Installation of reinforced PP pipes

Installation of reinforced polypropylene pipes is quite simple, and it is quite possible to do it on your own if you have the necessary equipment for this. The main condition for joining is the creation of a strong sealed seam by melting the upper layer of the material.

Tools

The set of tools used during installation includes:

- a soldering iron-heater is a special welding machine for soldering polypropylene;

Special welding machine (soldering iron)

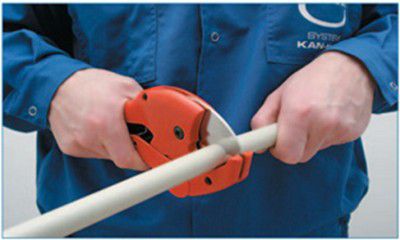

- a pipe cutter that will allow you to cut exactly at a right angle, which is very important for high-quality welding

This is how a pipe cutter works

- if a pipe with aluminum reinforcement is used, then a shaver is needed, with which the foil is removed before soldering and trimming (chamfering) is performed. The tool must have sharp and well-adjusted knives.

Shaver

- measuring tool - square, tape measure, building level, marker.

If you plan to make a reliable heating circuit so that it lasts for many years without various problems, you cannot use improvised means, you need specialized tools.

Preparing for installation

Before the installation of pipes in the system, short preparatory work is carried out. So that they do not drag out, a scheme of the entire wiring is drawn up in advance, accurate measurements are made and entered into the scheme. The parts necessary for connection are also indicated there, in the figure they are placed in the places where they will be located directly in the system:

- acting according to the scheme, measure and cut pipe sections;

- chamfer is removed from their outer edges;

- the place where the connection will take place is cleaned and degreased;

- the welding machine is fixed on a stand, and connected to the network, it must be heated to 255-260 degrees.

The heating time is determined according to a special table and depends on the type of part, wall thickness and pipe diameter.

Penetration depth and heating time

How to solder reinforced polypropylene pipes

The parts are connected to each other as follows:

Two parts prepared in advance for welding are taken. The penetration depth is marked on the pipe with a marker. After that, the shaped part is mounted on a cone-shaped element - a mandrel, and the pipe is inserted into the sleeve up to the set mark.

soldering process

- After heating, the time of which is in strict accordance with the table, the parts are removed from the soldering iron heater and quickly connected to each other. You need to insert them progressively, without scrolling and without applying extra effort. After the joint cools down, a tight hermetic seam is formed.

- A correctly made connection does not require constant monitoring, such as, for example, for metal pipes with threaded connections. This can be considered an advantage of reinforced polypropylene products, because they can be embedded in a wall without fear of accidents.

- For laying heating mains in a wall, it is necessary to draw up an exact scheme for the passage of pipes, tying it to a specific room and taking into account the characteristics of the material of the walls and ceilings of the building.

- Pipes are also placed along the wall, fastening them to it with special clamps (clips), which are screwed onto dowels. Pipes are inserted into the clamps and closed with a latch.

Fastening pipes to walls

You need to know that it is impossible to connect polypropylene pipes directly to the boiler nozzle if heating is laid in a private house. The transition from polypropylene to a heater is made using a piece of steel pipe, 45-50 centimeters long.

Classification

Leading manufacturers of polypropylene pipes produce several types of products that differ in wall section thickness.As well as the presence of reinforcing layers, including fiberglass, or aluminum foil as part of them. There are single-layer parts and multi-layer ones.

Pipes produce gray, white, black, green. Color does not affect the quality, product characteristics (except that black ones are resistant to sunlight).

Classification table

| Classes | Character | Purpose and maximum temperature | Pressure |

| PN10 | With thin walls | for cold water supply and floor heating (up to 20 or 45 degrees C) | 1MPa |

| PN16 | station wagon | for cold and hot water supply up to 60 degrees C |

1.6MPa

|

| PN20 | station wagon | for cold and hot water supply up to 95 degrees C | 2 MPa |

| PN25 | with reinforcement | for hot water and heating up to 95 degrees C | 2.5 MPa |

Before buying structural heating elements, it is imperative to clarify what temperature the products are designed for, calculate the maximum possible pressure.

