations:

The most convenient, practical and inexpensive are plastic devices, they are best used for small immersion depths of electric pumps of low and medium power. If the immersion depth is large (large mass of water in the pressure pipe) or the electric pump is large and heavy for pumping significant volumes, it is better to use stronger steel or cast iron heads

Although the terminal box makes it much easier to connect and disconnect the electric pump from the power supply, its use must be approached with caution when operating powerful equipment. The fact is that the version proposed by the manufacturer and the terminal strips themselves are too unreliable method of connecting wires, and with a high current consumed by powerful electric pumps, overheating of the contacts, melting of the plastic of the head or cable insulation is possible

Also, high humidity in the head area, even with reliable insulation of the terminal box (from the point of view of a domestic manufacturer), can lead to corrosion of the contacts, their overheating or short circuit.

Well caps

dust, dirt, sand, foreign objects, amphibians and dirty water when flooded by spring waters, the upper end of the casing pipe is equipped with a head - a plug that hermetically closes its neck.

The head mounted on the pipe provides a reliable suspension of the electric pump, wires and water hose.

In winter, sealing saves the well from freezing, and also, if there is a locking device, it will protect against unauthorized entry.

The most popular on the market are domestically produced heads Gillex and Aquarius

, combining low price and the desired quality.

Borehole head "Dzhileks" is designed for well equipment with a casing pipe with a diameter of 90 to 160 mm and pumps with PVC pipes with a diameter of 25, 32 and 40 mm. They are made from cast iron or plastic.

The “Aquarius” head is made of plastic and is designed for shallow wells with a casing pipe diameter of 113-127 mm and a pressure pipe diameter of 32 mm.

Another manufacturer is "Aquarobot" produces caps

made of plastic and cast iron for wells with an outer pipe diameter of 107-159 mm and a pump pipe diameter of 32 and 40 mm.

How to make your own headband

So, the most important thing is the construction of a homemade headroom. For convenience and clarity, this process should be divided into 2 stages: the construction of its main parts and the installation of the resulting structure at the wellhead.

Stage 1: preparation of parts

Plastic lids are characterized by good performance and light weight.

Start by actually creating the main parts of the structure. The first thing to decide is the material. Heads are metal (made of steel, cast iron or aluminum) and plastic. For self-creation, only metal is suitable.The most popular options are stainless steel, aluminum.

You will need:

- one sheet of selected metal with a thickness of 1 cm;

- 6 or 8 bolts;

- 3 eye bolts;

- 1 carabiner (to the lower eyebolt);

- strong metal cable;

- inlet fittings;

- plastic pipe for water supply.

And now you need to understand the structure of the structure:

- Make a flange from a sheet of metal. The inner diameter of the flange is measured by the outer diameter of the casing pipe: it should be 1-2 mm larger than the pipe diameter.

- When the flange is cut, cut a plug to it; The size of the plug must match the size of the flange. Its thickness should be 8-10 mm. Make holes in the cover: for the pump power cable and water pipes, 6-8 holes for bolts (respectively, the same number as on the flange), 3 holes for eyebolts.

- Install the inlet fittings for cable and pipes in the holes made.

- Install 3 eye bolts in the previously made holes: 1 at the bottom of the cover, 2 at the top of it. The lower eyebolt will serve to secure the pump, and the upper eyebolts will make it easier to lift the pump.

- The last task at this stage is the rubber gasket that will be laid between the cover and the flange. Naturally, in size it must correspond to both parts, more precisely, their inner diameter.

Stage 2: assembly of prepared parts and installation of the structure

Finally, when you understand the device of the head and the main parts for it are ready, you can proceed to the stage of installing the device on the well with your own hands.

Therefore, with its preparation, the entire installation begins:

- The casing pipe should be cut perpendicularly. This step is necessary in order for the pipe to fit the dimensions of the cover. Sand the edges of the pipe, completely remove all irregularities and cover the edges with anticorrosive.

- The second step is to lower the pump into the well. The first step is to measure the desired length of the cable and cut off the desired piece. Prepare the pump for immersion in accordance with the rules specified in the instructions supplied with the pump. Now take the plastic pipe and pump power cable. Fasten the plastic pipe, cable and cable together: this is done with clamps.

- The pipe with the cable and cable must be passed through the head cover. To the eyebolt, which is attached to the cover from below, attach the carabiner. Attach one end of the cable to this carabiner.

- It's time to weld the flange to the casing. When the flange is fixed on the pipe, put a gasket on it and lower the pump. Place the cap that covers the top of the casing on top.