Fittings for polypropylene parts

To guarantee a strong connection, the fittings must be selected in the appropriate dimensions of the same manufacturer. Their inner diameters must be equal to the outer diameters of the pipes.

Tightness will be ensured only by a welding joint using an RRG welding machine, or a special soldering device. Glued, threaded, compression fastening is not reliable enough, as it leads to curvature, deformation of products. What fittings are needed for propylene pipes, types of products?

- Coupling - a hollow piece used when connecting two ends of the same diameter. Two segments are inserted into it from different sides, fixed by welding. Collapsible couplings with a union nut are necessary for areas that are subject to cleaning, disassembly (to remove elements, counters).

- American - when installing a threaded joint of a metal product and a polypropylene heating pipe. At one end, a detachable element with a metal thread is twisted, at the other end it is welded to a plastic section.

- Choke fittings are needed when combining hoses with pipes.

- Adapters - elements of joining sections of unequal diameters. Among the range of products there are threaded parts for connecting metal and polypropylene pipes, or between sections of heating elements.

- corners. They are used in corners, have different sizes or the same angles and diameters, in combination with adapters.

- A cross, a tee is necessary for the articulation, removal of three or more branches of the pipeline. They differ in configurations, angles. Threaded models - for parts made of distinctive materials (metal, plastic). Smooth, threadless fittings connect PPR polypropylene pipes for heating.

- Contours. It is not recommended to bend polypropylene, therefore, when circling any wire line, special concave, curved parts - contours are welded into the structure.

- Loops - compensators for polypropylene heating pipes are used to regulate thermal heating expansions.

- Valves, taps are used polypropylene or brass, in the presence of adapters.

Connecting elements, plugs, clamps, fasteners made of polypropylene are convenient. They are practical and low cost.

WATCH VIDEO

The main dimensions of the diameter are 20 - 40 mm.

It is equally important to install according to the instructions. Bonding elements of pipes and fittings implies a secure fixation, without rotation

Welding of parts will become reliable and tight only after the pipes have solidified.

Be careful, there are a lot of scammers on the market today who offer a fragile, short-lived fake under the brand name of a well-known company. Such pipes instantly become unusable.

Pay attention to the original certificates and license

What to look for when choosing pipes

Products are single-layer and multi-layer

Multilayer pipes are more expensive, but they are reinforced, so they can easily cope with high temperature conditions.

Marking

All single-layer plastic products contain a marking that makes it possible to find out the composition, respectively, and where they can be found.

use.

| Marking | peculiarities | application |

| PPH | High hardness

Not ready for operation at low temperatures |

SHV

Ventilation Industrial pipe line |

| PPB | Flexibility

Frost resistance |

SHV

"warm floor" Production of shock-resistant pipes and fittings |

| PPR | High strength

Withstand temperature fluctuations of +110 degrees Celsius Fully recover after defrosting Resistant to aggressive environments noiseless |

SHV

SGV "warm floor" Heating for a private house Transportation compressed air |

Reinforcement

When soldering at the joints, you will have to remove the reinforced layer.

a) Aluminum foil, may be closer to the outer surface or inner. In any version, installation with features.

Layers are of two types

- Perforated - foil with holes. At the time of pipe casting, liquid polypropylene penetrates through the holes, creating a solid monolith.

- A solid layer is three glued layers.

b) Reinforced with fiberglass - fiberglass filler is added to polypropylene.

- Welding without features

- High pipe rigidity

- Thermal expansion 25%

- Monolithic connection

Color

Does color affect product quality? Experts are sure that this fact should also be taken into account.

Grey

- Withstands high temperatures

- Resistant to aggressive environments

- Long service life

- Does not harm the environment

- sealed

Black

- Does not transmit ultraviolet rays

- Resistant to aggressive media and chemicals

- Doesn't dry out

- Increased strength

Green

Low price category, suitable for arranging the irrigation system of the site.

Manufacturer

Using products of well-known manufacturers, there is a guarantee of quality and compliance with markings and standards.

- Banninger, Aquatherm, Wefatherm, Pexay - Germany

- Ecoplastic, FV – Plast – Czech Republic

- TEBO, Pilsa, Vesbo, Vaitek, FIRAT, Kalde, Jakk0 – Turkey

- PRO AQUA, CROSS, RBC, Heisskraft, Santrade, Politek - Russia

- BLUE OCEAN, Dyzain - China

Sewer pipes

This is a separate type of pipe. They are made strictly according to SNiP 2.04.01 and Sp 40.107

Requirements for sewer system products

- High anti-corrosion properties

- Resistance to aggressive environment

- Maximum temperature +95 degrees

- Service life 50 years

- pH 2-12

- Availability of a certificate

- Act of compliance with sanitary standards.

Technical characteristics of polypropylene sewer pipes

- Deformation temperature from +150

- Density 0.9 g/cm3

- Breaking load 35 N/mm2

- Fluid limit 25 N/mm2

- Linear expansion 0.15 mm/m

- Heat capacity (at +20) 2kJ/kgf

- Thermal conductivity (at +20) 024 W/ms

Dimensions

- Product diameter: 200, 160, 130, 110, 80, 50, 40, 32.

- Pipe length: 3m, 2m, 1m, 0.75m, 0.5m.

- Sewer pipes are not elastic and do not have flexibility. Fittings are used for installation.

Polypropylene pipes fully justify the price-quality ratio. Properly selected and installed products will last a long time without repair.

Leading manufacturers

Rehau has been considered the unchanging leader among manufacturers of polypropylene pipes and fittings for many years. The company's developers have come up with a reliable method for connecting pipes using angles and other connecting elements.

However, since rehau fittings have appeared, a lot of water has flowed under the bridge. The market was literally filled with companies offering their own polypropylene novelties. Each manufacturer strives to stand out with their products, but who is really worth trusting? Here we denote only those brands that are marked as the best by the consumers themselves.

Polypropylene can be used to make the entire heating system, even in large houses

The first are German companies. They are ideally able to produce high-quality products by introducing the unique resistant properties of polypropylene into their plastic products: Akwatherm, Banninger, Rehau.

Reliable manufacturers of polypropylene pipes, fittings - Czech Republic WavinEcoplastic, Valtec - Italian parts.

Fittings Rehau Germany, products of the Turkish company KALDE, Russian RVC are popular. Reviews about goods from China, Turkey, Ukraine vary: laudatory alternate with negative ones. Such a confrontation is connected with numerous underground falsifications. Wear-resistant products ppr, produced by industrial plants, do not receive any complaints.

General information about pipe classification

Pipes are made of polypropylene.

Homopolymer

PPR standards

- GOST 21553 - The material melts at a temperature of +149 degrees Celsius

- GOST 15139 - density 0.9 g / cm3

- GOST 11262 - stretching 24-25 N / sq. mm, elongation when it reaches 50%

- Tensile strength 34-35

- GOST 15173 thermal expansion coefficient - 0.15 mm / mms

- GOST 23630 heat capacity 2 kJ/kg at +20 Celsius

- German standard. Thermal conductivity 0.24 watts per m/s at +20 Celsius

PPR Features

- No corrosion or decay. Long service life. Heating and hot water supply - 50 years, cold water supply - 100 years

- The inner diameter does not change during operation, the walls are smooth, no sticking is formed.

- Loyal price

- Lungs

- Does not require paintwork. Repair without features. Replacement of the damaged area is carried out without expensive special equipment

- It is connected in a monolithic system, which guarantees complete waterproofing. Threaded connections are kept to a minimum.

- Minimum condensation. Low thermal conductivity.

- Virtually silent

- Unaffected by temperature fluctuations

- Withstands well in harsh environments

- The material is environmentally friendly

Application

- Plumbing installation

- Creation of a heating system

- Sewer system and storm sewer

- Transportation of aggressive chemicals

- For transporting compressed air

- For irrigation system

- For drainage devices

Which pipes will be used for installation is directly related to the scope of application. Products have different characteristics. For example, for a sewerage system, the main indicators are the maximum temperature and pressure, and for a water main, the requirements are increased.

Technical specifications

- PN 10 - pressure not higher than 10 atmospheres, temperature 20 degrees. Can be used for cold water and technical water.

- PN16 - pressure up to 16 atmospheres, temperature +60 degrees Celsius. Outer diameter 1.6 -11 cm. Well suited for underfloor heating.