- It remains only to press the gasket more tightly between the cover and the flange and connect them with bolts.

https://youtube.com/watch?v=evCaLRk3_tE

Ready! The work can be considered completed. You have made your own cap, it remains only to enjoy the fruits of your labors. If you followed the recommendations described here, you can be sure that a homemade tip will increase the life of your well no less than a store-bought one could.

Pros and cons of a homemade headband

The simplest home-made well cover is a piece of polyethylene that closes the well from above and is tied with wire or rope to the casing. Summer residents wrap the head with polyethylene at the end of the summer season, after the pumps and hoses are removed. Such a primitive device does not protect well even from bad weather, and with a high degree of probability, the well will have to be flushed before use.

The advantage of this method is its extremely low cost. This is the only plus.

The disadvantages of an impromptu lid include its non-tightness. The correct cover should ensure reliable and tight closure of the head of the casing caisson pipe, completely eliminating the ingress of groundwater, sand and debris.

Metal heads are welded or firmly drilled to the casing, so accidental pranks and clogging of wells are excluded from mischief.

The tight cover is all the more necessary when carrying out work on the insulation of the water intake for the winter. The construction of a pit, backfilling of insulation, conducting underground water communications, all this is impossible to imagine without well-organized protection of the cleanliness of the well.

What is a borehole head and why is it needed

The head is a design element of the upper part of the well, made as a plug of the end of the casing pipe emerging from the ground. If we draw an analogy with a domestic well, well heads perform the same functions as a well superstructure and a gate for lifting water, namely:

- Source protection. The cap provides protection against dirt, debris and external precipitation from entering the borehole channel; in winter, the cap prevents surface water from freezing.

- Fixing equipment. Sufficient strength of the head ensures reliable fastening of the cable, excluding it, to its carabiners in the lower part of the cover, on which the submersible electric pump is suspended. In addition, a convenient place is provided in the head for the location of the power cable of the electric pump.

- Channel sealing. In cold weather, to protect water from freezing, a heating electric cable is often used, which is placed in the deep wells of the source. The tight-fitting cover prevents heat loss and, accordingly, saves energy for heating, it also simplifies additional insulation with soft materials, preventing the well from getting inside the insulation particles.

- Theft protection. The price of submersible pumps installed in the well can reach up to 2000 USD. (Grundfos SP9), therefore, when using expensive equipment, it is necessary to take measures to protect it from theft. The special design of the heads and the technology of their fastening make it much more difficult or almost impossible to remove an expensive electric pump from a well.

Rice. 2 Sectional head on casing

- Pipe connection. The cap provides a convenient connection of the pressure pipe from the electric pump to the water supply system - for this, in its central part there is a hole through which the pipeline coming from the electric pump is led out and fixed. After cutting the pressure pipe with an angled or straight compression fitting, it is connected to the water main going into the house.

- Increasing debit. Using a sealed cap for the well, it is possible to artificially maintain a stable level. This is due to the fact that in shallow wells, a decrease in the height of the water table creates an area of rarefaction that prevents this process.

- Simplification of dismantling. In traditional models of heads, when removing the electric pump from the well for repair work and maintenance, it was necessary to unscrew the bolts and completely remove the device, disconnect the power cable from the home network and pull it out through the cover. Modern models allow you to remove and put the pump into the well without unscrewing the fastening bolts due to the removable central part of the top cover. Another advantage of such devices is the presence of a terminal box in the side of the housing, which allows you to disconnect and connect the power cable of the electric pump to the electrical network without pulling it to the house.

Structural device

The design of a standard borehole head is not very complex and consists of the following components:

Lid. The base part of the product, on which the main parts are located, is made in the form of a disk, its edges protrude beyond the inner ring and rest on the ends of the casing. In the center of the disk there is a hole for fixing a HDPE plastic pipe with a standard diameter of 25, 32, 40 mm, which corresponds to 1, 1 1/4 and 1 1/2 inches.

The outer diameter of the disk tray has different sizes, in the standard version it overlaps two adjacent casing pipe sizes in the range from 90 to 160 mm. Also in the cover there are holes for fixing bolts and an electric cable coming from the pump.

Flange. An annular part with holes for fastener bolts, put on over the casing pipe, when connected to the cover, forms a single structure tightly fixed on the pipe surface.

Sealant. It is a rubber ring of round section, placed between the head cover and the flange when they are connected, seals the joint and helps to tightly hold the head on the pipe.

Carbine. The device is used to secure the cable on which the downhole pump is suspended.