- PN20 - pressure 20 atm. Temperature 95 degrees Celsius. Ideal for CH

- PN 25 - the material contains aluminum foil or fiberglass. Clad with high strength. Pressure 25 atm., Maximum temperature 95 degrees Celsius.

| Outer Diameter (mm) | PN10 | PN20 | PN25 | ||||

| Diameter inside | Wall thickness | Diameter inside | Wall thickness | Diameter inside | Wall thickness | ||

| 16 | 10,6 | 2,7 | |||||

| 20 | 16,2 | 1,9 | 13,2 | 3,4 | 13,2 | 3,4 | |

| 25 | 20,4 | 2,3 | 16,6 | 4,2 | 16,6 | 4,2 | |

| 32 | 26,0 | 3,0 | 21,2 | 5,4 | 21,2 | 3,0 | |

| 40 | 32,6 | 3,7 | 26,6 | 6,7 | 26,6 | 3,7 | |

| 50 | 40,8 | 4,6 | 33,2 | 8,4 | 33,2 | 4,6 | |

| 63 | 51,4 | 5,8 | 42 | 10,5 | 42 | 5,8 | |

| 75 | 61,2 | 6,9 | 50 | 12,5 | 50 | 6,9 | |

| 90 | 73,6 | 8,2 | 6 | 15 | |||

| 110 | 90 | 10 | 73,2 | 1,8,4 | |||

| Equivalent passage (mm) | Outer Diameter (mm) |

| 10 | 16 |

| 15 | 20 |

| 20 | 25 |

| 25 | 32 |

| 32 | 40 |

| 40 | 50 |

| 50 | 63 |

| 65 | 75 |

| 80 | 90 |

| 90 | |

| 100 | 110 |

| 125 | 125 |

| 150 | 160 |

| 160 | 180 |

| 200 | 225 |

| 225 | 250 |

| 250 | 280 |

| 300 | 315 |

| 400 | 400 |

| 500 | 500 |

| 600 | 630 |

| 800 | 800 |

| 1 000 | 1 000 |

| 1 200 | 1 200 |

|

Temperature

Celsius |

Life time |

Pipe type | |||

| PN10 | PN16 | PN20 | PN25 | ||

| Permissible overpressure kgf/cm2 | |||||

| 20 | 10 | 13,5 | 21,7 | 21,7 | 33,9 |

| 20 | 25 | 13,2 | 21,1 | 26,4 | 33,0 |

| 20 | 50 | 12,9 | 20,7 | 25,9 | 32,3 |

| 30 | 10 | 11,7 | 18,8 | 23,5 | 9,3 |

| 30 | 25 | 11,3 | 18,1 | 22,7 | 28,3 |

| 30 | 50 | 11,1 | 17,7 | 22,1 | 27,7 |

| 40 | 10 | 10,1 | 16,2 | 20,3 | 25,3 |

| 40 | 25 | 9,7 | 15,6 | 19,5 | 24,3 |

| 40 | 50 | 9,2 | 14,7 | 18,4 | 23,0 |

| 50 | 8,7 | 13,9 | 17,3 | 23,5 | 21,7 |

| 50 | 25 | 8,0 | 12,8 | 16,0 | 20,0 |

| 50 | 50 | 7,3 | 11,7 | 14,7 | 18,3 |

| 60 | 10 | 7,2 | 11,5 | 14,4 | 18,0 |

| 60 | 25 | 6,1 | 9,8 | 12,3 | 15,3 |

| 60 | 50 | 5,5 | 8,7 | 10,9 | 13,7 |

| 70 | 10 | 5,3 | 8,5 | 10,7 | 13,3 |

| 70 | 25 | 4,5 | 7,3 | 9,1 | 11,9 |

| 70 | 30 | 4,4 | 7,0 | 8,8 | 11,0 |

| 70 | 50 | 4,3 | 6,8 | 8,5 | 10,7 |

| 80 | 5 | 4,3 | 6,9 | 8,7 | 10,8 |

| 80 | 10 | 3,9 | 6,3 | 7,9 | 9,8 |

| 80 | 25 | 3,7 | 5,9 | 7,5 | 9,2 |

| 95 | 1 | 3,9 | 6,7 | 7,6 | 8,5 |

| 95 | 5 | 2,8 | 4,4 | 5,4 | 6,1 |

Criterias of choice

The following parameters help to choose the right polypropylene pipes for heating:

Length - straight sections of various lengths (2-5 m) are convenient for transportation, storage. Customized parts are available.

Diameter - distinguish between internal and external, outer diameters. The outer diameter is indicated in mm. (16 mm - 500 mm and more), in inches internal. This parameter is important when calculating fluid flow rates, heating temperature operating parameters and acceptable pressure norm criteria. Based on the diameter, choose fittings, connecting fittings for the installation of the pipeline.

The diameter of polypropylene pipes for heating is divided into the following categories depending on the size.

- Details of small sections (16-63 mm) are equipped in high-rise, small houses, public buildings. They are installed for heating, water supply structures, connecting lines to centralized heating networks.

- Products of medium size (75 - 135 mm) are used for ventilation, sewer structures of houses, various buildings. Involved in the transportation of chemical industrial substances, volumes of compressed air. The most popular size diameter is 110mm (for the sewer system inside).

- Pipes of large diameter (more than 400 mm) are used only for sewer systems for outdoor use, the main water supply line, and at industrial enterprises.

To select household products, they often rely on the following calculation of the diameter of the pipe for heating:

20 mm - for plumbing and heating branches inside apartments; 25 mm - for risers and wiring at low-rise buildings, for laying heating lines, arranging heated floors; 32 mm - on the construction of risers, for the installation of supply lines in houses of 5 floors or more.

Temperature. The maximum temperature limit for which polypropylene pipes of the PN20 and PN25 grades are designed is 95 degrees C. PN25 is chosen for heating structures. But here the constant maximum temperature of hot water is indicated, which does not affect the condition of the pipe. At the same time, they perfectly withstand a high level of 120 degrees, but only for a short period of time.

The melting point of plastic is 175 degrees C - the complete destruction of the material.

Reinforcement. Reinforced polypropylene avoids the critical expansion of the pipe during hot water supply, a pipe reinforced with thicker fiberglass can withstand temperature loads much better than without filler. A temperature of 140 degrees softens the product, it quickly loses its configuration and structure. Reinforced polypropylene for heating or not - it will definitely fall apart when the overestimated norm is exceeded.

Pressure. Each plastic sanitary industrial product has a unified diameter of polypropylene pipes, standard tasks and corresponding marking

When choosing a package, pay attention to the calculation of thermal conductivity, technical characteristics and pressure parameters, the period of operation of the pipeline branches depends on this

The marking of polypropylene pipes consists of:

the letters "PN", which indicate the nominal pressure;

numbers "10, ..., 25" - the value of pressure in atmospheres.

Advantages of pipes made of durable polypropylene

Polypropylene pipes are used in various industries of repair and construction. The technical characteristics of the products have already been highly appreciated by consumers around the world, so polypropylene for heating has become indispensable in the construction of water lines.

These pipes are connected for heating using diffusion welding (melting of materials through heating to high temperatures). Diffusion bonding thus creates an inseparable bond.

They represent a connecting structure of an elastic shape, similar in appearance to a loop. The connection element compensates for the expansion of temperatures during sudden changes in temperature inside the pipe or with an increase in water pressure. Metal-plastic parts in this case will definitely break.

Polypropylene products labeled "for heating" have many positive advantages, regardless of the type of reinforcement:

- are not subject to corrosion and reproduction of harmful fungi or bacteria;

- resistant to mechanical and chemical influences from the outside;

- low heat loss (plastic, unlike metal, does not get very hot from hot water passing through the line);

- quick and easy installation / dismantling;

- a wide range of fittings (connection elements)

- layering makes them resistant to wear;

- light weight simplifies delivery to the assembly site;

- an impenetrable hermetic heating system is created;

- painting is not required;

- maximum environmental friendliness;

- there is no vibration, noise from the movement of water;

- the material does not conduct electricity;

- fire resistance;

- water flows with strong pressure are steadfastly maintained;

- hot water of a suitable temperature does not spoil the shape and quality of the product;

- the average price available to each owner.

There are a huge number of variations in the decoupling of such pipes.

Polyethylene or polyvinyl chloride lines for heating do not have such qualities, and GOST of polypropylene pipes guarantees, with proper installation, to serve them flawlessly for decades.