Rice. 6 Well head - main structural elements

Eyebolts.They are bolts with an annular head located in the upper part of the cover, sometimes one of them is turned down and serves to secure the cable. Eye bolts are designed to lift or install massive well pumping equipment with a winch or special equipment together with a head - this greatly facilitates the work.

Cable entry. To protect the power cable from contact with the walls of the opening in the lid through which it passes, a pressure seal is used, which is screwed into the lid and insulating the power cord from its surface.

Collet clamp. The compression fitting is located in the central part of the head and securely fixes the pipe coming out of it in a stationary state.

Mounting bolts. The elements connect the flange and the sealing ring with a removable cover, some models have a more complex anti-vandal design - in it the bolts are recessed into the cover and can only be unscrewed with a special key.

Terminal box. Some manufacturers equip their models with this type of addition, in the block they mount the wiring of the electric pump and connect it to the network cable coming from the house.

The procedure for self-manufacturing of the headband

The cover for the well is made of fasteners and metal of great thickness. The thickness of the sheet must be greater than 10 mm.

For better tightness of the structure, a caisson is used, which is a waterproof container. This device is effective in cold weather. It protects the mine from freezing and contributes to the regular operation of pumping equipment.

The caisson houses filtration structures and elements of automatic control and monitoring.

The casing pipe is pre-prepared. It is trimmed, and irregularities are eliminated from its surface. The edges are primed and painted with an anti-corrosion effect.

Self-construction work consists of the following stages:

- A fixing flange and a cover are cut out of metal. Both parts are the same size.

- Fittings for fastening pressure water supply and cables are attached to the cover. The bolt is mounted to the bottom surface to attach the cable holding the pump. Bolts are attached to the upper part, for which the cover rises.

- A ring is made of rubber, which is used as a gasket between the main parts.

- A flange and a sealing ring are installed on the column. The last detail is put on with some effort. In this case, machine oil or grease is used. In this case, there should be no gaps between the product and the pipe. The rubber ring is designed to increase the sealing level of the system.

- Under the lower part of the head is a carabiner, to which the pump is attached. One end of the hose is also attached to it. Details for fixing are selected from stainless steel.

- Then the cable is laid. A pump is attached to the cable and released into the mine. The cable is selected from stainless material. A steel product will deteriorate under the influence of moisture.

- When the cable is stretched, a cover is installed on the casing. Bolt holes are mounted opposite each other on the flange and cover.

- Bolts are then inserted and securely tightened with nuts.

- A flange is installed on the pipe.

High-quality sealing increases the efficiency of the well. With a decrease in pressure in the pipe during the operation of pumping equipment, the debit of the source increases.

WATCH VIDEO

During operation, the cable, water pipe and cable are fastened with plastic clamps. This prevents sagging.

If you use fasteners with secret heads during installation, this will serve as additional protection for the installation.

Having chosen high-quality materials and having studied all the stages of installation work, this device is made by hand.

The principle of operation of the protective cap

The device of the protective cap is quite simple.Various materials are also used for manufacturing. Steel tips are considered the most reliable, but a plastic tip can be used for plastic casing. The disadvantages of plastic are obvious. This is poor resistance to temperature fluctuations, insufficient strength in frost, cracks will appear on the plastic head fairly quickly and it will cease to perform its function.

The composition of the lid is as follows. This is the cover itself, a clamp made of brass or plastic, eyebolts, plastic or steel entries, a rubber ring, a carabiner, a mounting device, a flange.

The structure is installed with bolts.

The pump hose is immersed through the cover using eyebolts.

To install the head, it is necessary to make an accurate and even cut of the casing pipe. Clamp the cable pump to the cable and outlet pipe. After you lower the pump into the well, you can put on the shelter cover.

It should be noted that most of the large companies that arrange wells include in their services the device of the head. Perhaps, when ordering drilling a well, it should be clarified whether this necessary service is performed.

It is best to use factory-made heads.

Arranging your own well on a personal plot will allow you not to depend on the vagaries of the central water supply. But it is worth knowing that any extraction of water from aquifers following the first near-surface one requires a mandatory license. And in order to obtain such a license, it is necessary to collect a lot of preliminary permits for. And in your house there will always be enough water for domestic use and watering the garden.

Do-it-yourself head for a well

If you are limited in funds, but have locksmith skills and prefer to do everything yourself, then making a headband will not be difficult

.

There are many options for homemade heads, here is a description of one of them. The head made in this way is suitable for any type of wells, because it is made of durable material - sheet metal and pipe cutting.

Let's start with the manufacture of the head cover

. We cut out a square blank from sheet metal, on which we measure and mark the holes for the adapter flange of the water pipe, for cable entry and for eyebolts. Using a drill or drilling cutters, we cut the marked holes and clean them from burrs with a file.

We process the seams with a grinder, and we clean the entire structure with sandpaper and cover it with a primer, and then with paint to protect it from corrosion.

At the final stage, we proceed to the assembly:

- install a water pipe connection adapter, filling the gaps with silicone sealant to ensure tightness;

- we mount the eye - bolts; four covers on top for raising and lowering the pump and one on the bottom for a safety cable;

- install the cable entry device.

Installation of the mounted structure in the well is similar to that described above. A cover with a welded flange is put on the casing pipe without any additional fastening. Sealing from below can be achieved with an insulating tape.

How to make your own headband

Sometimes there are situations when, for some reason, the dimensions of the casing string have a non-standard outer diameter (180 mm), and it is impossible to find a suitable or remake a standard tip with the highest size of 160 mm. In this case, the only way out is to make a home-made metal structure using electric arc or gas welding, and this will also require a household power tool (grinder, drill). The work performed consists of the following stages:

- In a hardware or hardware store, they find a sealing ring made of paronite or rubber on the outer diameter of the casing pipe, the ring must be put on the pipe with some effort.

- From sheet steel with a thickness of at least 5 mm. grinder or jigsaw cut the top cover in the form of a steel circle 80 - 100 mm larger than the outer diameter of the pipe.

- From the same steel, a flange ring is cut with the outer diameter of the cover and the inner size of the casing.

- They combine both parts (it is better to use a clamp) and drill holes in them for mounting bolts - for uniform pressing, you need to make 6 or 8 equidistant holes around the entire perimeter.

- With special crowns for metal, two holes are made in the lid - under 32 mm. a threaded pipe for connecting a water main and a smaller diameter for a fitting in which a pressure seal will be placed, insulating the electric cable of the pump from the metal cover.

- If desired, two diametrically spaced holes are made in the lid with a metal drill, into which eyebolts are then screwed.

- Using a welding machine or a gas burner, they are welded into a 32 mm threaded cover. a fitting for connecting a water line and a fitting for placing an electric cable, a ring for hanging a carabiner is welded on the bottom of the cover.

You can easily do without a welding machine by screwing all the fittings and the carabiner ring to the cover with cap nuts, if you first equip the parts to be connected with threads for fasteners.

A homemade head is placed on the pipe surface in the above way, the bolts are screwed in gradually until the compressed rubber ring fixes both parts on the pipe.

Rice. 11 The main stages of work in the manufacture of a do-it-yourself head

The cap is an important element in the arrangement of a water intake deep source, ensuring the reliability of the placement of pumping equipment, the ease of connecting and removing the electric pump from the well during repair and maintenance work.

The average cost of factory models is about 40 USD, this amount can be saved by making the top cover and flange from sheet steel with your own hands, the main difficulty in this is finding a rubber o-ring of a suitable size.

Buy or make your own

The head for the well is selected in the store. Typical models are offered, the installation of which is carried out according to the instructions. Products are made of plastic, steel or cast iron material.

Do-it-yourself well cover is made of the following materials: stainless steel or aluminum.

Each option must be sealed.

Professional and homemade designs have advantages and disadvantages:

In self-manufacturing, improvised material is selected. When buying, you can choose products made of metal or plastic

The metal cover for the well is durable, and the plastic elements are resistant to corrosion.

When creating a design on your own, it is recommended to pay attention to the tightness of the product. In professional production, the reliability of the element is tested.

Do-it-yourself heading for a well has the advantage of a low price. Lack of errors in the creation and further maintenance of the device.

Instruction on self-manufacturing of a cap for wells

The cost of a purchased product is formed from several components: material, manufacturer, casing size and seasonality. These products are more expensive during the summer season.

Conclusions and useful video on the topic

Video #1 Elementary insulation of the walls and the cover of the caisson with foam plastic from the inside:

Video #2 Arrangement of a well with the help of a caisson, with the disclosure of the topic of insulation:

Freezing of a well and a water supply system is fraught not only with a cessation of water supply, but also with damage to equipment and elements of the system, the repair of which will require money and considerable effort. It is better to perform high-quality insulation work once and get constant access to water for many years.

The cover on the well is necessary to protect against the ingress of dirt, rainwater and debris water intake zone, protection of walls and equipment.

First of all, the cover is needed to protect against accidental pranks of children and adolescents, the actions of pets.